A leveling treatment method for karst landform rock slope

A technology for rock slope and leveling treatment, which is applied in the direction of working accessories, manufacturing tools, stone processing tools, etc., can solve problems such as uneven slope surface, affecting construction progress, drilling and blasting hazards, etc., to achieve easy control, The effect of improving construction efficiency and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention are further described below, but the claimed scope is not limited to the description.

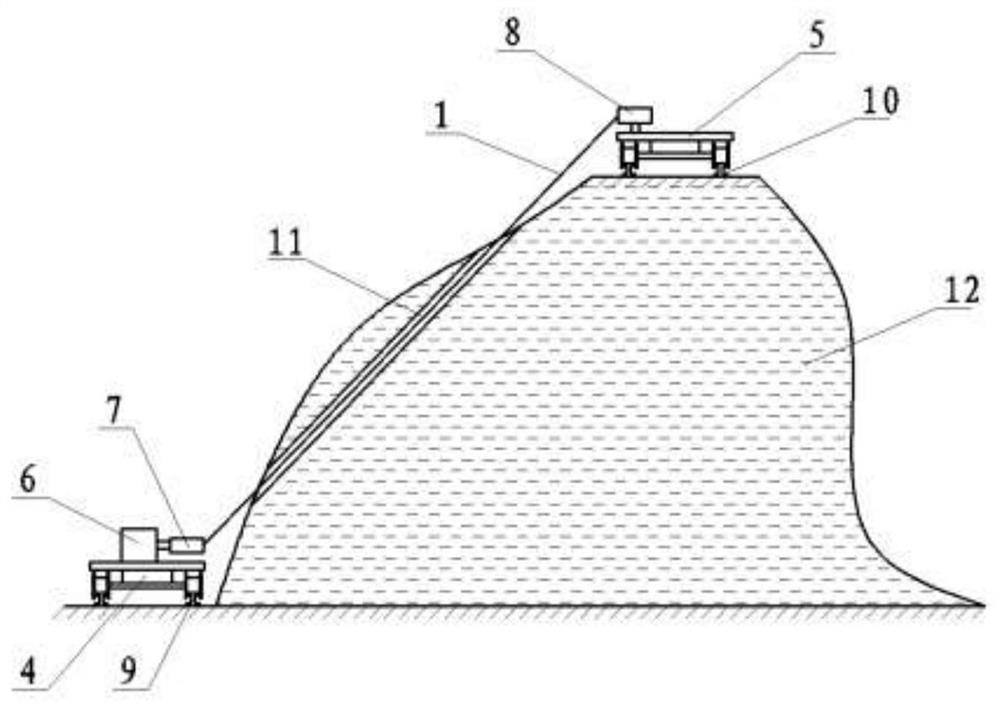

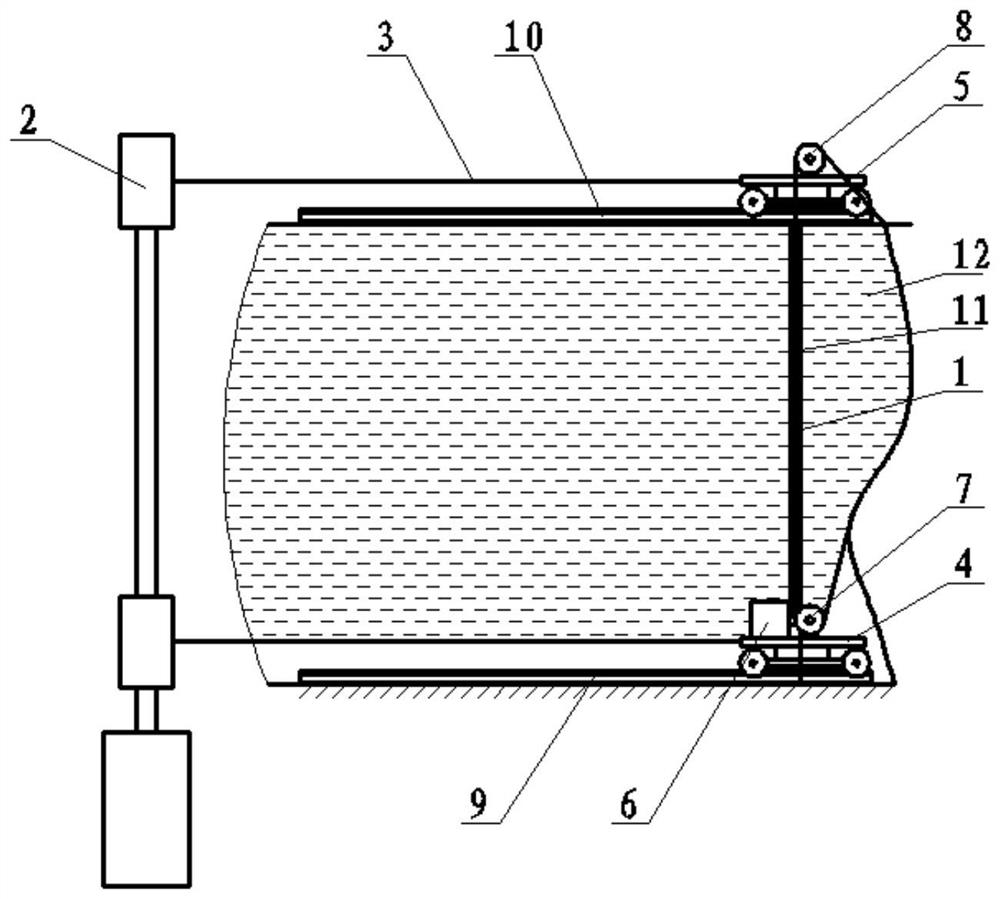

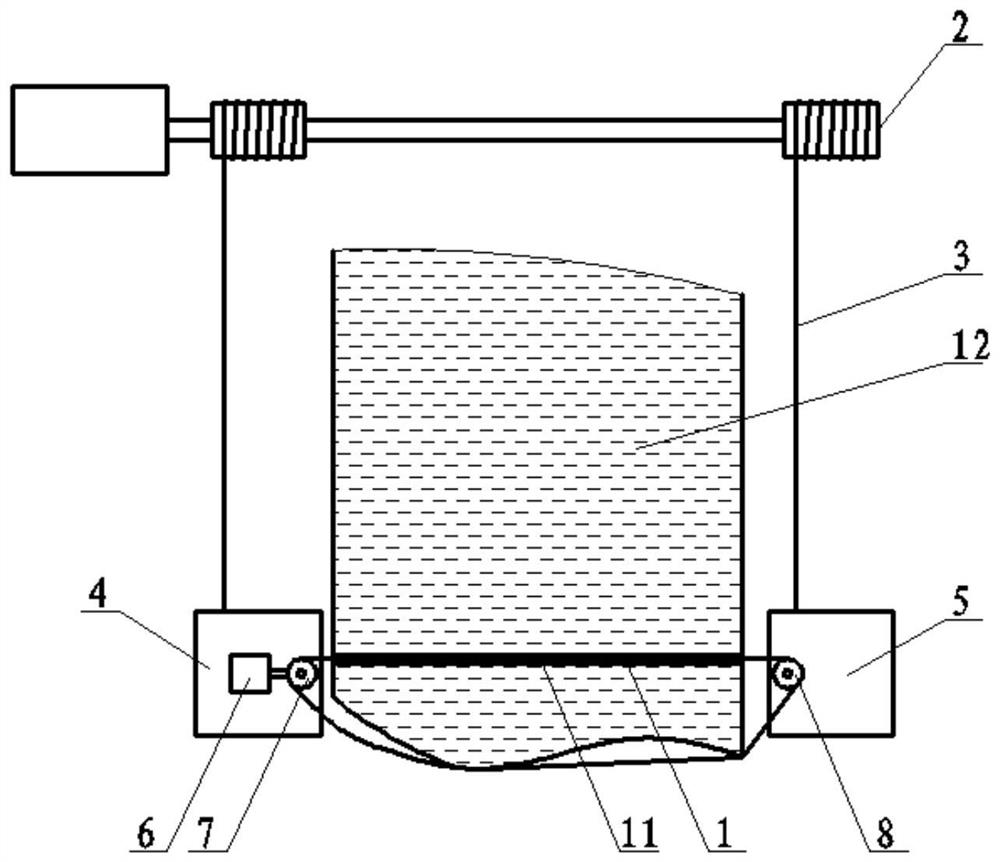

[0023] like figure 1 , figure 2 and image 3 As shown, the present invention provides a method for leveling a karst landform rocky slope, comprising the following steps:

[0024] Step 1: dig a rope hole 11 inside the slope, one end of the rope hole 11 is close to the bottom of the slope, and the other end of the rope hole 11 is close to the top of the slope;

[0025] Step 2: Deploy a cutting device on one side of the side slope 12. The cutting device includes a saw wire 1. After the saw wire 1 is passed through the wire rope hole 11 in step 1, the ends of the saw wire 1 are fixedly connected together. A traction drum 2 is deployed on the other side of the traction drum 2, a wire rope 3 is wound on the outer peripheral surface of the traction drum 2, and the end of the wire rope 3 is fixedly connected with the cutting device;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com