COB (Chip on Board) packaged LED (Light-Emitting Diode) module and manufacturing process thereof

A technology of LED module and manufacturing process, which is applied in household, office lighting, and commercial fields, can solve the problems of cost reduction and light color consistency, and achieve the effects of reducing production costs, ensuring light color consistency, and improving reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

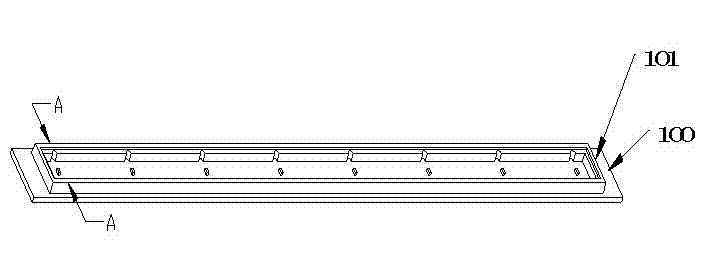

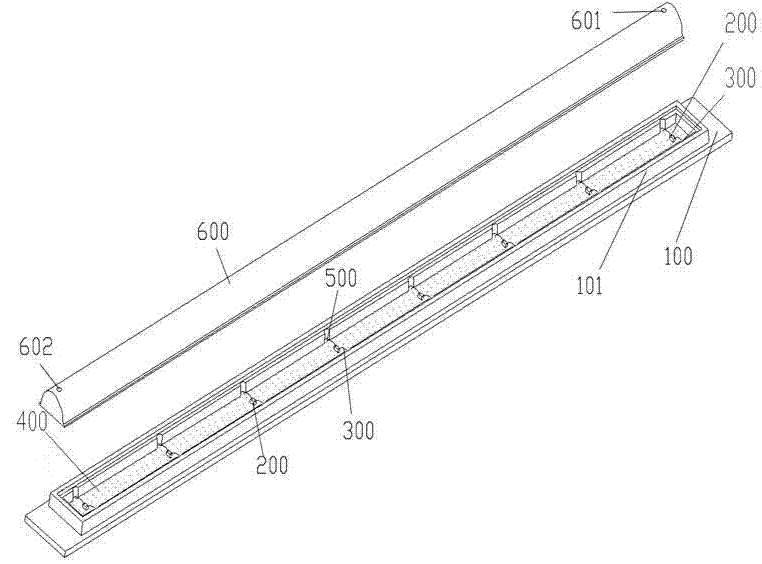

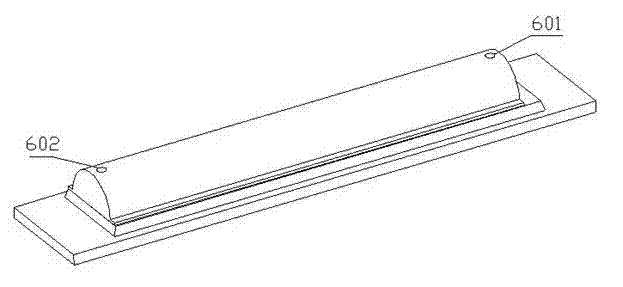

[0050] figure 1 It is a schematic diagram of the aluminum substrate after injection molding of the present invention; figure 2 It is a schematic diagram of the structure of the lens of the present invention opened; image 3 It is a schematic diagram of the external structure of the present invention; Figure 4 for figure 1 A cross-sectional view of the A-A direction.

[0051] Please refer to Figure 1 to Figure 4 , a COB packaged LED module, including an aluminum substrate 100, eight LED chips 200, an optical lens group, sixteen gold wires 300, eight solid crystal positions (not shown in the figure) and sixteen welding pads 500. The shape of the aluminum substrate 100 is rectangular, and the optical lens group preferably includes an optical lens 600 .

[0052]Wherein, the eight LED chips 200 are arranged on the upper surface of the aluminum substrate 100, the optical lens 600 is arranged on the top of the aluminum substrate 100, the optical lens 600 covers all the LED c...

Embodiment 2

[0069] The difference between Embodiment 2 and Embodiment 1 is that the fluorescent adhesive layer 400 is not arranged on the LED chip 200, the phosphor particles are far away from the LED chip 200, and are not in direct contact with the LED chip 200. In Embodiment 2, the fluorescent adhesive layer 400 is set On the optical lens 600 , specifically, the fluorescent glue layer 400 is disposed on the inner surface of the optical lens 600 .

[0070] Since the phosphor is excited by the blue light chip with a low wavelength, the phosphor itself will also have heat after excitation, and the heat of the chip itself will form a superposition of heat. If the phosphor is kept away from the LED chip, the heat will not be superimposed. The heat dissipation effect is good, which can prolong the service life. At the same time, the fluorescent powder is located on the inner surface of the lens or inside the lens body, so that the light is more uniform and the light effect is good.

[0071] ...

Embodiment 3

[0089] The difference between Embodiment 3 and Embodiment 1 is that the fluorescent adhesive layer 400 is not arranged on the LED chip 200, the phosphor particles are far away from the LED chip 200, and are not in direct contact with the LED chip 200. In Embodiment 3, the fluorescent adhesive layer 400 is set On the optical lens 600, specifically, the phosphor particles are mixed in the material for making the optical lens 600 (that is, the body of the optical lens 600 is mixed with phosphor), and the fluorescent adhesive layer 400 and the optical lens 600 are set as an integrated structure. for one.

[0090]The difference between Embodiment 3 and Embodiment 2 is that in Embodiment 2, the fluorescent adhesive layer 400 is arranged on the inner surface of the optical lens 600, and in Embodiment 3, phosphor particles are mixed in the material for making the optical lens 600 (that is, The body of the optical lens 600 is mixed with fluorescent powder), and the fluorescent glue lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com