Double-acceleration synchronous tracking fixed-length flying shear

A technology of synchronous tracking and flying shears, applied in the field of flying shears, can solve the problems of high cost of servo motors, low shearing precision, and bulky equipment, so as to improve the accuracy of sizing, improve the response speed, and reduce the overall The effect of machine size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

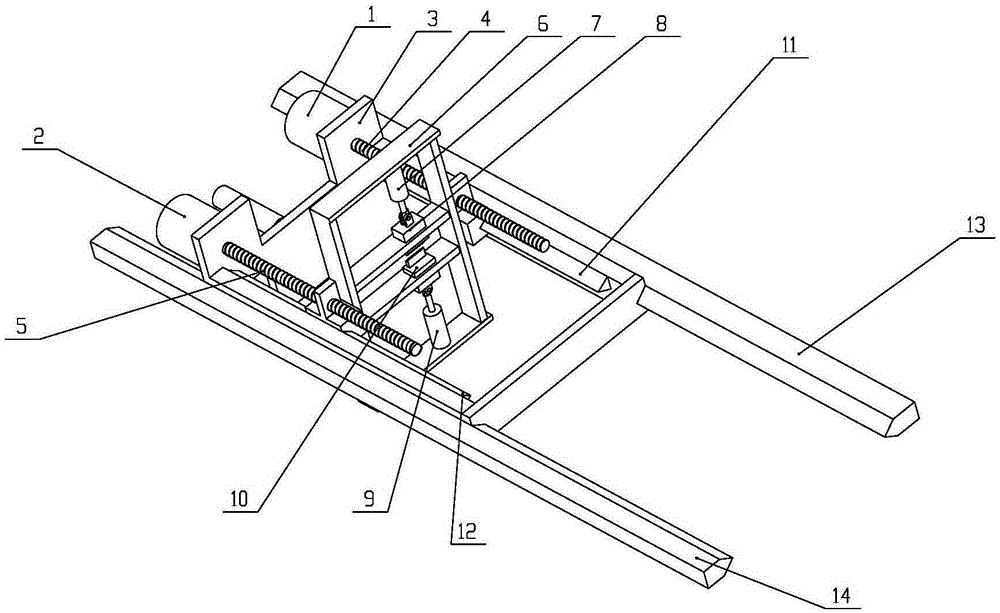

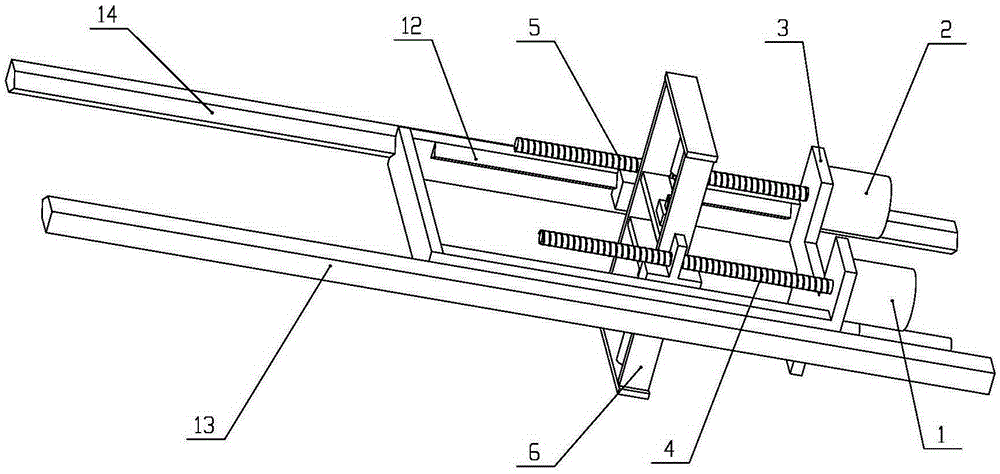

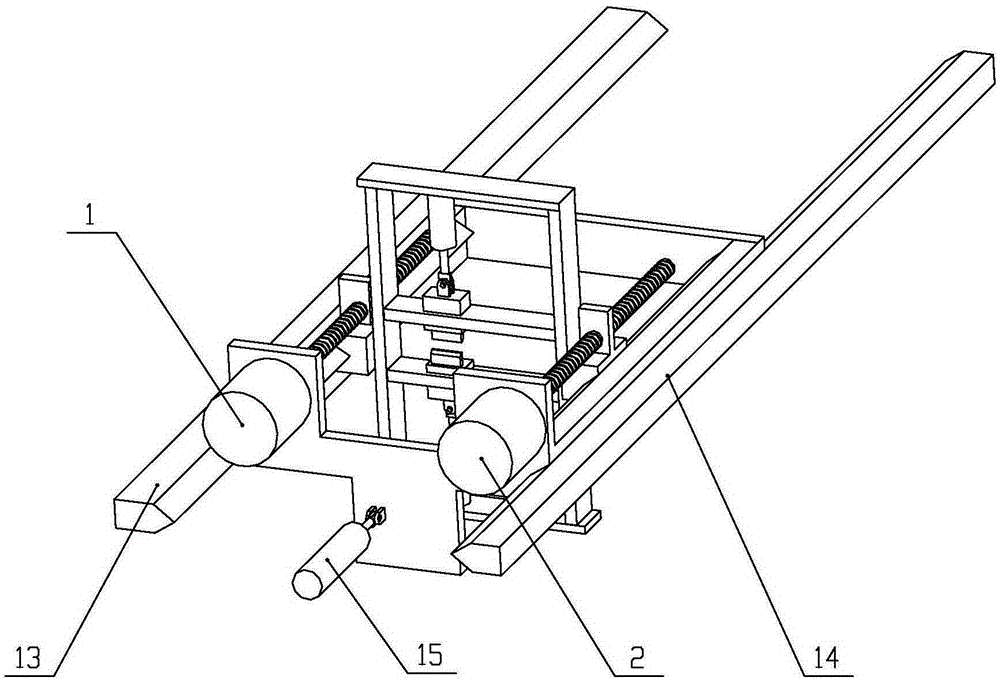

[0017] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode and in conjunction with the accompanying drawings.

[0018] A double-acceleration synchronous tracking fixed-length flying shear, consisting of a first servo motor 1, a second servo motor 2, a first sliding bracket 3, a first screw 4, a second screw 5, a second sliding bracket 6, a first A hydraulic cylinder 7, the first scissors module 8, the second hydraulic cylinder 9, the second scissors module 10, the first guide rail 11, the second guide rail 12, the third guide rail 13, the fourth guide rail 14, the third hydraulic cylinder 15, the first Composed of a rotary encoder 16, a control unit 17, and a second rotary encoder 18, the third guide rail 13 and the fourth guide rail 14 are fixedly installed, the cylinder body of the third hydraulic cylinder 15 is fixedly installed, and the extension rod of the third hydraulic cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com