Pixel position specifying method, method of correcting image offset, and image forming device

A technology of pixel position and specific method, which is applied in the direction of printing equipment, image communication, photolithography process exposure equipment, etc., can solve the problems of image quality reduction, difficulty in applying multi-head exposure equipment, etc., and achieve the effect of preventing offset or overlapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

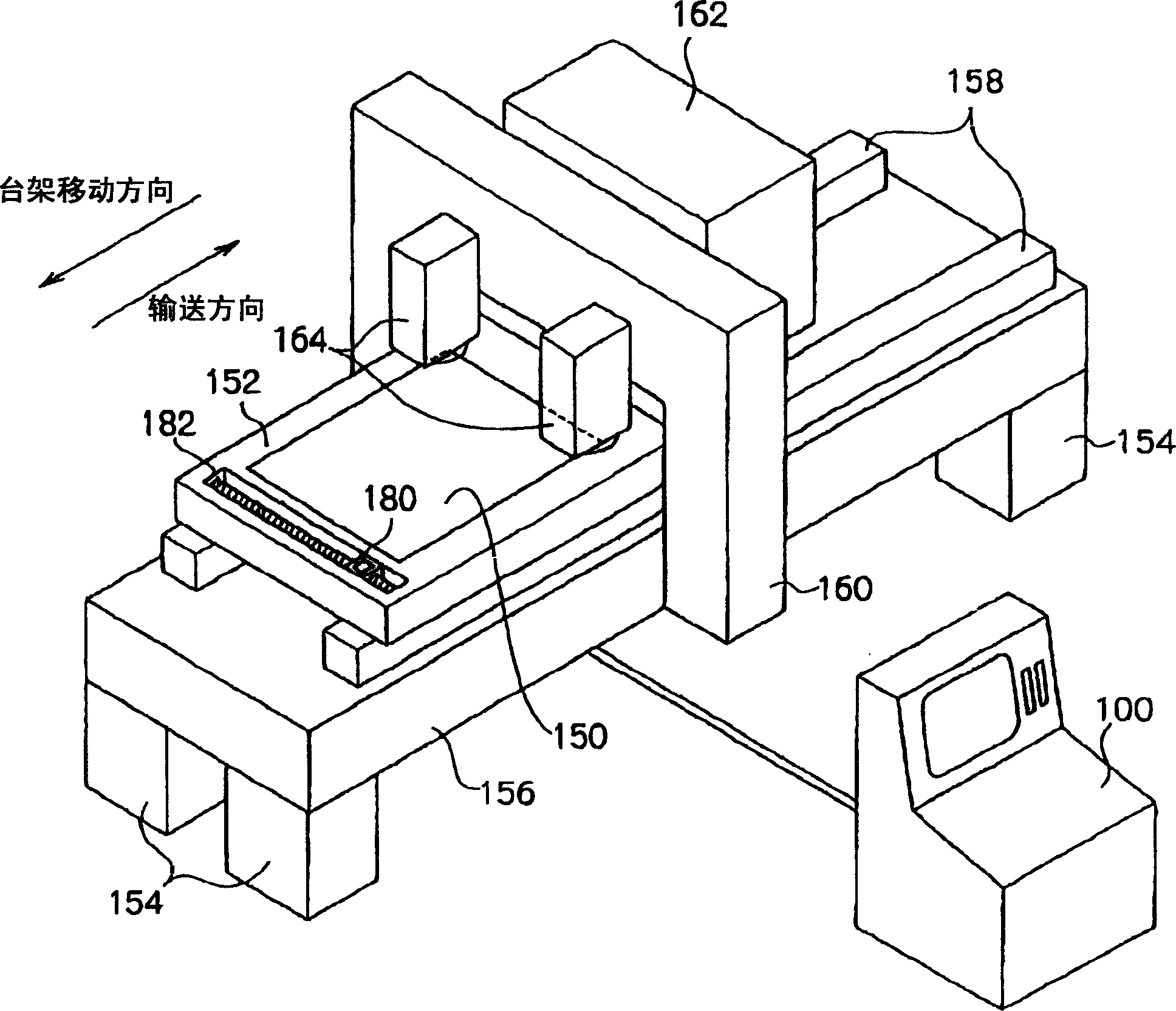

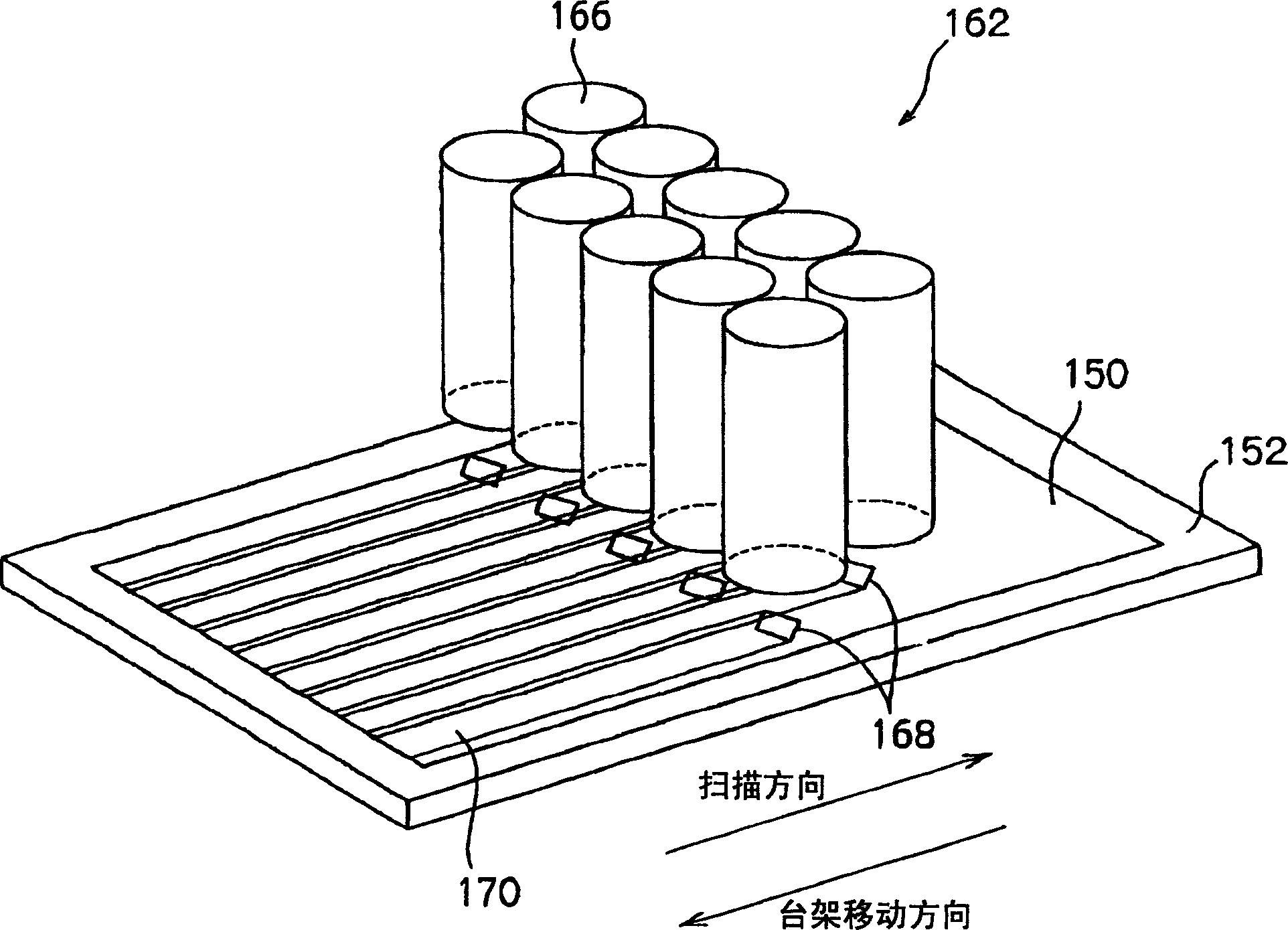

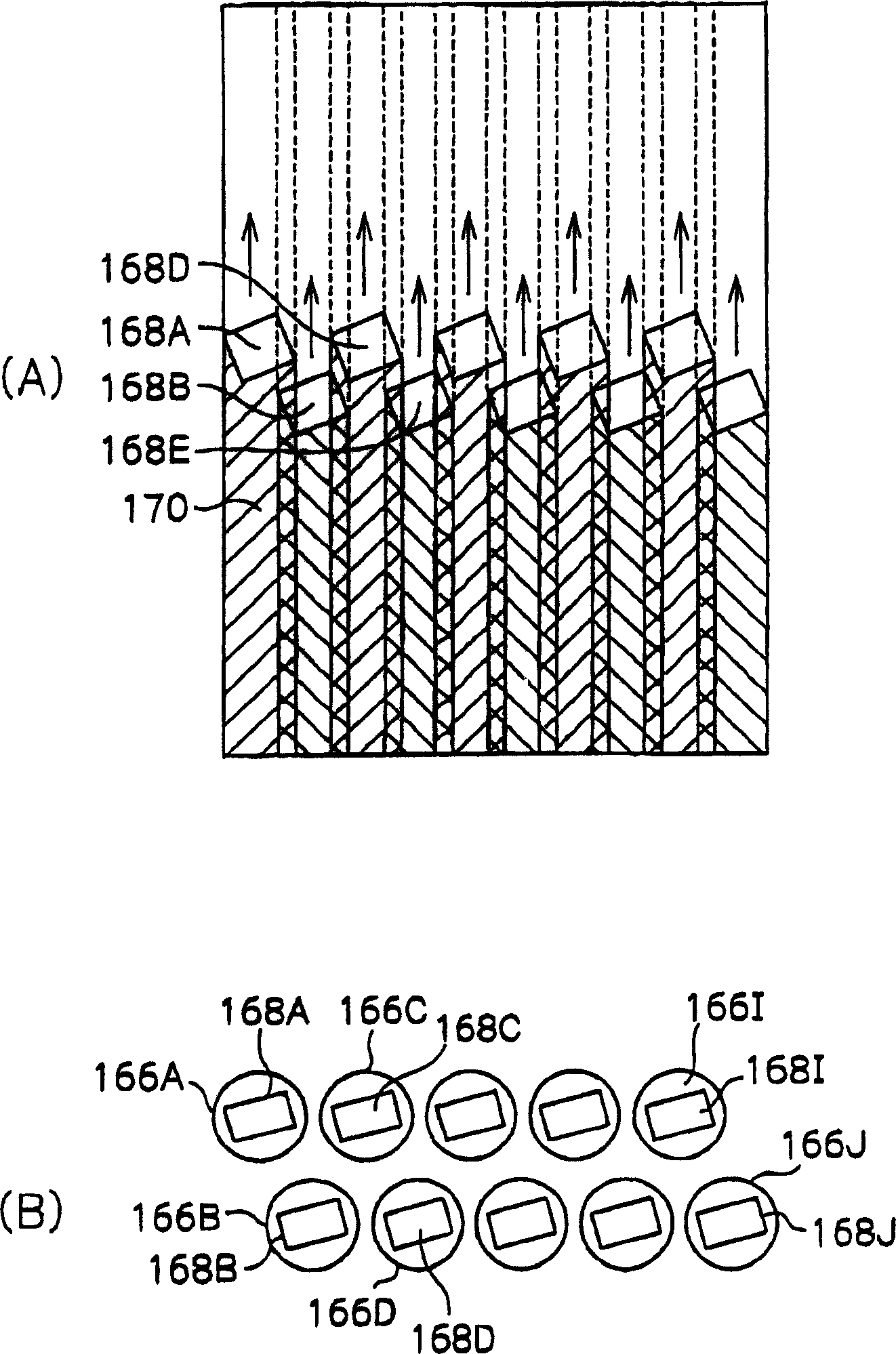

[0186] An example of the exposure device included in the image forming apparatus of the present invention, its overall configuration is shown in figure 1 .

[0187] The exposure apparatus of Embodiment 1 is a so-called flat plate type, such as figure 1 As shown, a stand 152 is provided which absorbs a sheet-shaped photosensitive material 150 on its surface to maintain a flat shape. The side surface of the stage 152 that absorbs and holds the photosensitive material 150 and the exposed surface of the photosensitive material 150 correspond to the image forming surface in the image forming apparatus of the present invention.

