Double-crank frame type flying shears

A flying shear, frame type technology, applied in the direction of shearing device, shearing machine equipment, accessories of shearing machine, etc., can solve the problems of complex structure and movement, low production efficiency and high manufacturing cost, and achieve easy manufacturing and maintenance. , The effect of small structure size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

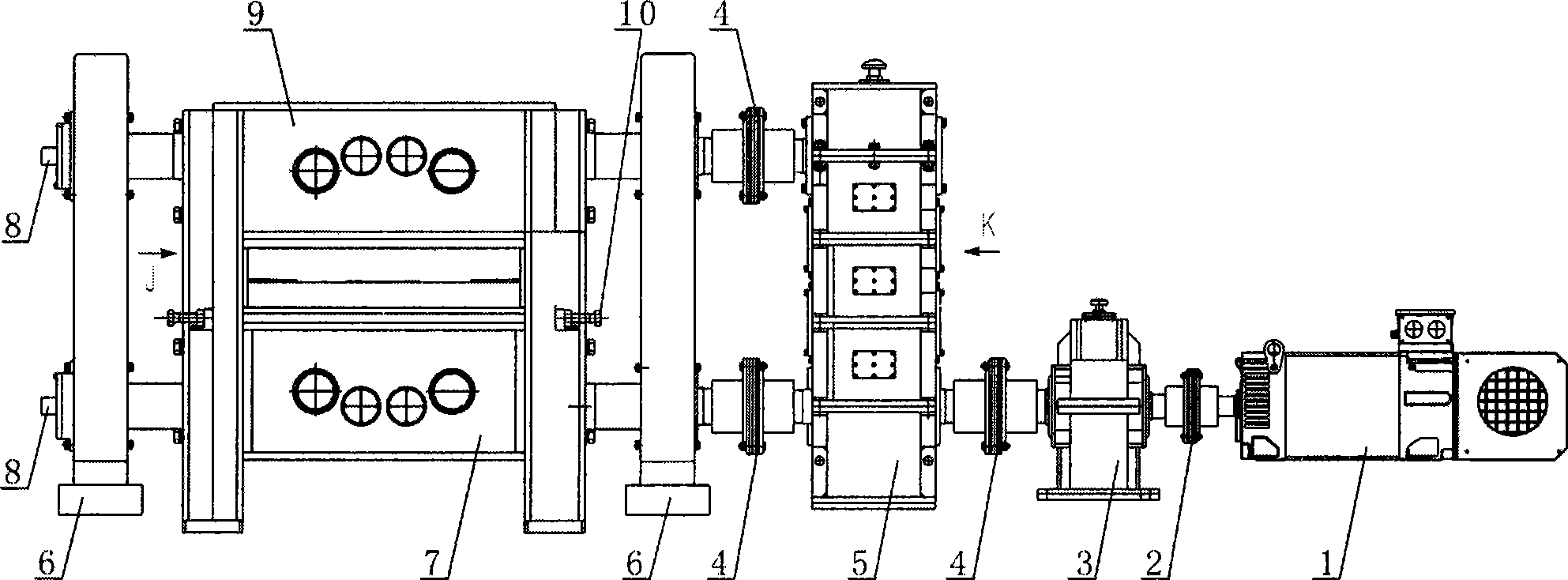

[0026] figure 1 Instructions marked in: Motor 1, No. 1 Coupling 2, Reducer 3, No. 2 Coupling 4, Gear Distribution Box 5, Fixed Base 6, Lower Tool Holder 7, Encoder 8, Upper Tool Holder 9, Blade gap adjustment device 10'.

