Saw cutting device for tube rows with positioned length

A sawing device and hydraulic cylinder technology, applied in sawing machine, shearing device, metal sawing equipment, etc., can solve the problems of inconvenient adjustment, inaccurate positioning, complex structure, etc., and achieve improved yield and high sizing accuracy. , control simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

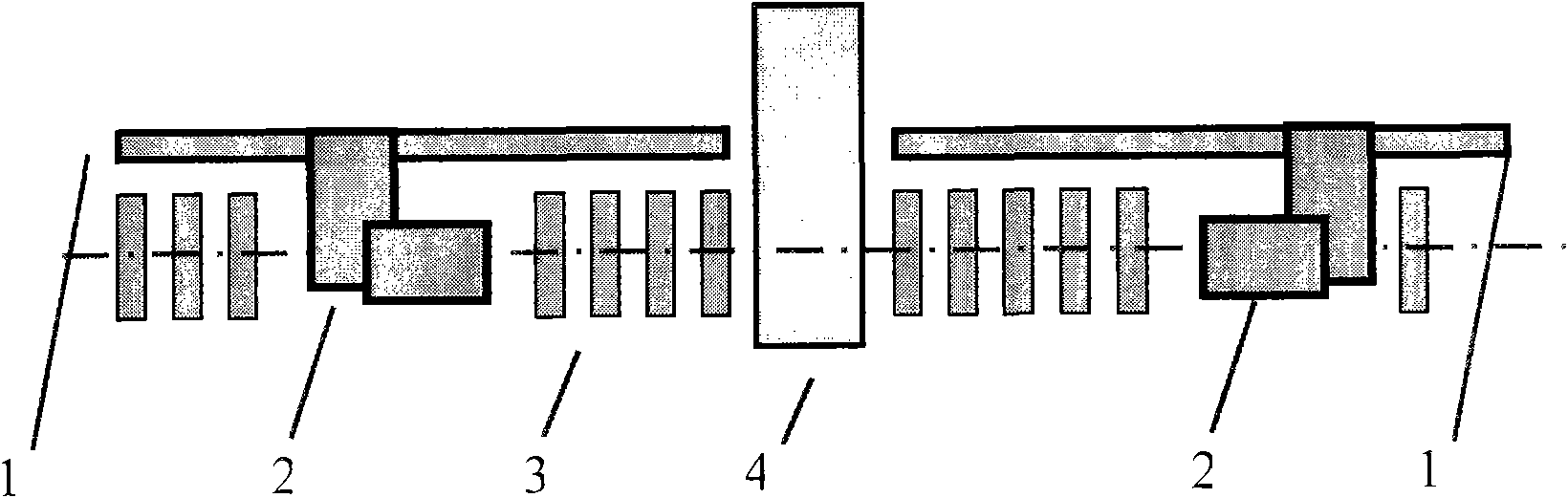

[0018] see figure 1 Summary of the invention: the present invention is made up of walking track 1, positioning device body 2, roller table 3 in rows and saw machine 4 in rows with fixed rack for walking and V-shaped groove for positioning.

