Box type raw silk dryer

A box-type, dryer technology, applied in dryers, progressive dryers, drying and other directions, can solve the problems of long time, high cost, complex structure, etc., and achieve simple structure, low cost and convenience. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

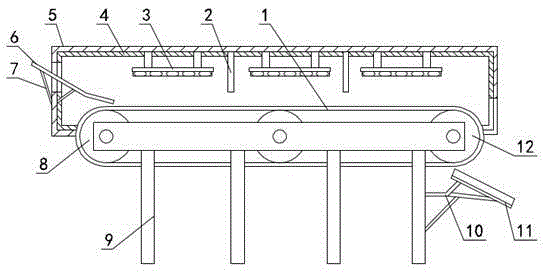

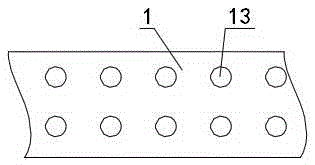

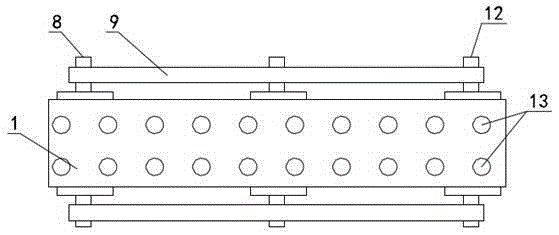

[0022] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the box-type raw silk dryer includes a workbench 9, a driving roller 8, a driven roller 12 and a box body 5, one driving roller 8 is arranged on the left side of the workbench 9, and two driven rollers 12 One, respectively arranged in the middle and the right side of the workbench 9, a driving roller 8 and two driven rollers 12 are evenly distributed laterally on the workbench 9, and a conveyor belt 1 is installed on the driving roller 8 and the driven roller 12 , the box body 5 is above the conveyor belt 1, and the bottom of the box body 5 is fixed on the workbench 9. The conveyor belt 1 is made of heat-resistant material, and the upper left corner of the box body 5 is provided with an inlet for raw silk drying. The feed plate 6 and the feed plate 6 are fixed on the upper left side of the workbench 9 through the feed plate bracket 7. The angle between the feed plate 6 and the conveyor belt 1 is 25 degrees,...

Embodiment 2

[0026] This embodiment is changed on the basis of Embodiment 1, the angle between the feed plate 6 and the conveyor belt 1 is changed to 30 degrees, and the distance between the feed end of the feed plate 6 and the conveyor belt 1 becomes 40mm, the distance between the feeding end of the discharge plate 11 and the conveyor belt 1 becomes 40mm, the distance between the bottom of the separator 2 and the conveyor belt 1 becomes 500mm, the thickness of the insulation layer 4 becomes 30mm, and the adjacent ventilation The spacing between the holes 13 becomes 500 mm. Others are the same as embodiment one.

Embodiment 3

[0028] This embodiment is changed on the basis of Embodiment 1, the angle between the feed plate 6 and the conveyor belt 1 is changed to 28 degrees, and the distance between the feed end of the feed plate 6 and the conveyor belt 1 becomes 30mm, the distance between the feeding end of the discharge plate 11 and the conveyor belt 1 becomes 30mm, the distance between the bottom of the separator 2 and the conveyor belt 1 becomes 300mm, the thickness of the insulation layer 4 becomes 50mm, and the adjacent ventilation The spacing between the holes 13 becomes 400 mm. Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com