High-precision and high-efficiency fixed-length shearing control method and device for bars

A shearing device and cutting-to-length technology, which is applied to positioning devices, feeding devices, manufacturing tools, etc., can solve the problem of low shearing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

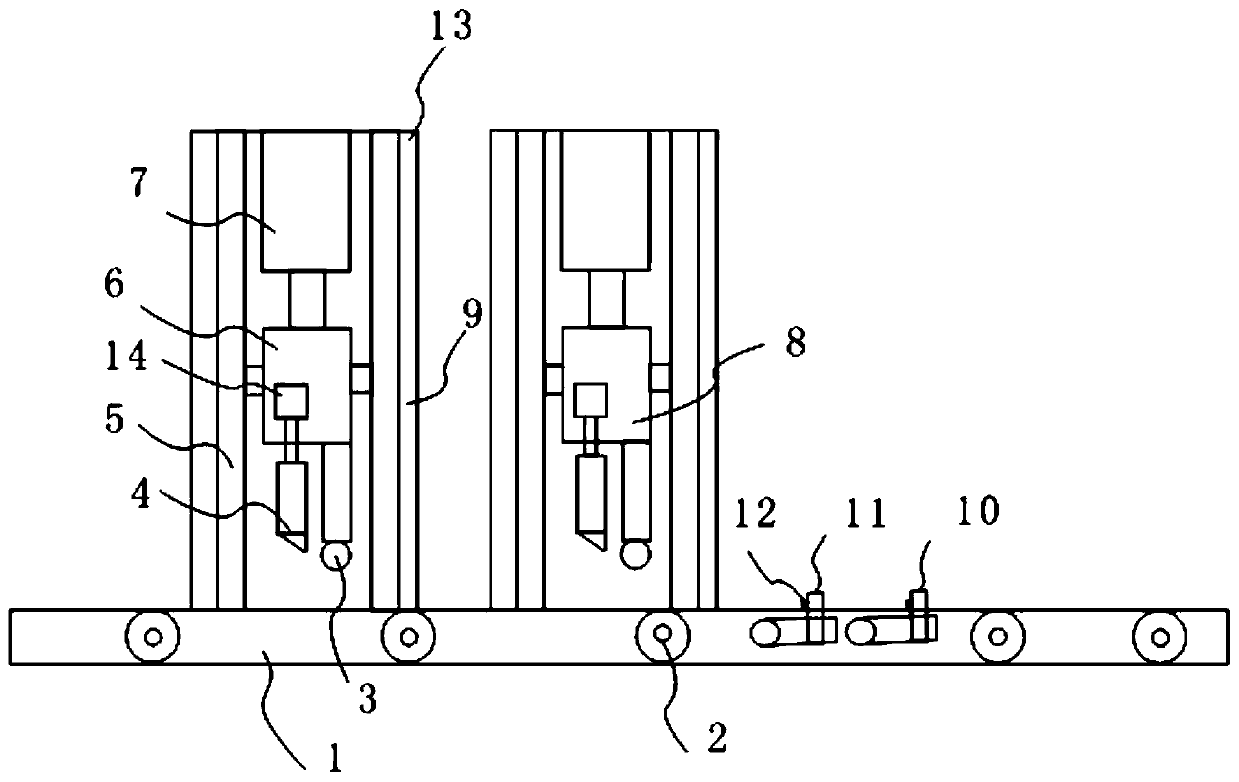

[0019] A high-precision and high-efficiency cut-to-length control method for rods, which includes the following process flow:

[0020] ——Install the first shearing device and the second shearing device above the bar conveying track, and the distance between the shearing knives of the first shearing device and the second shearing device is set between 9.02m and 9.03m;

[0021] ——In the front of the first shearing device and the second shearing device, the first material baffle plate and the second material baffle plate are hinged, and touch switches are respectively installed on the two material baffle plates, and the first material baffle plate and the second material baffle plate The distance between the shearing knives of the second shearing device is set between 9.02m and 9.03m, and the distance between the second baffle plate and the shearing knives of the second shearing device is set between 12.02m and 12.04m.

[0022] Optimized, the distance between the first shearing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com