Patents

Literature

86results about How to "Prevent overlapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

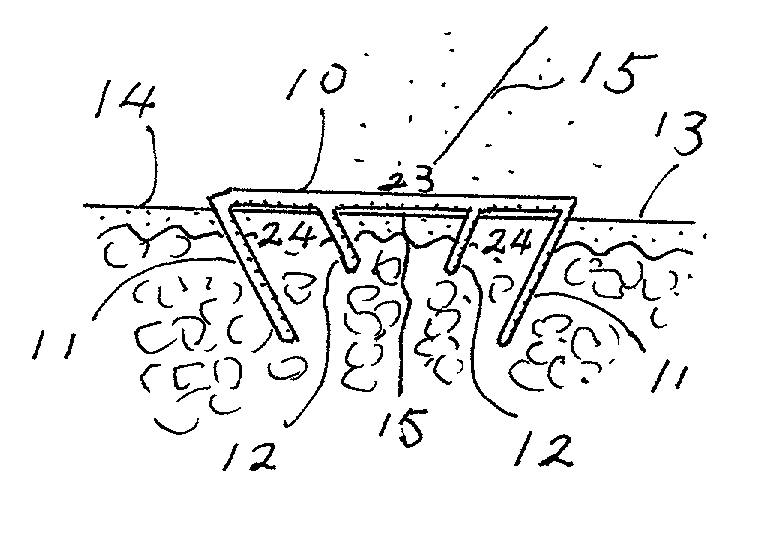

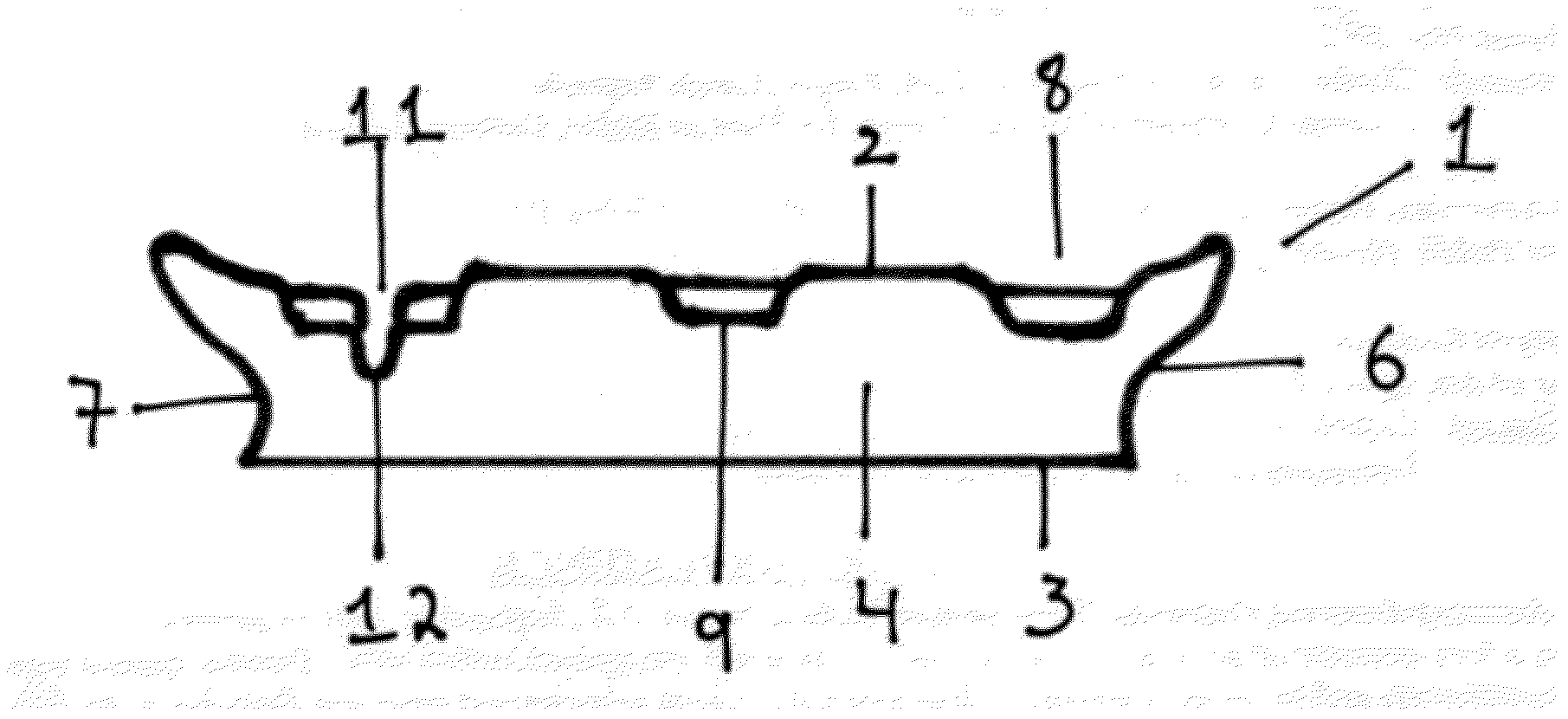

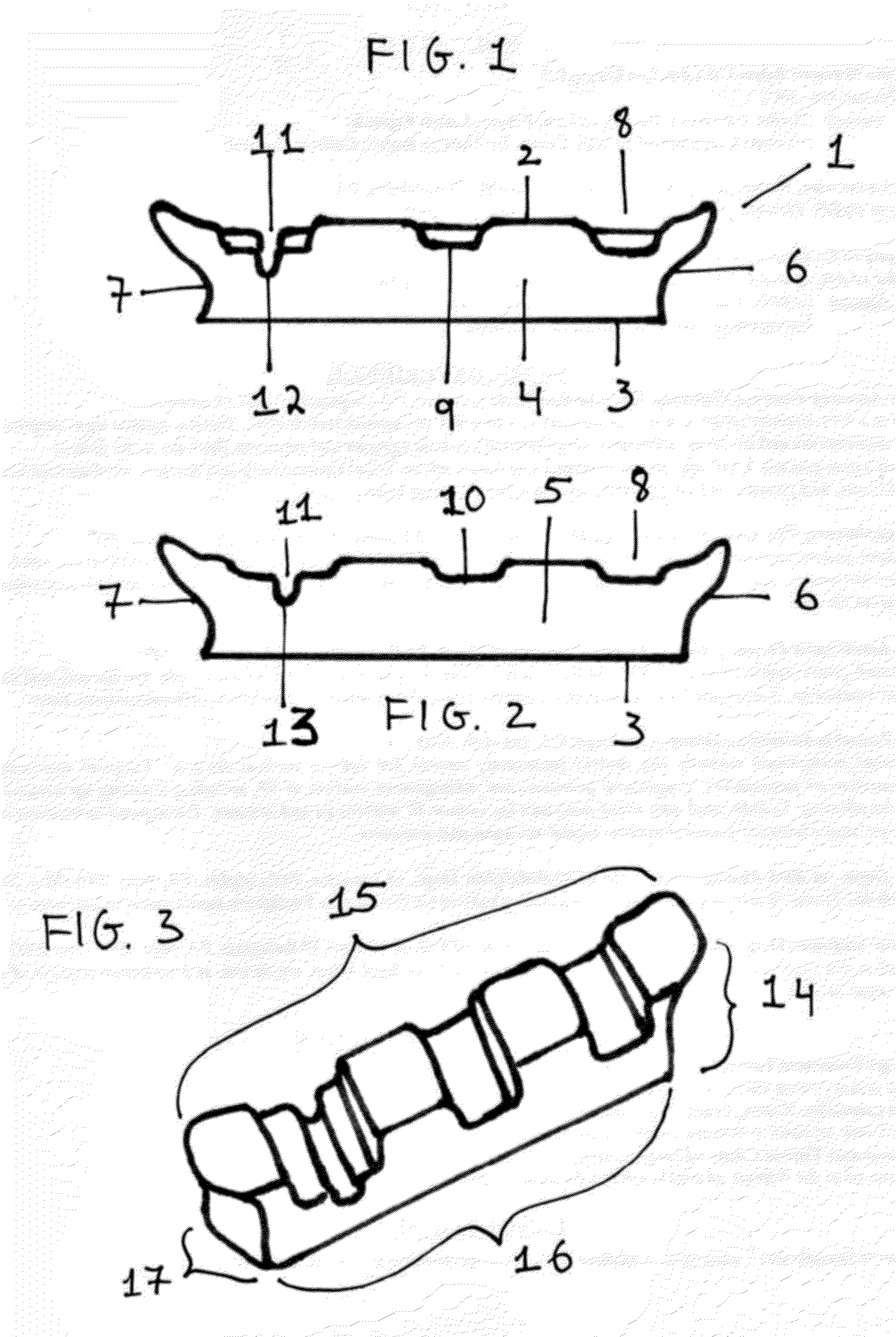

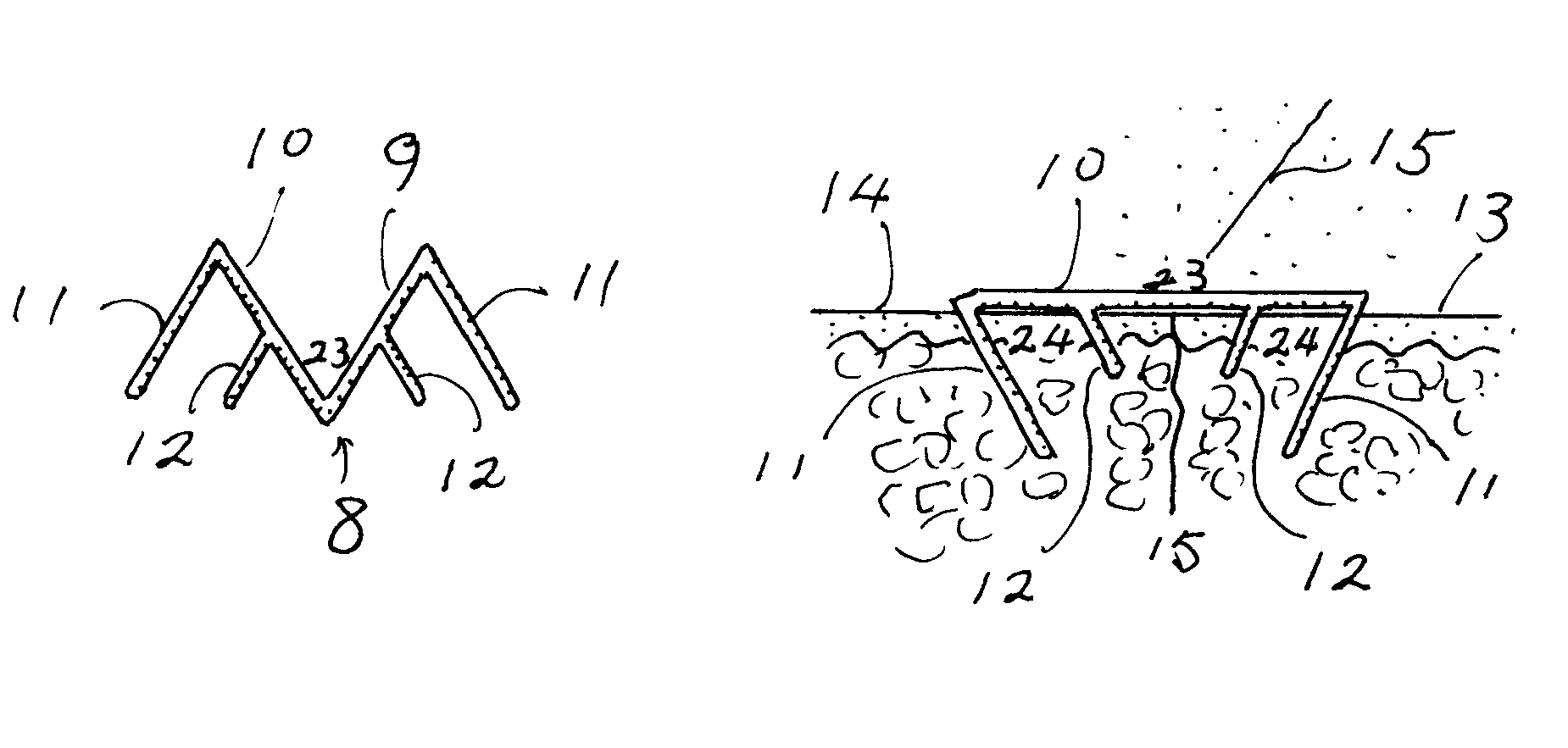

Four-spikes surgical skin staple

InactiveUS20020133181A1Prevent overlappingImprove stabilityStaplesJoint implantsSkin stapleGeneral surgery

A four-spikes surgical skin staple is composed of two stems which form a 60 degree angle V-shaped figure and four spikes, which are composed of two identical outer long spikes and two identical inner short spikes. Each of the two identical outer long spikes is fixed at a 60 degree angle to the outer end of each stem and each of the two identical inner short spikes is fixed at a 60 degree angle to the middle of each stem. The two outer long spikes are used to approximate the surgical incision wound and the two inner short spikes are used to stabilize the incision skin edges to prevent the overlapping of the skin edges. With no overlapping of the incision skin edges, the surgical incision wound can heal better and faster.

