A device and method for improving the precision of special steel bar marshalling and sizing

A bar, sizing technology, applied in the field of metallurgical rolling steel online finishing, can solve the problems of uneven length of finished products, not in line with production conditions, etc., to improve the accuracy of sizing and solve the effect of uneven length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

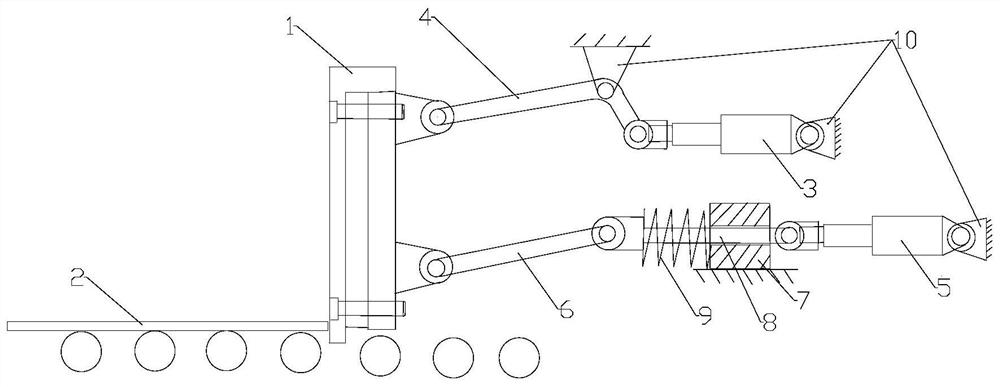

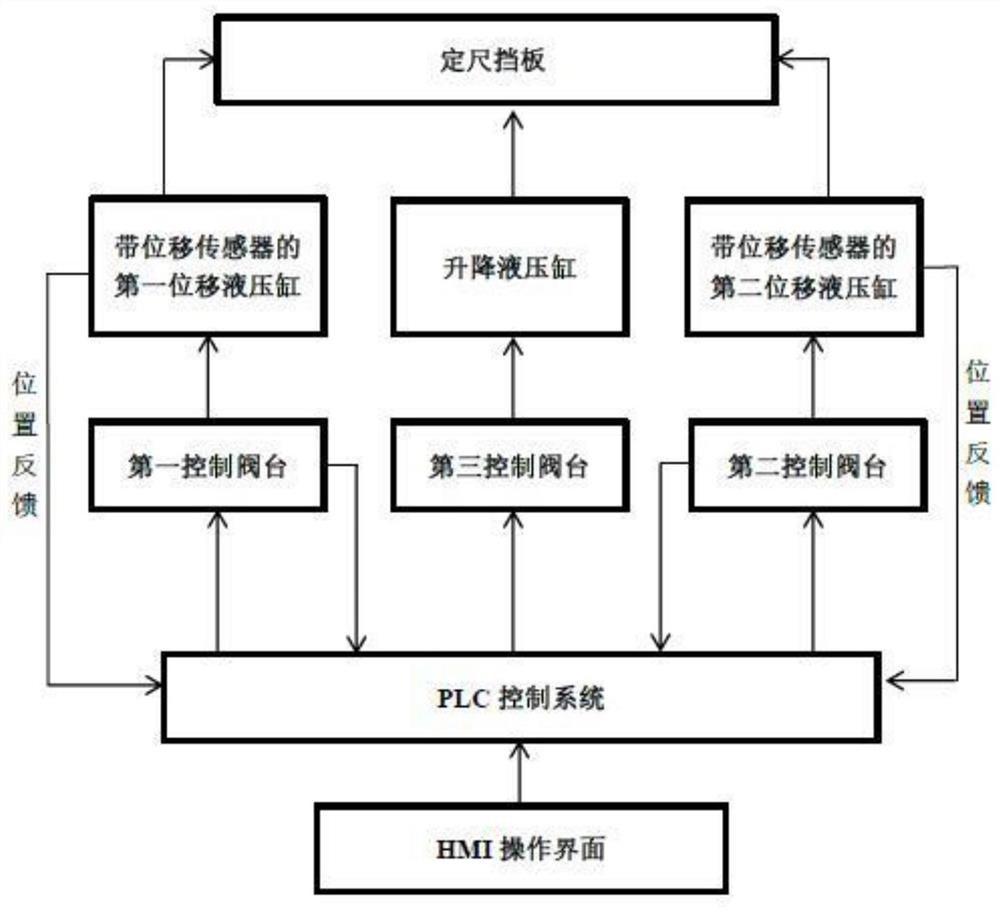

[0044] According to the specifications, steel types, temperature and theoretical shrinkage of the double-length parent material, the cooling shrinkage of the fixed-length bar 2 is calculated, and the fixed-length baffle 1 moves together with the fixed-length frame 10. When the required length of the finished product is six When the operator moves the measuring frame 10 to the six-meter fixed-length position, the length from the fixed-length baffle plate 1 to the sawing or shearing center line is six meters + the preset cooling shrinkage, and one of the displacement hydraulic pressures is adjusted separately. Cylinder 5, move one end of the fixed-length baffle 1 horizontally toward the saw machine or shearing machine by 5mm, so that the fixed-length baffle 1 becomes a certain slope; for each bar 2, when each sawing or shearing 3 times Finally, the operator will horizontally move the baffle plate 1 to a length of 5mm toward the saw or shearing machine.

Embodiment 2

[0046] The sizing baffle 1 moves together with the sizing frame 10. When the required finished product length is 9 meters, the operator moves the sizing machine to the 9-meter sizing position. The sizing baffle 1 reaches the sawing or shearing center line The length is 9 meters + the preset cooling shrinkage, adjust one of the displacement hydraulic cylinders 5 separately, and move one end of the fixed-length baffle 1 horizontally toward the saw machine or shearing machine by 7mm, so that the fixed-length baffle 1 becomes a certain oblique For each bar 2, when each sawing or shearing 3 times, the operator will move the baffle plate 1 horizontally to the direction of the saw or shear by 6mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com