Efficient and accurate round steel automatic sizing system

An accurate and automatic technology, applied in automatic control devices, measuring/indicating equipment, feeding devices, etc., can solve the problems of complex installation, commissioning, operation and maintenance, low sizing accuracy, and low efficiency, and achieve simple installation, commissioning and operation and maintenance. , The effect of high fixed-length precision and simple calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

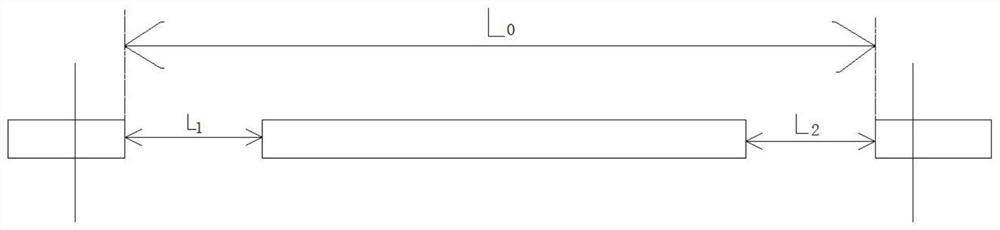

[0053] combine figure 1 The steel ball billet measurement diagram of the existing steel bar in the workshop without fixed length. After the steel billet is unfolded on the display table, a CCD camera is set at the material turning position, and the distances L1 and L2 between the CCD camera and the billet are measured respectively. The blank length L=L0-L1-L2 is calculated by the controller. The length measurement adopts the camera length measurement equipment with high precision, and the repeat error of a single equipment is ±0.5mm.

[0054] After the steel bar is measured by the machine vision system, the length of the steel bar is accurately measured to be 5600mm, and the length is determined. After the data is transmitted to the computer, the program runs, and the program calculates that the steel bar is divided into 28 sections, with an average length of 200mm. . The turning mechanism automatically turns the blank with a measured length to the cutting position. At this ...

Embodiment 2

[0058] combine figure 1 The steel ball billet measurement diagram of the existing steel bar in the workshop without fixed length. After the steel billet is unfolded on the display table, a CCD camera is set at the material turning position, and the distances L1 and L2 between the CCD camera and the billet are measured respectively. The blank length L=L0-L1-L2 is calculated by the controller. The length measurement adopts the camera length measurement equipment with high precision, and the repeat error of a single equipment is ±0.5mm.

[0059] After the steel rod is measured by the machine vision system, the length of the steel rod is accurately measured to be 6650mm, and the length is determined. After the data is transmitted to the computer, the program runs, and the program calculates that the steel rod is divided into 33 segments, with an average length of 201.5 mm. mm. The turning mechanism automatically turns the blank with a measured length to the cutting position. At ...

Embodiment 3

[0063] combine figure 1 The steel ball billet measurement diagram of the existing steel bar in the workshop without fixed length. After the steel billet is unfolded on the display table, a CCD camera is set at the material turning position, and the distances L1 and L2 between the CCD camera and the billet are measured respectively. The blank length L=L0-L1-L2 is calculated by the controller. The length measurement adopts the camera length measurement equipment with high precision, and the repeat error of a single equipment is ±0.5mm.

[0064] After the steel rod is measured by the machine vision system, the length of the steel rod is accurately measured to be 5900mm, and the length is determined. After the data is transmitted to the computer, the program runs. The rod length is 5900mm. When the machine cuts a single 200mm, the final remaining 100mm After the program compiled by this algorithm, the steel bar is divided into 29 sections, each with an average of 203mm, the loss ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com