Owner:TONG KUN YUAN

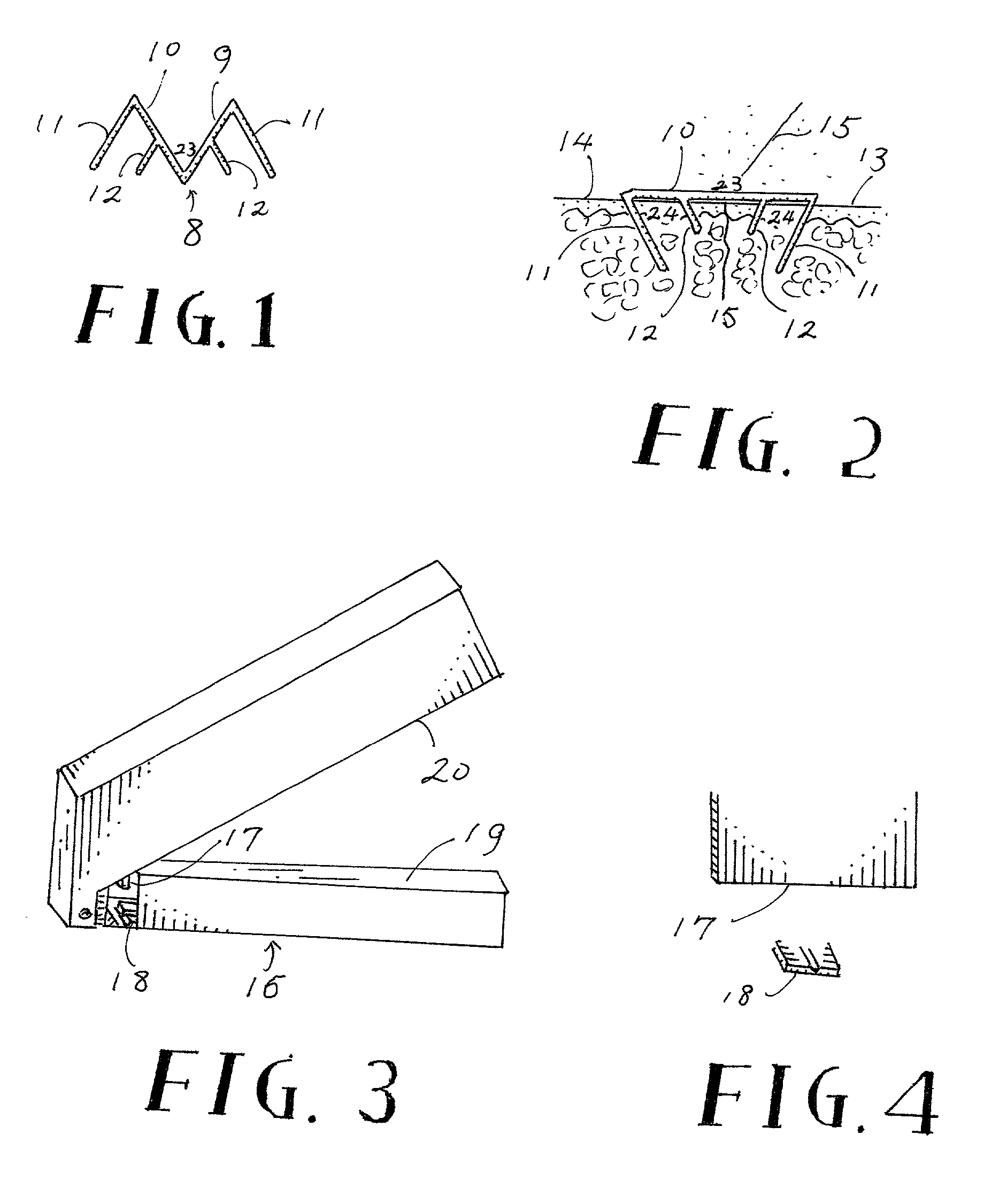

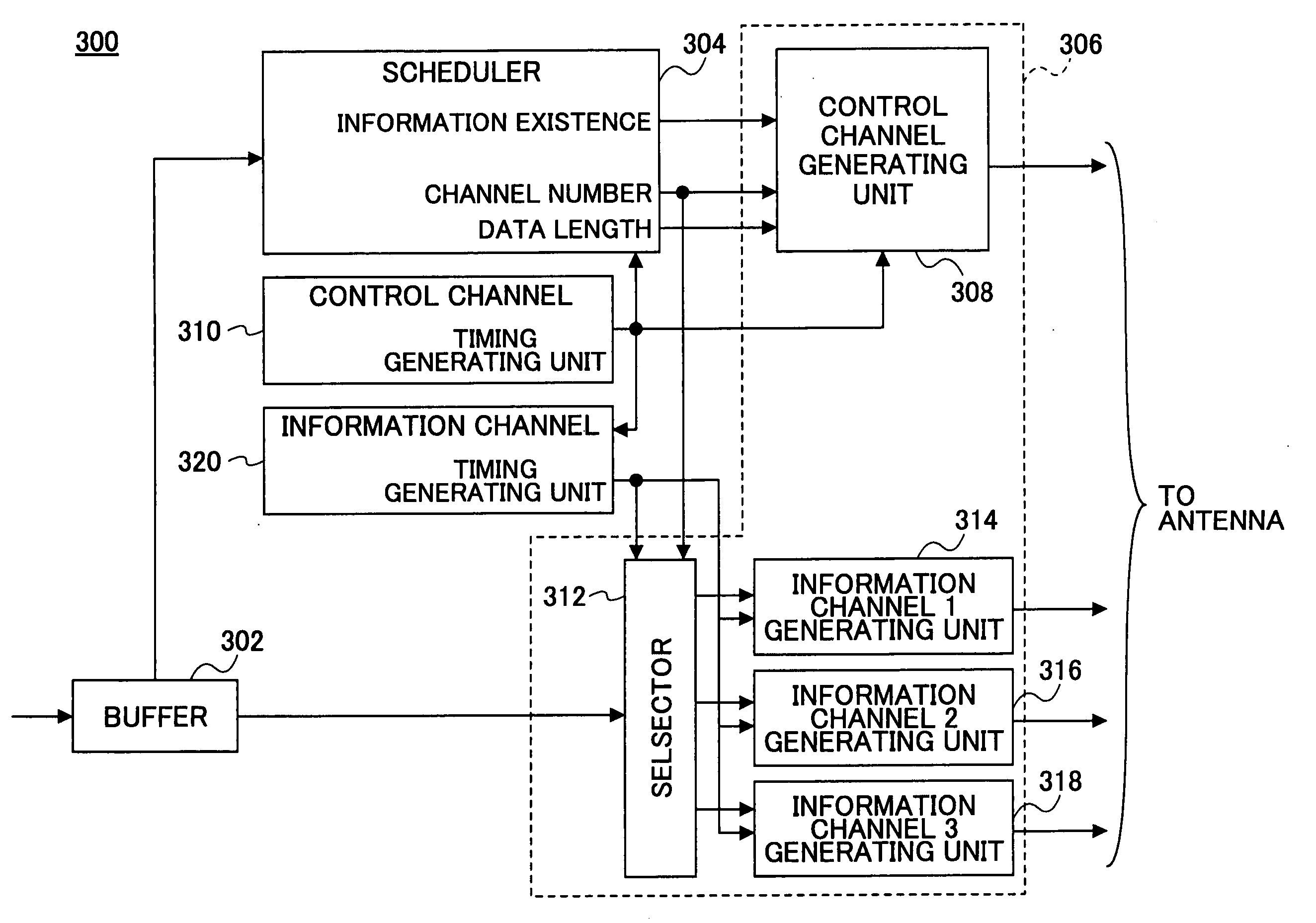

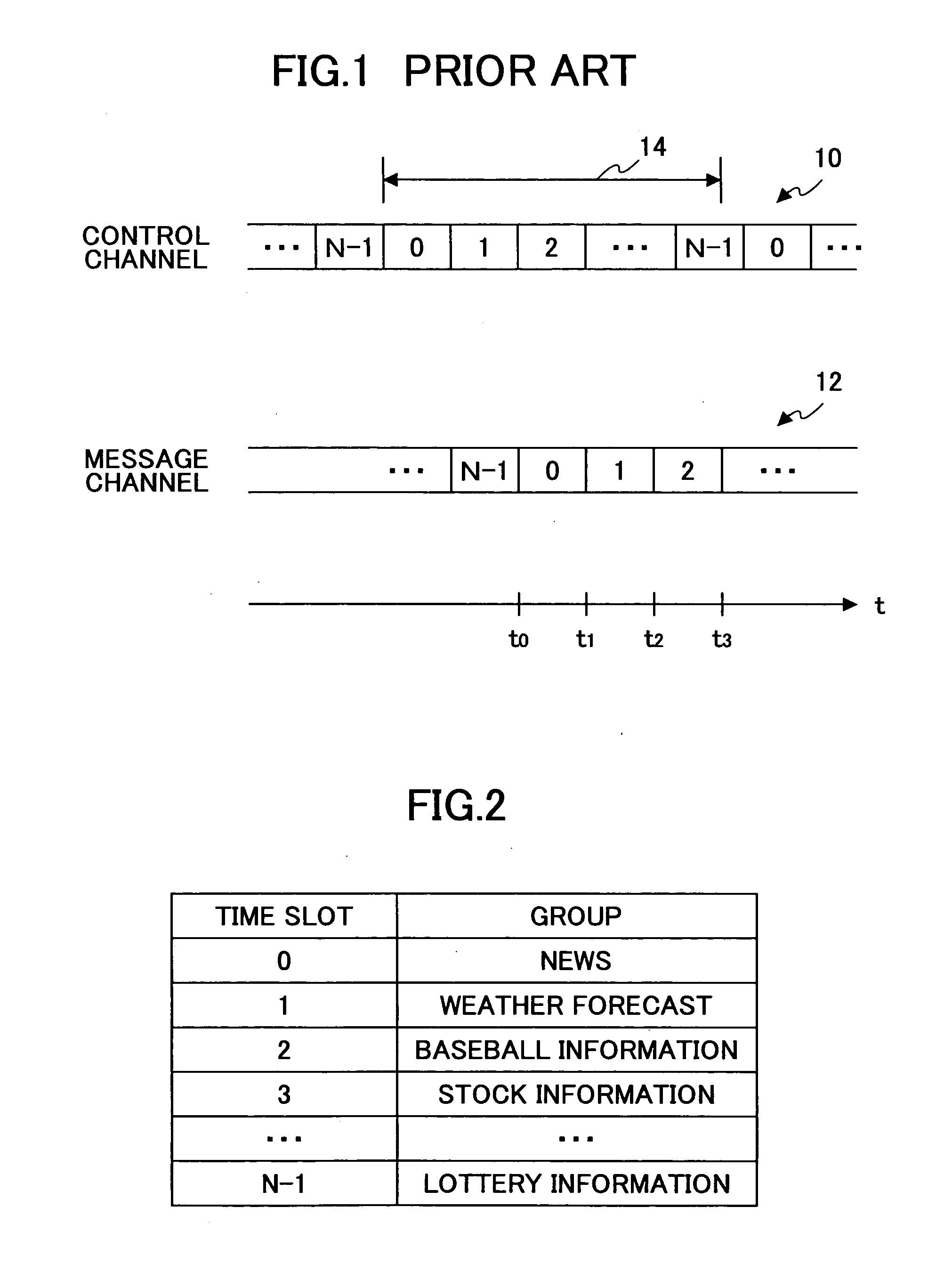

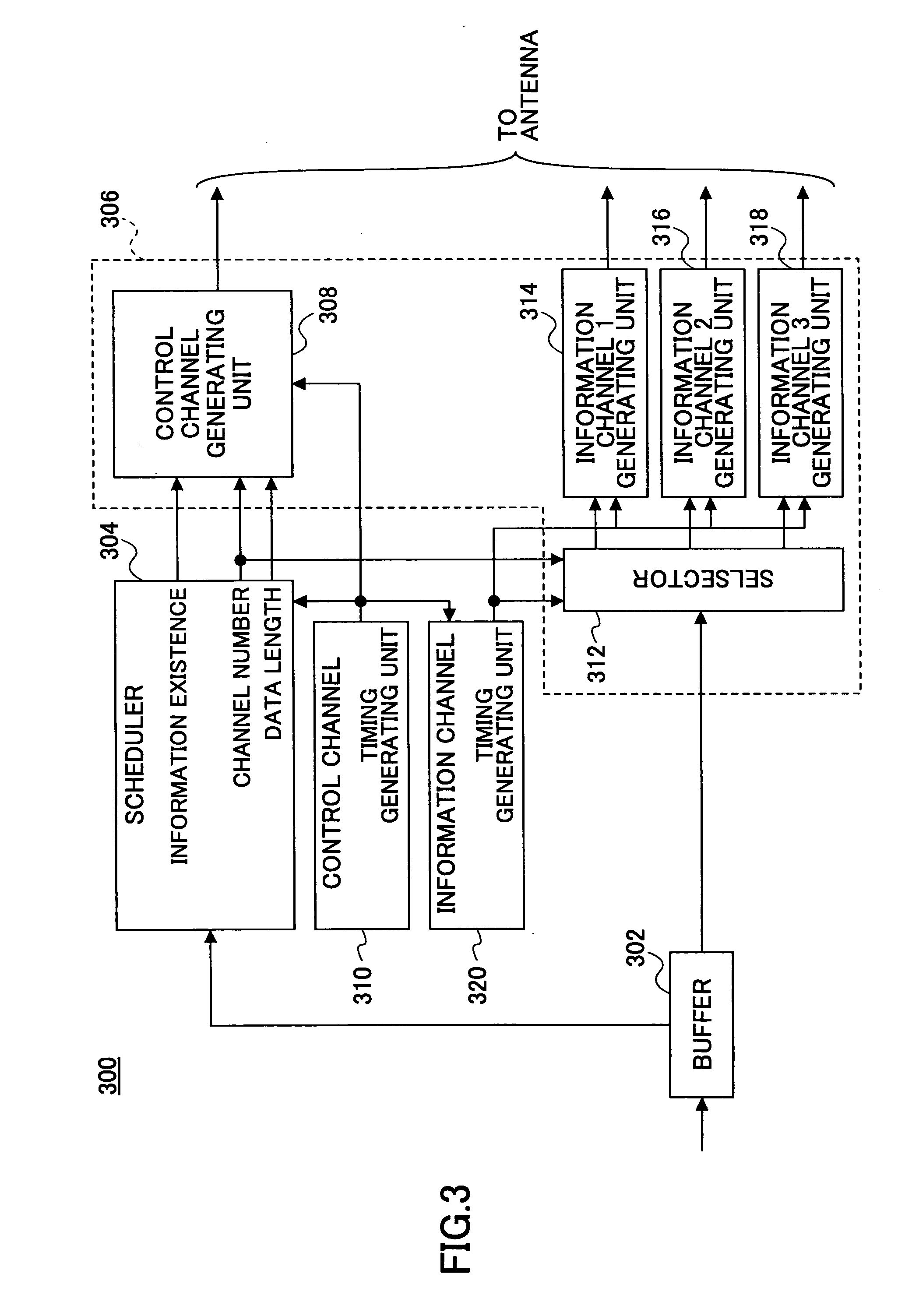

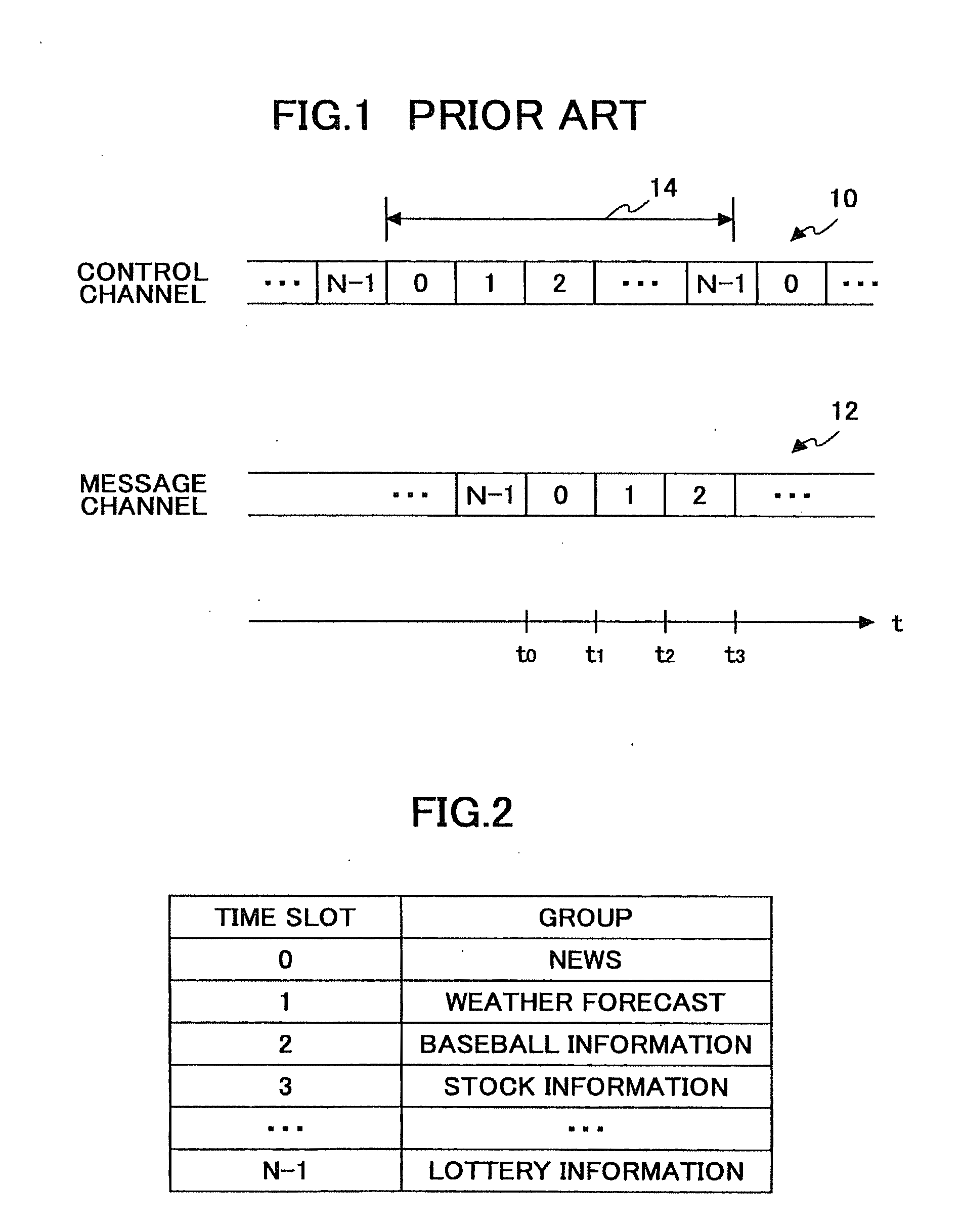

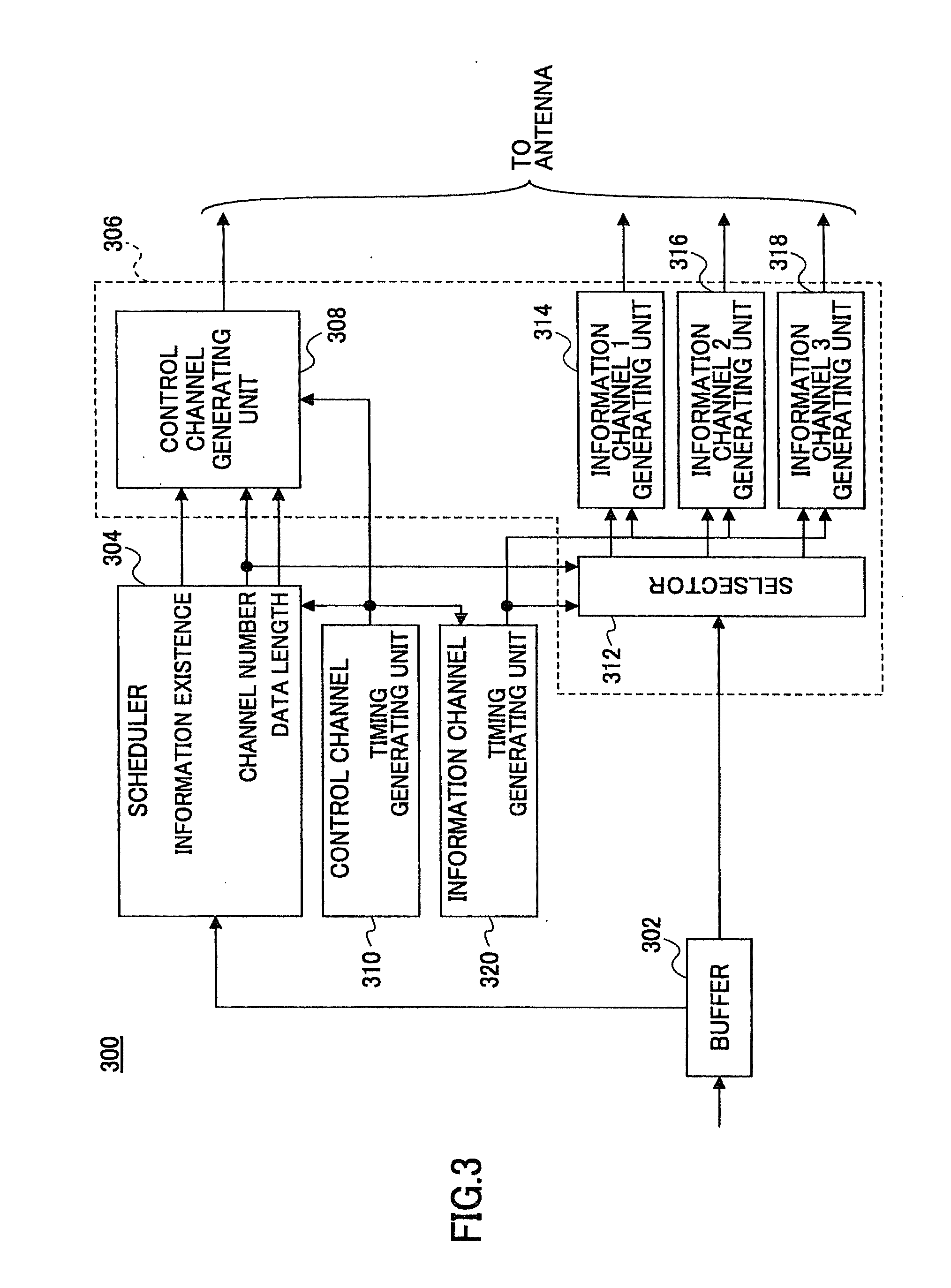

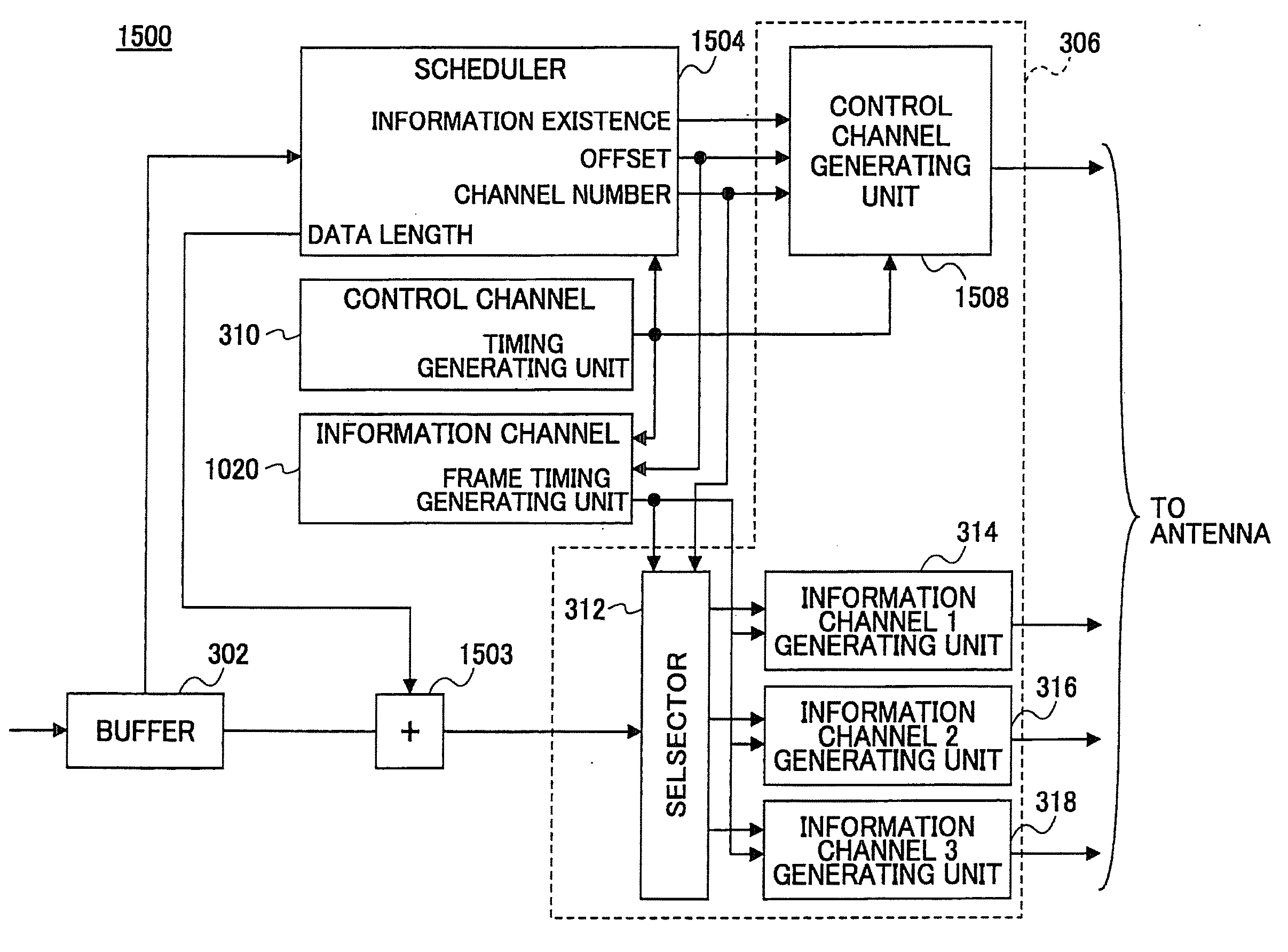

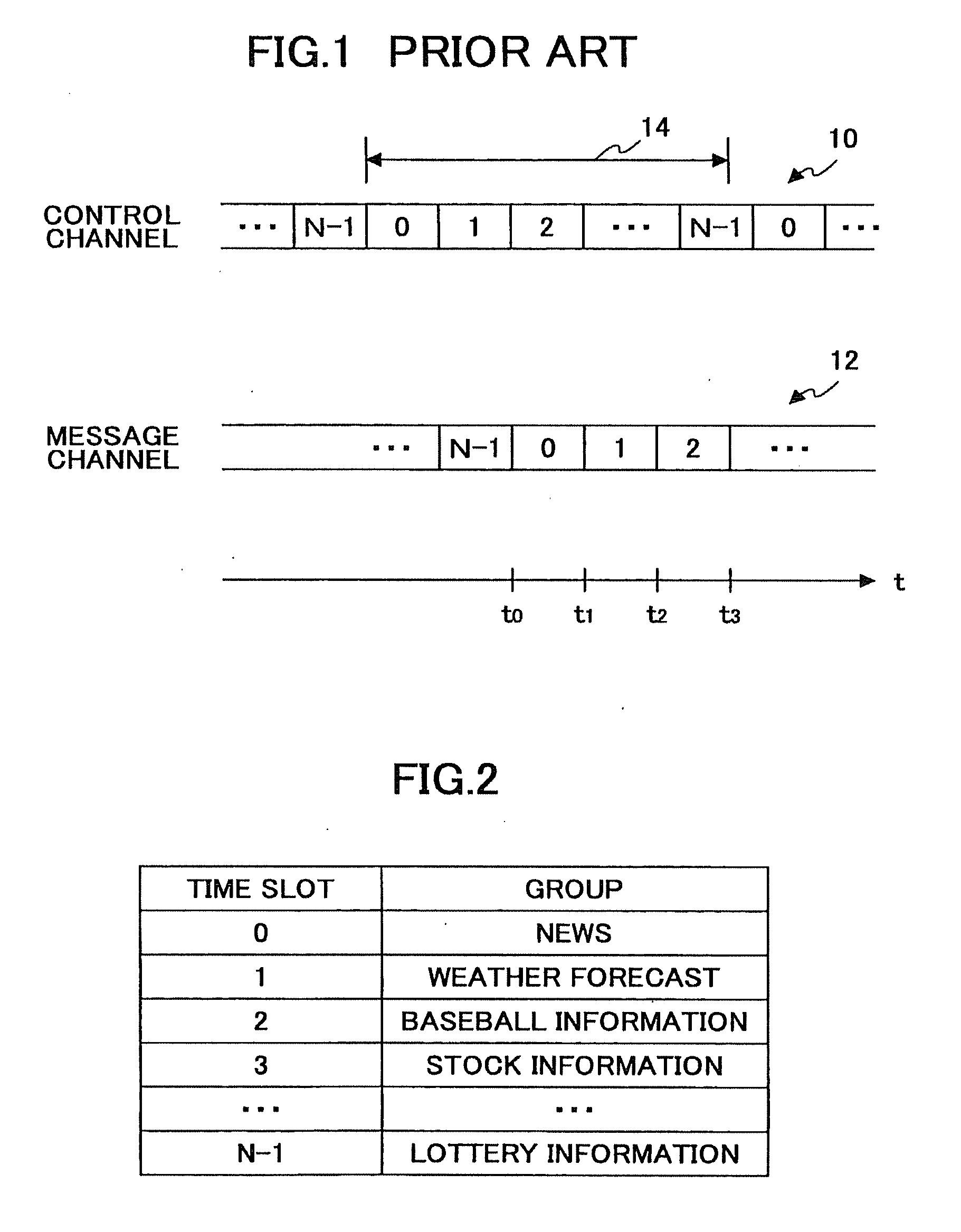

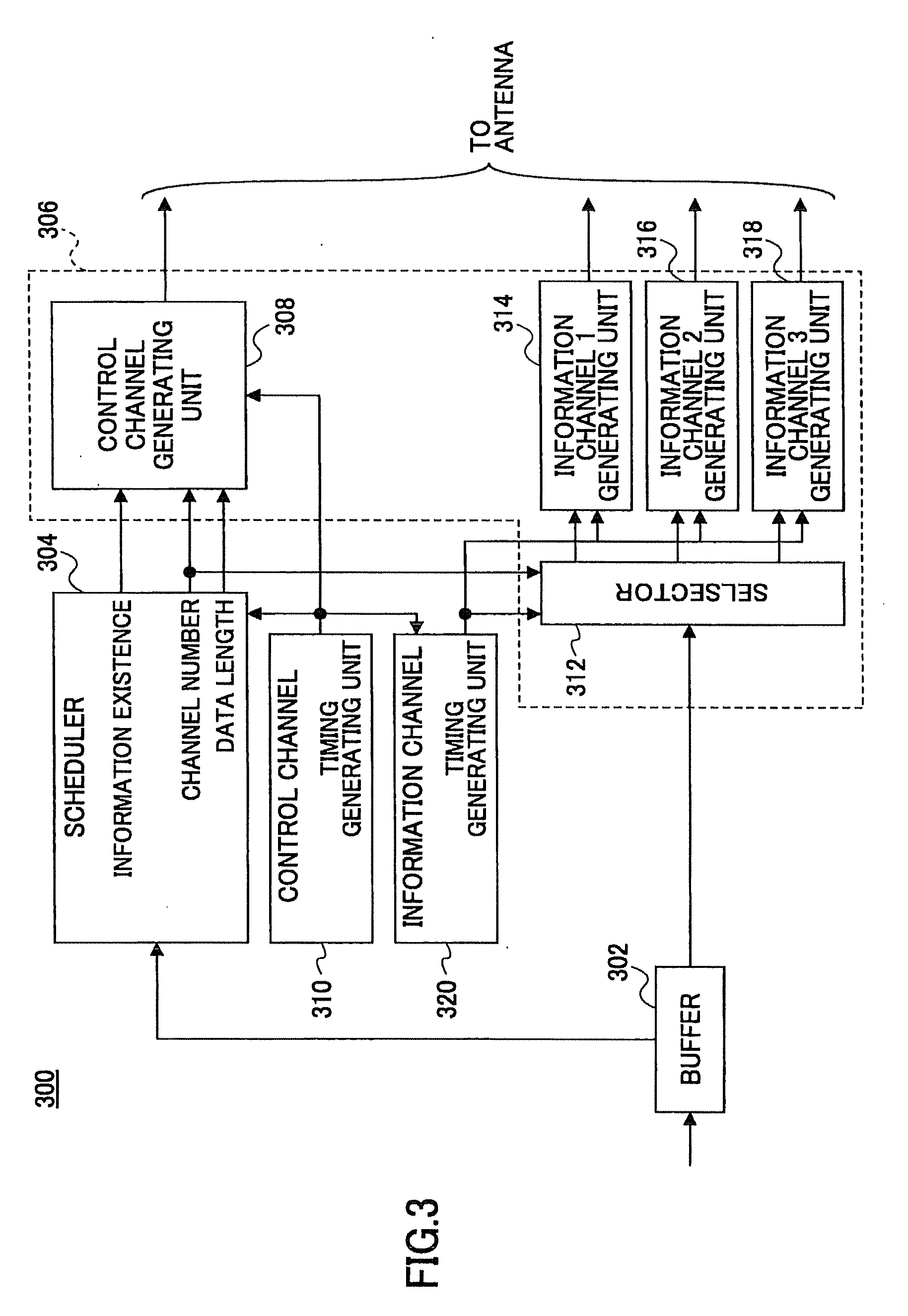

Information downloading apparatus and mobile terminal

ActiveUS20050243776A1Improve download efficiencyPrevent overlappingNetwork traffic/resource managementTime-division multiplexTelecommunicationsControl channel

A technique for improving the efficiency of downloading transmission data is disclosed. An information downloading apparatus downloads differing sets of information to predetermined groups to which a mobile terminal may belong. This apparatus includes a channel selecting unit for selecting from plural information channels an information channel for transmitting transmission data and a transmitting unit for transmitting transmission data using the selected information channel. The channel selecting unit selects an information channel so that sets of transmission data with differing destination addresses may be transmitted through differing information channels. The transmitting unit transmits to each group, through a control channel, information pertaining to whether a set of transmission data exists, the information channel to be used if the set of transmission data exists, and the data length of the set of transmission data. The control channel includes time slots that are associated with the groups.

Owner:FUJITSU LTD

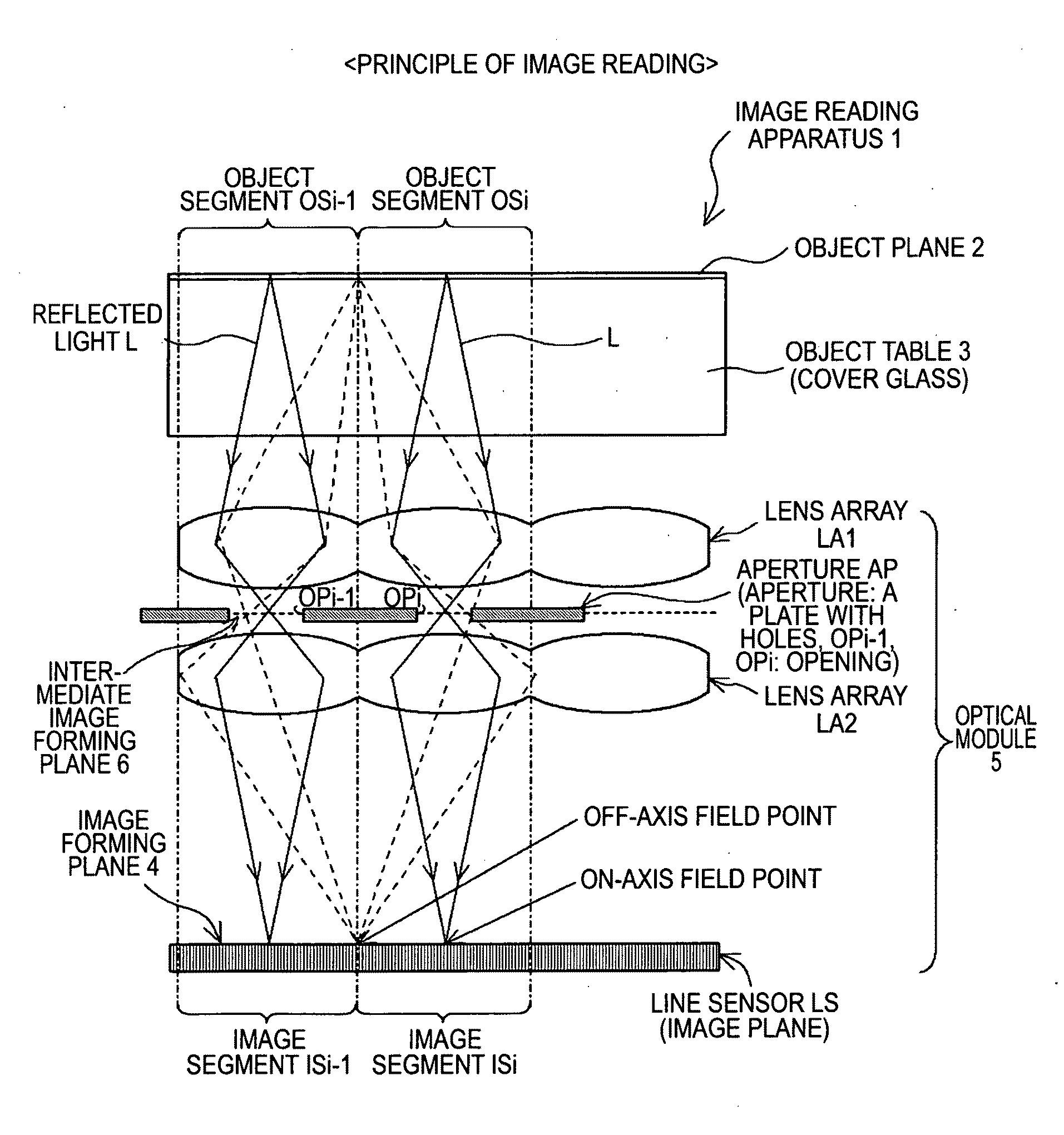

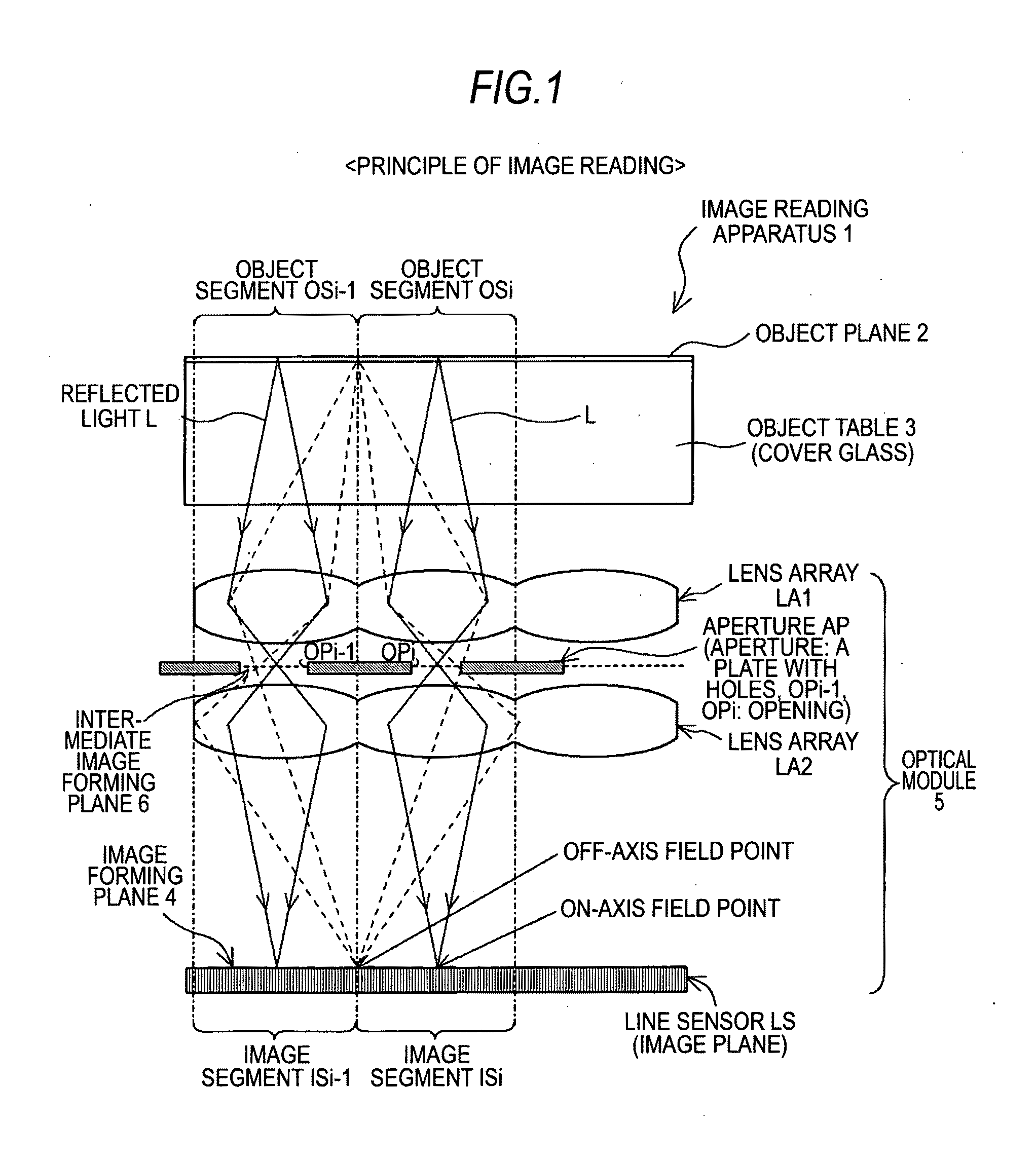

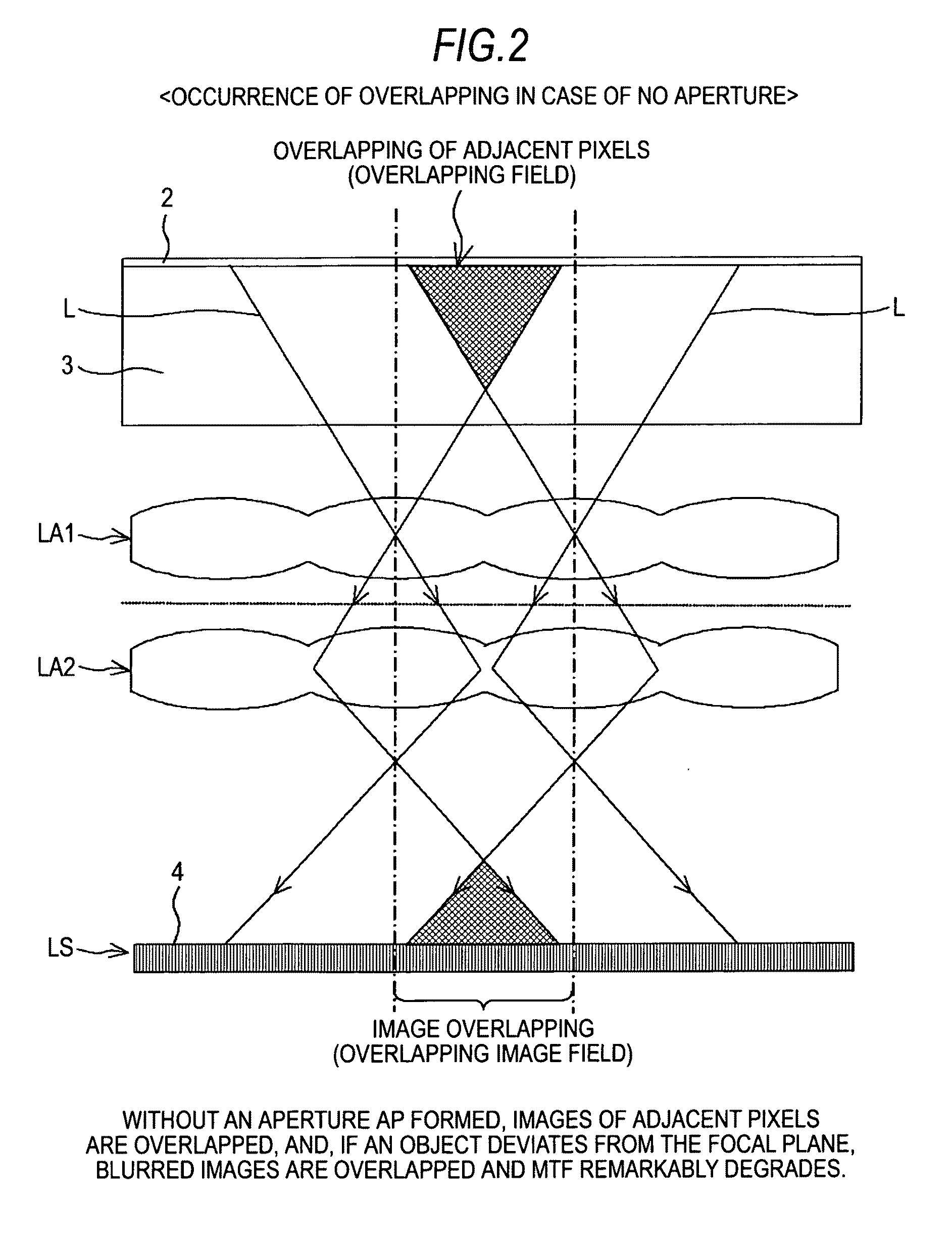

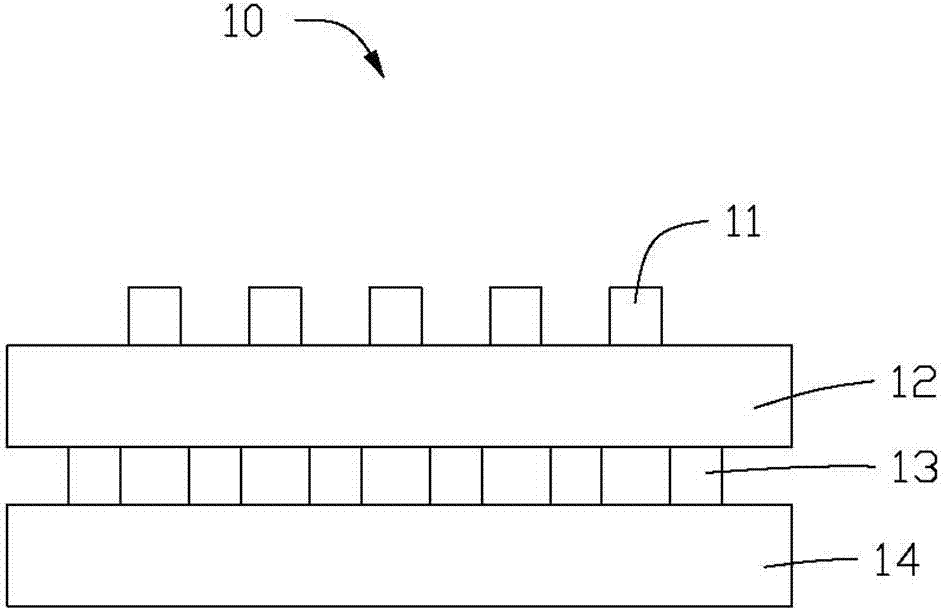

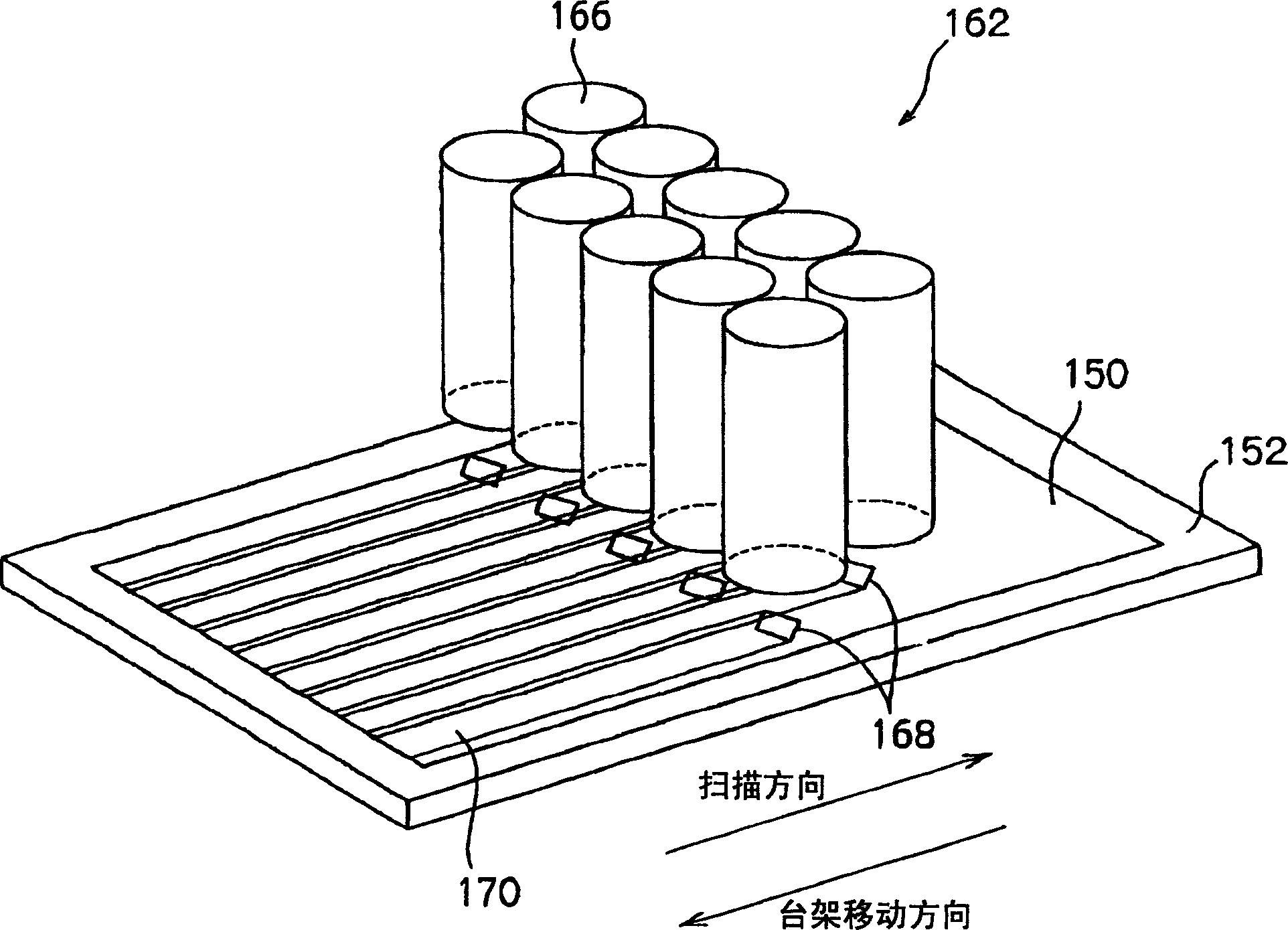

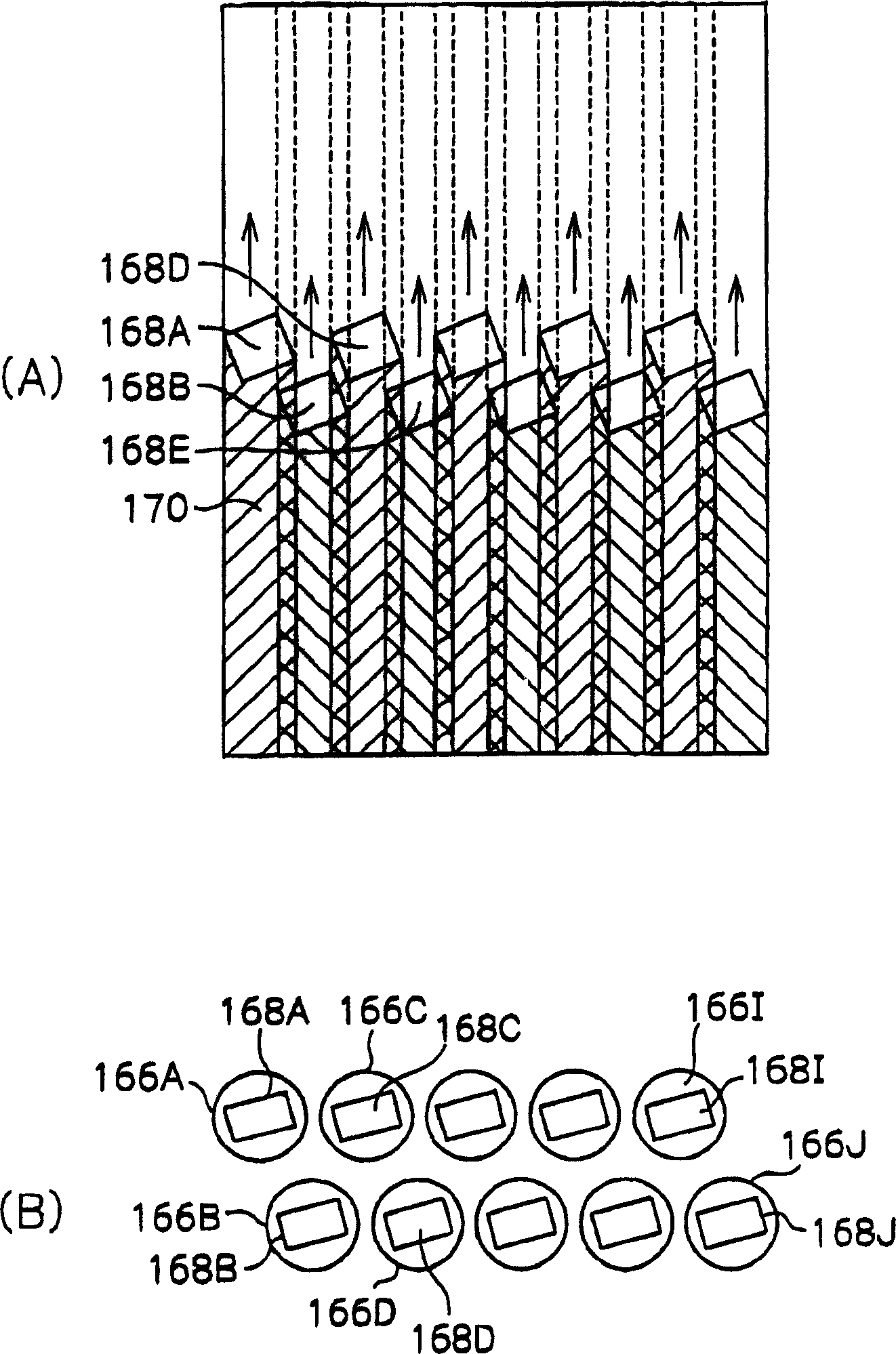

Image reading apparatus and optical module using the same

InactiveUS20110249304A1Improve accuracyLow costPictoral communicationOptical elementsOptical ModuleOptical axis

An image reading apparatus includes: alight irradiating means for irradiating light to a subject having images to be read; an image forming means for making the light from the subject incident on an image plane so as to form images as erected images; and a photoelectric conversion means for converting the incident light of the erected images into image signals, wherein the image forming means is constituted of a plurality of lens arrays that have a mutually identical shape and property and are sequentially disposed, sharing common light axes, between the subject and the photoelectric conversion means, and the respective lens arrays are formed by integral molding of a plurality of lenses, and an aperture provided with light passing holes with the light axes as the center is interposed at least between the plurality of lens arrays, and areas other than the light passing holes in the aperture form light shielding areas.

