Metal sheet intelligent screening equipment

A technology of metal flakes and screening equipment, which is applied in the directions of automatic packaging control, packaging, and packaging protection. It can solve the problems of high scrap rate of metal flakes, waste products produced by metal flakes, and increase costs, and achieve the effect of improving the pass rate of screening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments, but the implementation of the present invention is not limited thereto.

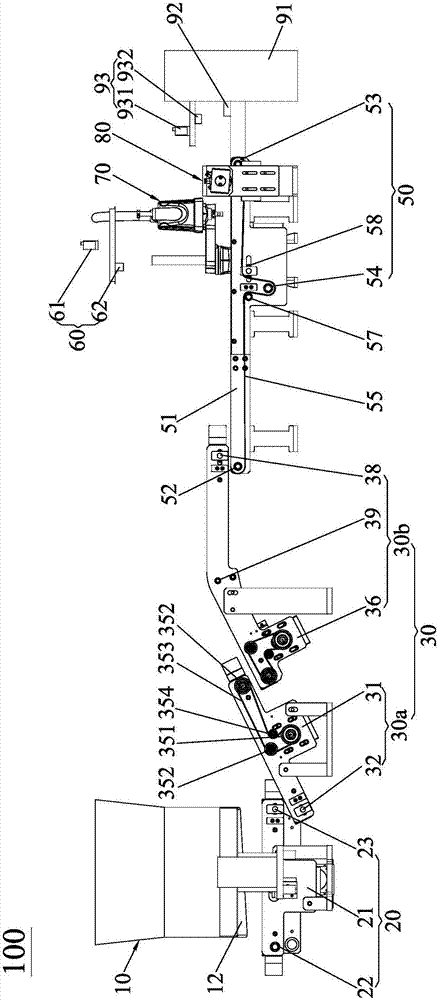

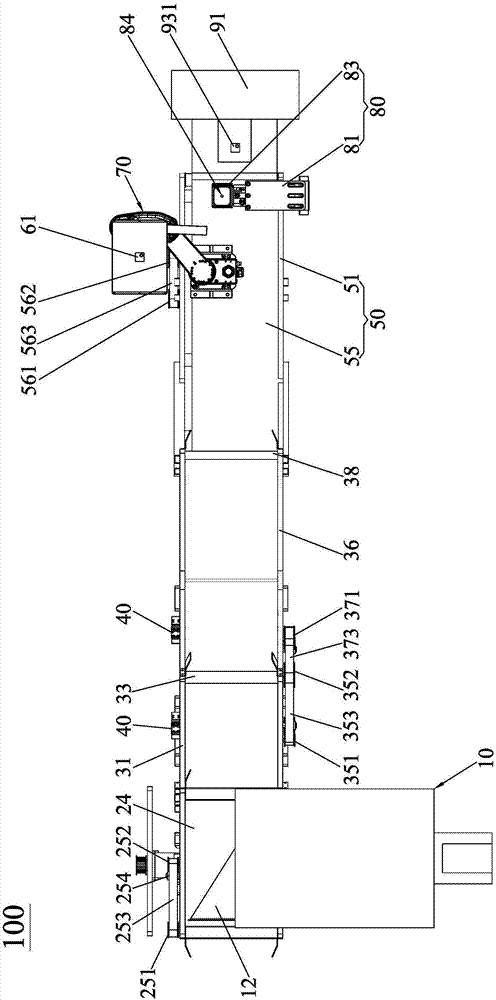

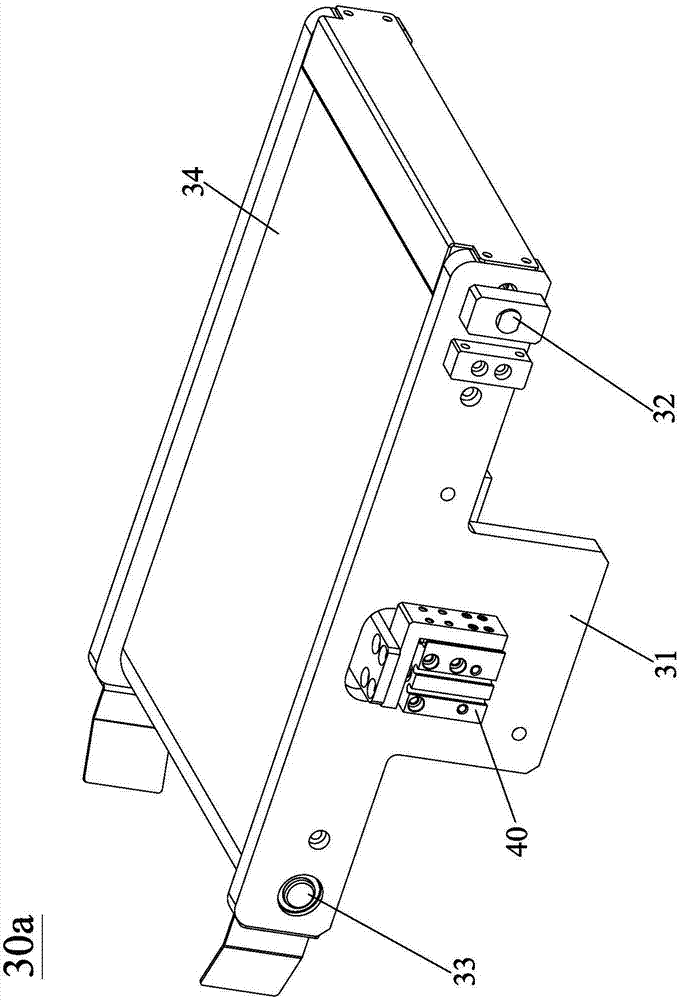

[0027] See figure 1 and figure 2 , The metal flake intelligent screening equipment 100 of the present invention is electrically connected to a controller to screen messy metal flakes, and includes a bulk material conveying device 10, a first horizontal conveying line 20, and forward and upward relative to the first horizontal conveying line 20 Inclined inclined conveying line 30, second horizontal conveying line 50, vision device 60, manipulator 70 and turning mechanism 70. Combine Figure 8 , The bulk material conveying device 10 includes a horizontal flat plate 11, an inclined flat plate 12, and a power source (not shown in the figure) that drives the horizontal flat plate 11 and the inclined flat plate 12 to vibrate; the horizontal flat plate 11 and the inclined flat plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com