Shear gauge system and use method thereof

A technology of sizing machine and reducer, which is applied to the accessories of shearing machine, shearing device, metal rolling, etc., can solve the problems of inaccurate sizing, heavy maintenance work, complex structure of sizing machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

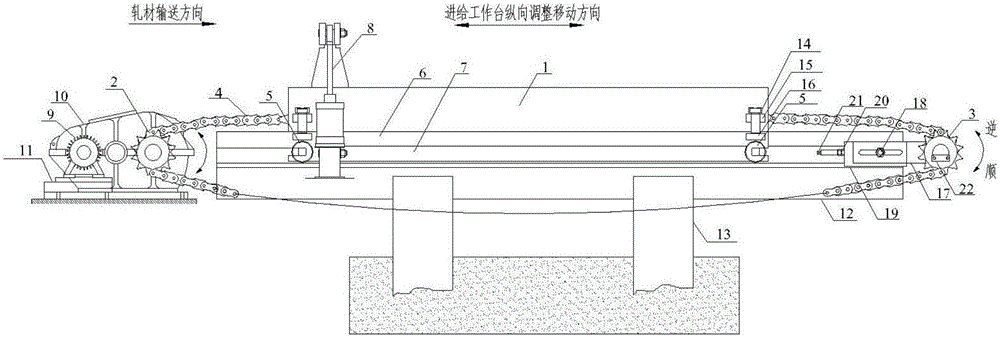

[0046] see figure 1 , is a schematic diagram of the general assembly structure of a sizing machine system provided by an embodiment of the present invention, including a motor 9, a reducer 10, a sprocket mechanism, a bearing mechanism, a feed table 1, a sliding screw mechanism and a sizing machine 8.