Owner:SONY SEMICON SOLUTIONS CORP

Table Utensil Rest

Owner:LE UYEN D

Four-spikes surgical skin staple

InactiveUS6726695B2Prevent overlappingImprove stabilityJoint implantsStaplesSkin stapleGeneral surgery

A four-spikes surgical skin staple is composed of two stems which form a 60 degree angle V-shaped figure and four spikes, which are composed of two identical outer long spikes and two identical inner short spikes. Each of the two identical outer long spikes is fixed at a 60 degree angle to the outer end of each stem and each of the two identical inner short spikes is fixed at a 60 degree angle to the middle of each stem. The two outer long spikes are used to approximate the surgical incision wound and the two inner short spikes are used to stabilize the incision skin edges to prevent the overlapping of the skin edges. With no overlapping of the incision skin edges, the surgical incision wound can heal better and faster.

Owner:TONG KUN YUAN

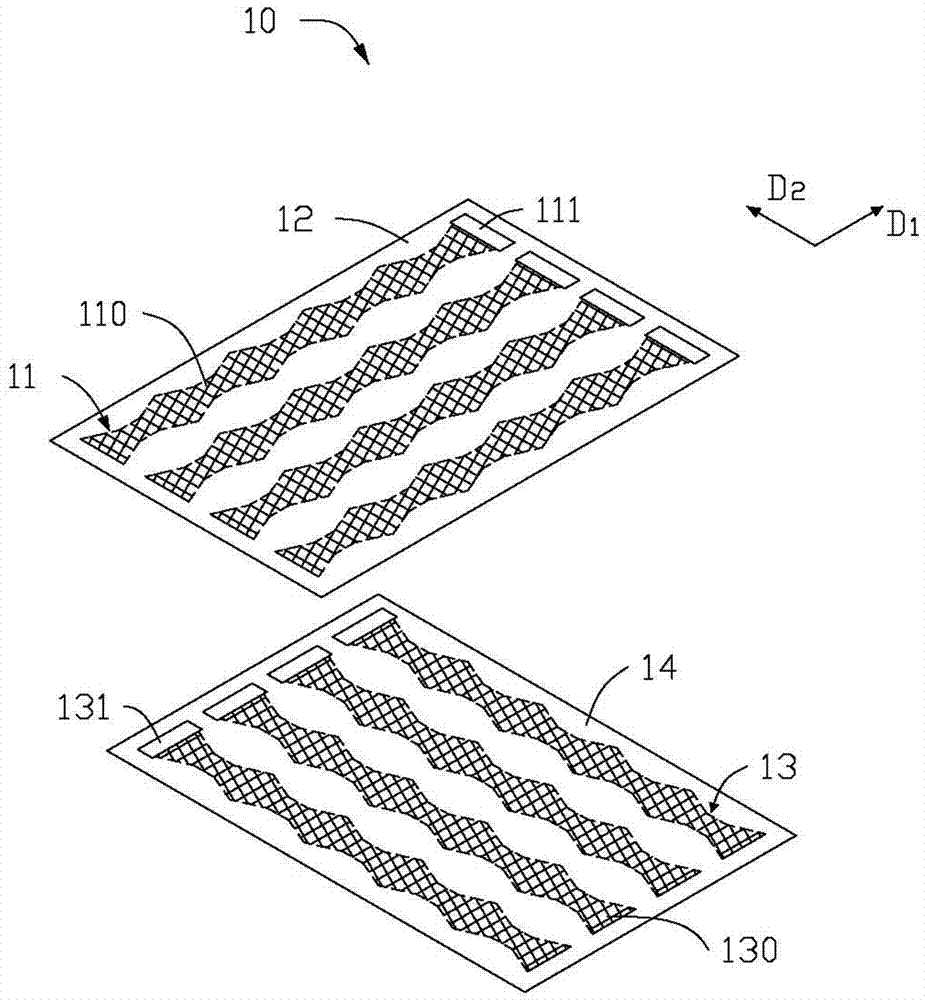

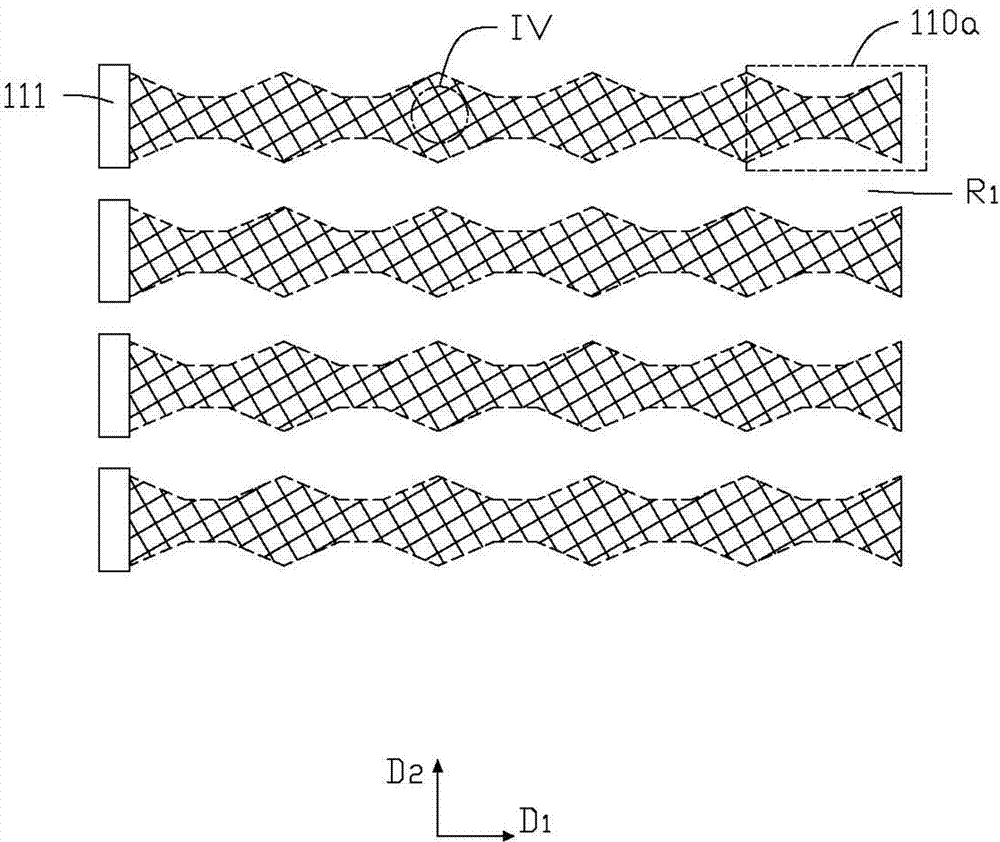

Touch panel and manufacturing method thereof

InactiveCN104123037APrevent overlappingNo interference fringesInput/output processes for data processingAcute angleEngineering

The invention provides a touch panel and a manufacturing method thereof. The touch panel comprises a plurality of first electric conducting patterns and a plurality of second electric conducting patterns, wherein the first electric conducting patterns and the second electric conducting patterns are arranged on a substrate, form an electric conducting structure, and are insulated from one another. The extension direction of each first electric conducting pattern is the first direction, and the extension direction of each second electric conducting pattern is the second direction. Each first electric conducting pattern comprises a plurality of first parallel metal lines and a plurality of second parallel metal lines. The first metal lines and the second metal lines form a plurality of square grids. A first acute angle is formed between each first metal line and the first corresponding direction. Each second electric conducting metal line comprises a plurality of third parallel metal lines and a plurality of fourth parallel metal lines. The third metal lines and the fourth metal lines form a plurality of square grids. A second acute angle is formed between each third metal line and the first corresponding direction. The first acute angle is different from the second acute angle.

Owner:INTERFACE OPTOELECTRONICS SHENZHEN +1

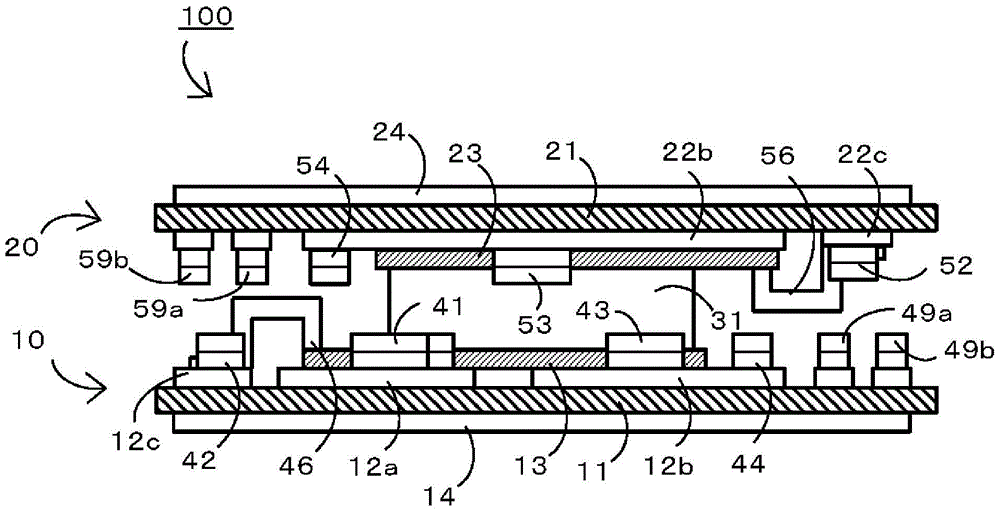

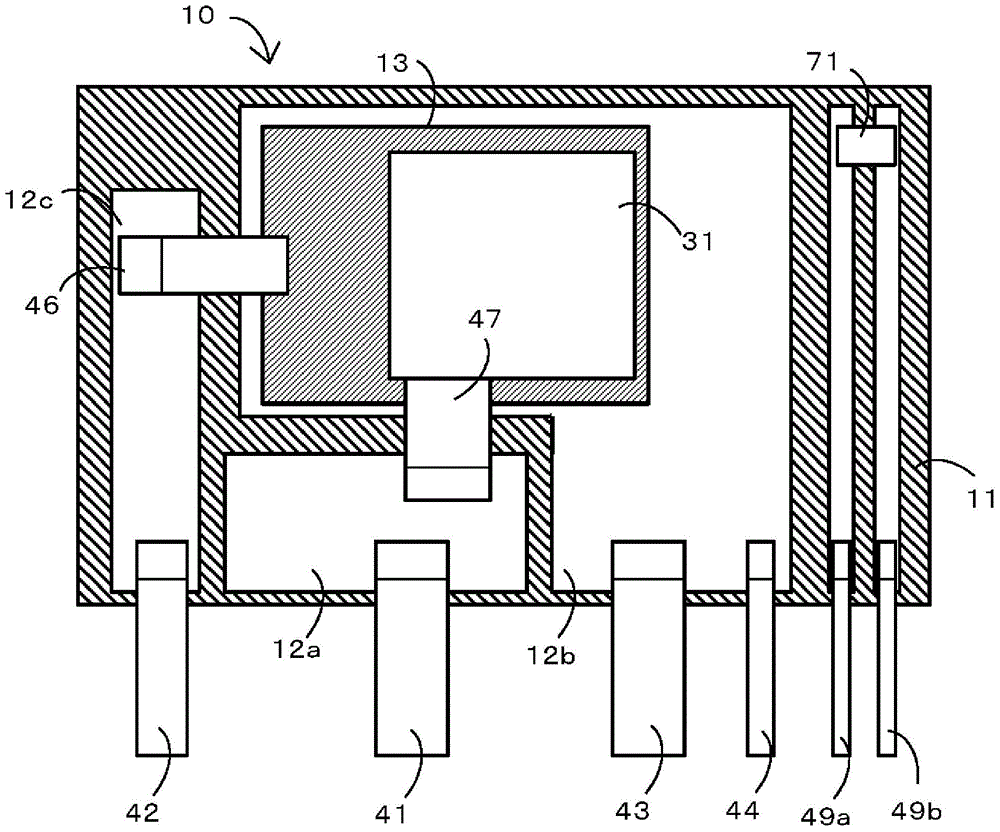

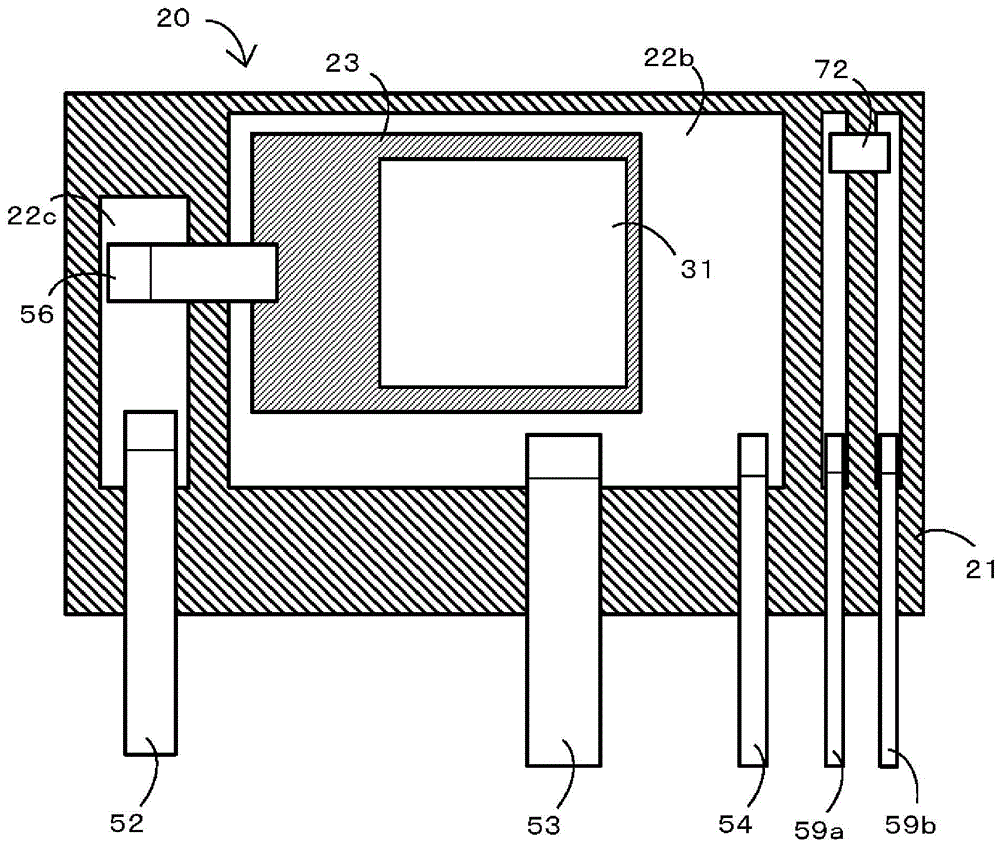

Semiconductor module

ActiveCN106463501AShorten the up and down directionLess quantitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorEngineering

A semiconductor module (100) having: a first member (10); a second member (20); a conductor column (31) extending in the vertical direction, between the first member (10) and the second member (20); and a sealing resin (80) covering a first conductor layer (12) and first power device (13) in the first member (10), a second conductor layer (22) and second power device (23) in the second member (20), and the conductor column (31). The horizontal positions of the first power device (13) and the second power device (23) are displaced, the second conductor layer (22) is not provided in the vertical direction of a first connection section (46) connected to the first power device (13), and the first conductor layer (12) is not provided in the vertical direction of a second connection section (56) for the second member (20) and connected to the second power device (23).

