An automatic screening device for dropping pills combined with image recognition

An automatic screening and image recognition technology, applied in the fields of sieving, solid separation, sorting, etc., can solve problems such as residues and multi-dropping pills, and achieve the effects of reasonable structure, high screening efficiency, and high screening pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these specific implementations. Those skilled in the art will realize that the present invention covers all alternatives, modifications and equivalents as may be included within the scope of the claims.

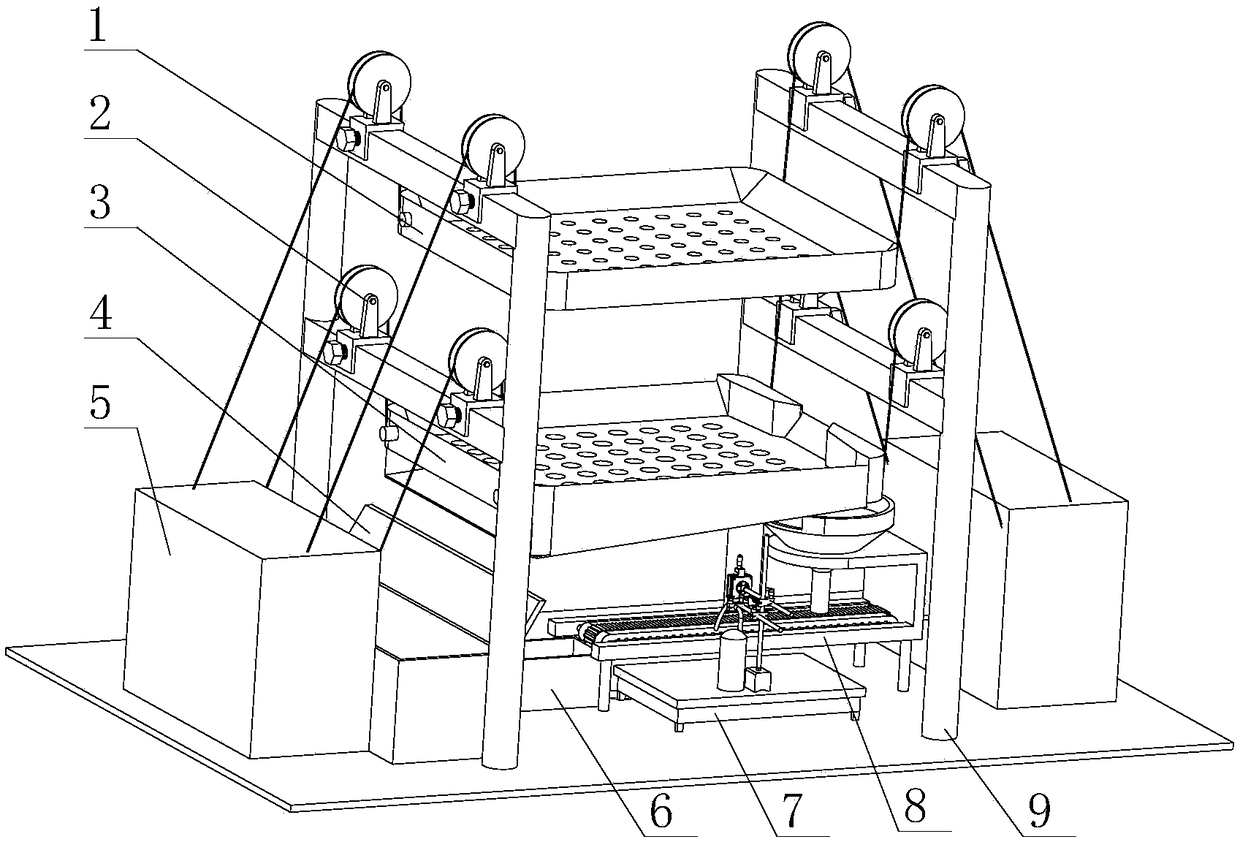

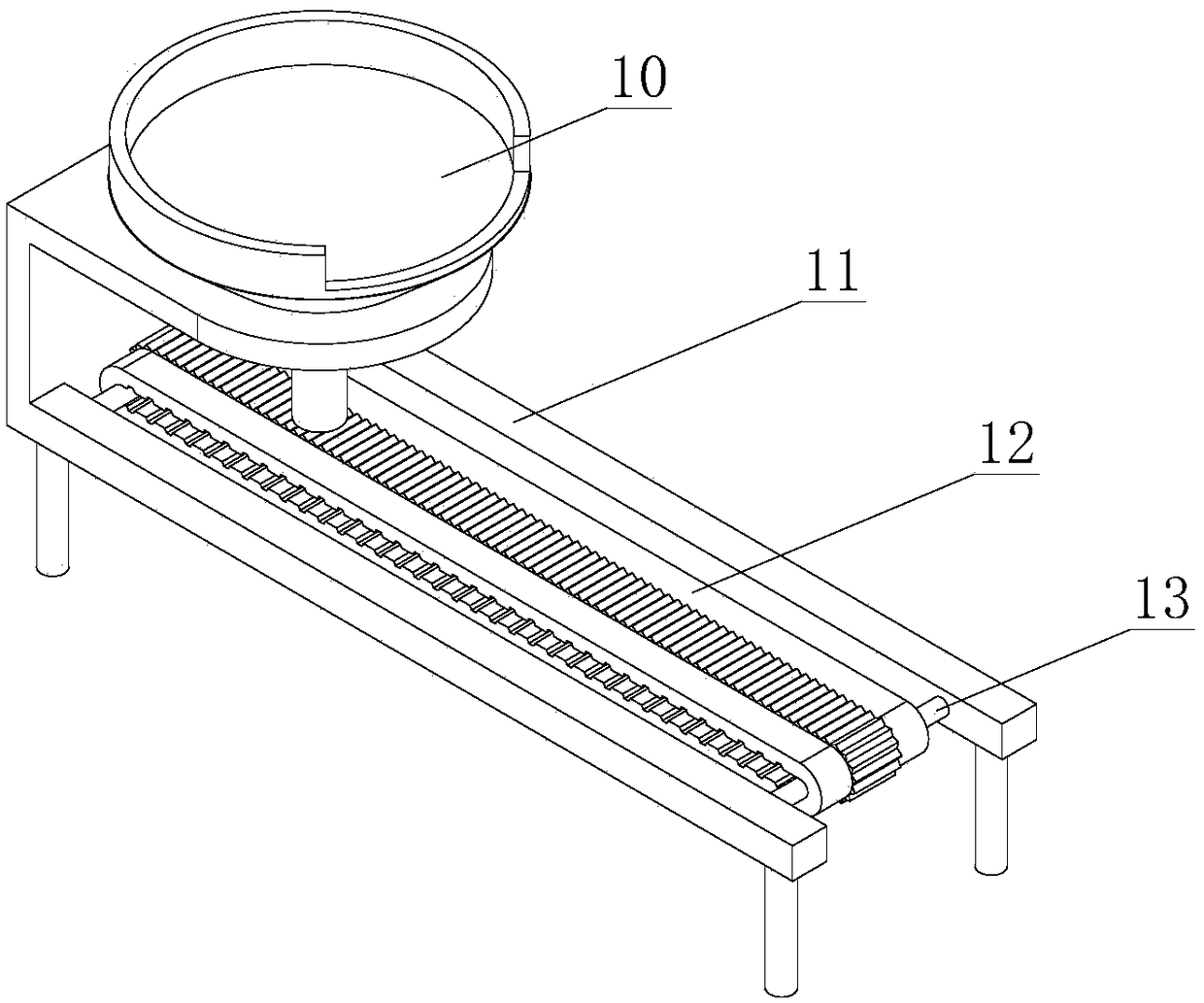

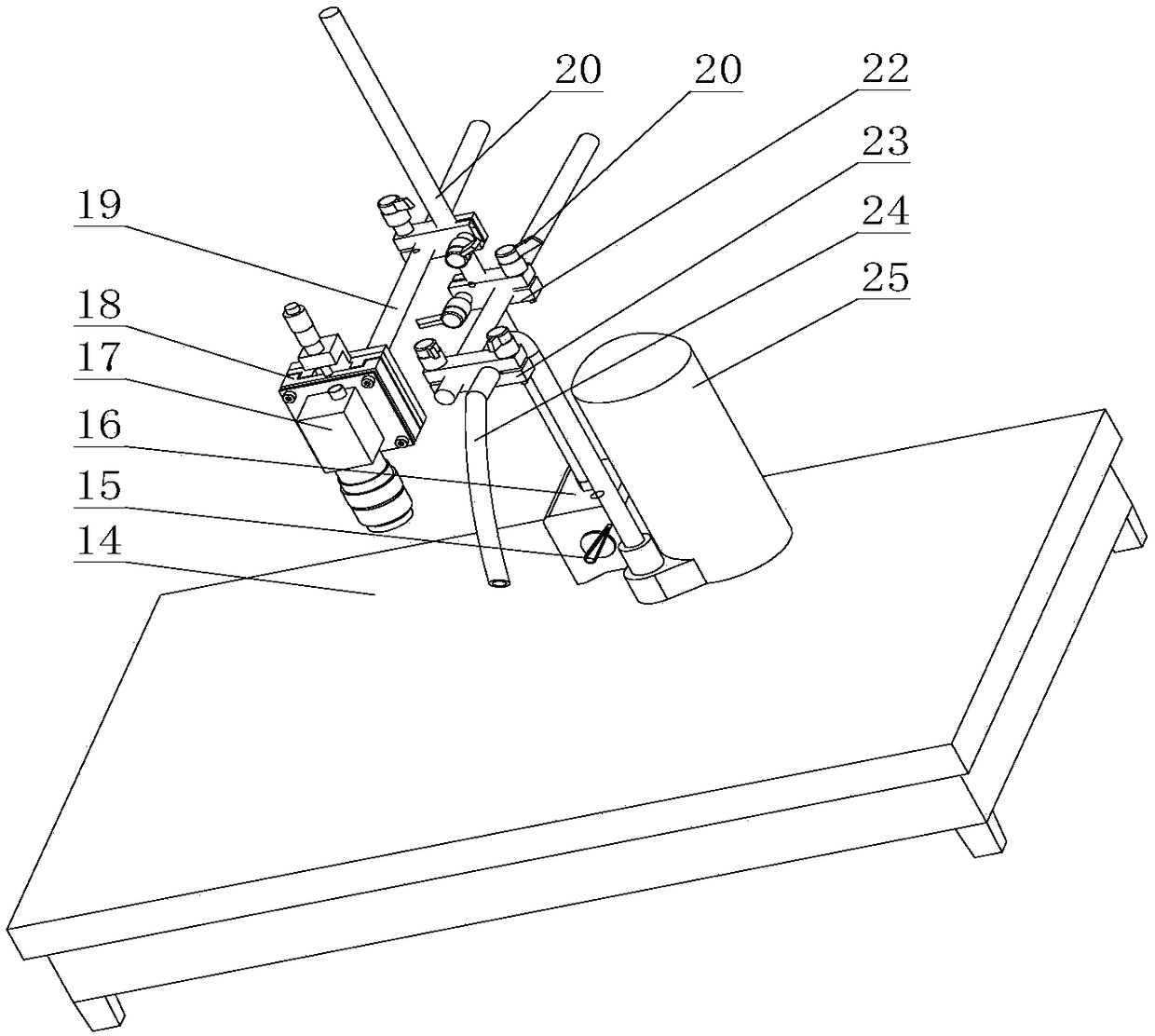

[0021] Such as figure 1 As shown, an automatic dripping pill screening device combined with image recognition includes an upper sorting screen 1, a pulley assembly 2, a lower sorting screen 3, a waste grain basket 4, a motor control box 5, a dripping pill basket 6, and an image screening assembly 7. Transmission component 8, bracket 9. On the support 9, the upper sorting screen 1 for filtering the large dripping pills, the lower sorting screen 3 for filtering the small dripping pills, the transmission assembly 8 for transmitting qualified dripping pills and the image screening assembly for filtering the dripping pills are installed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com