Novel hot-rolled round steel cut-to-length system

A cut-to-length and round steel technology, applied in the field of mechanical engineering, can solve the problems of being easily affected by the external environment during the following process, frequent stop adjustment, poor product adaptability, etc. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiments.

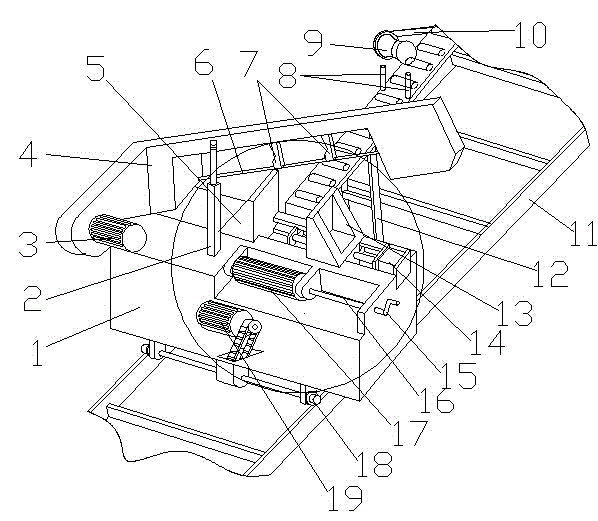

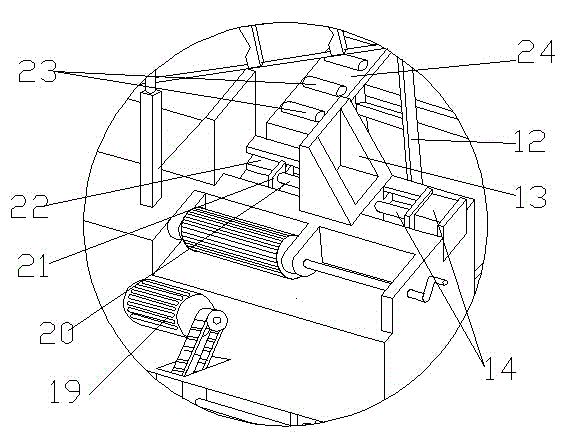

[0025] like figure 1 and figure 2 As shown, a novel hot-rolled round steel fixed-length shearing system includes a feeding car 1, a shear frame 4, a supporting device and a guide rail 8, and the shear frame 4 is hinged on one end of the feeding car 1, and the material The other end of the car 1 is provided with an automatic clamping mechanism and a manual supporting structure. The automatic clamping mechanism includes a first clamping plate 5 and a second clamping plate 13 fixed on the upper end surface of the material truck 1. The end face has a "ten" shaped groove along the front of the first splint 5, the other end of the "cross" shaped groove is fixed with a second hydraulic cylinder 14, and the movable end of the second hydraulic cylinder 14 is connected to the second splint 13 One end of the base is fixedly connected, and the other end surface of the base of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com