Owner:SHINDENGEN ELECTRIC MFG CO LTD

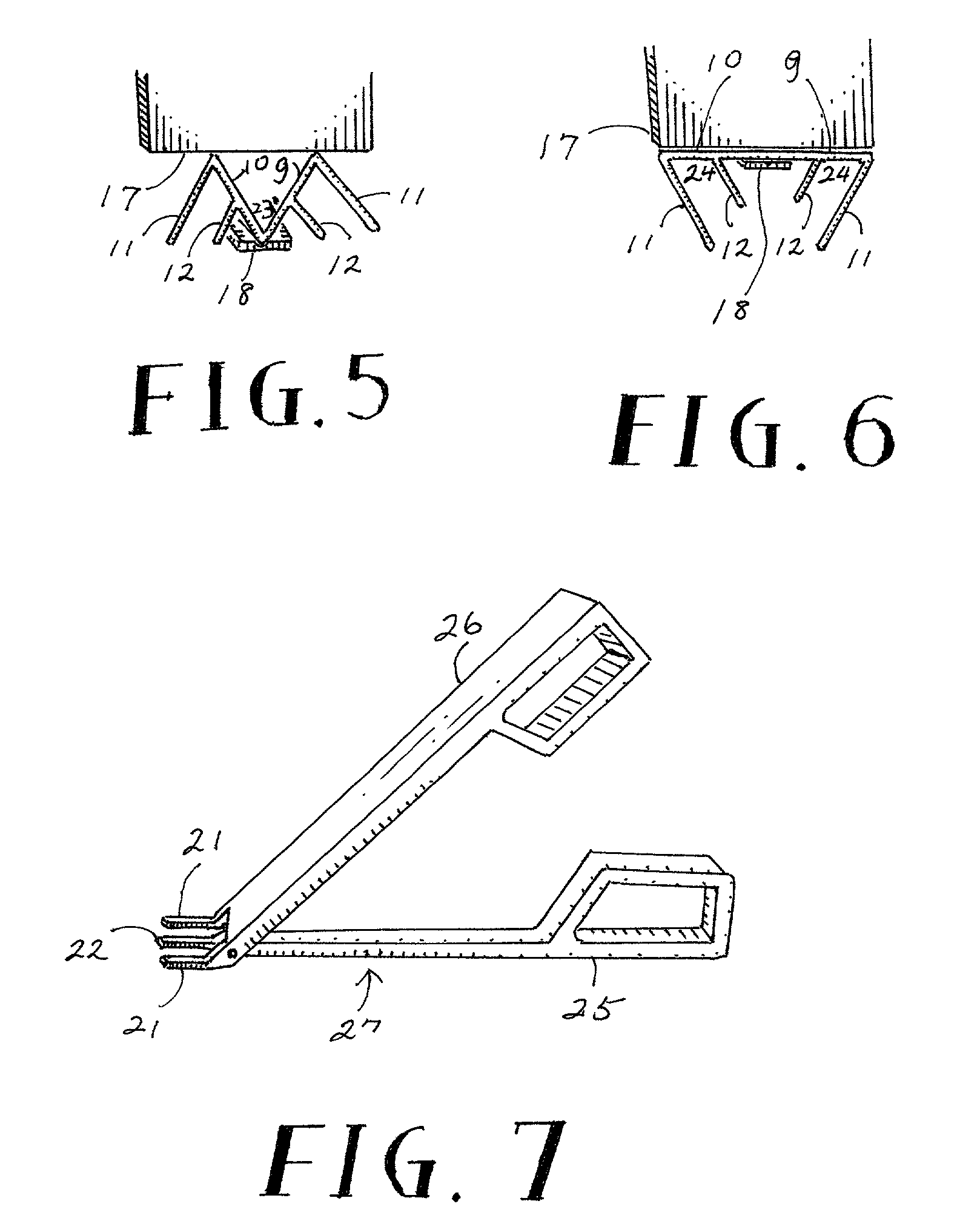

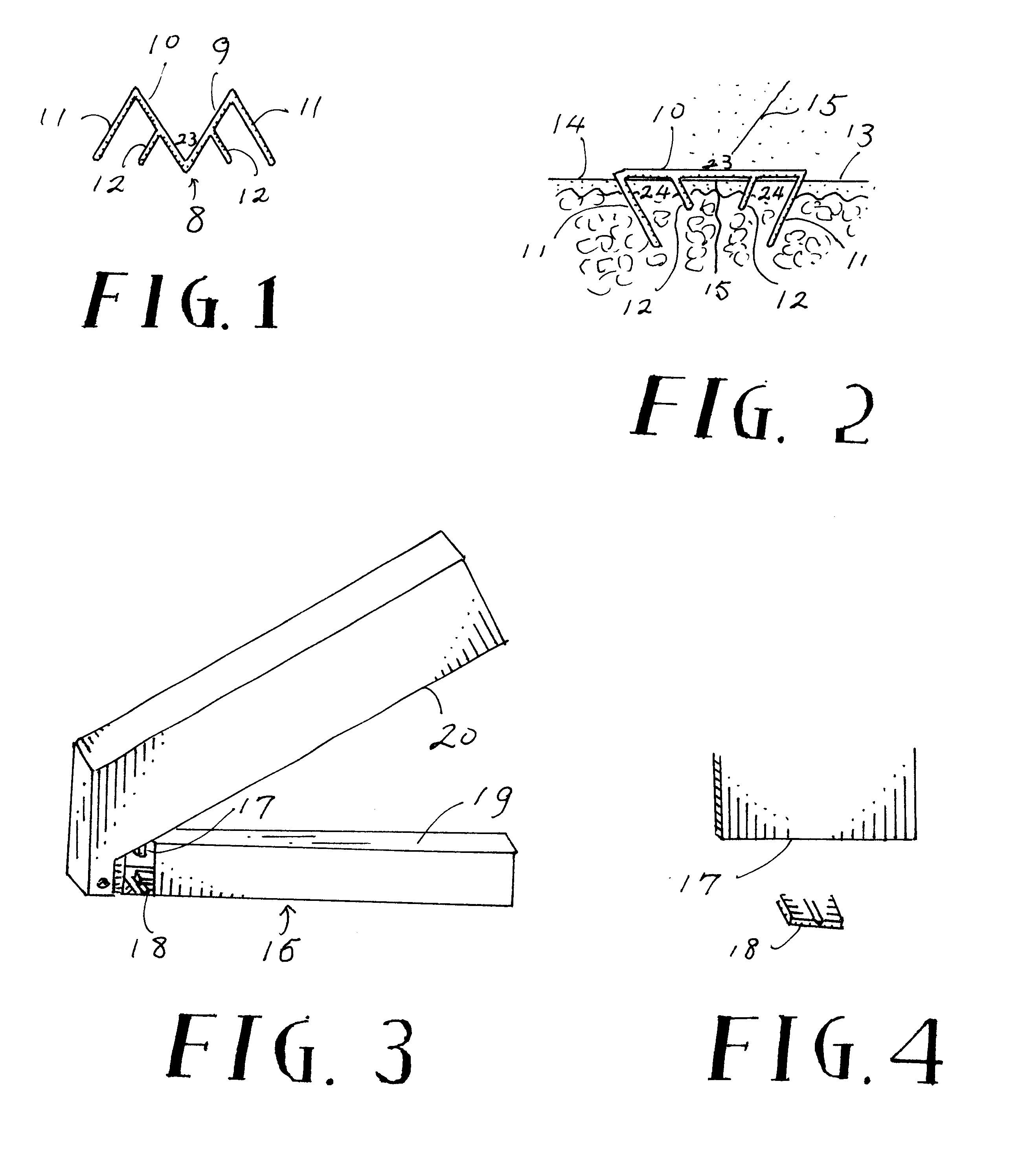

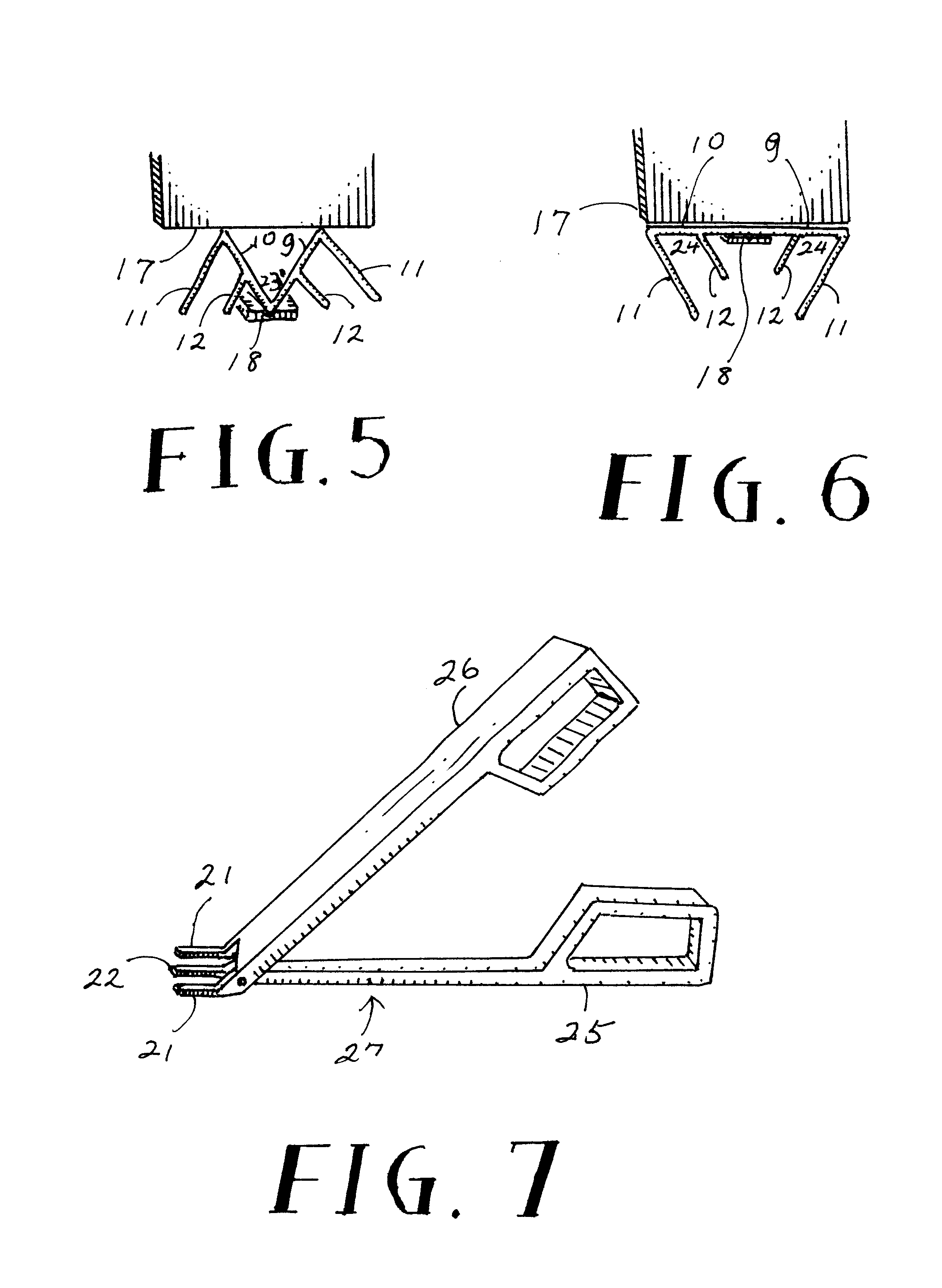

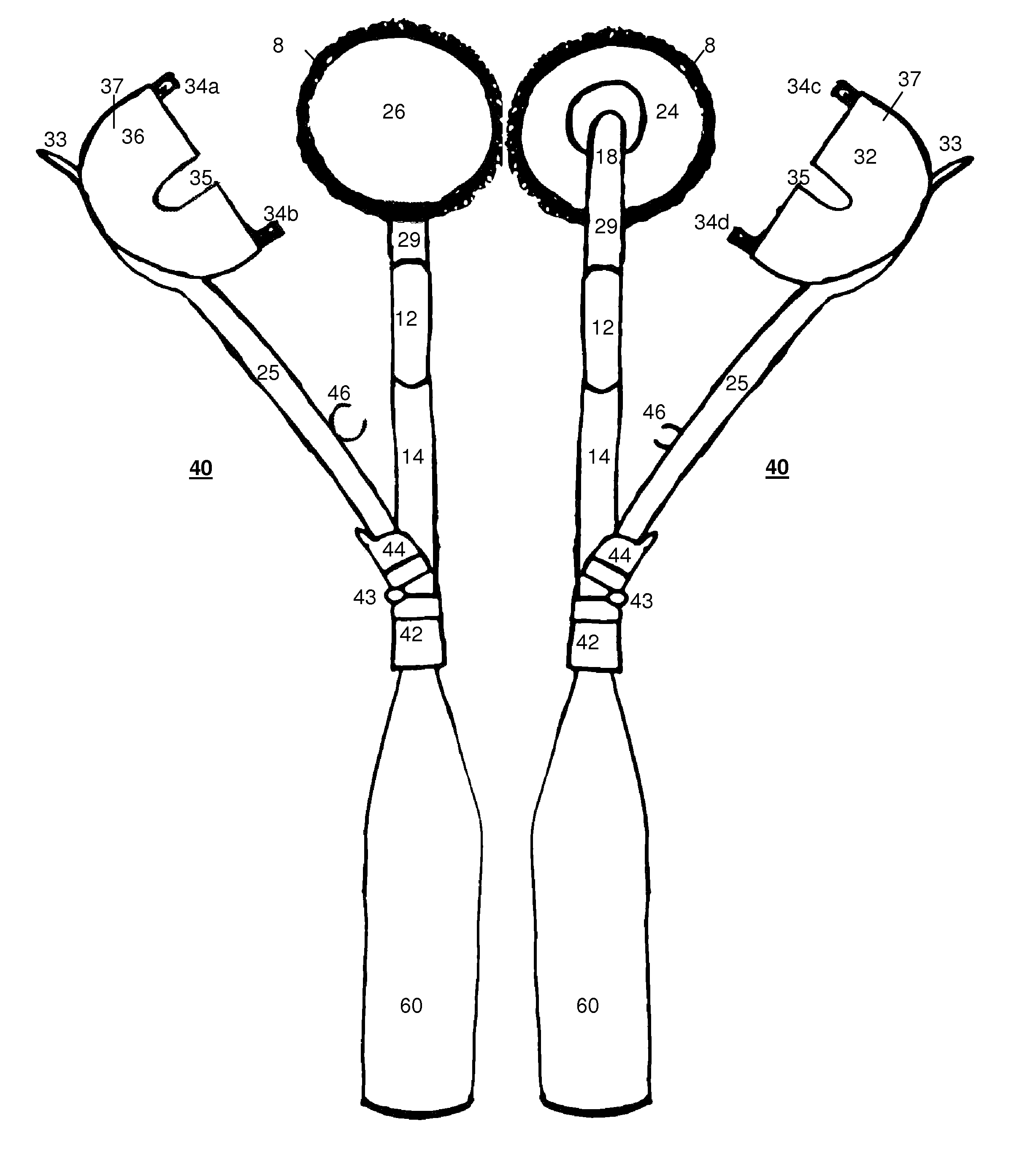

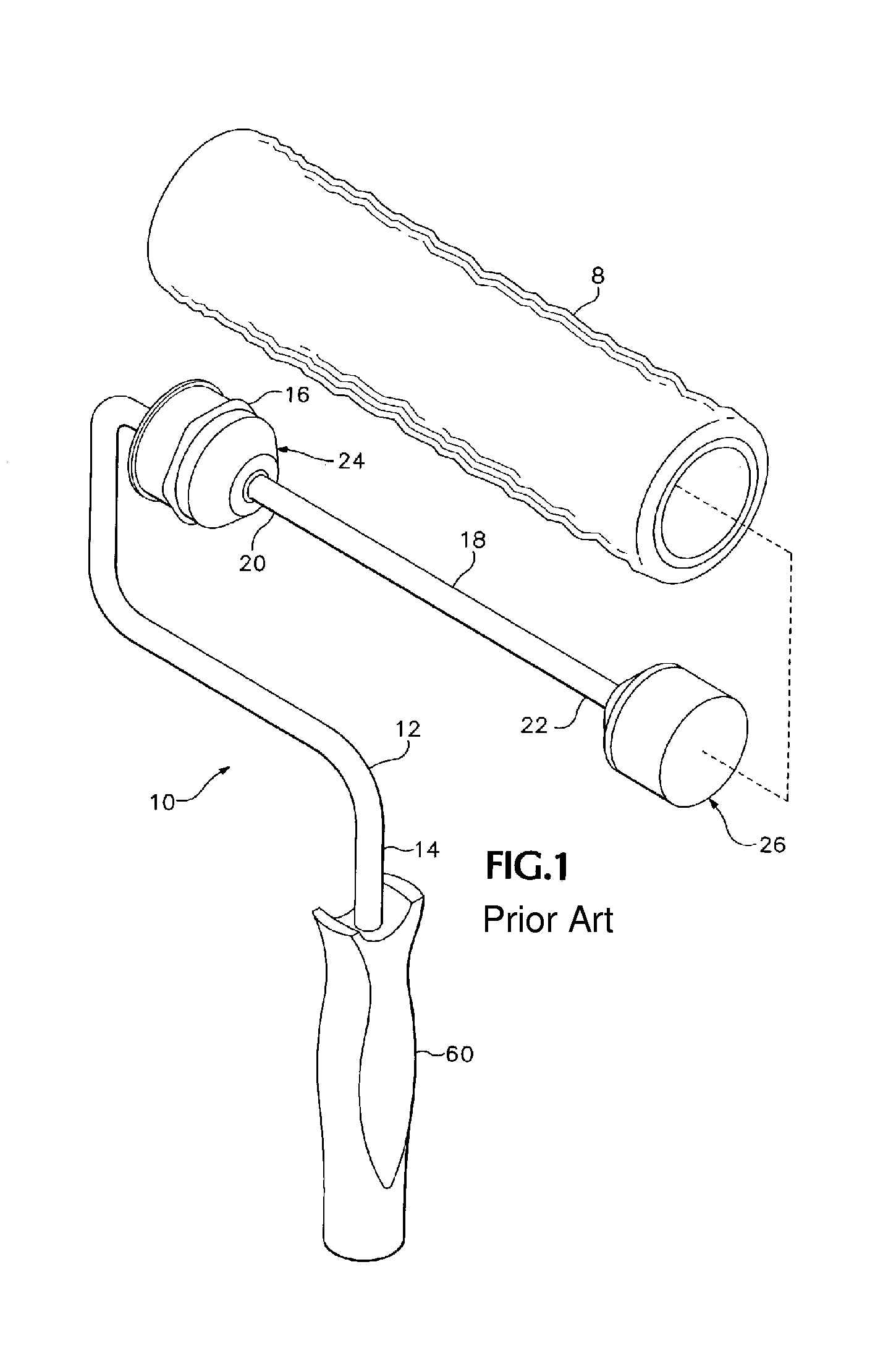

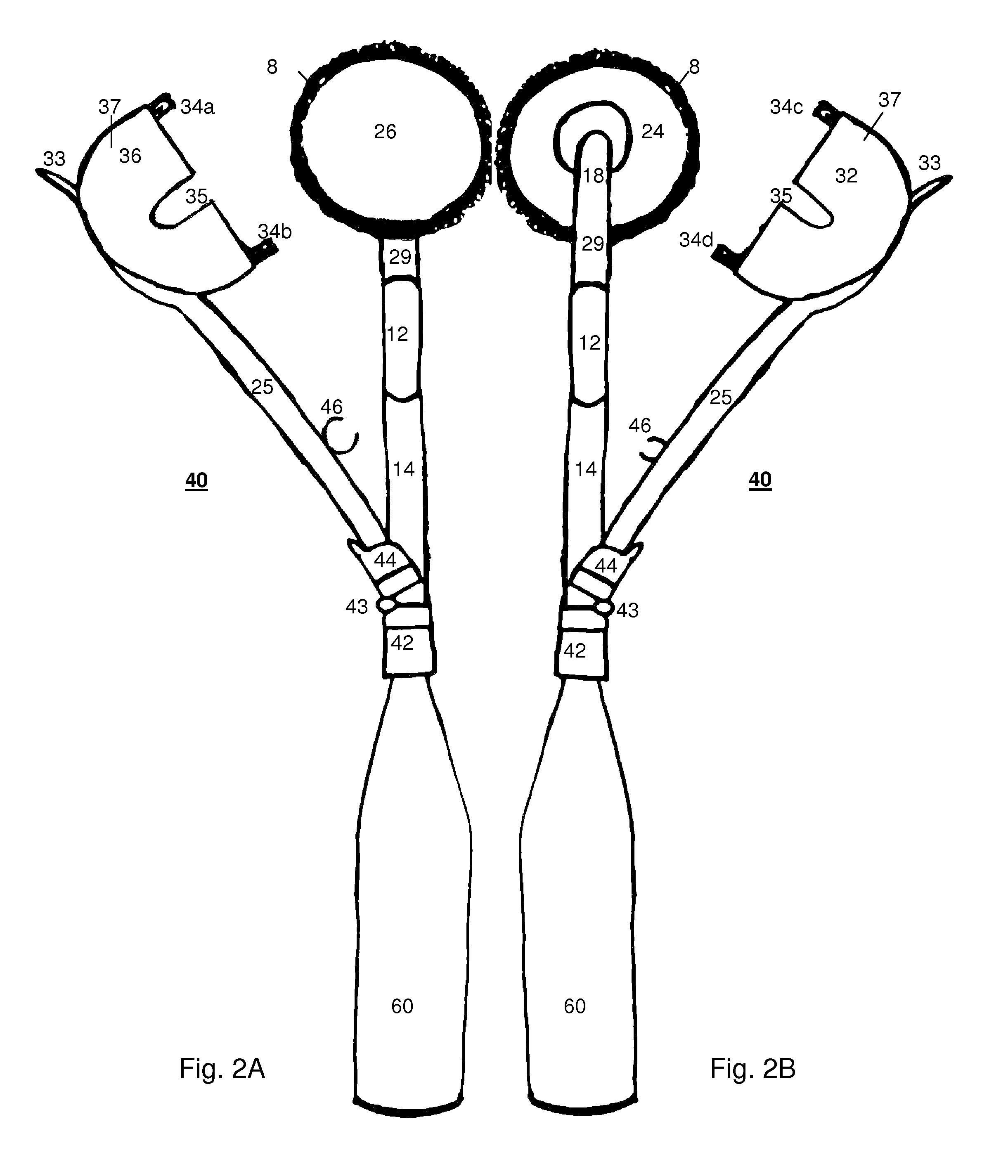

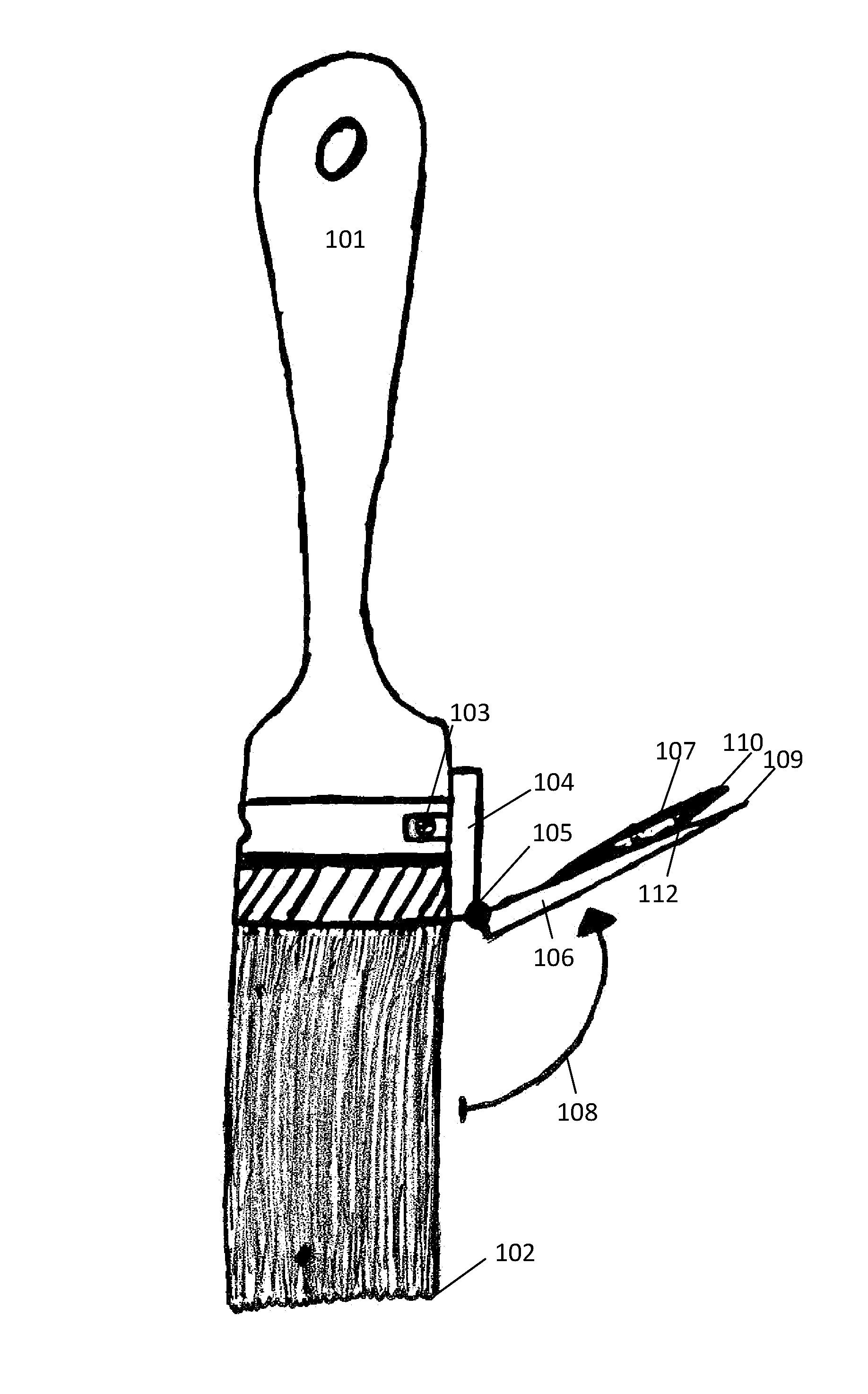

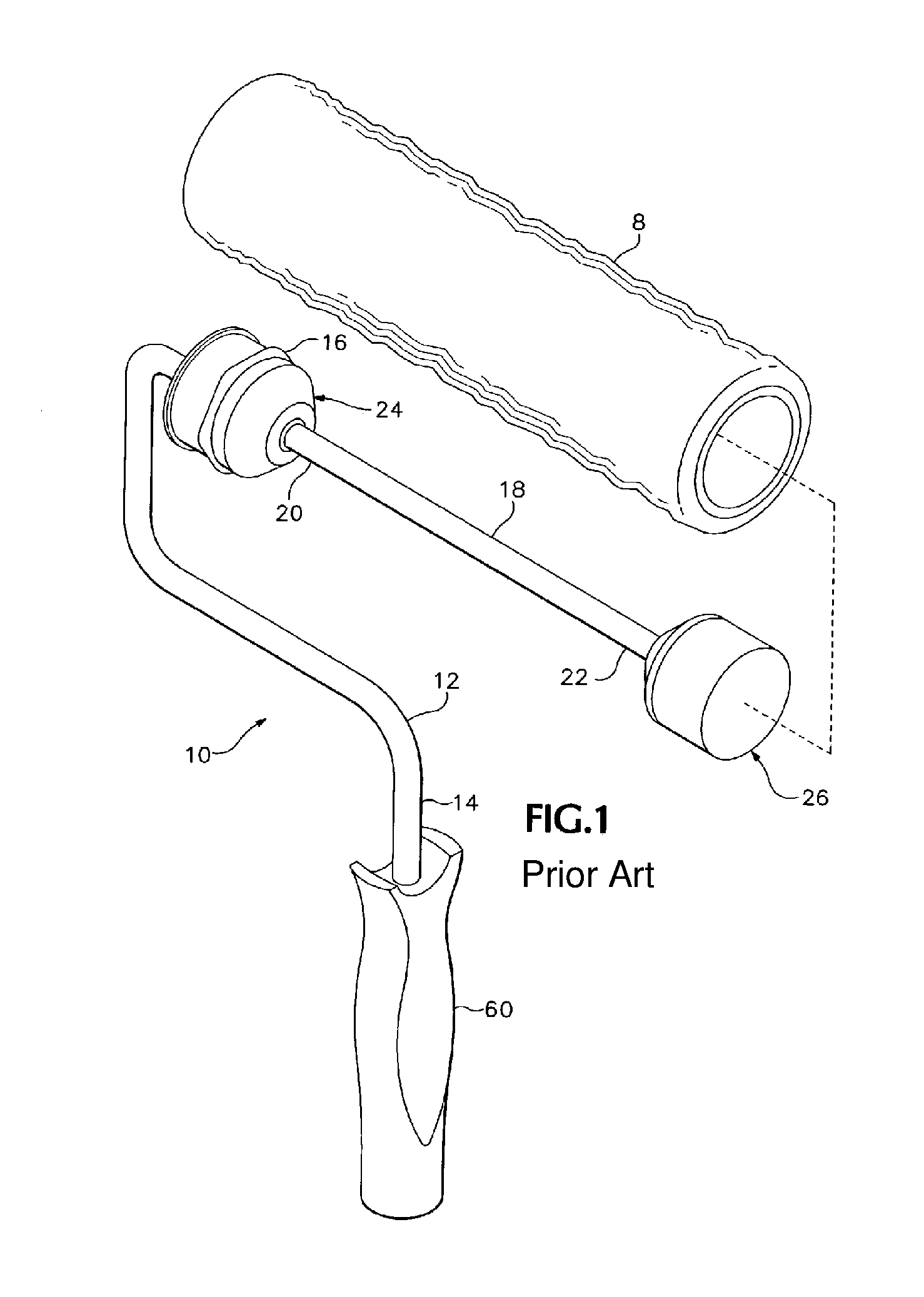

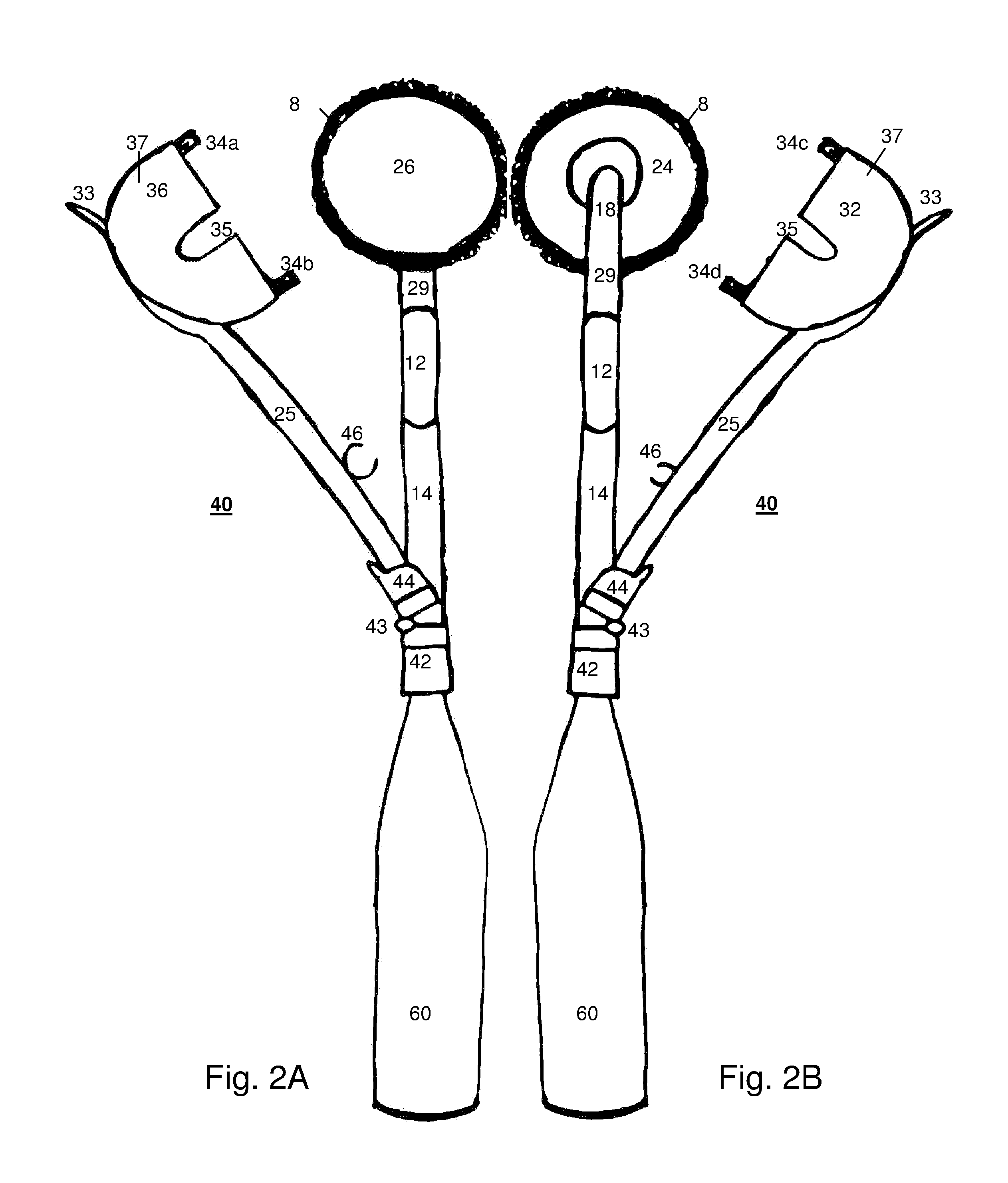

Paint edger devices

ActiveUS9272304B1Prevent overlappingPrevent surfaceLiquid surface applicatorsBrushesPaintbrushEngineering

An edger for a paint roller, comprising: a roller frame; a roller cover, having lateral edges, the lateral edges being outside a painting width of the paint roller and being configured to glide against a surface without marring the surface; a displaceable mount, configured to have a first position in which a roller cover is fully engaged over the paint roller and a second position in which the roller cover is disengaged from the paint roller; and at least one auxiliary brush, located on at least one lateral edge of the roller cover, configured to provide painting coverage adjacent to an edge of the roller. A paintbrush edger comprising a linked pair of selectively deployed shields, separated by a wicking space, having tips which glide in a corner, protecting a from contact with paint, while withdrawing paint which seeps into the corner into the wicking space.

