Flexible circuit board laser cutting equipment

A flexible circuit board and laser cutting technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low winding efficiency and irregularity, reduce the workload of workers, prevent winding and overlapping, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

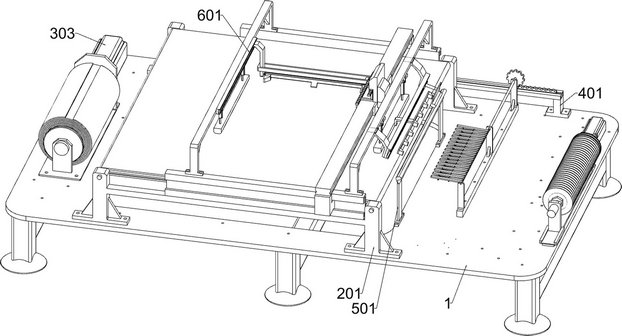

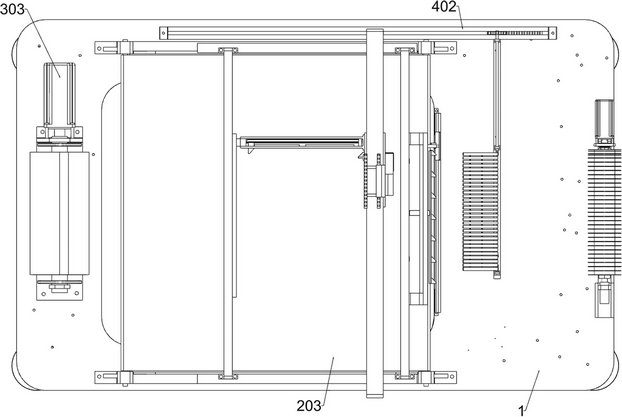

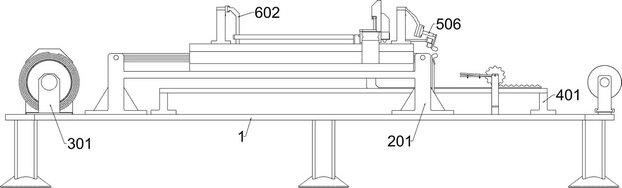

[0040] A flexible circuit board laser cutting equipment, such as Figure 1-12 As shown, it includes a fixed frame 1, a laser cutting unit, a transmission and winding unit, a carding unit and a grid pressing unit; The transmission and winding unit is installed on the left and right sides of the surface; the right side of the laser cutting unit is connected to the carding unit with a flexible circuit board; the lower side of the carding unit is connected to the fixing frame 1; And the grid pressing unit is located on the left of the carding unit; the lower side of the grid pressing unit is connected to the fixing frame 1 .

[0041] The laser cutting unit includes a first fixed plate 201, a second fixed plate 202, an electric conveyor belt 203, a first slide rail 204, a U-shaped frame 205, a first driving member 206, a first pressing plate 207, a second driving member 208, a first Two slide rails 209, a third driver 2010 and a laser cutting instrument 2011; the first fixed plate...

Embodiment 2

[0050] On the basis of Example 1, such as figure 1 and Figure 13-16 As shown, a detection unit is also included, and a detection unit is installed between the third driving member 2010 and the U-shaped frame 205 on the left, and the detection unit includes a sixth slide rail 601, a second L-shaped slide plate 602, a second connection Plate 603, separation dial 604, the third wedge-shaped block 605, the seventh fixed plate 606, the fourth wedge-shaped block 607, square plate 608 and detection probe 609; Six slide rails 601; the sixth slide rail 601 is slidingly connected with a second L-shaped slide plate 602; the lower part of the right side of the second L-shaped slide plate 602 is bolt-connected with a second connecting plate 603; the lower part of the right side of the second L-shaped slide plate 602 The separation dial 604 is connected with the torsion spring rotating shaft, and the separation dial 604 is located in front of the second connecting plate 603, and the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com