Winnowing type precise thresher

A thresher and sophisticated technology, applied in threshing equipment, applications, agricultural machinery and implements, etc., can solve the problems of affecting the threshing effect, blocking each other, crossing and overlapping corn cobs, etc., and achieve the effect of improving the threshing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

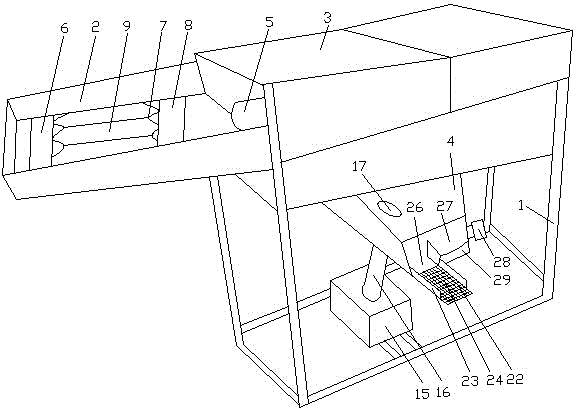

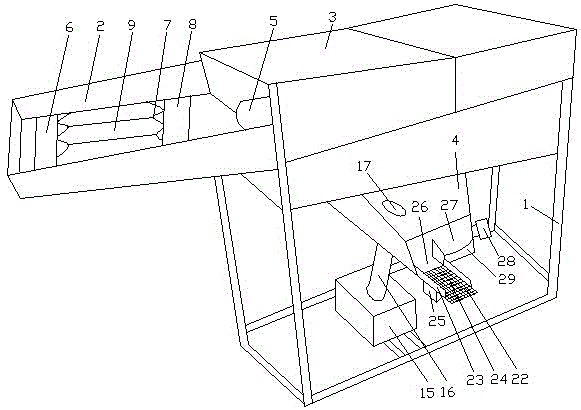

[0036] see figure 1 and figure 2 , a wind-selected precision thresher, comprising a frame 1, a feed hopper 2 connected to the frame 1, a threshing bin 3 and a discharge bin 4, and the feed hopper 2, the threshing bin 3 and the discharge bin 4 are connected , the threshing bin 3 is provided with a threshing drum 5, and a guide device is provided inside the feed hopper 2, and the guide device includes a first connecting plate 6, a guide plate 7 and a second connecting plate 8, and the guide The flow plate 7 is bent to form a flow guide groove 9, and there are multiple flow guide grooves 9. The widths of any two adjacent flow guide grooves 9 are different. One end of the first connecting plate 6 is connected to the flow guide plate 7, and the other end is connected to the flow guide plate 7. The bottom plate of the feed hopper 2 is connected, one end of the second connecting plate 8 is connected with the deflector 7, and the other end is connected with the bottom plate of the f...

Embodiment 2

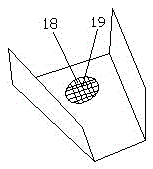

[0039] see figure 2 and image 3 , a wind-selected precision thresher, comprising a frame 1, a feed hopper 2 connected to the frame 1, a threshing bin 3 and a discharge bin 4, and the feed hopper 2, the threshing bin 3 and the discharge bin 4 are connected , the threshing bin 3 is provided with a threshing drum 5, and a guide device is provided inside the feed hopper 2, and the guide device includes a first connecting plate 6, a guide plate 7 and a second connecting plate 8, and the guide The flow plate 7 is bent to form a flow guide groove 9, and there are multiple flow guide grooves 9. The widths of any two adjacent flow guide grooves 9 are different. One end of the first connecting plate 6 is connected to the flow guide plate 7, and the other end is connected to the flow guide plate 7. The bottom plate of the feed hopper 2 is connected, one end of the second connecting plate 8 is connected with the deflector 7, and the other end is connected with the bottom plate of the f...

Embodiment 3

[0043] see figure 2 and image 3 , a wind-selected precision thresher, comprising a frame 1, a feed hopper 2 connected to the frame 1, a threshing bin 3 and a discharge bin 4, and the feed hopper 2, the threshing bin 3 and the discharge bin 4 are connected , the threshing bin 3 is provided with a threshing drum 5, and a guide device is provided inside the feed hopper 2, and the guide device includes a first connecting plate 6, a guide plate 7 and a second connecting plate 8, and the guide The flow plate 7 is bent to form a flow guide groove 9, and there are multiple flow guide grooves 9. The widths of any two adjacent flow guide grooves 9 are different. One end of the first connecting plate 6 is connected to the flow guide plate 7, and the other end is connected to the flow guide plate 7. The bottom plate of the feed hopper 2 is connected, one end of the second connecting plate 8 is connected with the deflector 7, and the other end is connected with the bottom plate of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com