Owner:EMERY LEITH SEANAN

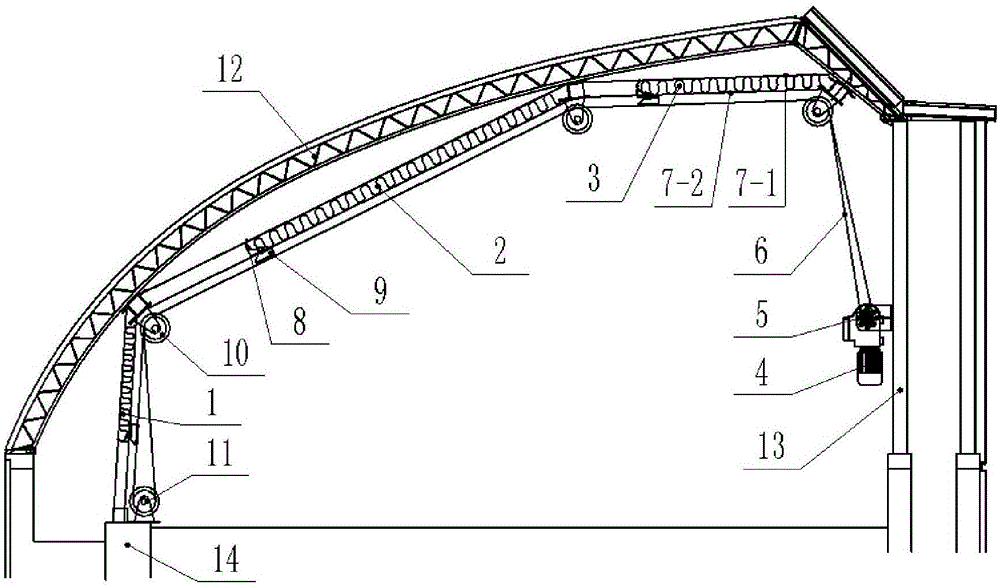

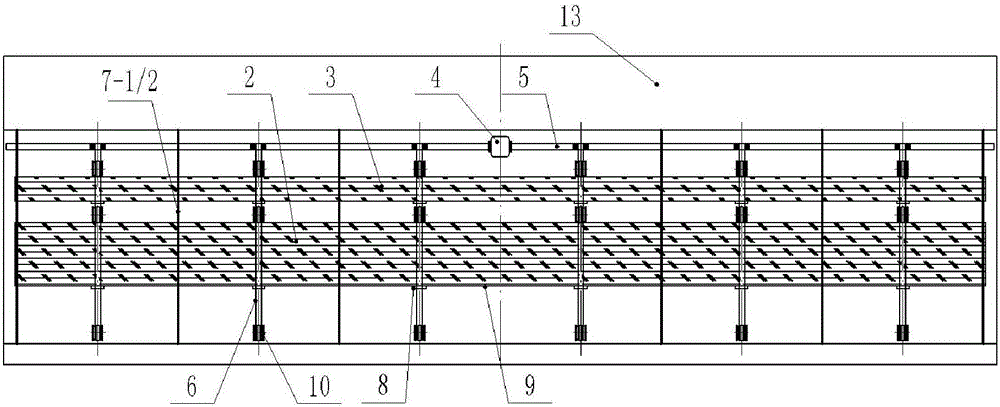

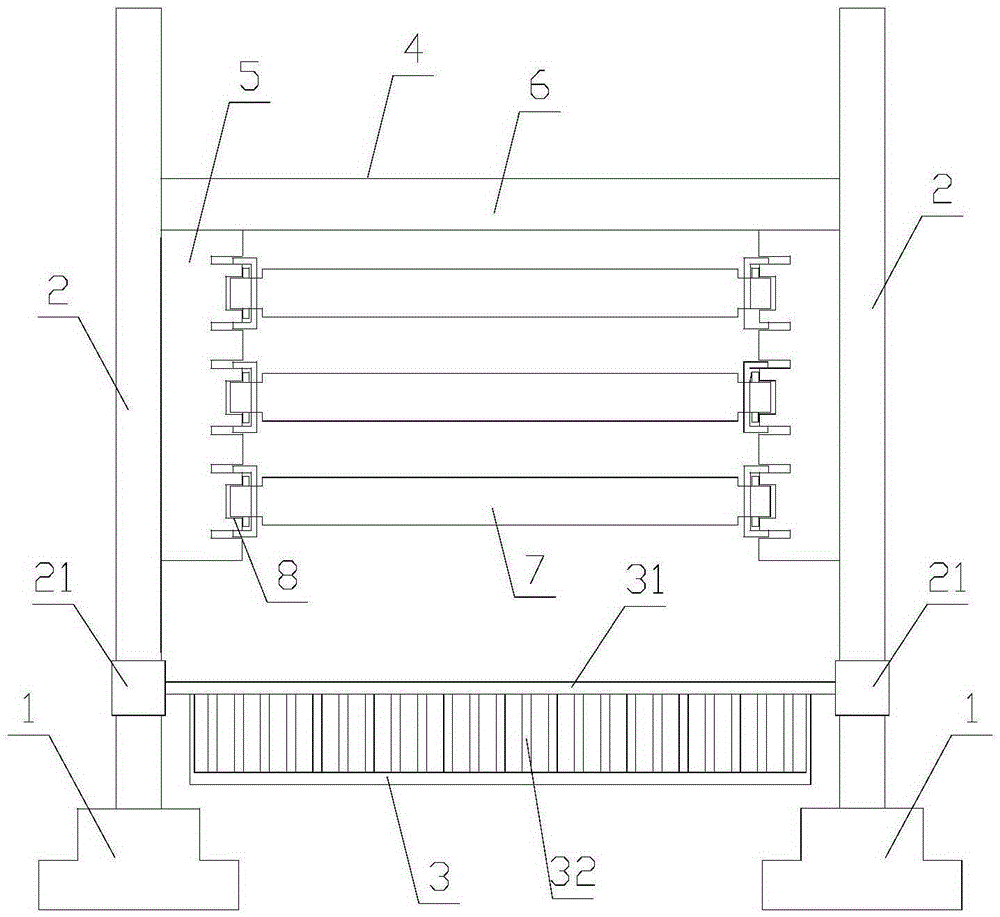

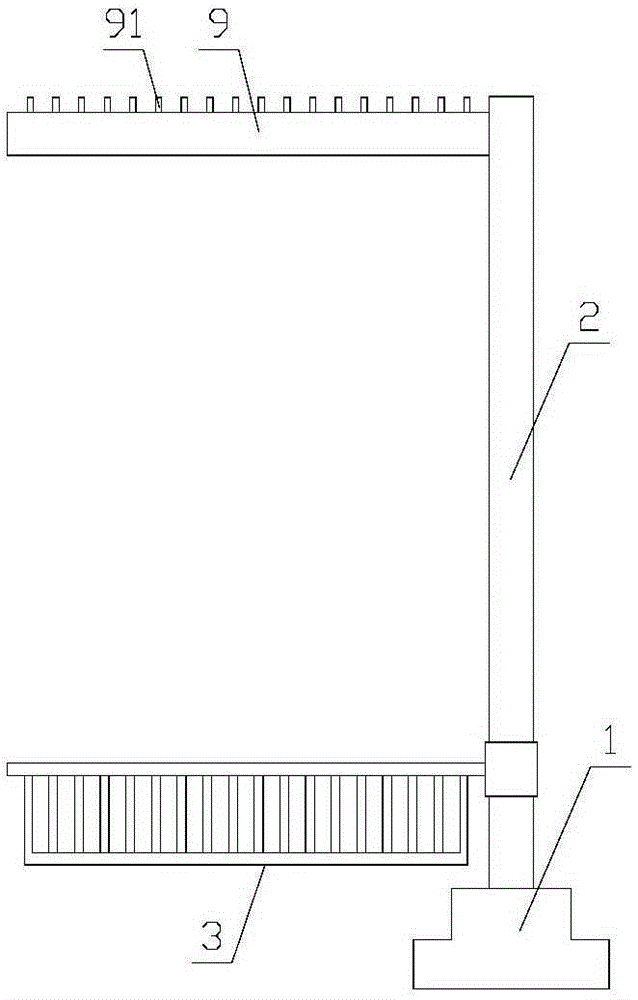

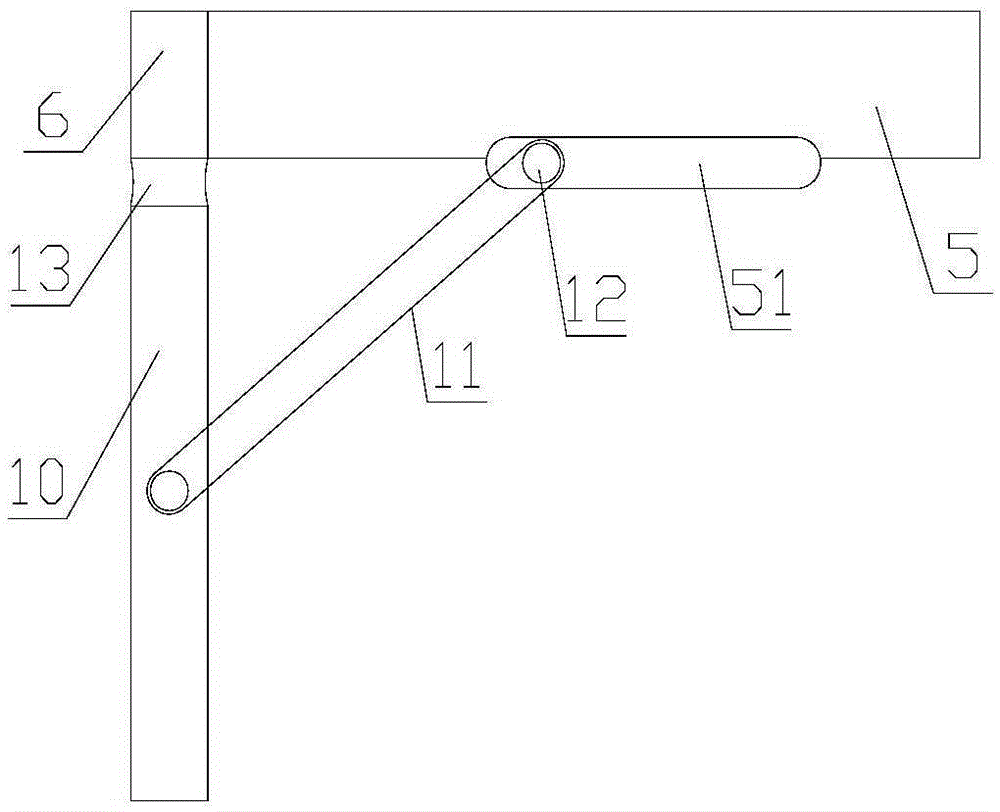

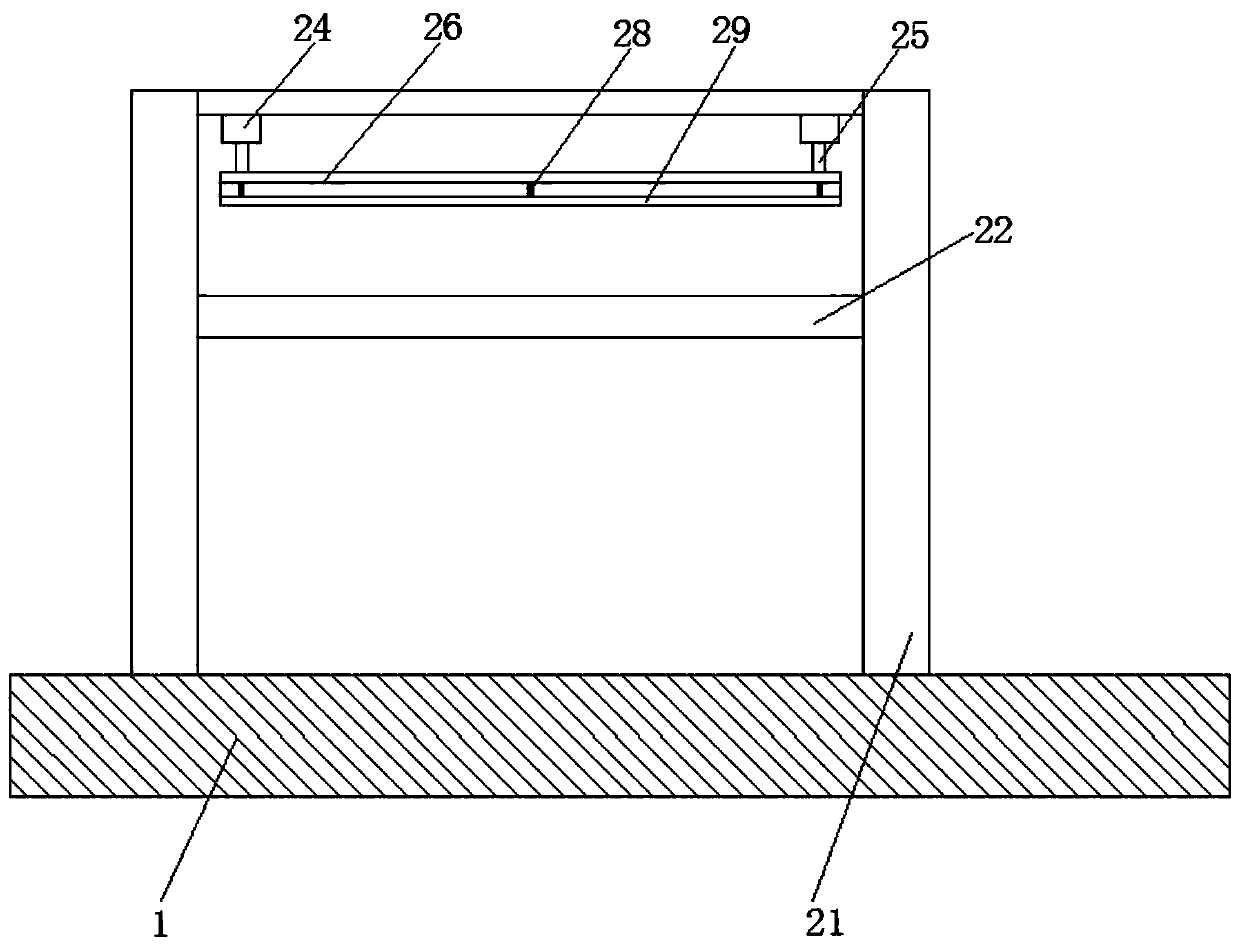

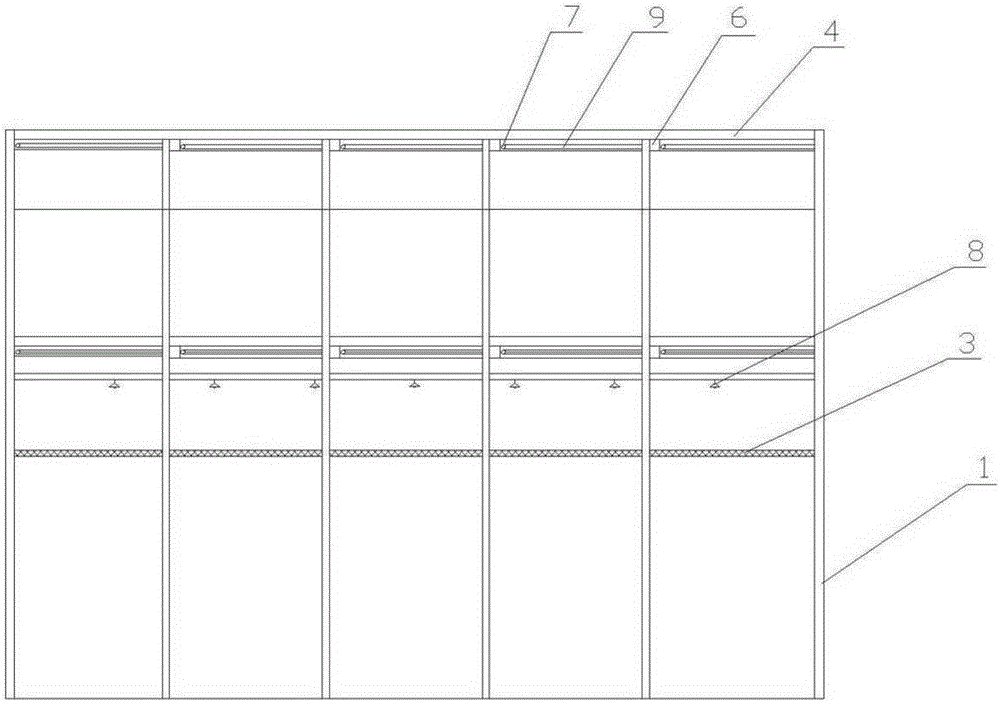

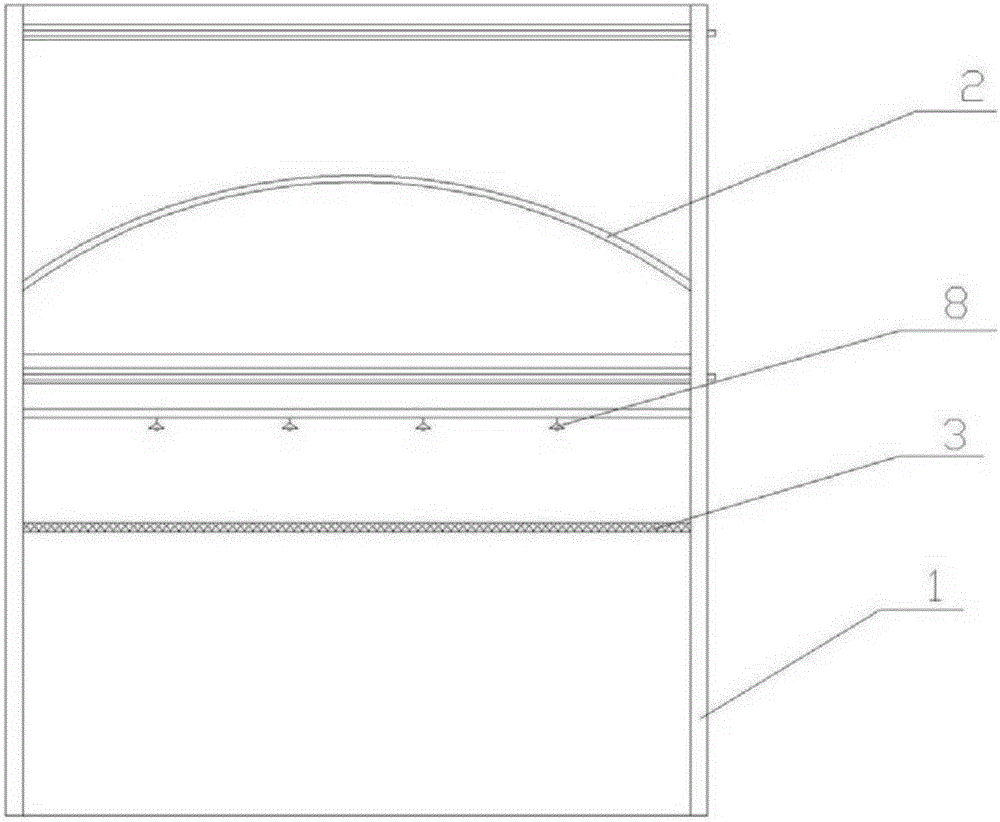

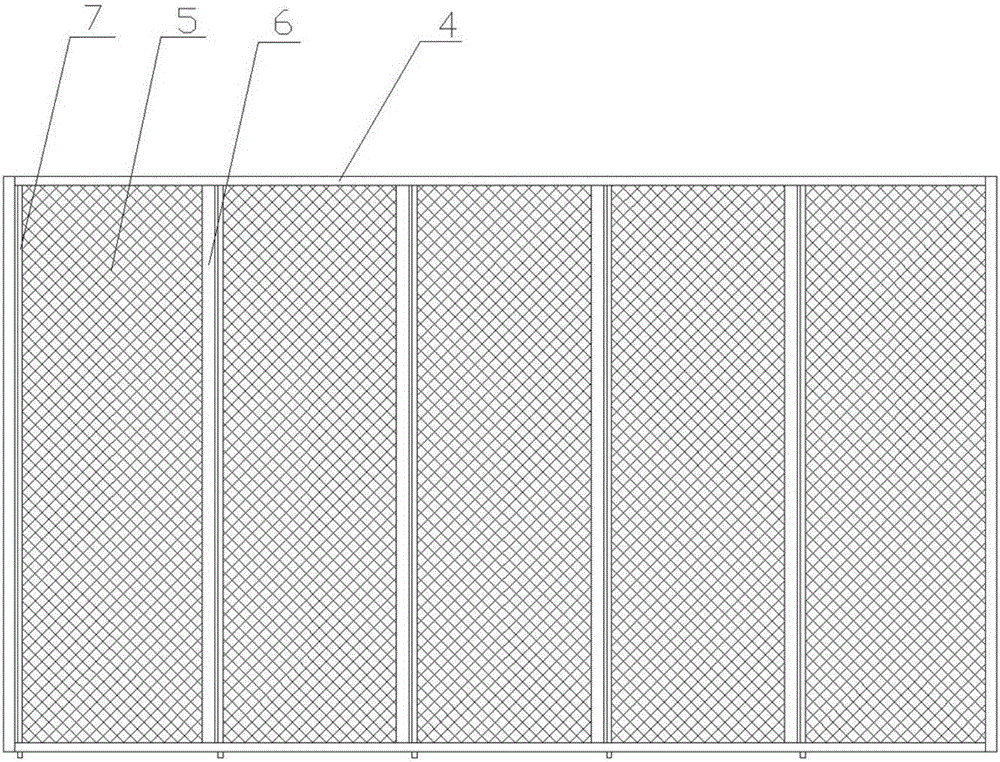

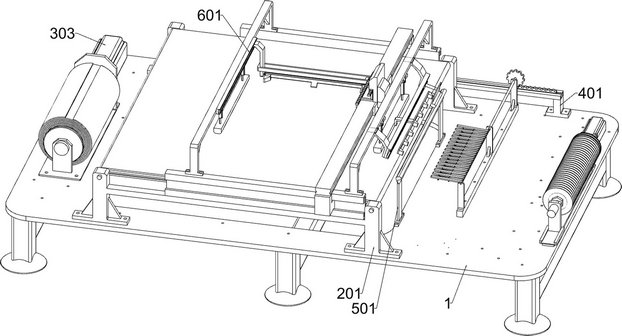

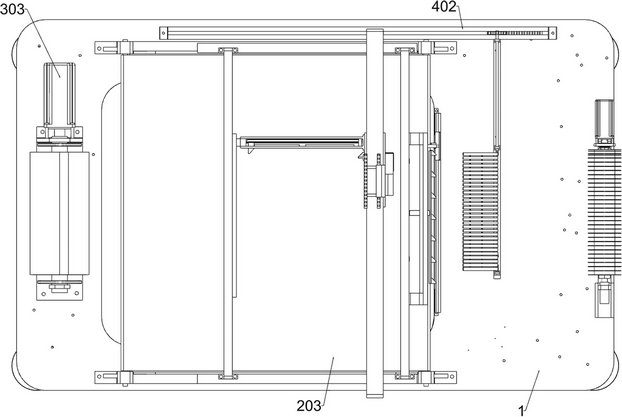

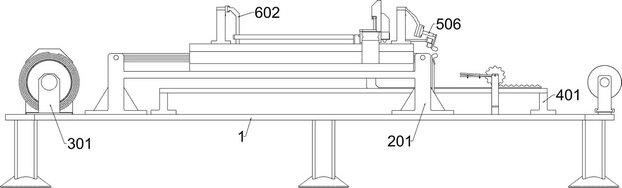

Multi-stage internal heat insulation shading system for greenhouse and greenhouse containing same

InactiveCN106034851AFlexible regulationReduce shadow areaClimate change adaptationGreenhouse cultivationDrive shaftGreenhouse

The invention relates to the field of environmental control of a sunlight greenhouse, in particular to a multi-stage internal heat insulation shading system for a greenhouse and the greenhouse containing the system. The internal heat insulation shading system comprises multi-stage internal heat-insulation shading screens, a screen pressing line and a screen supporting line, a plurality of pulling screen mechanisms, a driving shaft and a motor for driving the rotation of the driving shaft; each pulling screen mechanism comprises a driving steel cable and a reversing pulley, wherein one ends of the driving steel cables are wound on the driving shaft, and the other ends of the driving steel cables are wound on the reversing pulleys; one sides of the inner heat insulation screens are fixed, and the other ends of the inner heat insulation screens, as retracting and releasing ends, are respectively connected with the driving steel cables. The internal thermal insulation shading system not only has the advantages of simple structure, saving production cost, but also can flexibly regulate and control the indoor temperature and light according to the different needs of temperature and light by crops in different growing seasons and different time. Compared with traditional internal insulation and shading systems, the system provided by the invention has a greater application and promotion value.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

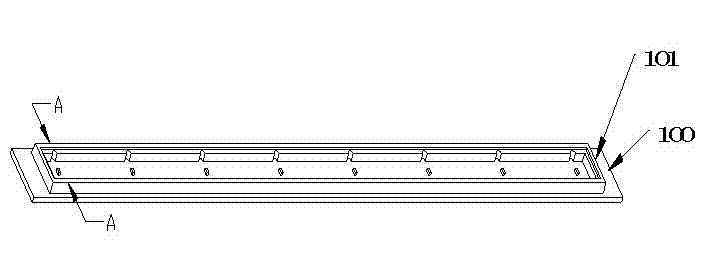

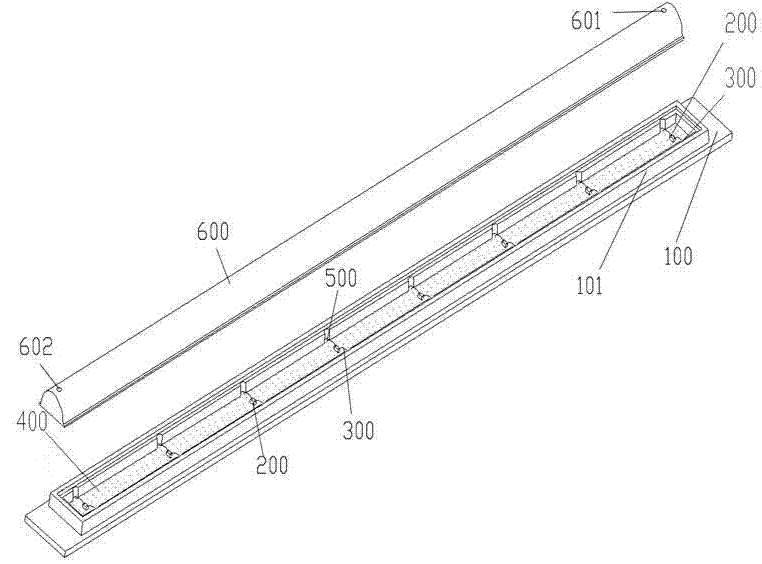

COB (Chip on Board) packaged LED (Light-Emitting Diode) module and manufacturing process thereof

ActiveCN103367616AImprove light extraction efficiencyEnsure light color consistencySemiconductor devicesOn boardRefractive index

The invention provides a COB packaged LED module and a manufacturing process thereof. The module comprises an aluminum substrate, an optical lens group and LED chips arranged on the upper surface of the aluminum substrate. The optical lens group comprises at least one optical lens which is a column-shaped one. The optical lens group is arranged above the aluminum substrate and covers all the LED chips inside the same glue housing. Transparent colloid is filled inside the optical lens. The transparent colloid filled inside the optical lens enables the LED module filled with the transparent colloid to effectively improve the light extraction efficiency due to the fact that the refractive index of the transparent colloid is higher than that of the air. Meanwhile, the transparent colloid is covered by the whole LED module. The photochromic consistency is ensured. The production yield rate is increased while the production cost is lowered.

Owner:HANGZHOU HPWINNER OPTO CORP

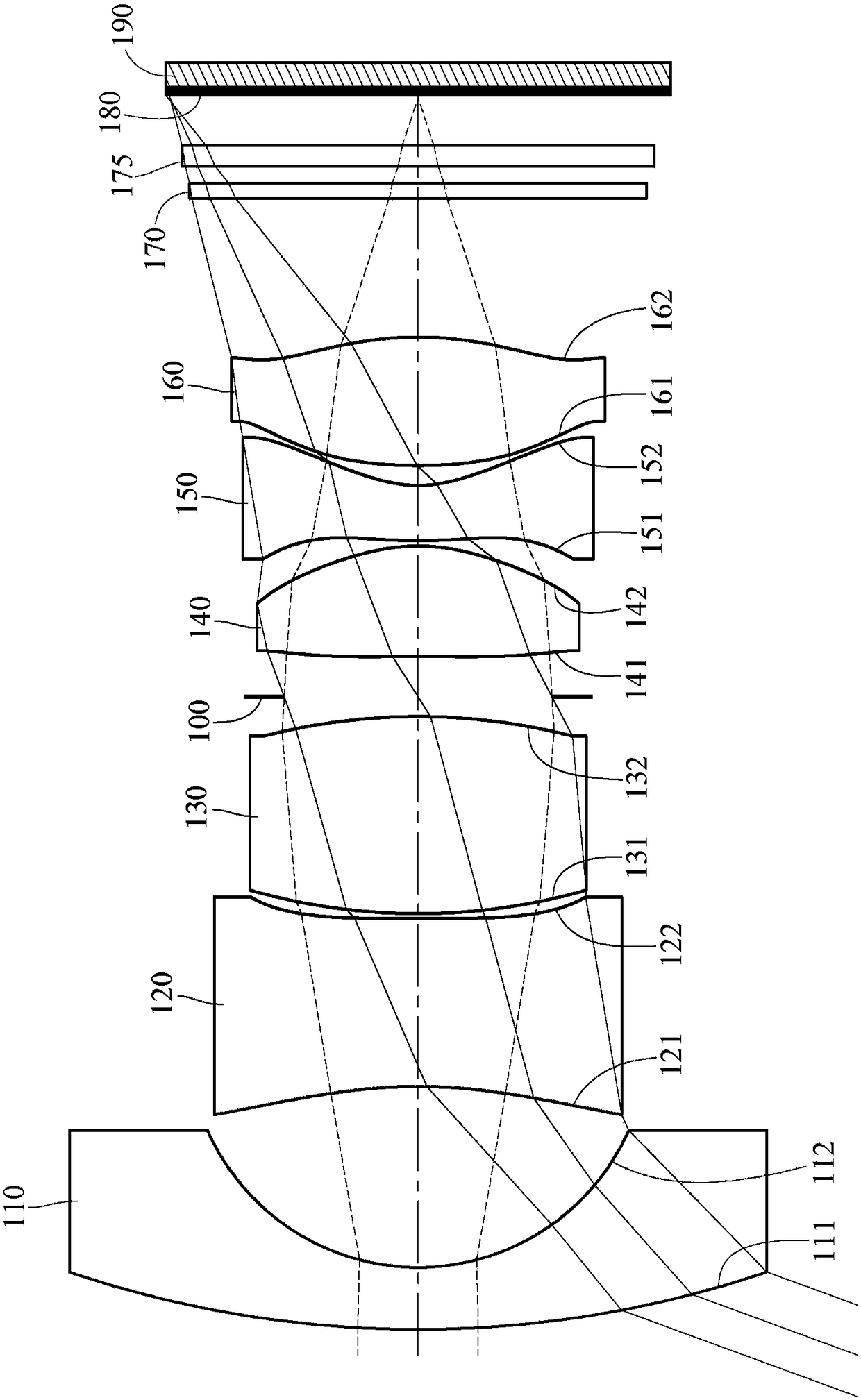

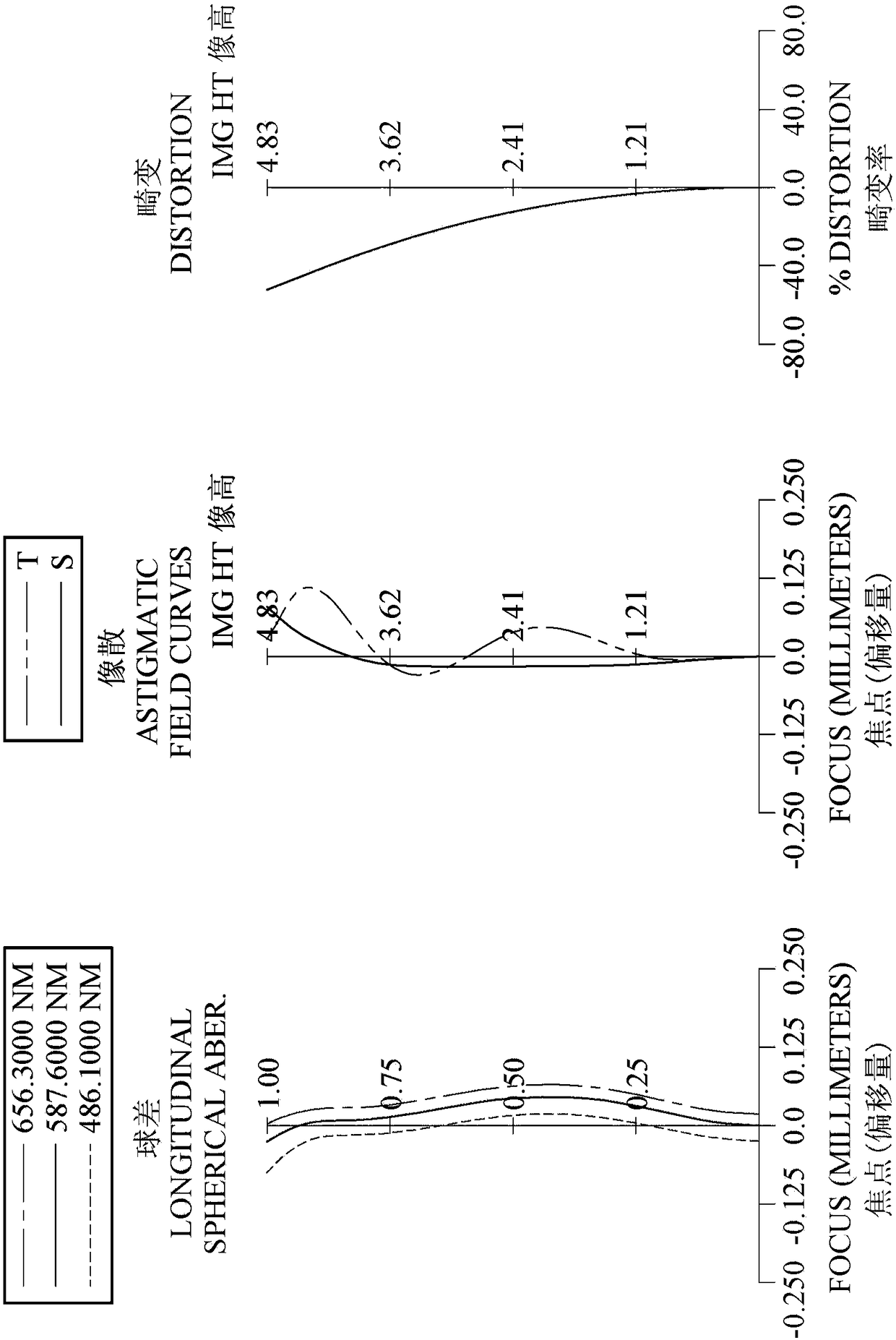

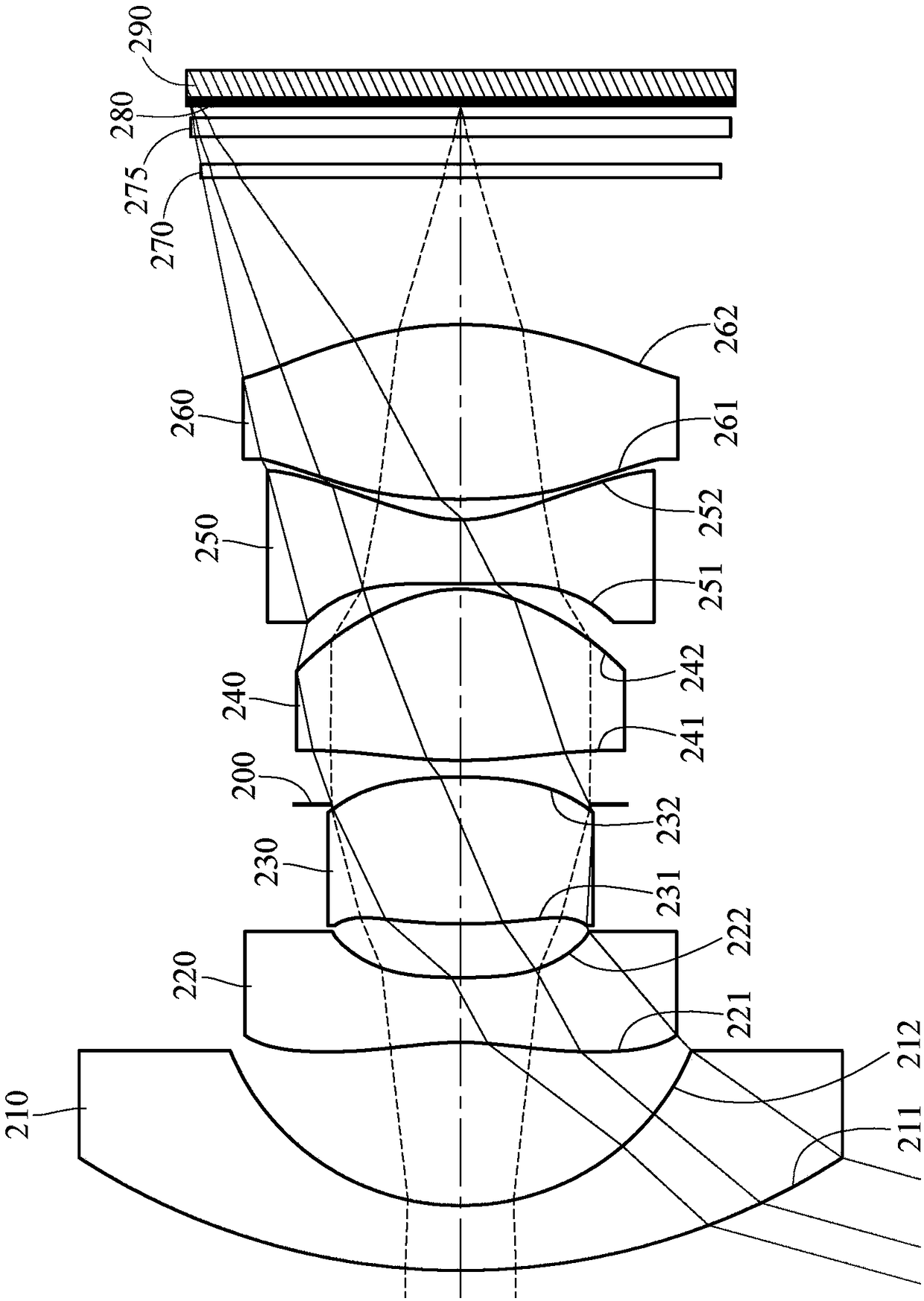

Imaging lens system, image capturing unit and electronic device

ActiveCN109425968AContributes to light gathering abilityShorter overall optical lengthOptical elementsOptical axisImaging lens

The present invention discloses an imaging lens system. The imaging lens system includes, in order from an object side to an image side: a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element and a sixth lens element. The first lens element with negative refractive power has an image-side surface being concave in a paraxial region thereof. The second lens element with negative refractive power has an object-side surface being concave in a paraxial region thereof. The third lens element with positive refractive power has an image-side surface being convex in a paraxial region thereof. The fourth lens element has positive refractive power. The fifth lens element with negative refractive power has an image-side surface being concave in aparaxial region thereof. The sixth lens element with positive refractive power has an object-side surface being convex in a paraxial region thereof.

Owner:LARGAN PRECISION

Paint edger devices

ActiveUS9549608B1Prevent overlappingPrevent surfaceLiquid surface applicatorsBrushesEngineeringPaintbrush

An edger for a paint roller, comprising: a roller frame; a roller cover, having lateral edges, the lateral edges being outside a painting width of the paint roller and being configured to glide against a surface without marring the surface; a displaceable mount, configured to have a first position in which a roller cover is fully engaged over the paint roller and a second position in which the roller cover is disengaged from the paint roller; and at least one auxiliary brush, located on at least one lateral edge of the roller cover, configured to provide painting coverage adjacent to an edge of the roller. A paintbrush edger comprising a linked pair of selectively deployed shields, separated by a wicking space, having tips which glide in a corner, protecting a from contact with paint, while withdrawing paint which seeps into the corner into the wicking space.

Owner:EMERY LEITH SEANAN

Leather processing technique adopting rotor drum ball

InactiveCN106868234AStrengthen and improve athletic performancePrevent overlappingTanning treatmentPre-tanning chemical treatmentEngineeringProcessing cost

The invention discloses a leather processing technology using drum balls, belonging to the technical field of leather processing. Put a certain number of drum balls together or separately, and rotate or paddle together with the leather through the drum balls. In the present invention, a drum ball is added to the drum to assist the leather processing. When the drum ball and the leather move together, the movement state of the leather is strengthened and improved, the leather is prevented from being overlapped or entangled, the leather processing efficiency is improved, and the leather quality is ensured; The use of drum balls can also reduce the use of water and chemical additives, effectively reducing processing costs and protecting the environment.

Owner:吴亚力

Information downloading apparatus and mobile terminal

InactiveUS20120002585A1Improve download efficiencyPrevent overlappingSemiconductor/solid-state device manufacturingBroadcast transmission systemsTelecommunicationsControl channel

A technique for improving the efficiency of downloading transmission data is disclosed. An information downloading apparatus downloads differing sets of information to predetermined groups to which a mobile terminal may belong. This apparatus includes a channel selecting unit for selecting from plural information channels an information channel for transmitting transmission data and a transmitting unit for transmitting transmission data using the selected information channel. The channel selecting unit selects an information channel so that sets of transmission data with differing destination addresses may be transmitted through differing information channels. The transmitting unit transmits to each group, through a control channel, information pertaining to whether a set of transmission data exists, the information channel to be used if the set of transmission data exists, and the data length of the set of transmission data. The control channel includes time slots that are associated with the groups.