[0188] The above-mentioned exposure apparatus is equipped with a thick plate-shaped installation table 156 supported by four supports 154 and two guide rails 158 on the installation table 156 . Rail 158 is provided along the figure 1 The direction of gantry movement indicated by the arrow in the middle. The stage 152 is configured such that its longitud...

Embodiment approach 2

[0219] Regarding another example of the exposure device included in the image forming apparatus of the present invention, Figure 10 The overall configuration is shown in . For the same components as those in Embodiment 1, repeated explanations will be omitted. The same symbols as in Embodiment 1 denote the same constituent elements in principle.

[0220] Like the exposure apparatus of Embodiment 1, the exposure apparatus of Embodiment 2 is a so-called flat plate type, such as Figure 10 As shown, there is provided a plate-shaped stand 152 on which a sheet-shaped photosensitive material 150 is adsorbed and held on its surface.

[0221]However, in the downstream end of the stage 152 along the stage moving direction, instead of the probe 180 included in the exposure apparatus according to Embodiment 1, a sensor is arranged along the X-axis direction, that is, in a direction perpendicular to the stage moving direction. A plane detector 184 with six plane detectors 184a-184f fi...

Embodiment approach 3

[0236] As another example of the exposure device included in the image forming apparatus of the present invention, its overall configuration is shown in Figure 12 middle. Descriptions of the same components as in Embodiment 1 are omitted, and the same symbols as in Embodiment 1 refer to the same components in principle.

[0237] The exposure apparatus of Embodiment 3 is the same as that of Embodiment 1, and is a so-called flat plate type, such as Figure 12 As shown, there is provided a plate-like stand 152 on which a sheet-like photosensitive material 150 is sucked and held on its surface.

[0238] However, at the end of the stage 152 on the downstream side in the stage moving direction, a surface probe 186 capable of moving in the X-axis direction by a high-precision transfer device 187 is provided, such as Figure 13 As shown, a groove 185 along the X-axis direction is provided over the entire width at the downstream end of the stand 152 . The face probe 186 slides in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com