Control method for sizing accuracy of high-speed reinforcement bar straightening machine

A control method and straightening machine technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of encoder control overcoming, cumbersome operation, control accuracy error, etc., to reduce machining and assembly time, The effect of simplifying the operation procedures and steps and reducing the failure rate of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

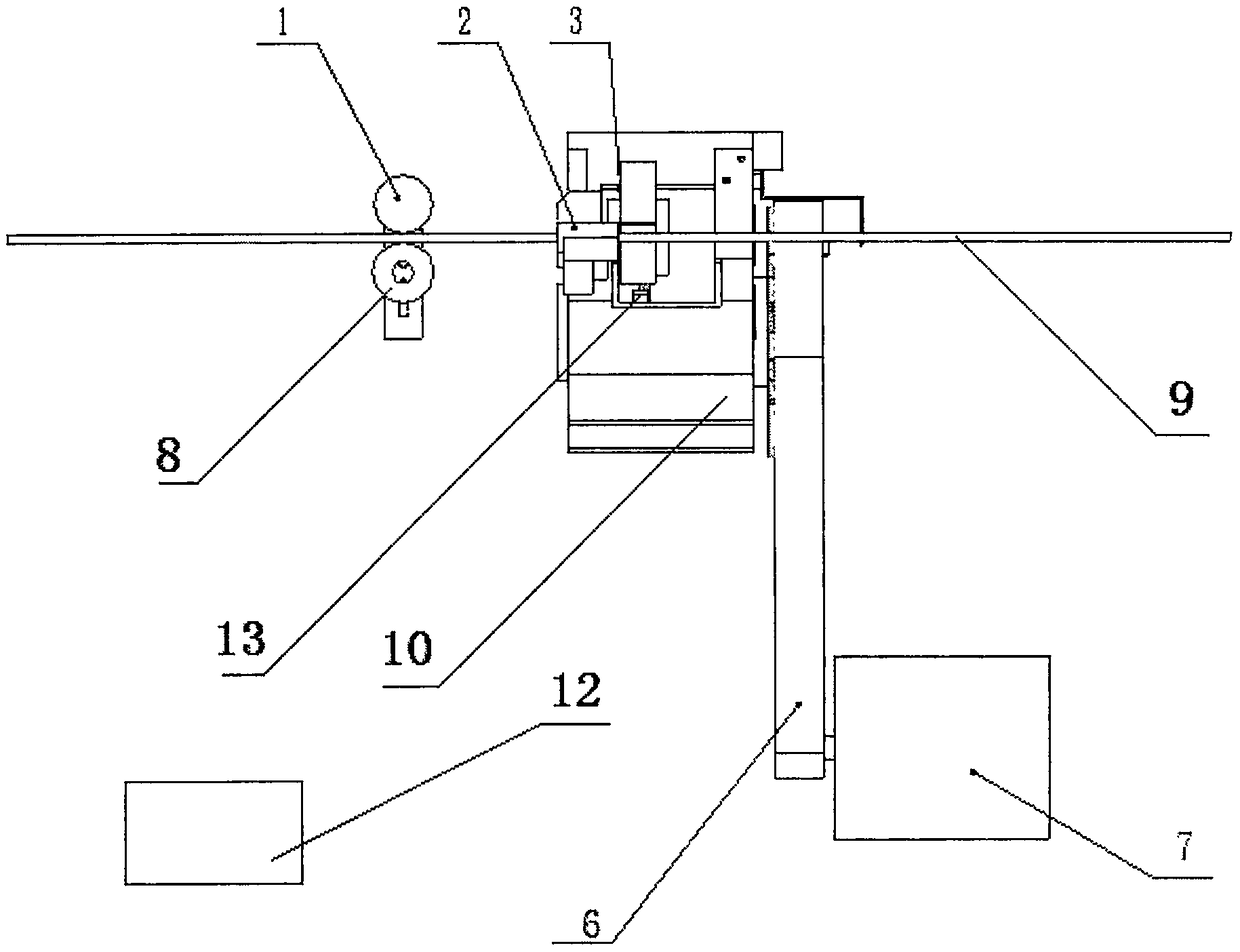

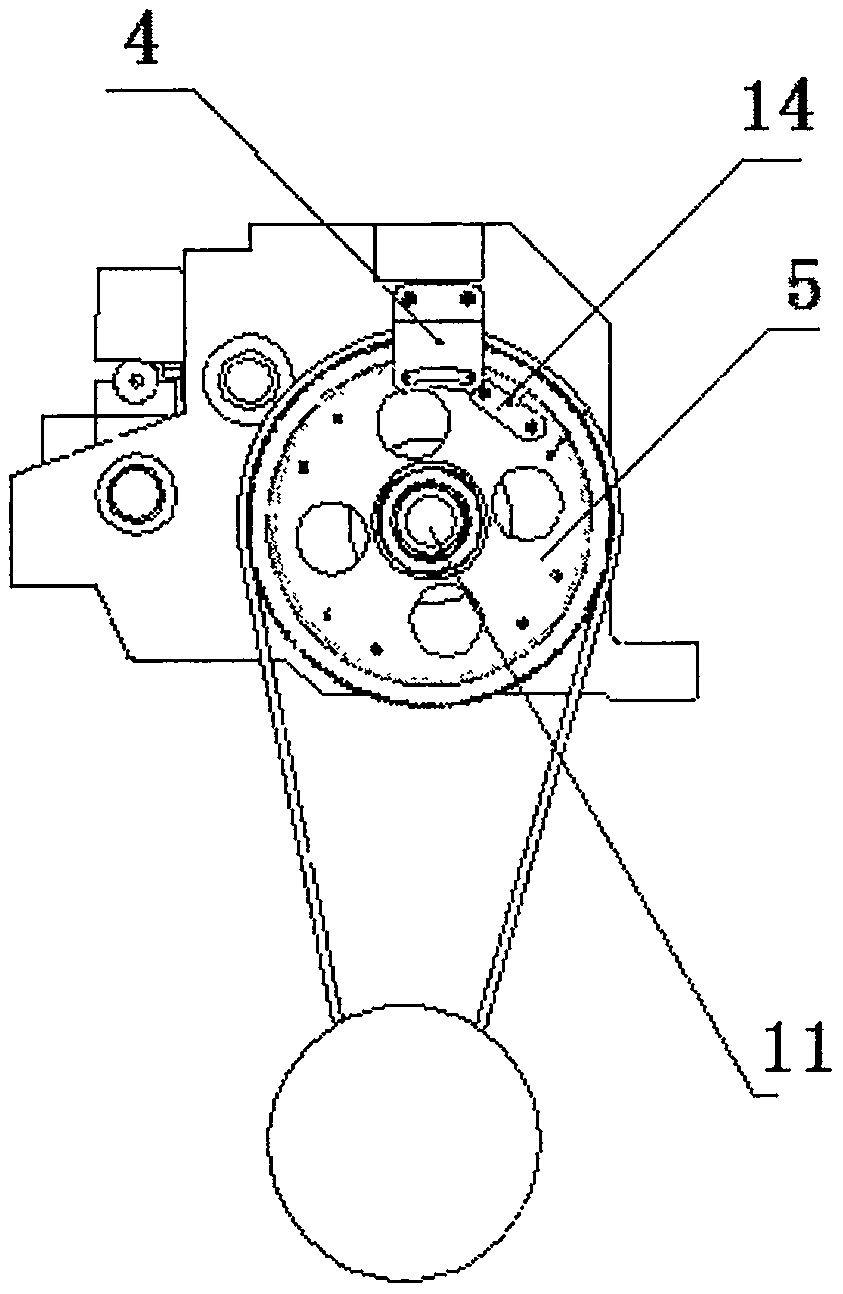

[0014] Embodiment 1: The PLC controller 12 real-time sets the length D418 of the steel bar 9 in the touch screen, the error correction D416, the distance D440 from the encoder 1 to the knife edge of the moving knife 3 (the steel bar 9 first passes through the encoder 1 and then reaches the knife edge of the moving knife 3, all This distance is called "encoder 1 to moving knife 3 knife-edge distances"), signal distance length D444 (PLC controller 12 receives the cutting signal to the response time period of moving knife 3 knife-edge shearing to steel bar 9, steel bar 9 and The conveying distance is called "signal distance length"), encoder 1 pulse number D410, encoder 1 measuring wheel circumference (unit mm) D412 is transmitted to PLC controller 12, and PLC controller 12 divides encoder 1 pulse number D410 by Encoder 1 measures the circumference of the wheel D412 to obtain the number of pulses corresponding to one millimeter D100; the second step adds the length of the set stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com