Owner:FUJITSU LTD

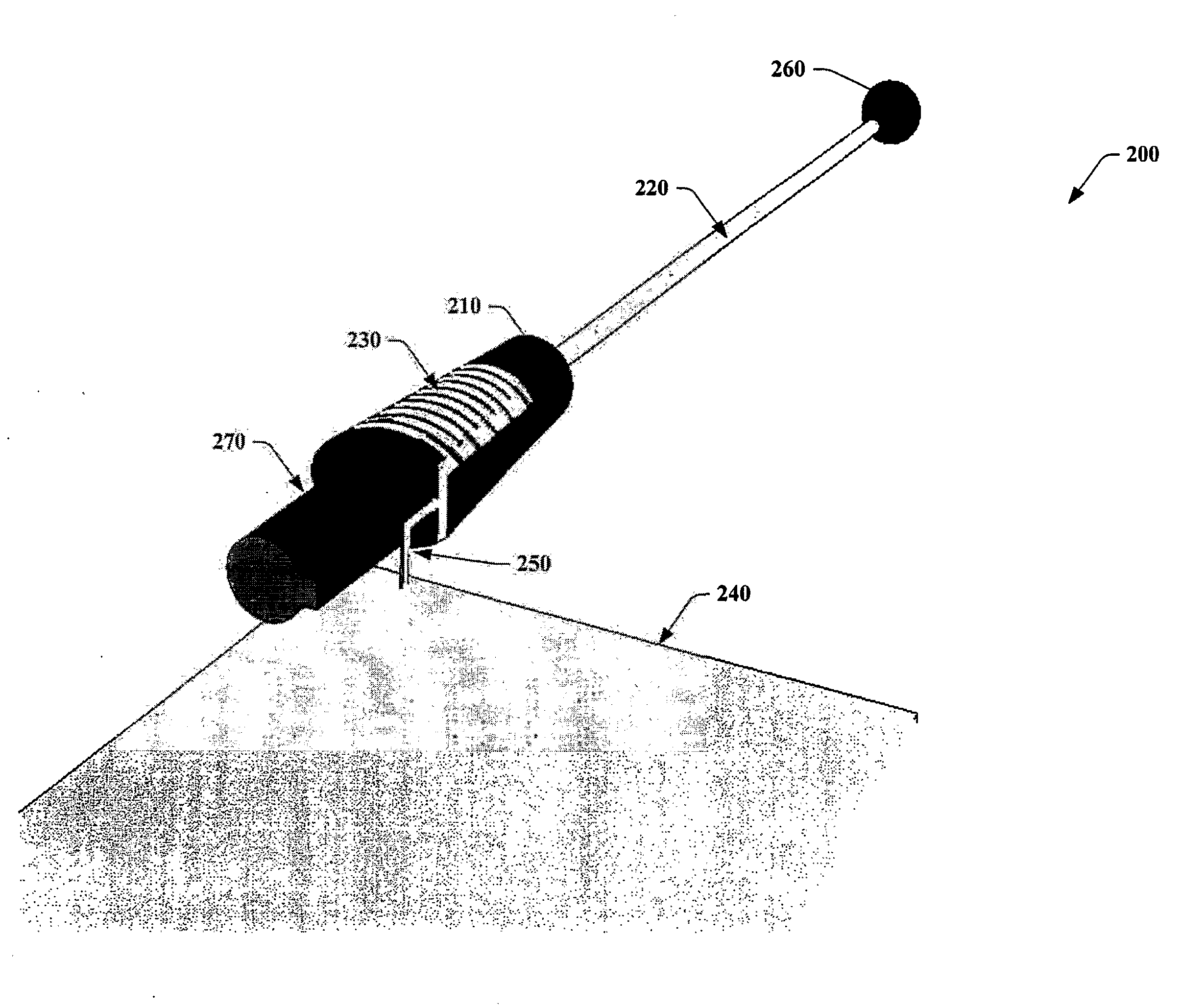

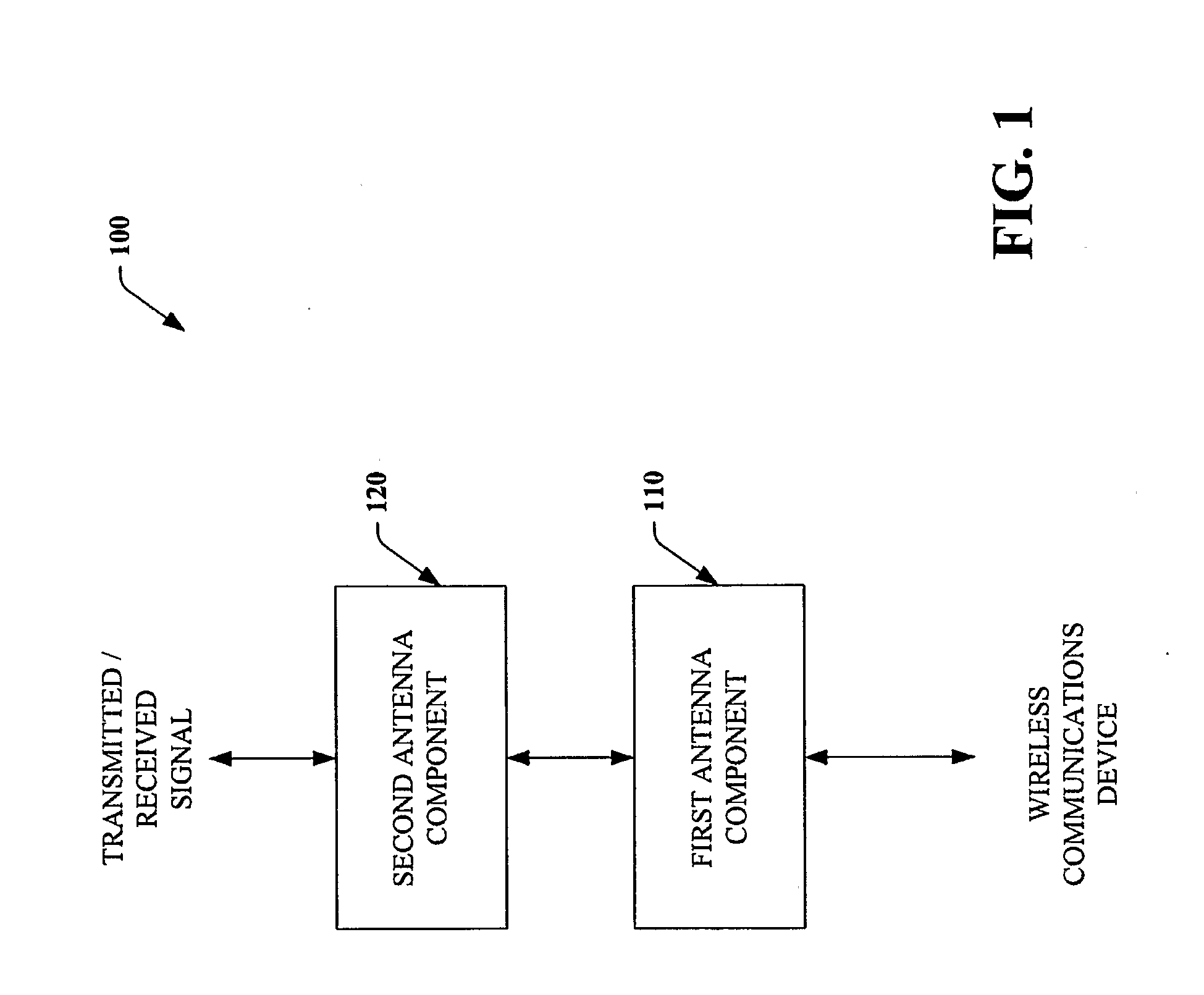

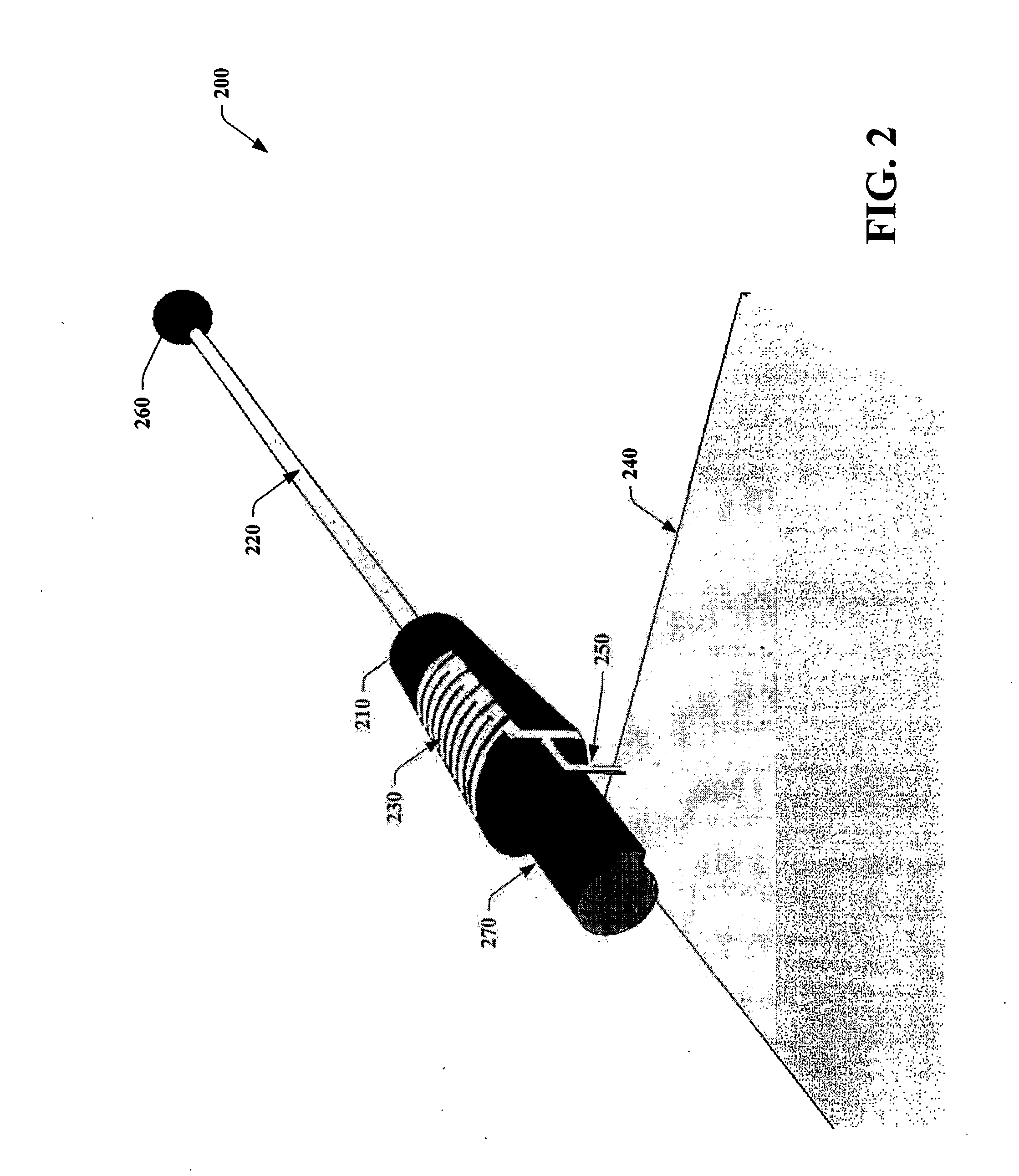

Systems and methods that utilize an active stub/parasitic whip antenna to facilitate mobile communication

ActiveUS20070159402A1Facilitates transmission and receptionCompact antennaAntenna supports/mountingsRadiating elements structural formsElectromagnetic couplingMulti band

The present invention provides systems and methods that facilitate transmission and / or reception of radio frequency (RF) signals within a mobile communications device. The systems and methods include a first antenna component such as an active stub that comprises one or more active elements and a second antenna component such as a parasitic whip that is electromagnetically coupled to the first antenna component. The systems and methods provide a relatively compact antenna structure for mobile devices with limited physical volume, or footprint. The antenna structure does not require a mechanical interface (e.g., a galvanic connection) between the active stub and parasitic whip to provide a conductive connection to the whip when it is in an extended position. The novel systems and methods yield reduced antenna wear, higher antenna gain and better radiation efficiency than conventional systems and do not require a matching circuit to achieve multi-band resonances.

Owner:RPX CORP

Multifunctional bathroom clothes pole

The invention discloses a multifunctional bathroom clothes pole which comprises installation bases, supporting rods, a hanging rack device, a clothes rod and a support. The supporting rods are installed on the installation bases. Detachable fixing rings are installed at the bottom ends of the supporting rods. A mesh basket body is installed between the fixing rings and is composed of a plurality of transverse rods and longitudinal rods. The transverse rods and the longitudinal rods are evenly distributed in a staggered mode. The clothes rod is arranged at the upper ends of the supporting rods. The supporting rods are fixedly installed on the installation bases, one end of the clothes rod is fixed to a wall, a plurality of evenly distributed protruding blocks are arranged on the clothes rod, firmness is improved, supporting force on articles is increased, and clothes can be prevented from being stacked. Supporting racks are provided with multiple fixing devices, the supporting rods can be placed in a selective mode, and space is reasonably used. The support and fixing racks are connected through rotary shafts. The support and the supporting racks are connected through connection rods. Articles can be placed whether the hanging rack device is folded or horizontally placed, and the clothes pole can be adjusted and is high in utilization rate.

Owner:YINGSHANG LONGYUYANG IND & TRADE

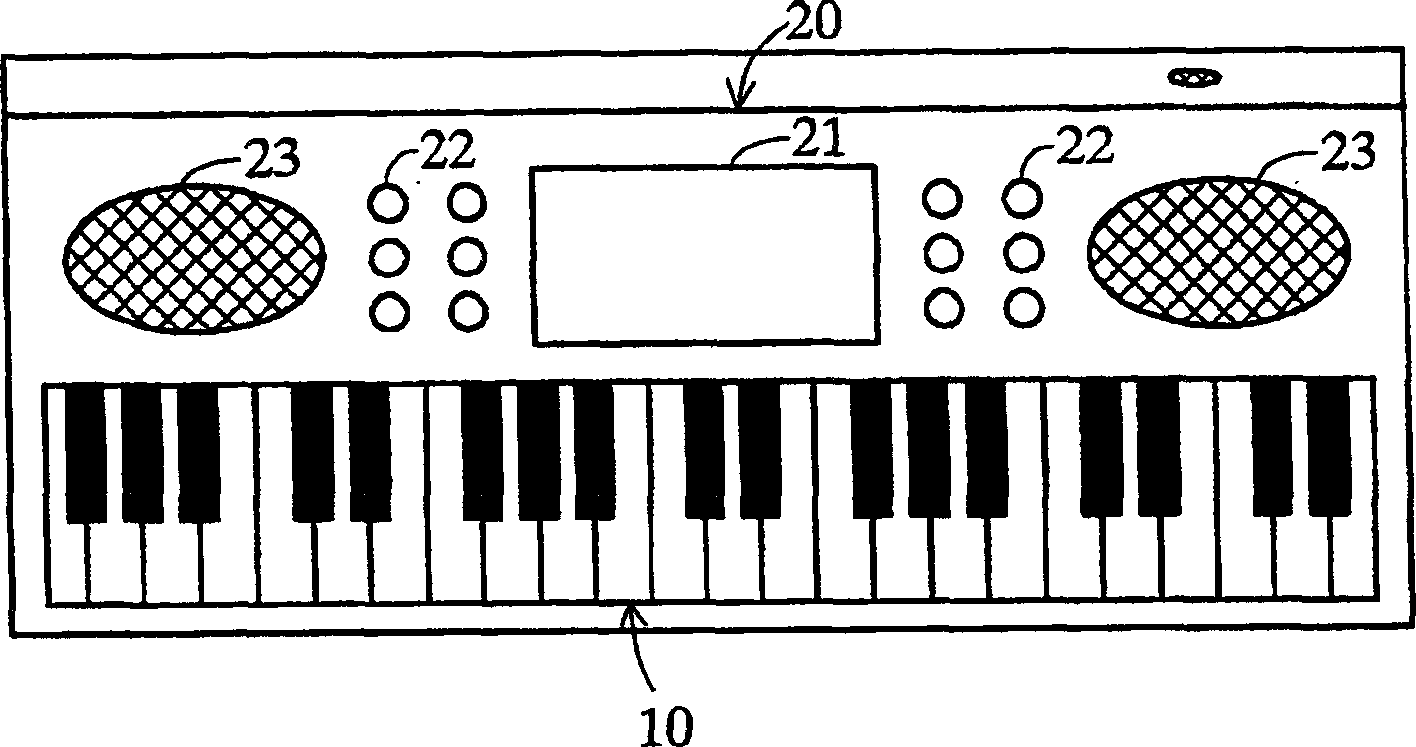

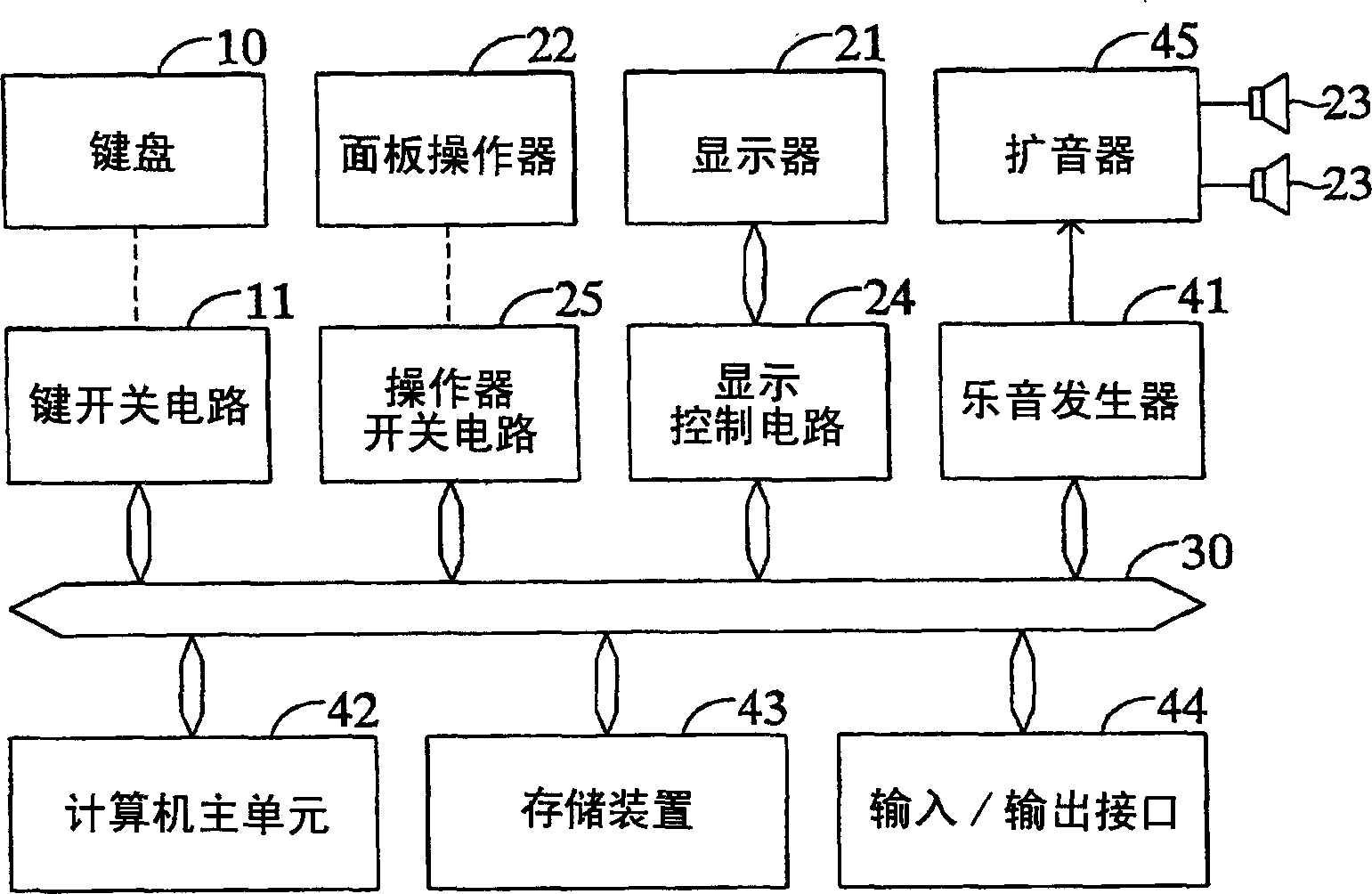

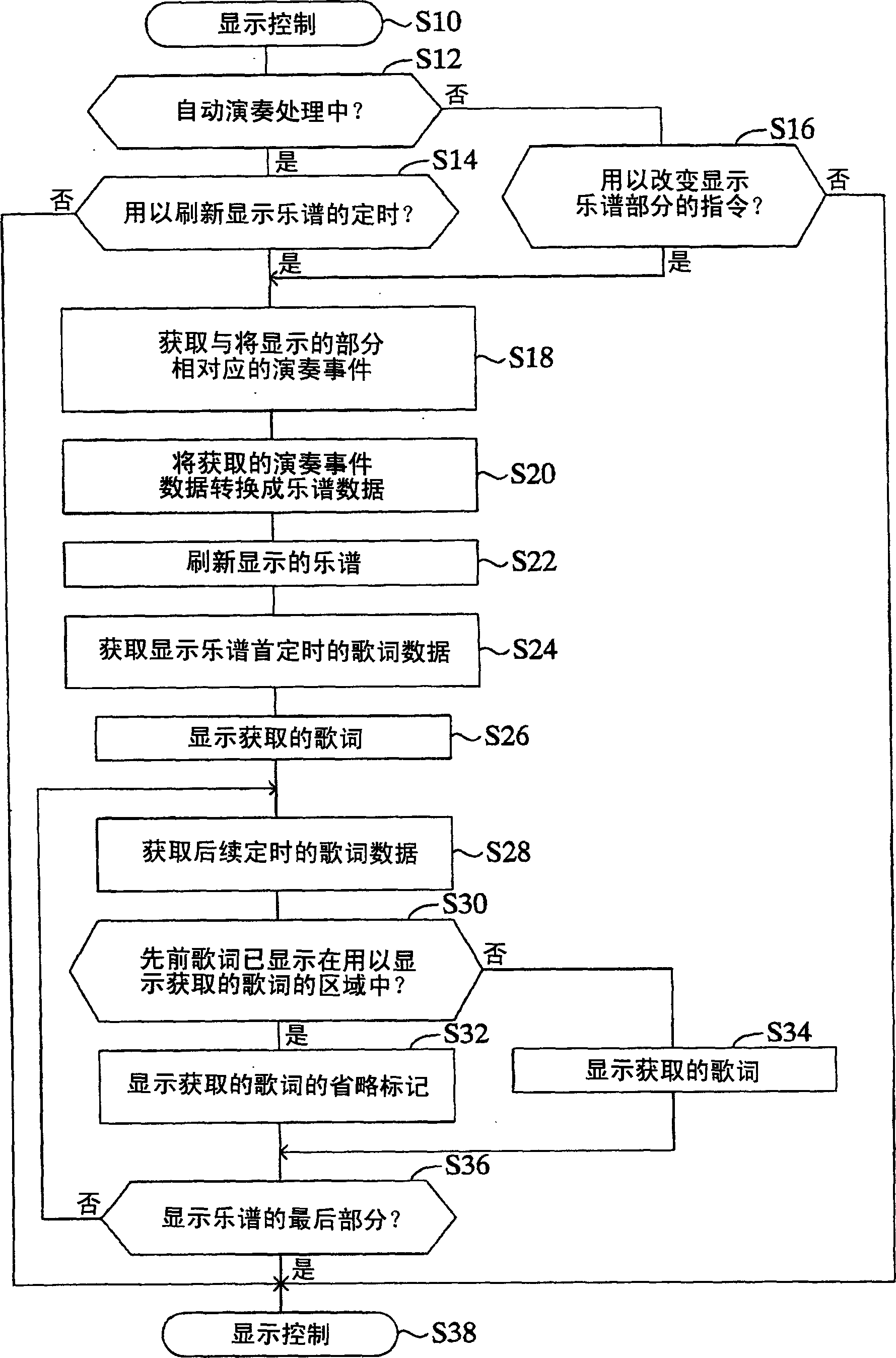

Apparatus and computer program for displaying a musical score

InactiveCN1551099APrevent overlappingGood lookingElectrophonic musical instrumentsCathode-ray tube indicatorsMusical toneDisplay device

An electronic musical instrument displays a musical score including lyric character strings on a displayer 21, using music data stored in a storage device 43, by program-processing by a computer main unit 42. The music data includes a series of data representative of a lyric character string separated by break of lyrics, word, or segment of a sentence, the series of data stored in associated relation with data representative of a timing indicative of progression of a musical piece. The computer main unit 42 displays, on the displayer 21, a lyric character string which is not provided with enough display space in a display style different from a display style used for a lyric character string provided with enough display space. For example, part or the whole of characters of either of adjacent overlapping character strings is omitted, with a mark representative of being omitted attached. Alternatively, part or the whole of a preceding character string is displayed in a reduced size or in rows. As a result, on displaying character strings for a musical piece in associated relation with a musical score, even in cases where there is not enough space to display the character strings, the character strings can be displayed appropriately.

Owner:YAMAHA CORP

Information downloading apparatus and mobile terminal

InactiveUS20100142431A1Improve download efficiencyPrevent overlappingNetwork traffic/resource managementBroadcast transmission systemsTelecommunicationsControl channel

A technique for improving the efficiency of downloading transmission data is disclosed. An information downloading apparatus downloads differing sets of information to predetermined groups to which a mobile terminal may belong. This apparatus includes a channel selecting unit for selecting from plural information channels an information channel for transmitting transmission data and a transmitting unit for transmitting transmission data using the selected information channel. The channel selecting unit selects an information channel so that sets of transmission data with differing destination addresses may be transmitted through differing information channels. The transmitting unit transmits to each group, through a control channel, information pertaining to whether a set of transmission data exists, the information channel to be used if the set of transmission data exists, and the data length of the set of transmission data. The control channel includes time slots that are associated with the groups.

Owner:FUJITSU LTD

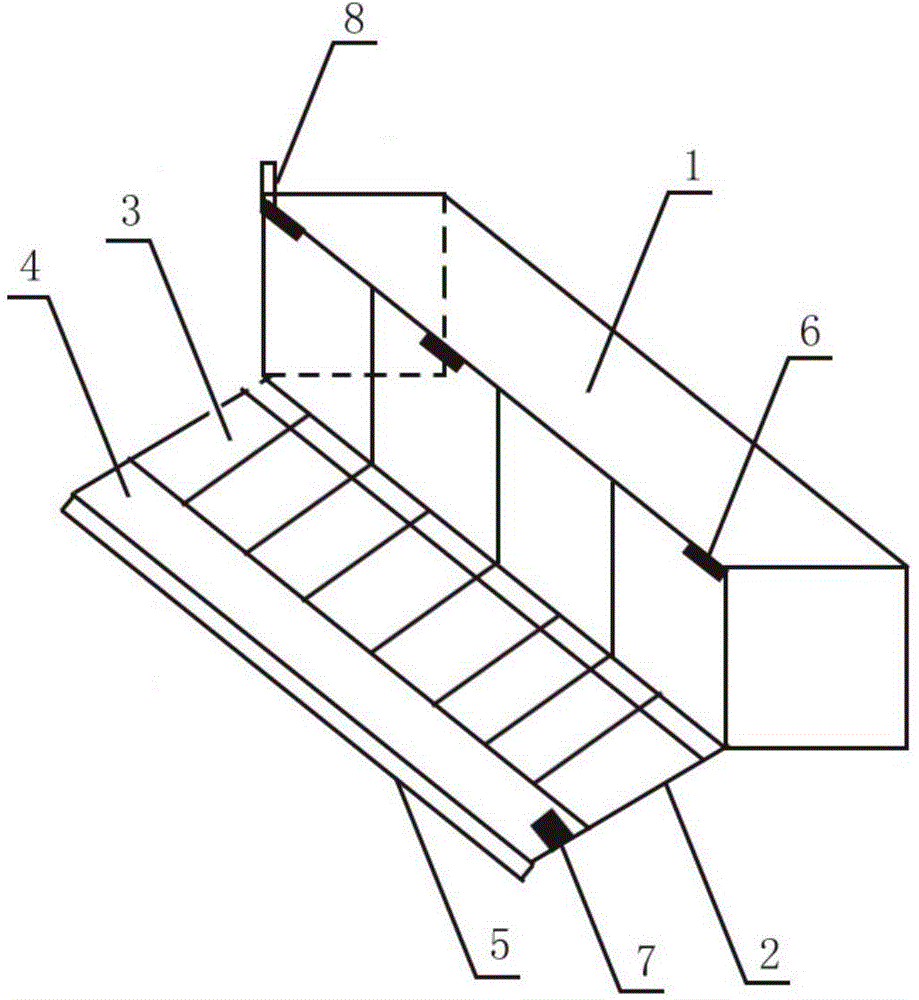

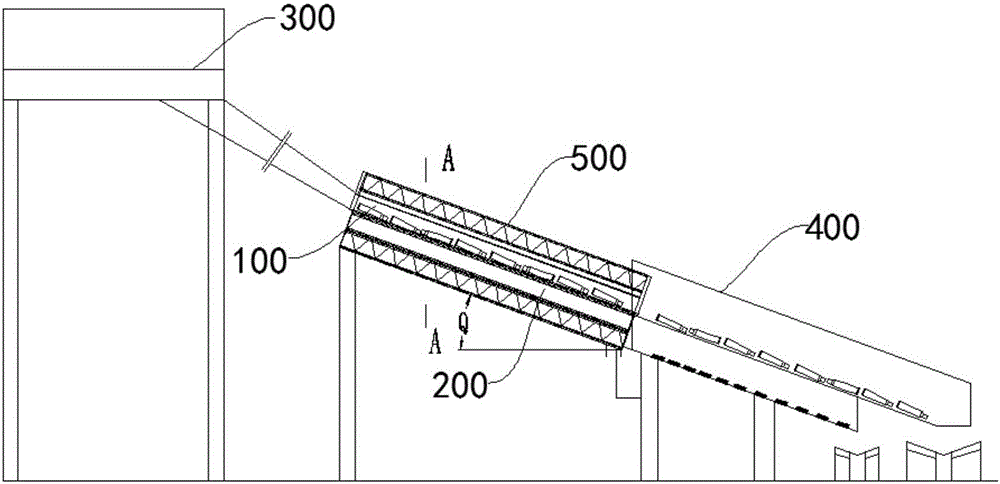

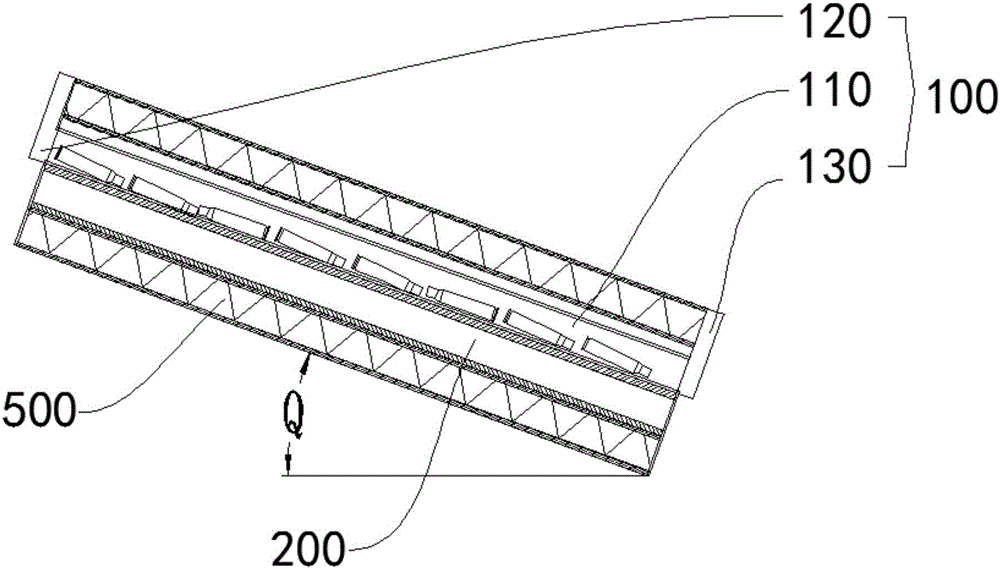

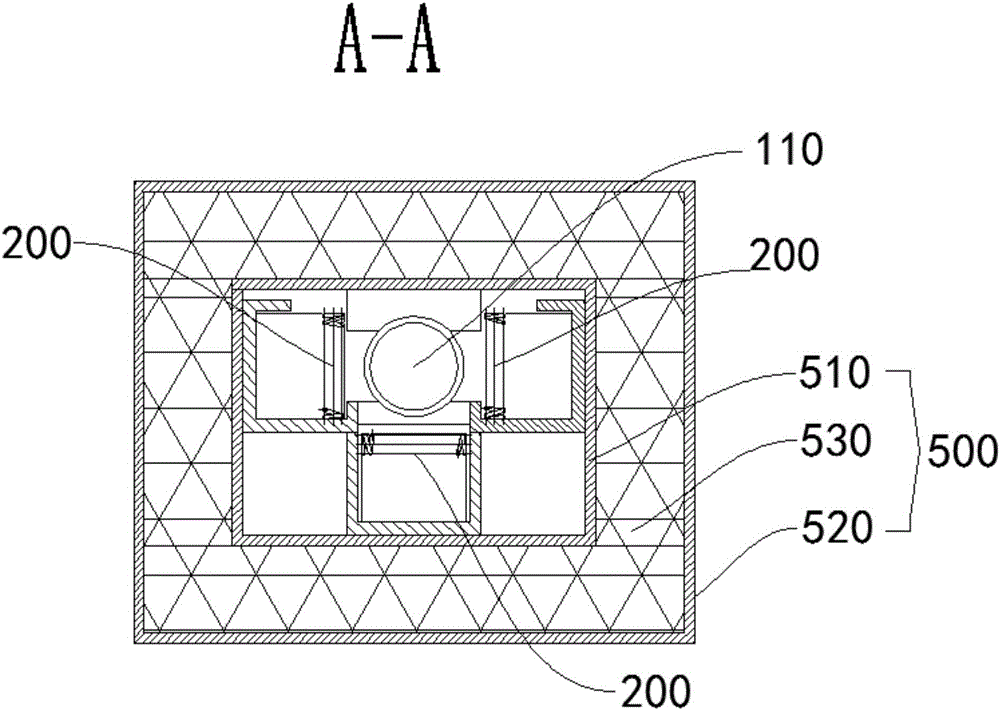

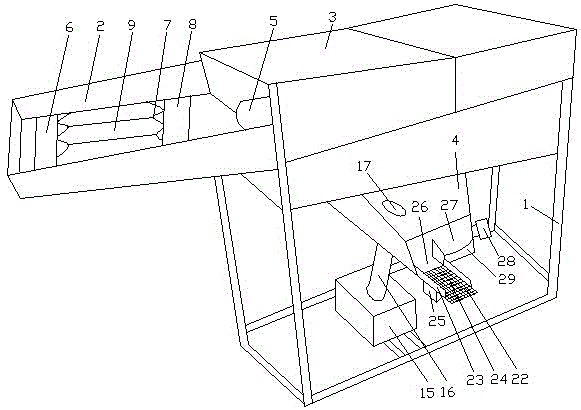

Guiding device for fowl egg collecting

InactiveCN104920246AQuality assuranceEffective monitoring of whereaboutsBird housingsFowlWeight monitoring

A guiding device for fowl egg collecting comprises a cage frame (1). An egg sliding device arranged behind the frame (1) comprises a slope fence (2), guiding track devices (3), a conveying belt device (4) and a buffering baffle (5). During operation, eggs fall into front end grooves of the guiding track devices (3). Interval way-splitting design is carried out in the grooves, so that the eggs are guided into different guiding track devices (3). After the eggs slide down to a conveying device, the eggs are conveyed to a collecting chamber. Video modules (6) are arranged on the two sides and in the middle of the frame (1) and are arranged on the upper portion of a cage back side net. The tail end of the conveying belt device (4) is provided with a weight monitoring device (7) which is connected with a control chamber. The hinting mode of a hinting device (8) is set to be sound or LED light displaying. Egg falling routes are separated quickly. Overlaying and breaking are avoided. Egg quality is guaranteed. Investment cost is low. The falling situations of eggs in cages at different layers are effectively monitored in a house.