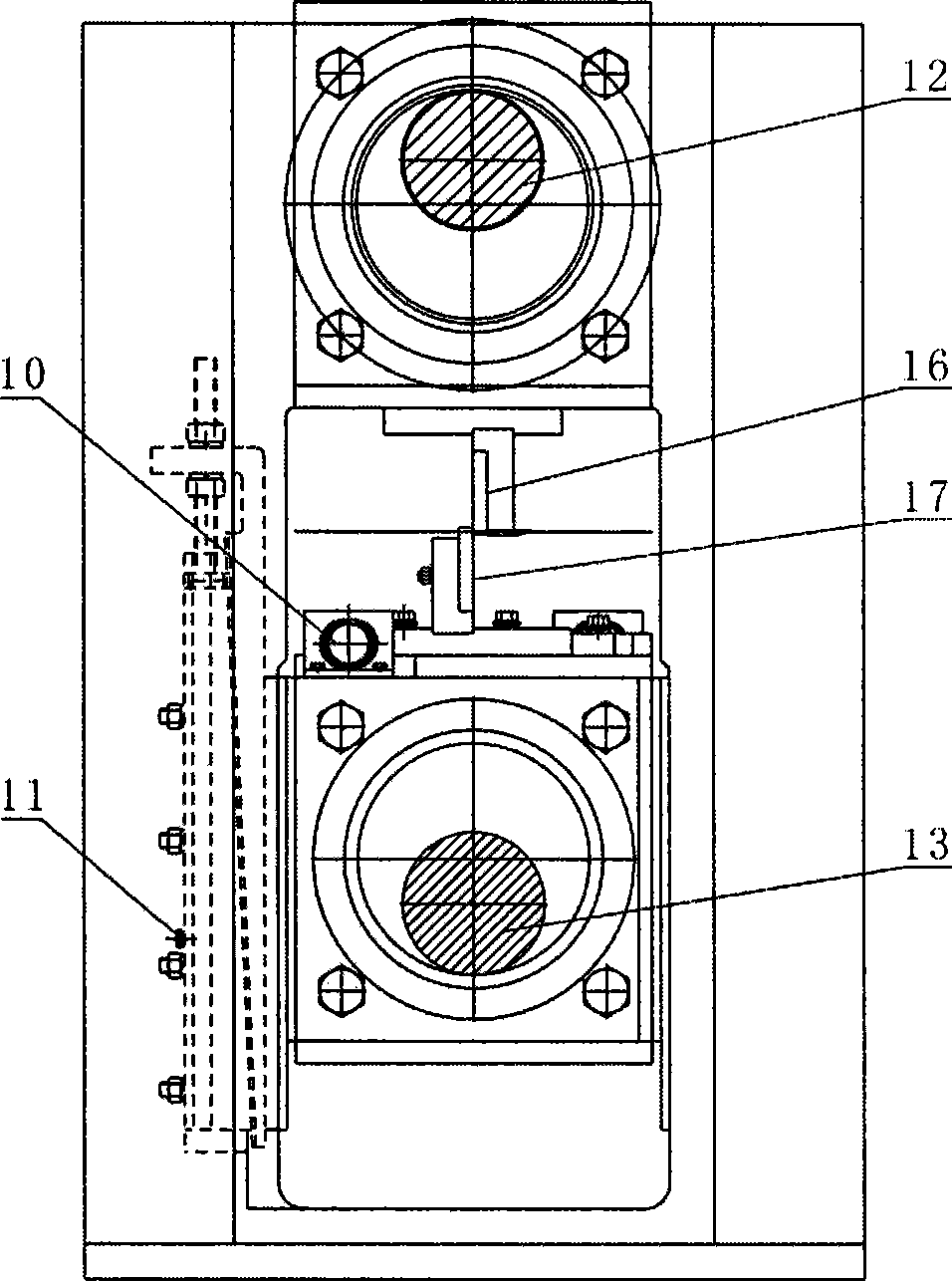

[0027] figure 2 Explanation of middle marks: slideway gap adjustment device 11, upper tool seat crankshaft 12, lower tool seat crankshaft 13, upper blade 16, lower blade 17.

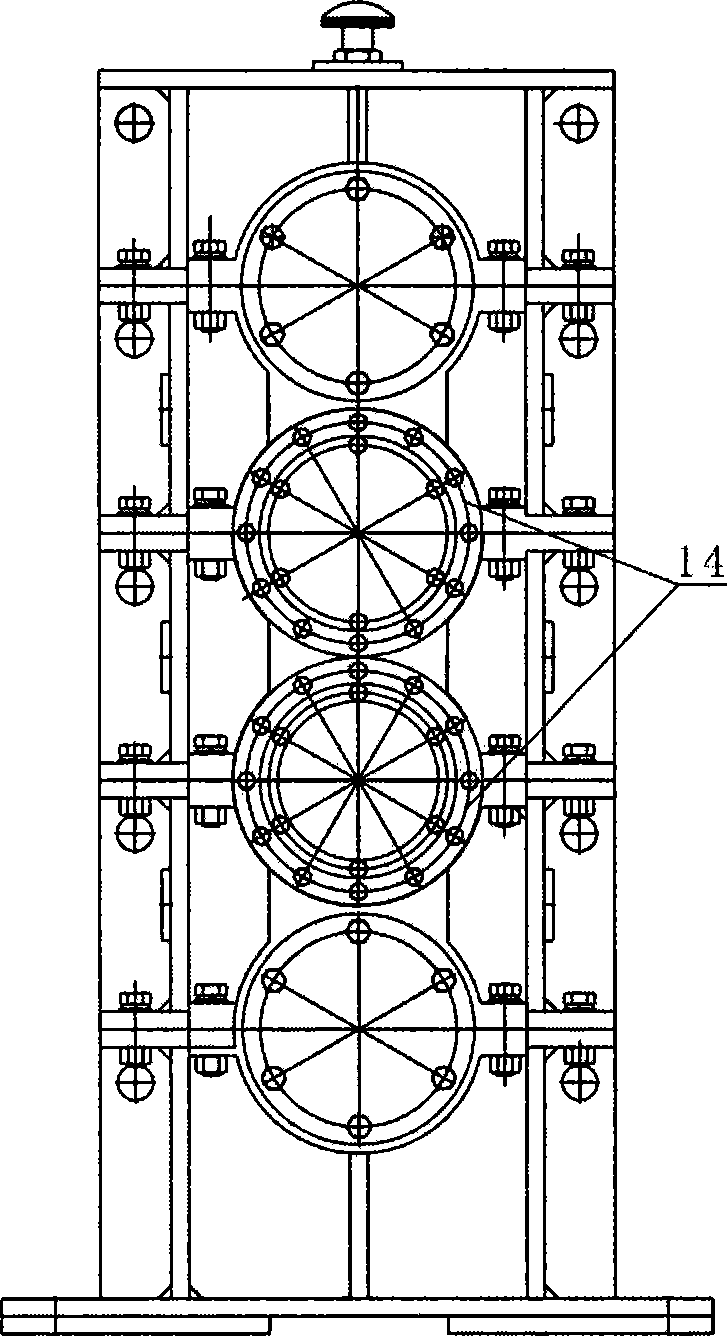

[0028] image 3 Instructions marked in: gear distribution box gear backlash adjustment device 14.

[0029] Figure 4 Instructions marked in: primary and secondary gear mechanism 15.

[0030] Depend on figure 1 , figure 2 , image 3 , Figure 4 It can be seen that the double crank frame type flying shear of the embodiment of the present invention mainly consists of motor 1, No. 1 shaft coupling 2, speed reducer 3, No. 2 shaft coupling 4, gear distribution box 5, fixed support 6, lower Knife seat 7, slideway clearance adjustment device 11, upper knife seat 9, blade clearance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com