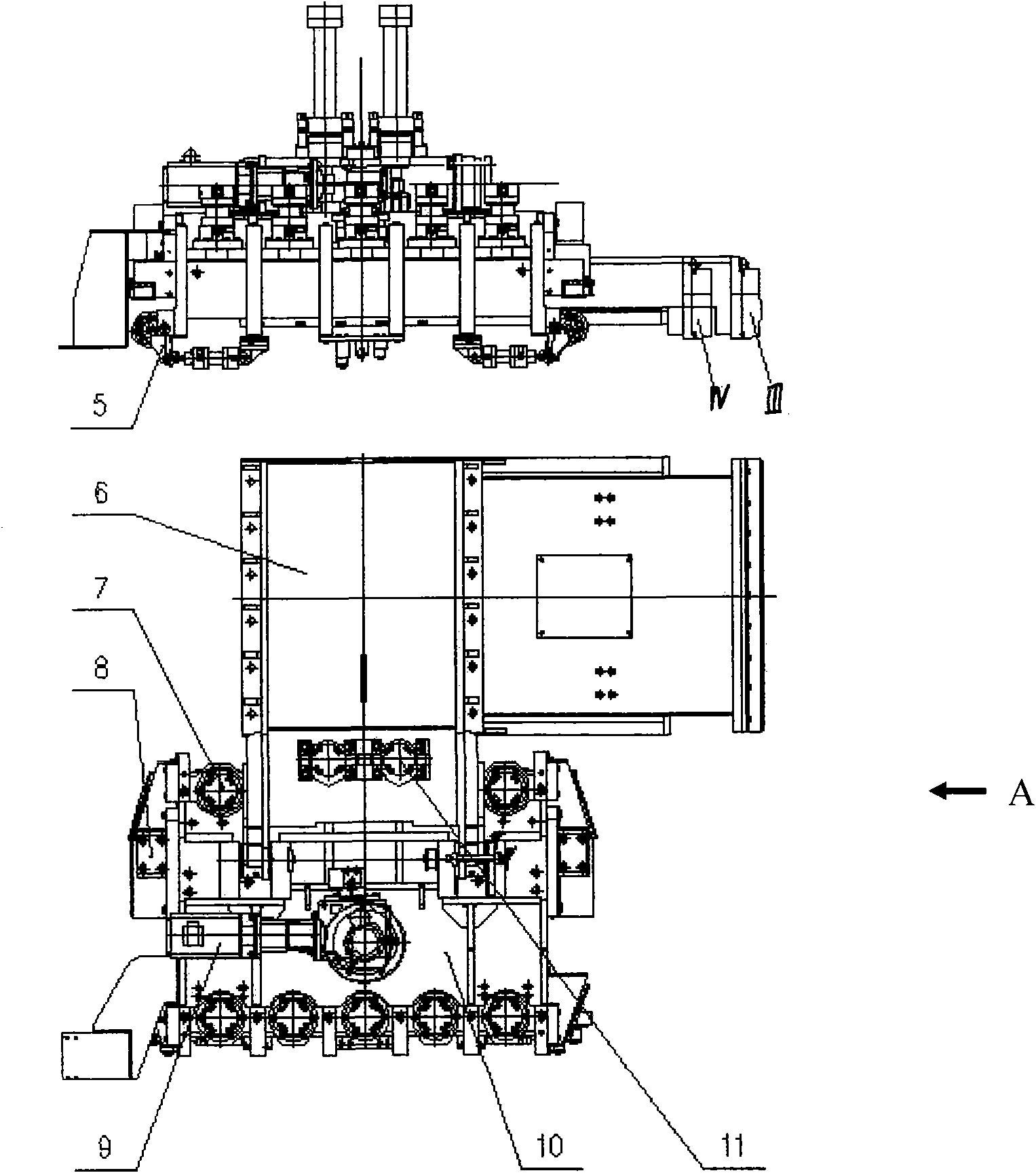

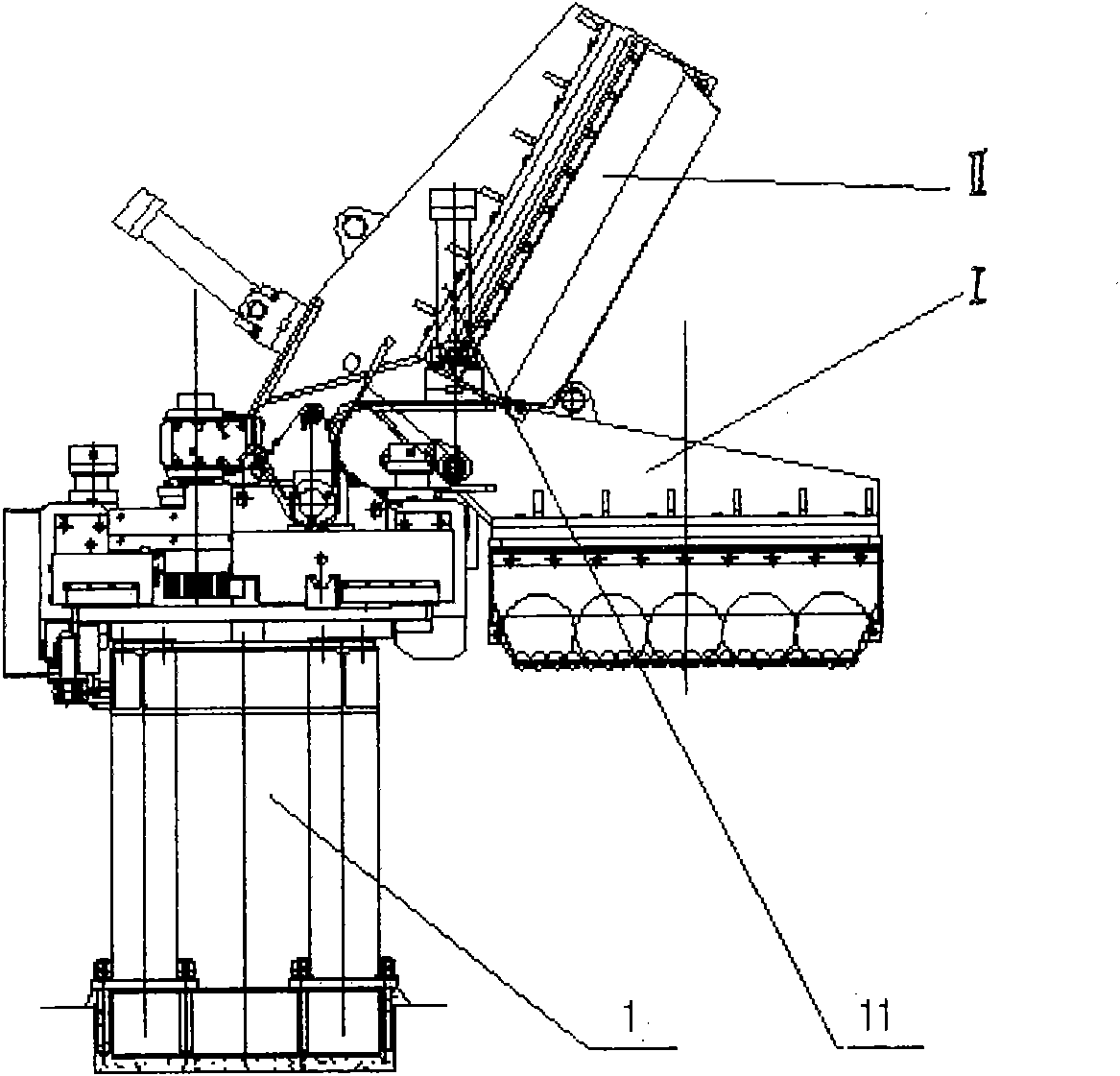

[0019] see figure 2 and image 3 : There are traveling rollers at the bottom of the vehicle frame 10 welded by steel plates, and there are 11 holes on it, and the traveling mechanism 9 driven by the servo motor is placed in the middle channel, and the gears mounted on the output shaft and the traveling track 1 10 locking hydraulic cylinders 7 are installed in the remaining 10 channels, and the head of the hydraulic cylinder is connected with a square wear-resistant steel plate; the hydraulic cylinder of the walking guide mechanism 5 is mounted on the lower part of the vehicle frame 10. The cylinder head is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com