Owner:ANHUI YILIU ELECTRONICS SCI & TECH

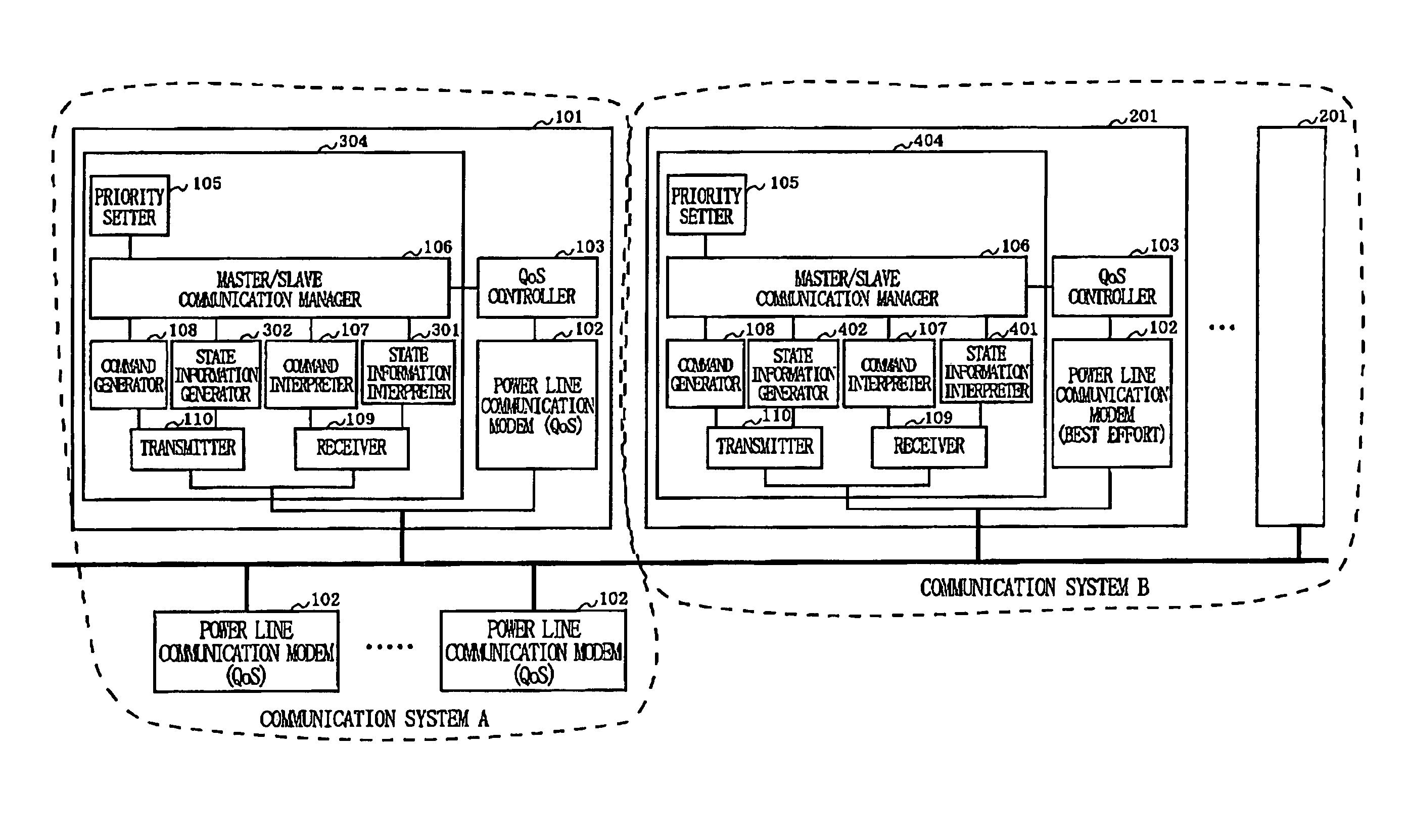

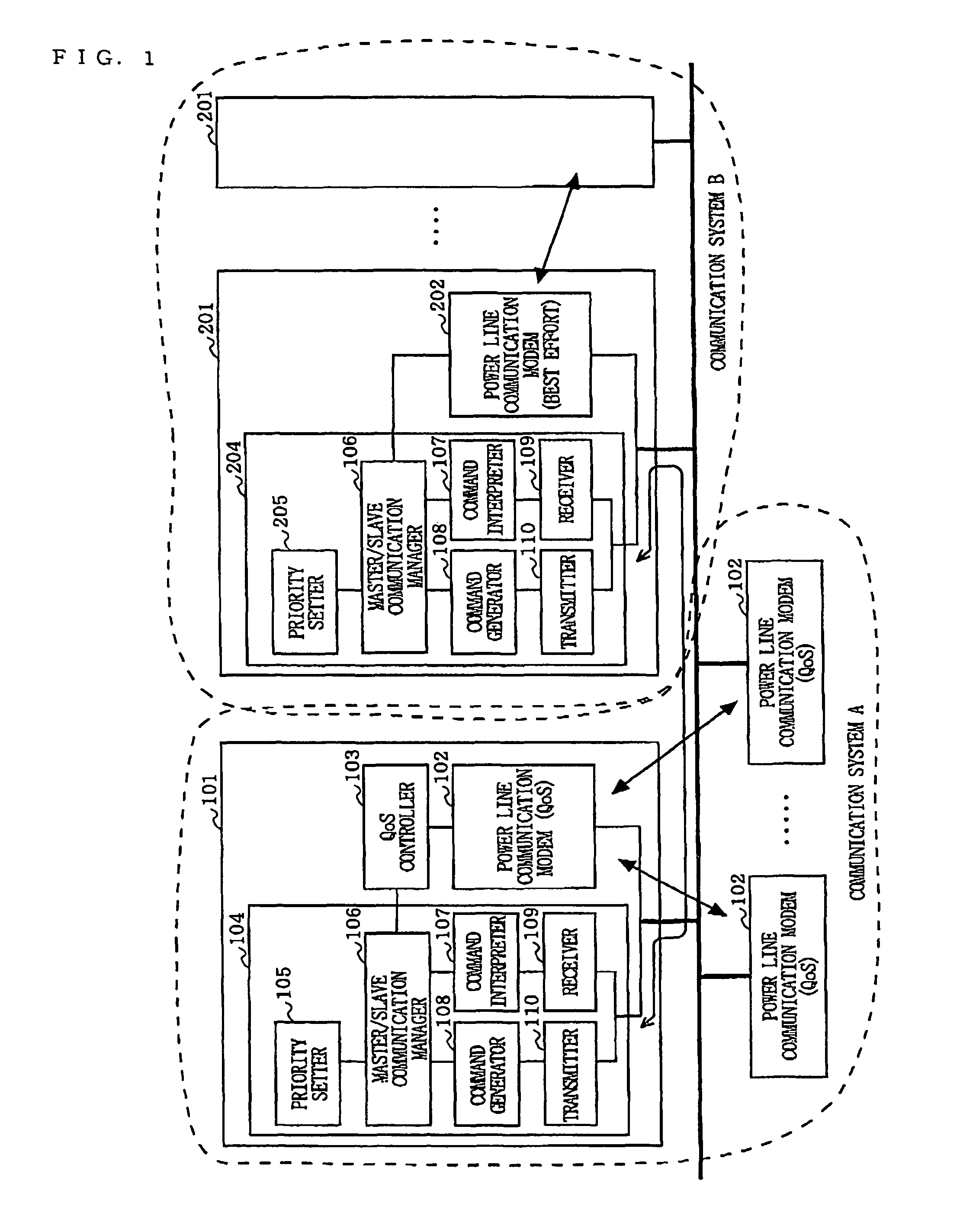

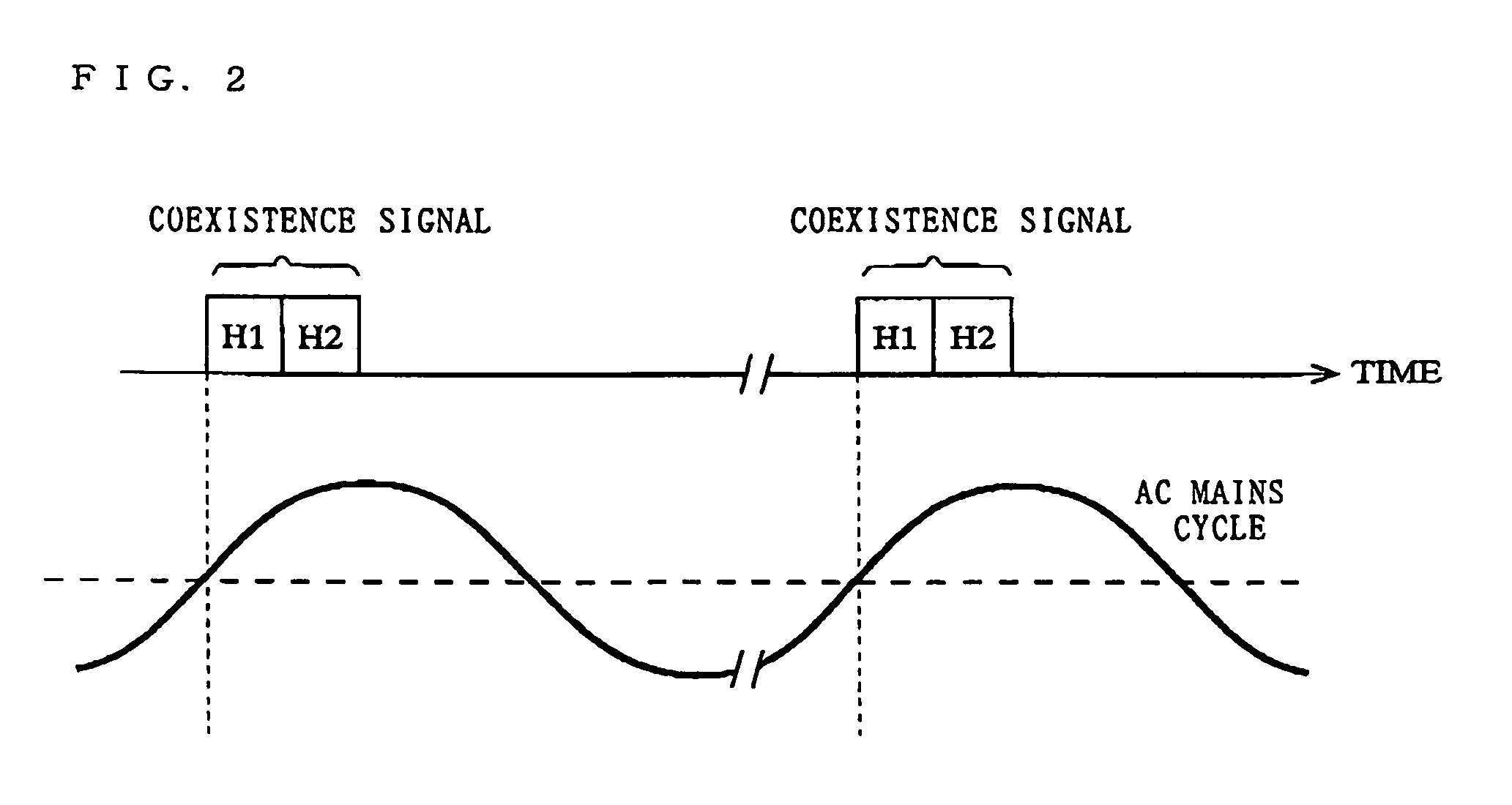

Communication apparatus enabling temporal coexistence of systems

ActiveUS7953105B2Prevent overlappingImprove efficiencyError preventionFrequency-division multiplex detailsModem deviceControl communications

A coexistence controller which performs management and control of time division for coexistence, is provided in a power line communication modem which has a function as a QoS controller for a QoS type communication system and a power line communication modem for a best-effort type communication system. In the QoS type communication system, by controlling allocation of a communication band in accordance with priorities given to the communication systems by cooperation of the coexistence controller and the QoS controller, the power line communication systems having different schemes can coexist.

Owner:PANASONIC CORP

Cartridge disassembling device and disassembling method thereof

ActiveCN106767198AThe dismantling process takes a short timeShort timeAmmunitionElectricityEngineering

The invention relates to a cartridge disassembling device and a disassembling method thereof. The cartridge disassembling device comprises a cartridge-loading device, a heating device and a control device, wherein an electric control part of the cartridge-loading device and the electric control part of the heating device are both electrically connected with the control device; and the heating device is arranged on the exterior of the cartridge-loading device and is used for heating a to-be-treated cartridge entering into the cartridge-loading device, so that a primer mixture in a primer of the to-be-treated cartridge can reach an ignition point under the effect of high temperature. The cartridge disassembling device has the beneficial effects that the to-be-treated cartridge fills the cartridge-loading device, and then the heating device is utilized to heat and the primer mixture in the primer of the to-be-treated cartridge can reach the ignition point under the effect of high temperature, so that the primer mixture on the cartridge can be disassembled; in the whole disassembling process, the correct position and direction of the cartridge need not be deliberately guaranteed; multiple cartridges can be simultaneously disassembled; the whole disassembling process is low in time consumption; the whole structure is simple; and the maintenance is convenient.

Owner:ARMY ENG UNIV OF PLA

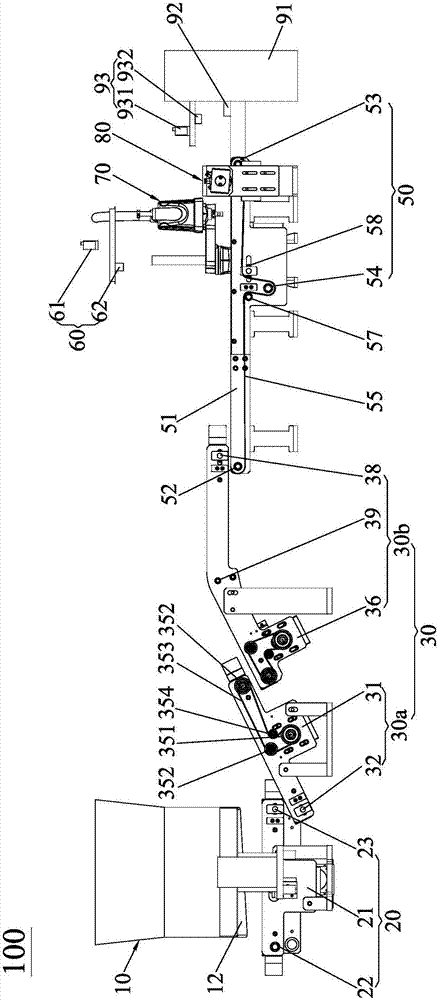

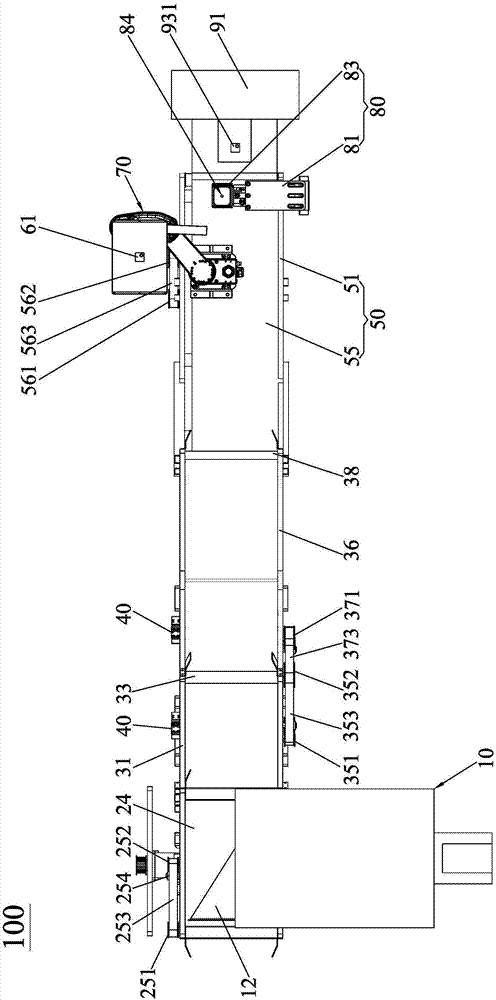

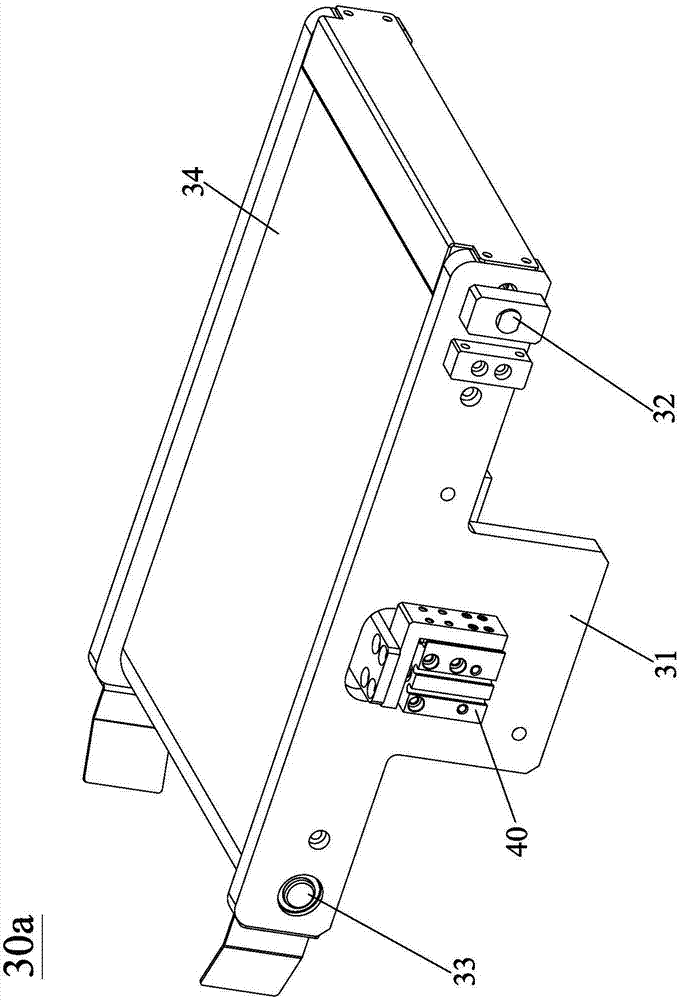

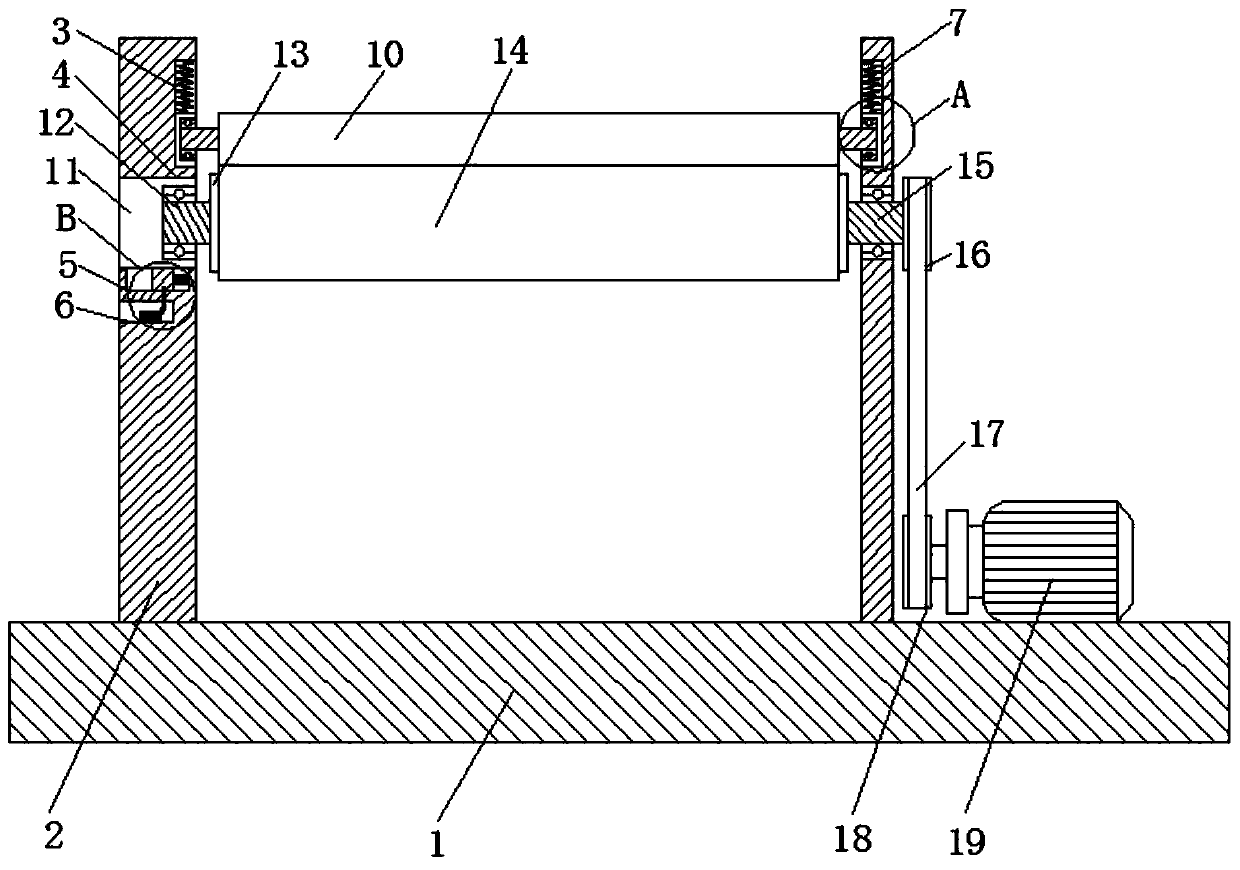

Metal sheet intelligent screening equipment

PendingCN107185848AImprove screening pass rateAvoid damagePackaging automatic controlSortingEngineeringThin sheet

The invention discloses metal sheet intelligent screening equipment comprising a bulk material conveying device, a first horizontal conveying line, a second horizontal conveying line, an inclined conveying line, a visual device, a manipulator and an overturning mechanism. The bulk material conveying device comprises a horizontal plate, an inclined plate and a power source. The first end of the first horizontal conveying line is located below a staircase structure and conveys metal sheets forwards in the horizontal direction. The first end of the inclined conveying line is located below the second end of the first horizontal conveying line and conveys the metal sheets obliquely to the upper front position. A vibration source is installed on the inclined conveying line. The first end of the second horizontal conveying line is located below the second end of the inclined conveying line and conveys the metal sheets forwards in the horizontal direction. The visual device detects the front and reverse positions of the metal sheets conveyed by the second horizontal conveying line. The manipulator grabs the metal sheets in the reverse position. The overturning mechanism overturns the metal sheets, in the reverse position, grabbed and conveyed by the manipulator to the front position, and the metal sheets fall onto the second horizontal conveying line, so that intelligent screening of the metal sheets is achieved.

Owner:DONGGUAN SANNIAN INTELLIGENT TECH CO LTD

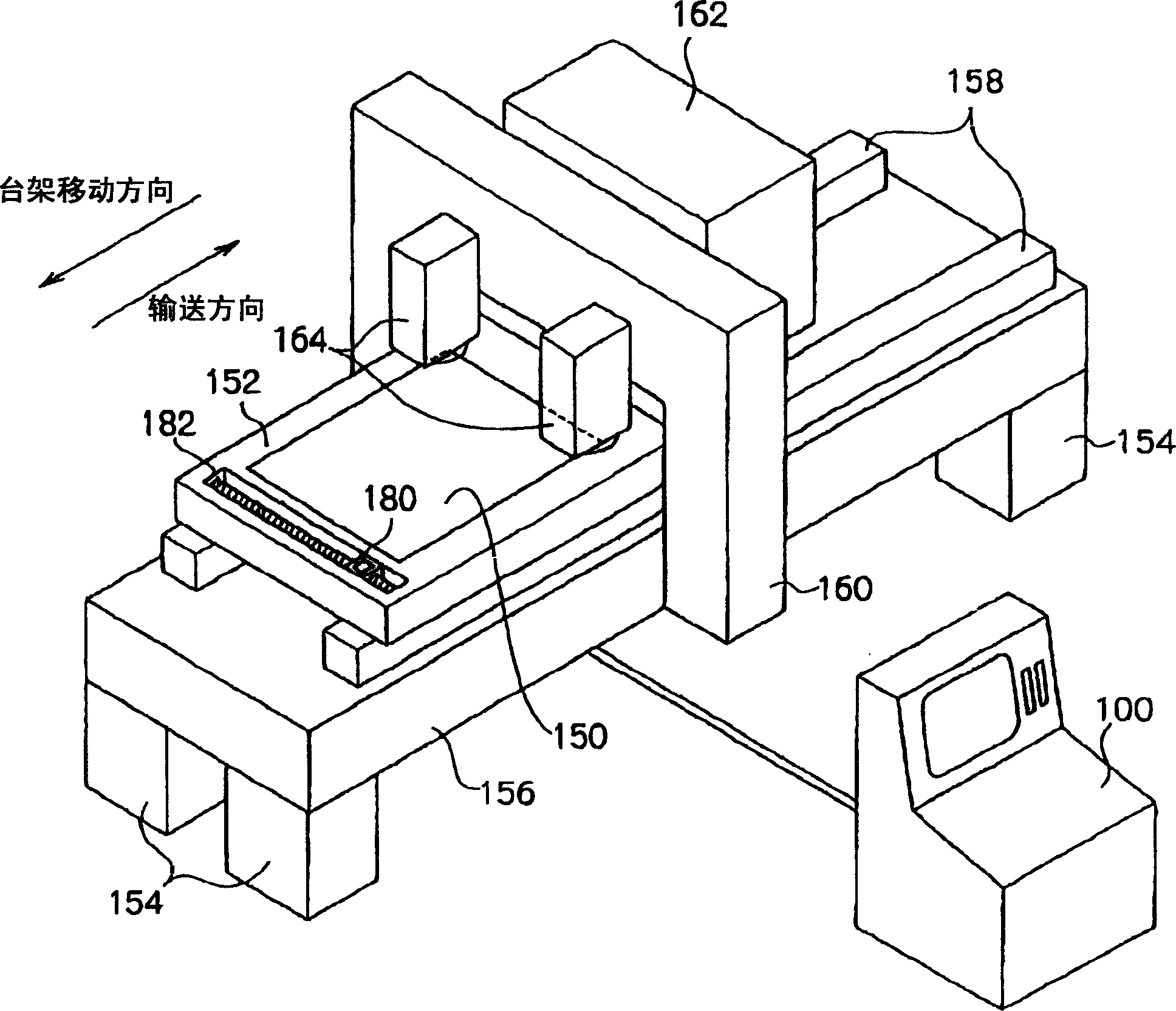

Pixel position specifying method, method of correcting image offset, and image forming device

InactiveCN1573414AAvoid offsetPrevent overlappingPhotomechanical exposure apparatusMicrolithography exposure apparatusLight beamImage formation

The invention provides a pixel positioning method, an image shift correction method and an imaging device, which comprises following steps: opening a first connecting pixel near a connecting joint of a first exposure head; moving a beam position detector along a Y axis; detecting a first exposure beam position in XY coordinate on the light receiving side; opening a second connecting pixel near a connecting joint of a second exposure head; moving the beam position detector along the Y axis; detecting the exposure beam position in XY coordinate on the light receiving side; positioning the first pixel and second pixel according to the motion quantity of the beam position detector along the Y axis and the exposure beam positions of the first exposure head and the second exposure head on the light receiving side. The pixel positioning method and image shift correction method as well as the imaging device has the advantages of reducing shift among the images formed by the exposure heads in the multi-head exposure devices.

Owner:FUJIFILM CORP

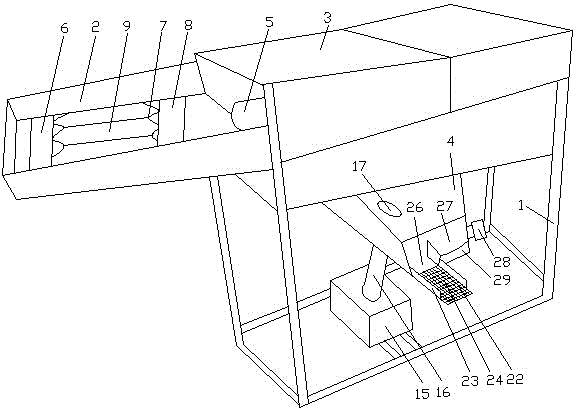

Winnowing type precise thresher

The invention discloses a winnowing type precise thresher and belongs to the technical field of agricultural machinery. The thresher comprises a feed hopper, wherein a flow guide device is arranged in the feed hopper and comprises a first connecting plate, a flow guide plate and a second connecting plate, the flow guide plate is bent to form flow guide grooves, one end of the first connecting plate is connected with the flow guide plate, the other end is connected with a bottom plate of the feed hopper, one end of the second connecting plate is connected with the flow guide plate, the other end is connected with the bottom plate of the feed hopper, a fan is fixedly connected onto a rack, a blowing port of the fan is connected with an air guide pipe, a discharge bin consists of a grain discharge bin and a husk discharge bin which are parallel, a suction fan is connected onto the side wall of the husk discharge bin, a bottom plate of the husk discharge bin is connected with an arc baffle, the grain discharge bin is sleeved with a sieve frame, a dust outlet is formed in a top plate of the grain discharge bin, a vent hole is formed in the bottom plate, and a grid plate is embedded at the vent hole and connected with the air guide pipe. With the adoption of the thresher, corn can be threshed in batches, the threshing efficiency can be improved, and threshed corn grains are clean and free of impurities.

