Dual-servo-motor angle shear machine

A dual-motor servo, angle shearing machine technology, used in glass manufacturing equipment, manufacturing tools and other directions, can solve the problems of low service life, poor action repeatability, slow shearing speed, etc., to improve service life, reduce shearing errors, The effect of smooth shearing motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

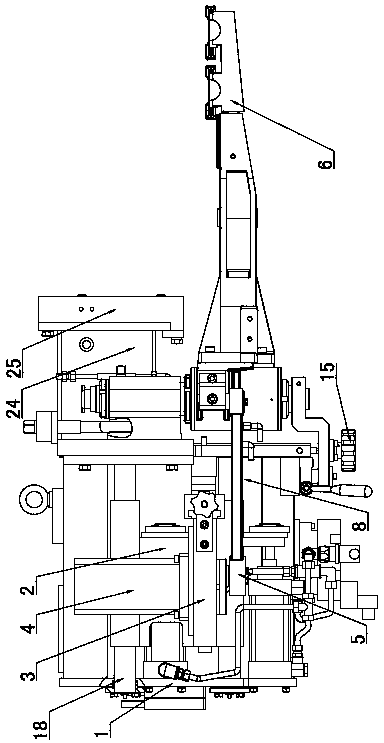

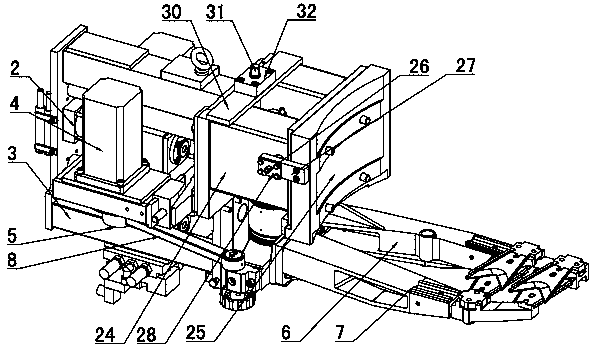

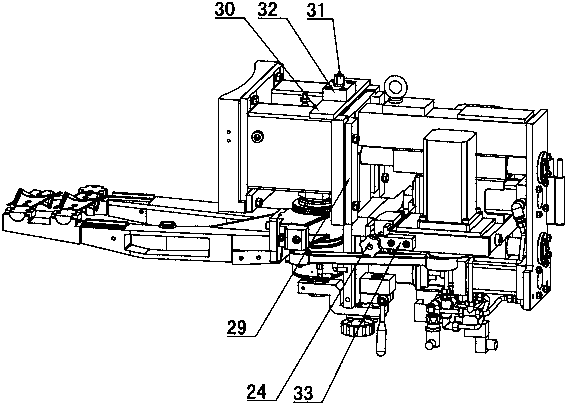

[0034] Figure 1~7 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~9 The present invention will be further described.

[0035] Refer to attached Figure 1-3: Double-motor servo angle shearing machine, including a support frame and a shearing device installed on the support frame. The upper part of the shearing device is equipped with a fixing device that can fix the entire device on the feeder. The support frame includes a support frame 1 and a motor support 3. The cylinder 2 is installed on the support frame 1. Two horizontal sliding shafts 18 are installed side by side on one side of the support frame 1. The motor support 3 is sleeved on the sliding shaft 18 and connected to the cylinder 2. Connected, the motor bracket 3 is driven by the cylinder 2 and can slide along the sliding shaft 18.

[0036] The shearing device comprises a servo motor 4, left and right linkages, a scissor arm supporting device, a left scissor arm 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com