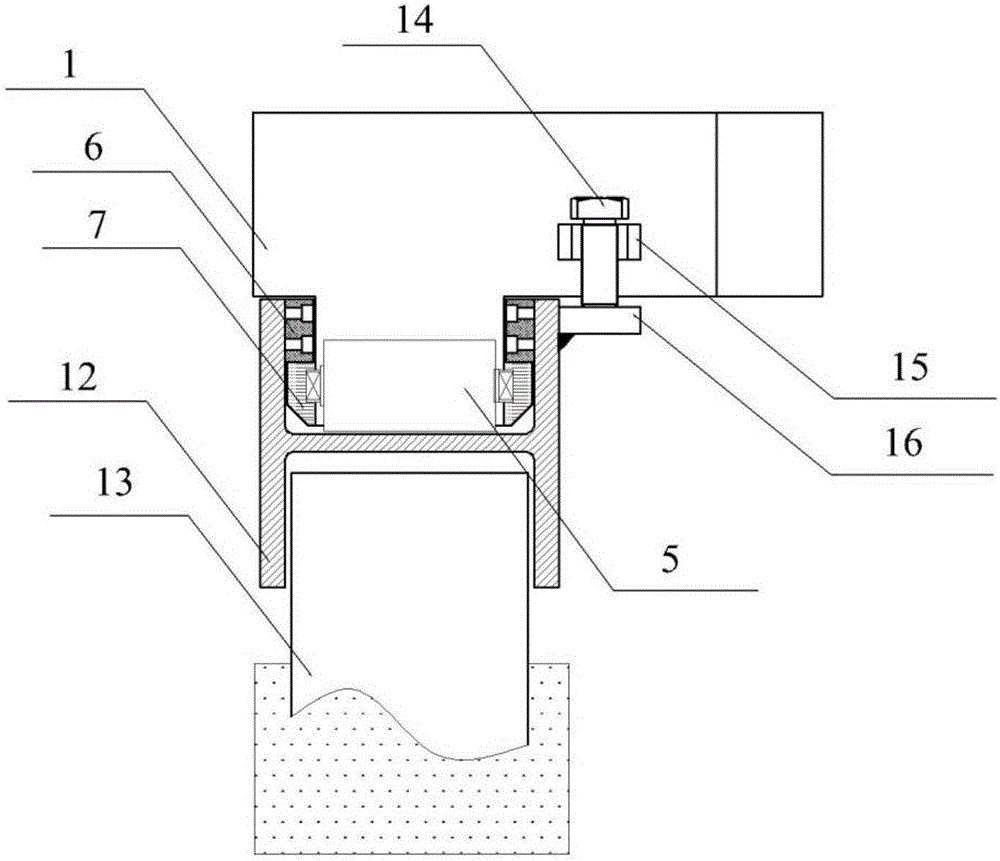

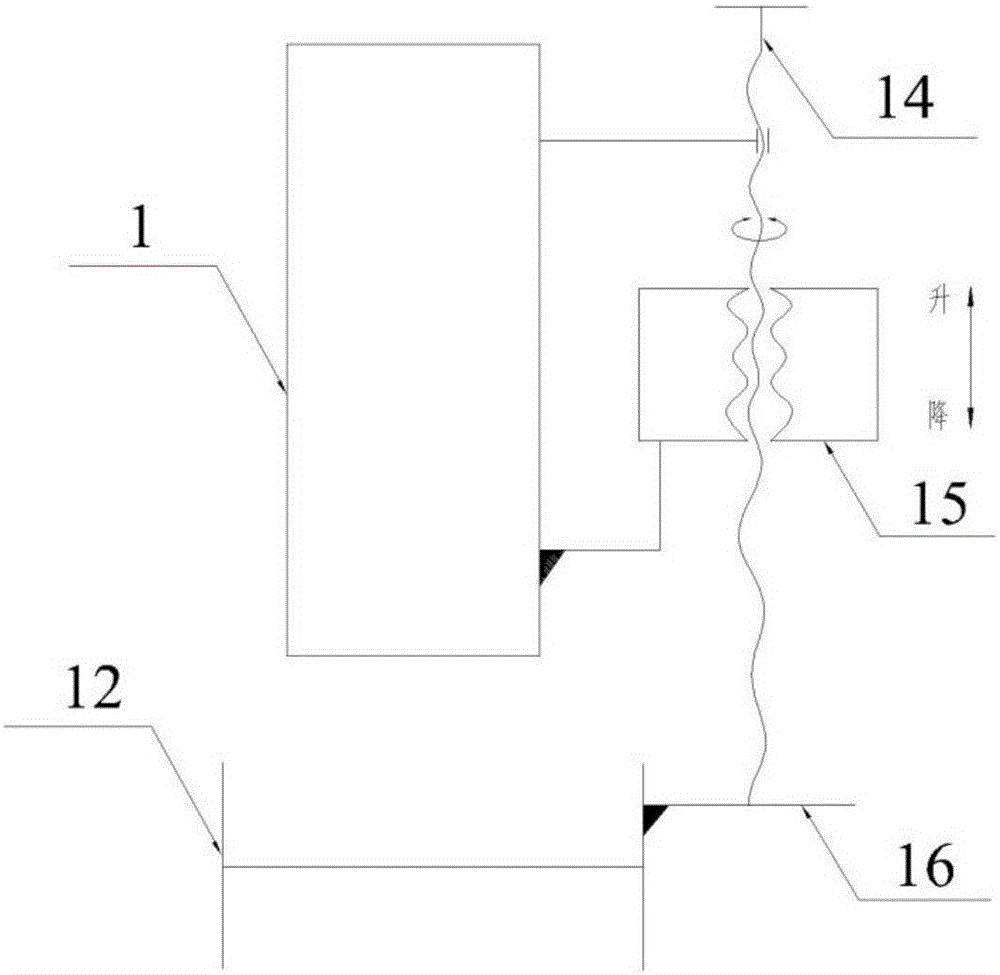

[0047] In order to carry the feed table 1, the carrying mechanism is set on the underside of the feed table 1, see figure 2 , the carrying mechanism is arranged below the feed table 1 and fixed to the ground, and its structure includes: a guide groove 12 , a supporting plate 16 and an upper friction plate 6 . The guide trough 12 can be fixed to the ground through uprights 13, and the number of the uprights 13 is greater than or equal to 2, which are evenly distributed under the guide trough. In the embodiment of the present invention, the guide groove 12 is designed as an H-shaped steel guide groove, and the column 13 is designed as an H-shaped steel column. Of course, the gui...

Embodiment 2

[0091] see Figure 8 , is a structural schematic diagram of another sizing machine system provided by an embodiment of the present invention, including a feed table 1, a sprocket mechanism, a bearing mechanism, a sliding screw mechanism, and a sizing machine 8. The present embodiment and the first embodiment The difference is that, in this embodiment, two sizing machines are fixedly connected on the feed workbench 1, namely the first sizing machine 08 and the second sizing machine 008, along the feed workbench 1 The feed direction intervals are fixed on the feed table 1. Under normal working conditions, the baffle plate of the first sizing machine 08 is the first baffle plate, and the baffle plate of the second sizing machine 008 is the second baffle plate, and the first baffle plate cooperates with the cold shearing machine. Cut to length, its main function is to instantly absorb the initial kinetic energy of the dynamic double-length rolling piece from the upstream process,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com