Steel plate shear gauge and gauging method thereof

A sizing machine and sizing technology, which is applied to metal processing machinery parts, measuring/indicating equipment, and accessories of shearing machines, etc., can solve problems affecting the sizing accuracy of steel plates, small transient response changes, and system instability. , to avoid the cumbersome positioning process, improve stability, and improve the effect of sizing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention. Wherein, this specific implementation mode is described by taking the sizing machine of the medium and heavy plate factory of Jinan Iron and Steel Co., Ltd. as an example.

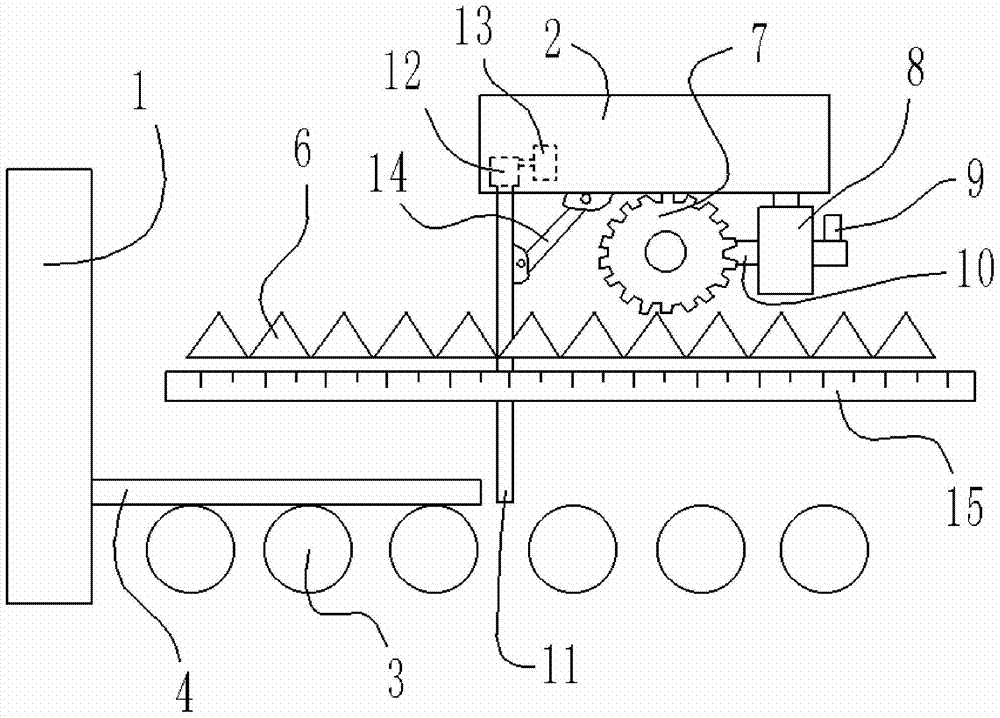

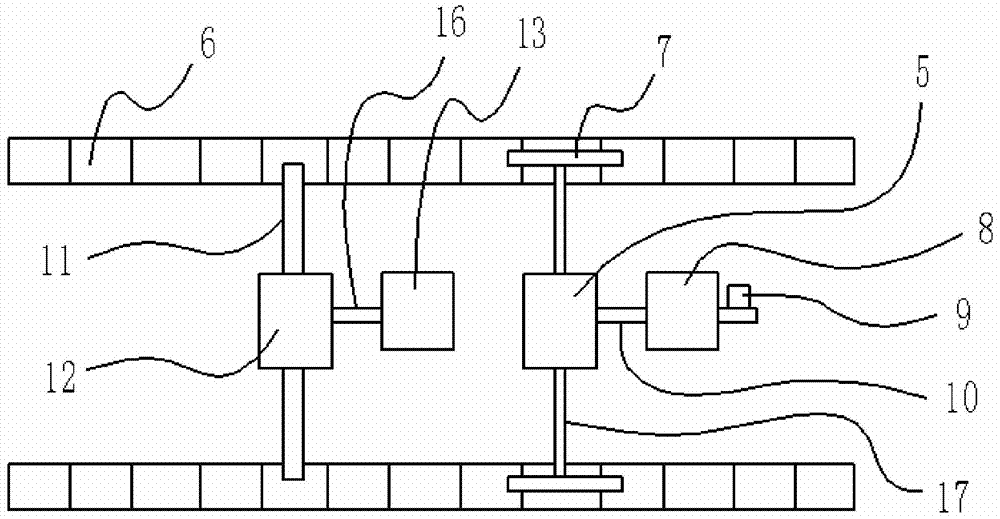

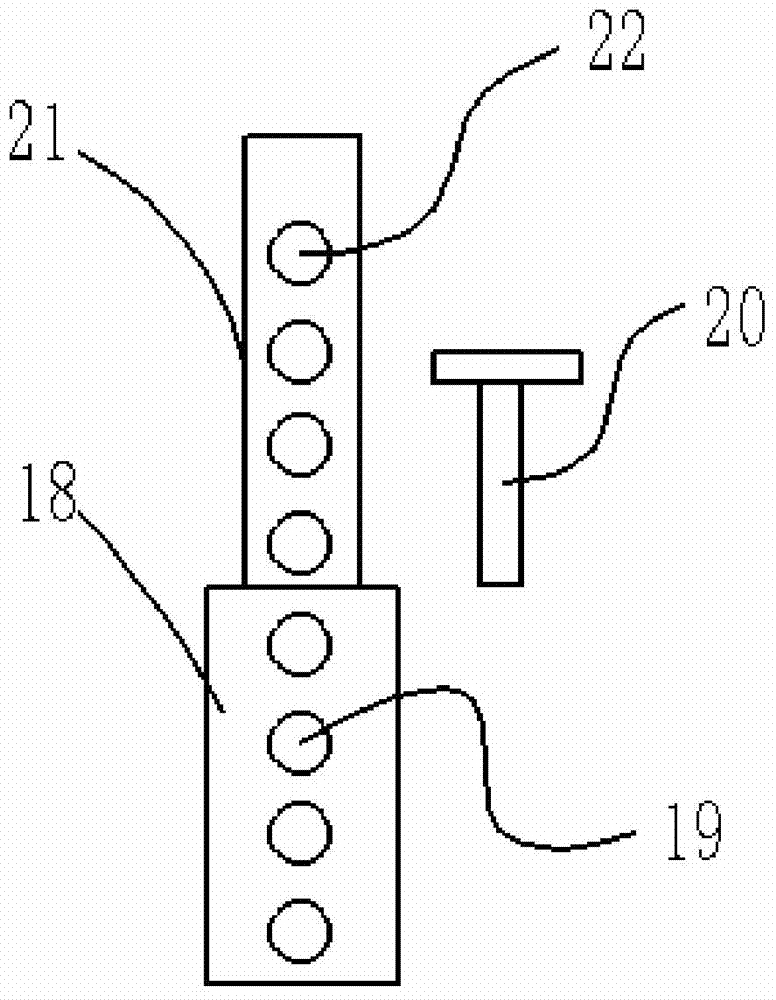

[0038] figure 1 , figure 2 It is a steel plate sizing machine of the present invention, comprising a sizing trolley 2, a trolley drive motor 8 for driving the sizing trolley 2 to move, and a conveying mechanism 3 for conveying the steel plate 4, and the top of the conveying mechanism 3 is provided with two parallel Rack 6, the rack 6 is distributed along the conveying direction of the steel plate 4, the trolley 2 to length is arranged on the top of the rack 6, the lower end of the trolley 2 to length is equipped with a gear 7 for walking, the gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com