Owner:DEYANG ZHIDA PRECISION ELECTRONICS

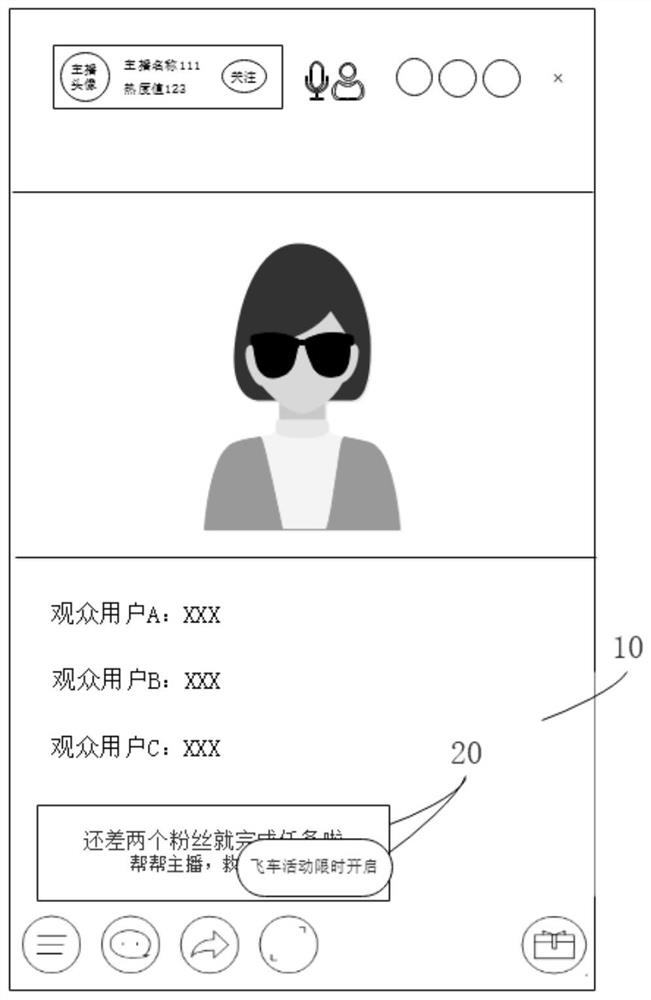

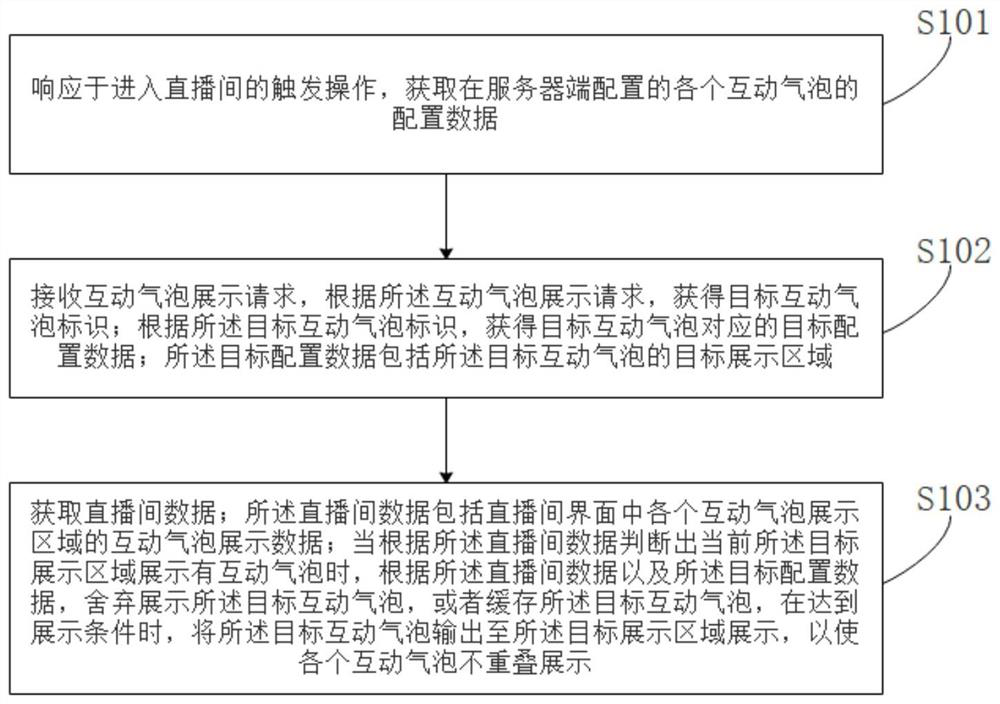

Display method and device of interaction bubbles in live broadcast room, medium and computer equipment

PendingCN114286124APrevent overlappingAvoid visual fatigueSelective content distributionHigh level techniquesComputer hardwareEngineering

The embodiment of the invention relates to the field of network live broadcast, and provides a live broadcast room interaction bubble display method and device, a medium and computer equipment, and the method comprises the steps: obtaining the configuration data of each interaction bubble configured at a server side; receiving an interaction bubble display request, and obtaining a target interaction bubble identifier according to the interaction bubble display request; obtaining target configuration data corresponding to the target interaction bubble according to the target interaction bubble identifier; acquiring live broadcast room data; and when it is judged that interaction bubbles are displayed in the current target display area according to the live broadcast room data, abandoning display of the target interaction bubbles or caching the target interaction bubbles according to the live broadcast room data and target configuration data, and when a display condition is met, outputting the target interaction bubbles to the target display area for display. Therefore, only one interaction bubble is displayed in the same display area at the same time, and the situation that a plurality of interaction bubbles are overlapped is prevented.

Owner:广州方硅信息技术有限公司

Anti-crease cloth rolling device capable of automatically shearing for spinning

The invention relates to the technical field of textiles, and discloses an anti-crease cloth rolling device capable of automatically shearing for spinning. The device comprises a base, the top portionof the base is fixedly connected with a cloth rolling frame, the cloth rolling frame is internally provided with a vertical sliding groove, a transverse sliding groove, a sliding cavity and a mounting cavity, the top of the vertical sliding groove is fixedly connected with a pressure spring, the bottom of the pressing spring is fixedly connected with a pressing sliding block, a pressing shaft ismovably connected to the interior of the pressing sliding block, the outer portion of the pressing shaft is movably connected with a pressing roller, the interior of the transverse sliding groove is movably connected with a disassembly and assembly sliding block, and a first cloth winding shaft is movably connected into the dismounting and mounting sliding block, and a mounting piece is fixedly connected to the outer portion of the first cloth winding shaft. Through cooperative use of the pressing spring and the pressing roller, cloth is always jacked and rolled, so that the cloth is preventedfrom wrinkling and overlapping, and the quality of the cloth is improved.

Owner:黄泽

Artificial cultivation method for kiwifruits

ActiveCN105706834AIncrease the effective coverage areaIncrease productionCultivating equipmentsHorticulture methodsActinidiaGreenhouse

The invention provides an artificial cultivation method for kiwifruits. The artificial cultivation method comprises the following steps: establishing a multi-span greenhouse comprising greenhouse support pillars (1), arched support rods (2), a plastic film, sunshade net structures, a steel wire mesh (3) and an illumination structure; planting kiwifruit seedlings from early of middle of December to early of middle of February of next year; shaping and pruning; from 9 a.m. to 3 p.m., performing illumination control according to the sunshade net structures and the illumination structure of the greenhouse: when average illumination intensity in the greenhouse is higher than 160,000 lux and lower than 220,000 lux, opening an upper layer of sunshade net structure; when the average illumination intensity in the greenhouse is higher than 220,000 lux, opening two layers of sunshade net structures simultaneously; when the average illumination intensity in the greenhouse is lower than 80,000 lux, opening the illumination structure. According to the artificial cultivation method provided by the invention, comprehensive regulation is performed on illumination intensity for the kiwifruits, so that an illumination environment of the kiwifruits is kept most suitable; the influence of outside illumination on the kiwifruits is reduced to be minimum, and therefore the yield of the kiwifruits is greatly increased.

Owner:ZHEJIANG WANLI UNIV

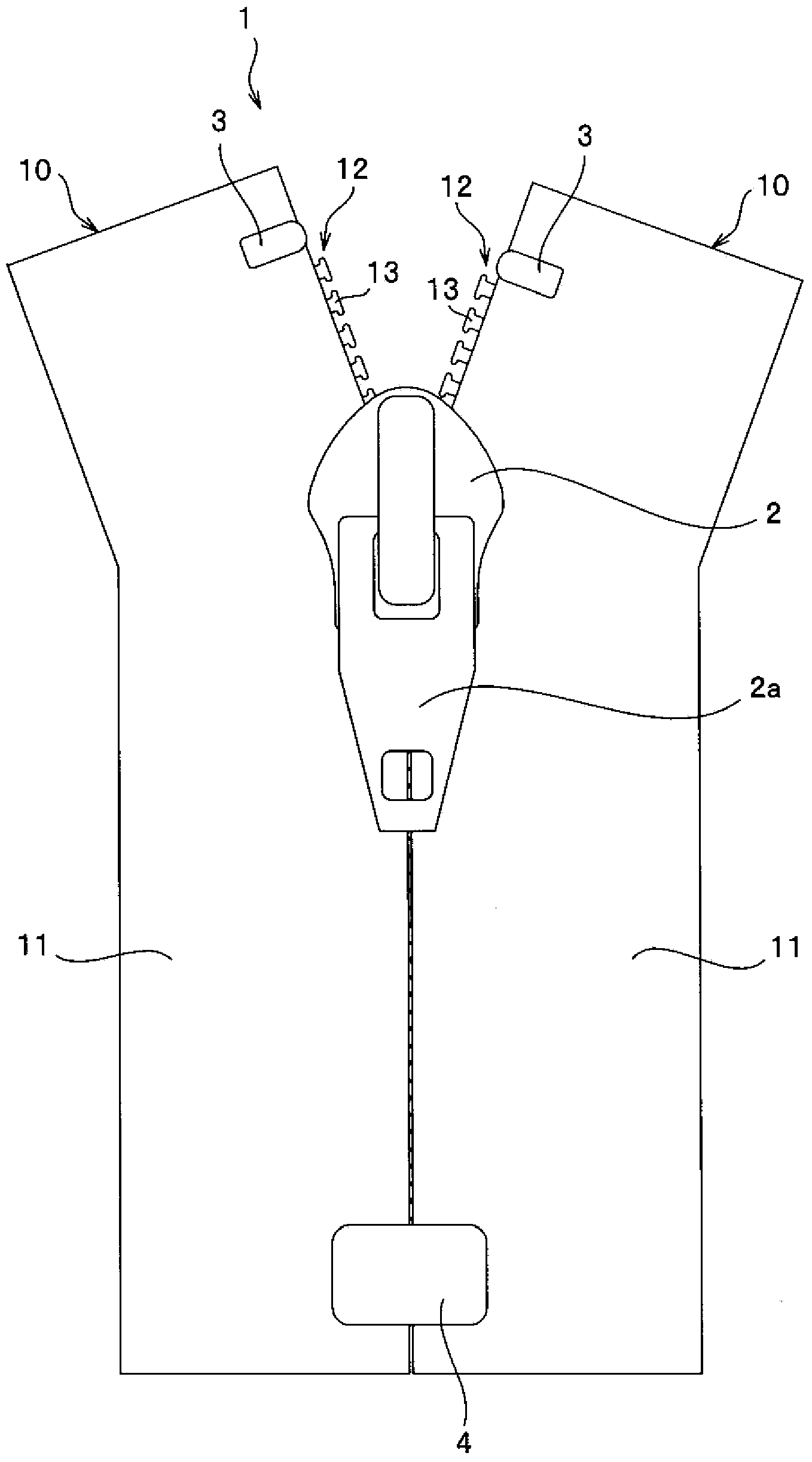

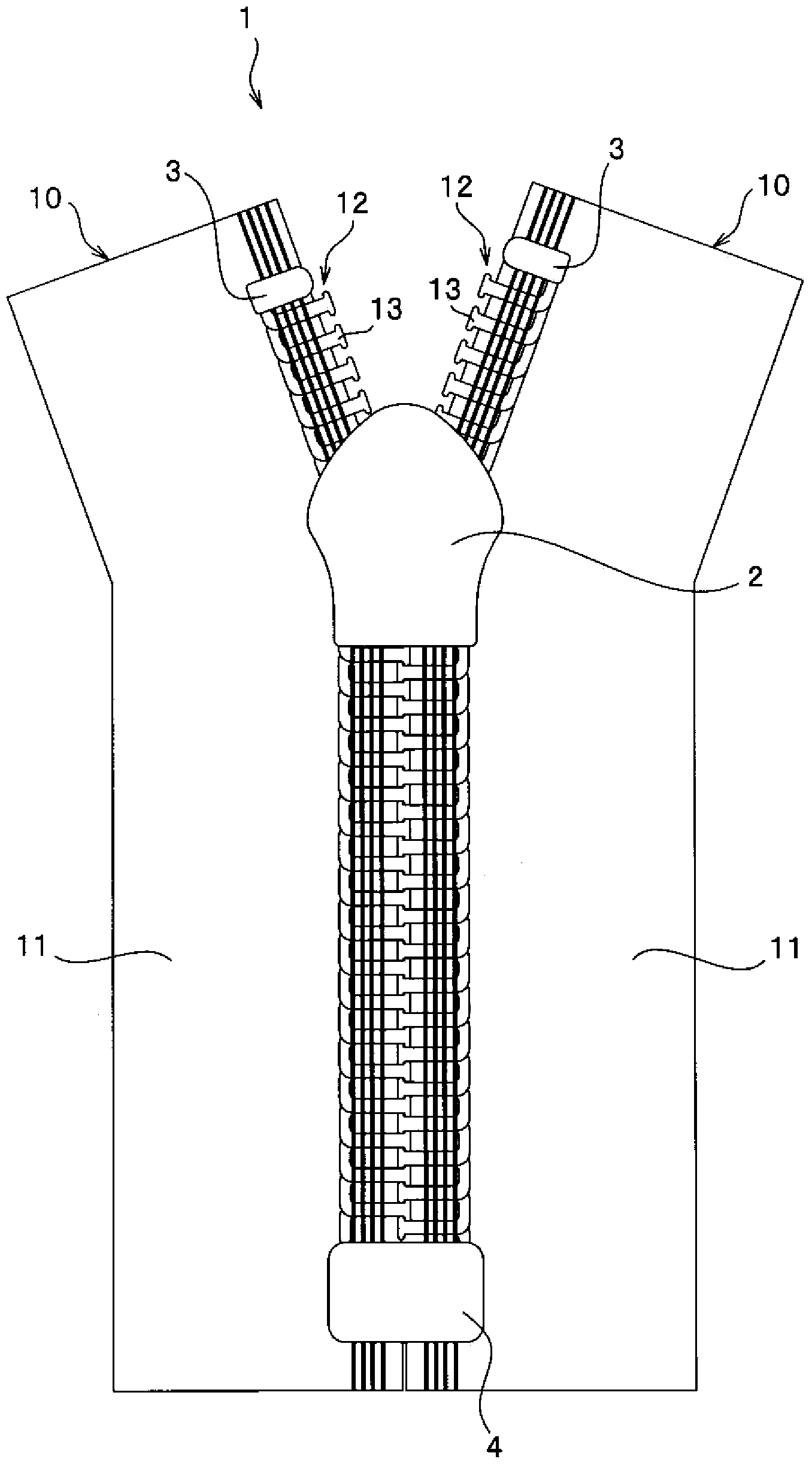

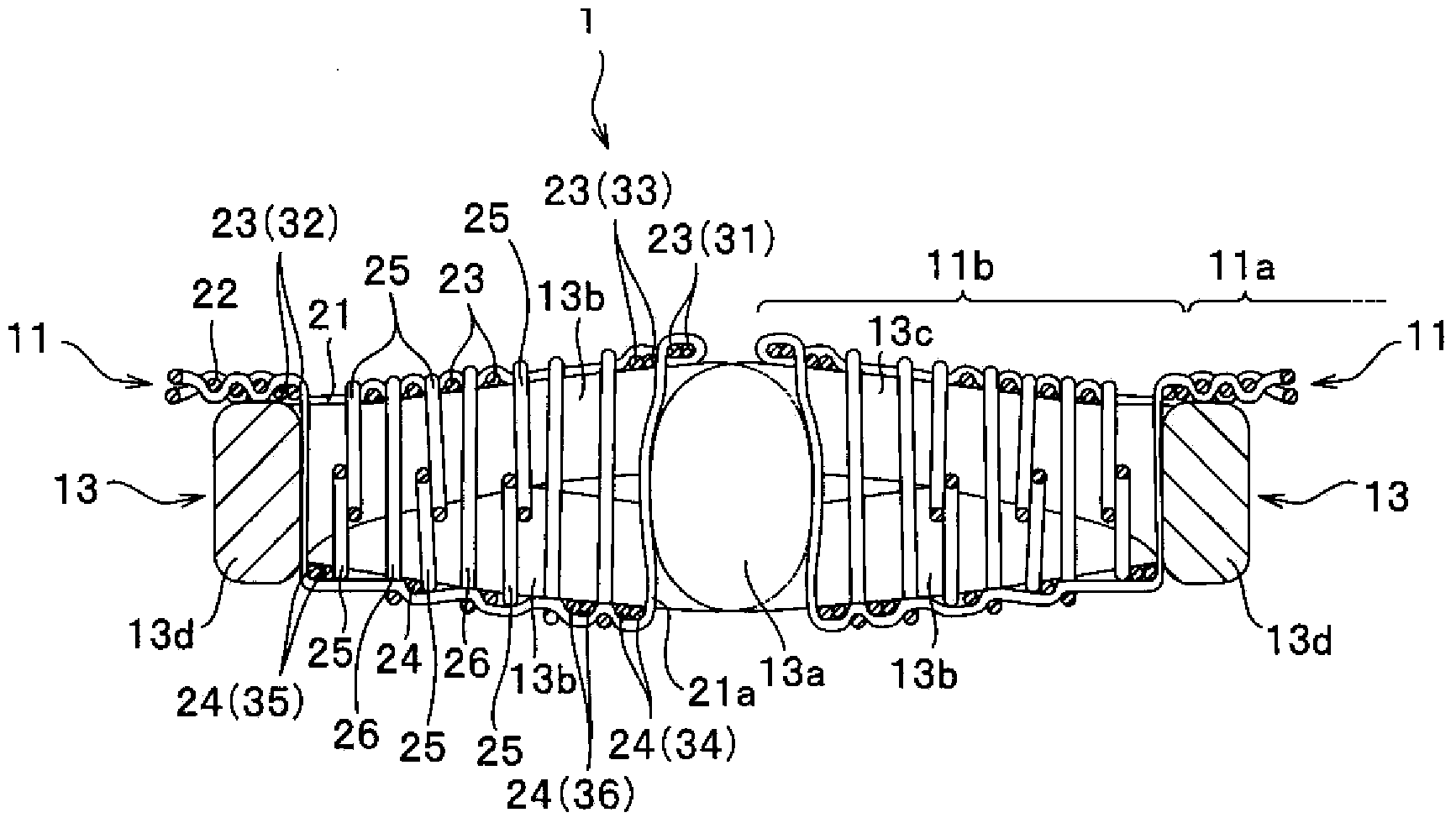

Woven fastener stringer and slide fastener

ActiveCN104023585AWeave into hard to seeEasy to seeSlide fastenersWoven fabricsMechanical engineeringFastener

In this woven fastener stringer (10, 40), a weft thread (21), on a side of an engaging head portion (13a) of a fastener element (13), is entangled with and doubles back along a top diversion portion (34, 44) composed of an upper fixing warp thread (24) and a bottom diversion portion (31, 41) composed of a lower fixing warp thread (23). In addition, a top extension portion (36, 46) that is composed of the upper fixing warp thread (24) is disposed adjacent to the top diversion portion (34, 44) on the side of a tape main body (11a), and a bottom extension portion (33, 43) that is composed of the lower fixing warp thread (23) is disposed adjacent to the bottom diversion portion (31, 41) on the side of the tape main body (11a). Thus, the fastener element (13) in an engaging state is less visible when a slide fastener (1) is used inside out.

Owner:YKK CORP

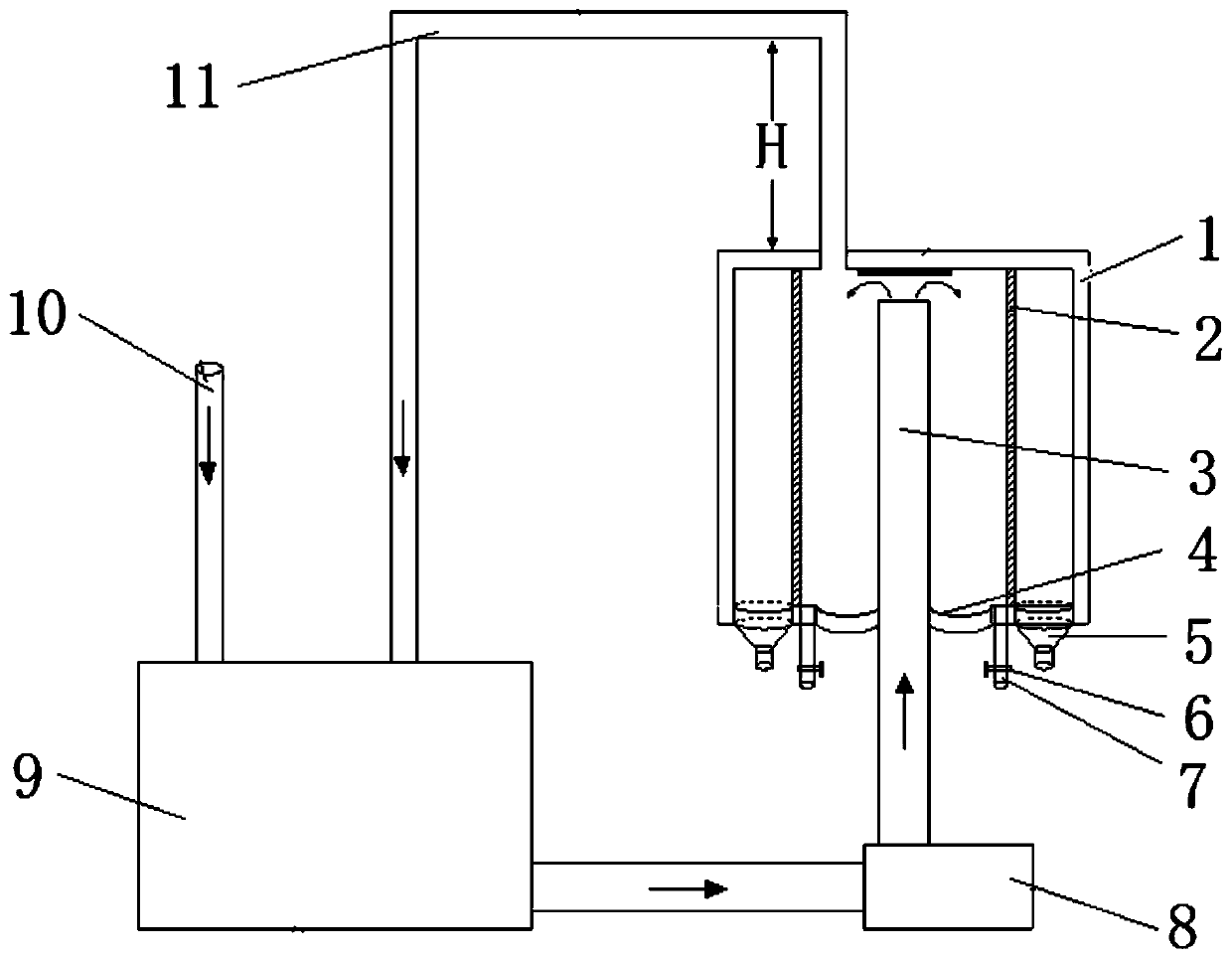

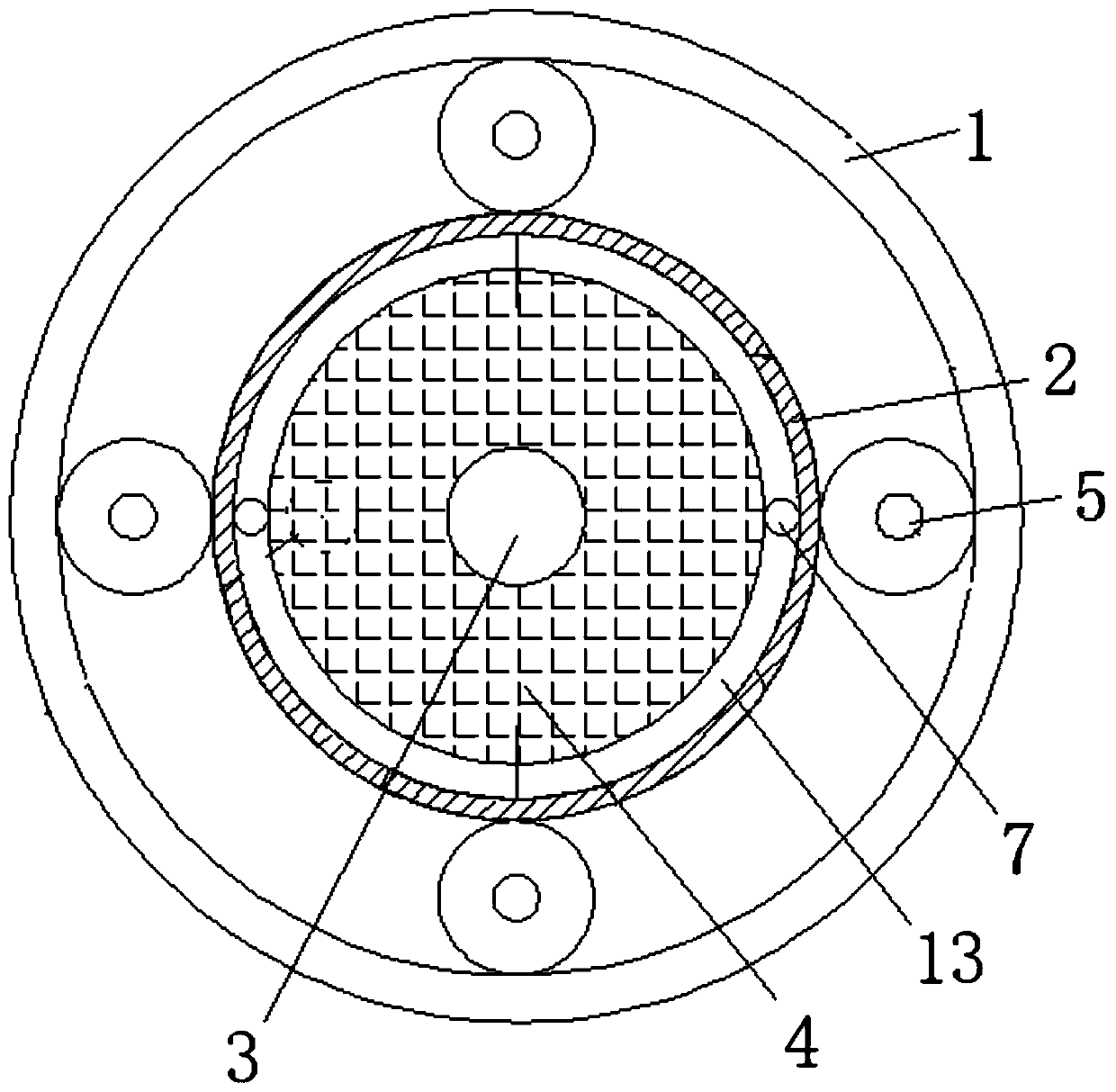

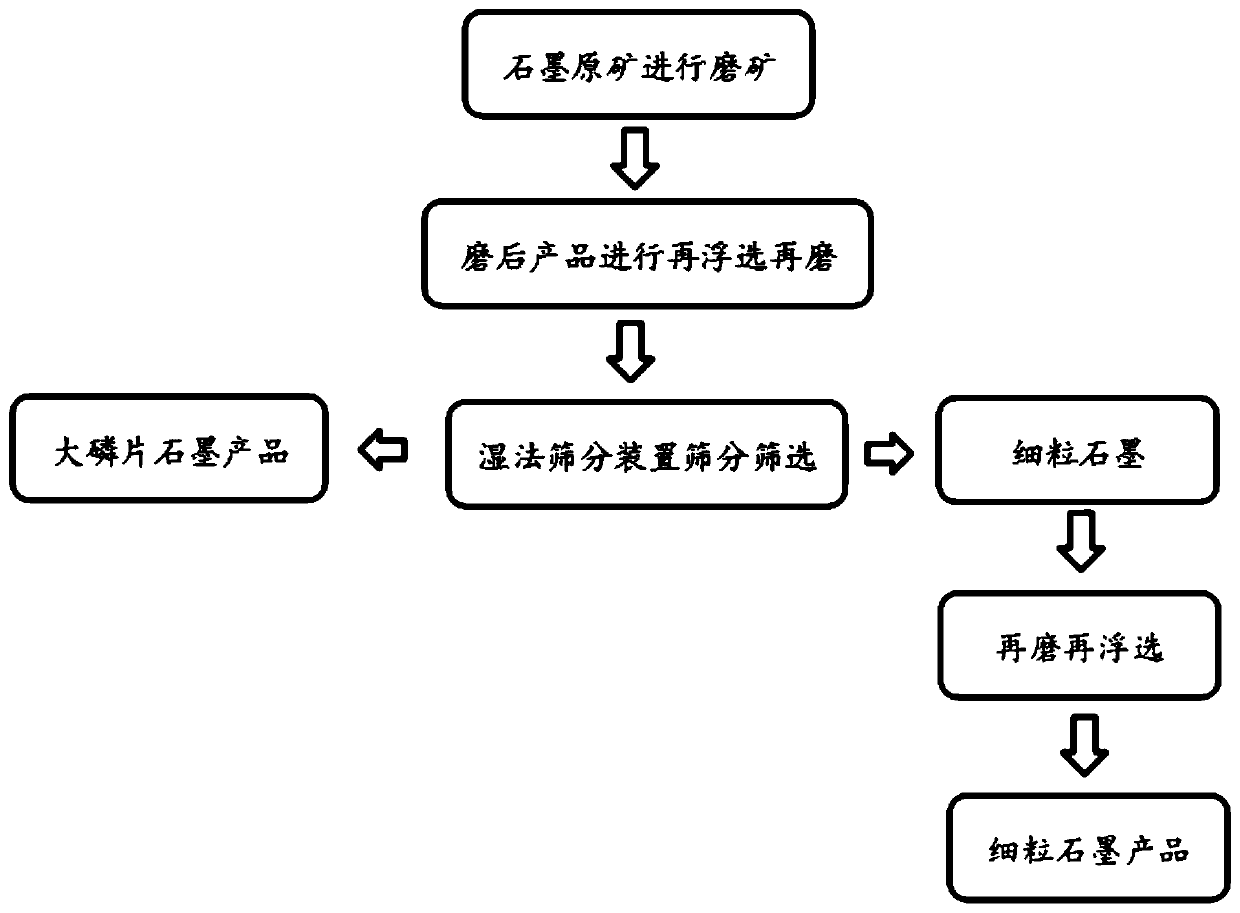

Wet screening device and graphite ore short-process purification method comprising wet screening

The invention discloses a wet screening device and a graphite ore short-process purification method comprising wet screening. The process comprises the step of screening after multi-stage ore grindingflotation for less times, wherein coarse grains obtained by screening are directly qualified concentrates, and obtained fine graphite ore enters a short process of regrinding of a lower-stage mill and re-flotation of a flotation machine; according to the process, the graphite ore screening process can be shortened, crystalline flake graphite is protected, the total graphite grade is improved, pulsating slurry feeding is achieved through a longitudinal screen adopted in the screening device, the problem that graphite is prone to settling and lap joint to form false large pieces to block the screen in the transverse screen screening process is effectively solved, the screening index is improved, and energy consumption and cost are reduced.

Owner:WUHAN UNIV OF TECH

Flexible circuit board laser cutting equipment

ActiveCN113977110ARealize automatic feeding processRealize functionLaser beam welding apparatusFlexible circuitsLaser cutting

The invention relates to the field of laser cutting, in particular to flexible circuit board laser cutting equipment. The technical problems that manual feeding and winding efficiency is low, cut strip-shaped lamp strip flexible circuit boards are bonded together or are not neat, and winding and overlapping of the strip-shaped lamp strip flexible circuit boards cannot be prevented are solved. According to the technical scheme, the flexible circuit board laser cutting equipment comprises a fixing frame, a laser cutting unit, a conveying and winding unit, a carding unit and the like; a laser cutting unit used for laser cutting of the lamp strip flexible circuit board is installed on the upper surface of the fixing frame. The left side and the right side of the upper surface of the fixing frame are provided with conveying and rolling units used for conveying and rolling the lamp strip flexible circuit board. The right side of the laser cutting unit is connected with a carding unit used for carding the cut lamp strip flexible circuit board. The conveying and rolling units are designed, the functions of automatic feeding and disc dividing and winding of the lamp strip flexible circuit board are achieved, the production efficiency is effectively improved, and the workload of workers is reduced.

Owner:苏州开密科智能装备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com