Semiconductor module

一种半导体、导体层的技术,应用在半导体器件、半导体/固态器件零部件、电固体器件等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0050] [constitute]

[0051] Next, a first embodiment of the semiconductor module according to the present invention will be described with reference to the drawings.

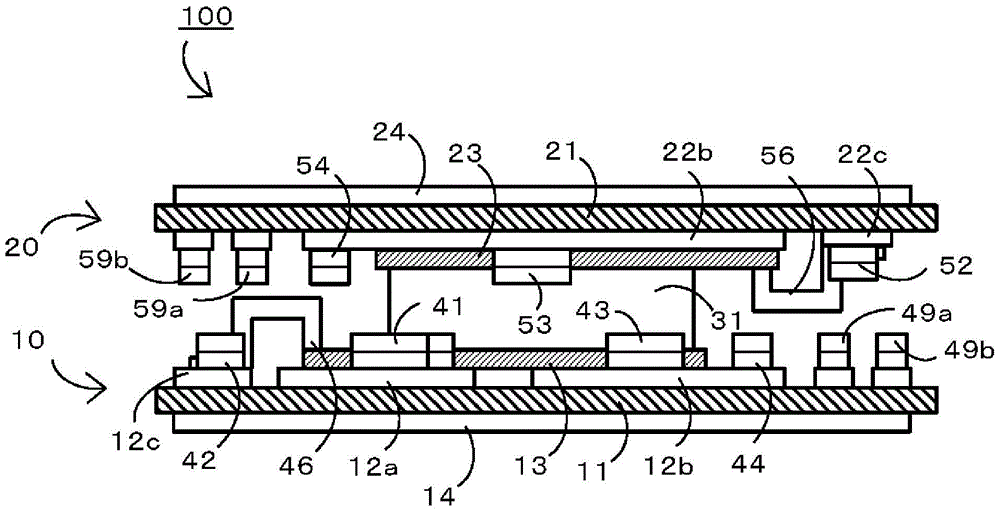

[0052] Such as figure 1 As shown, the semiconductor module 100 of this embodiment includes: a first member 10 , a second member 20 , and a conductor post 31 extending in the vertical direction between the first member 10 and the second member 20 . In this embodiment, the first insulating substrate 11 of the first member 10 and the second insulating substrate 21 of the second member 20 are mounted in parallel. In this embodiment, the extended surfaces of the first insulating substrate 11 and the second insulating substrate 21 ( figure 1 The extension plane towards the left and right direction) is called the horizontal plane; in the direction perpendicular to the horizontal plane (ie figure 1 The up and down direction) is called the up and down direction.

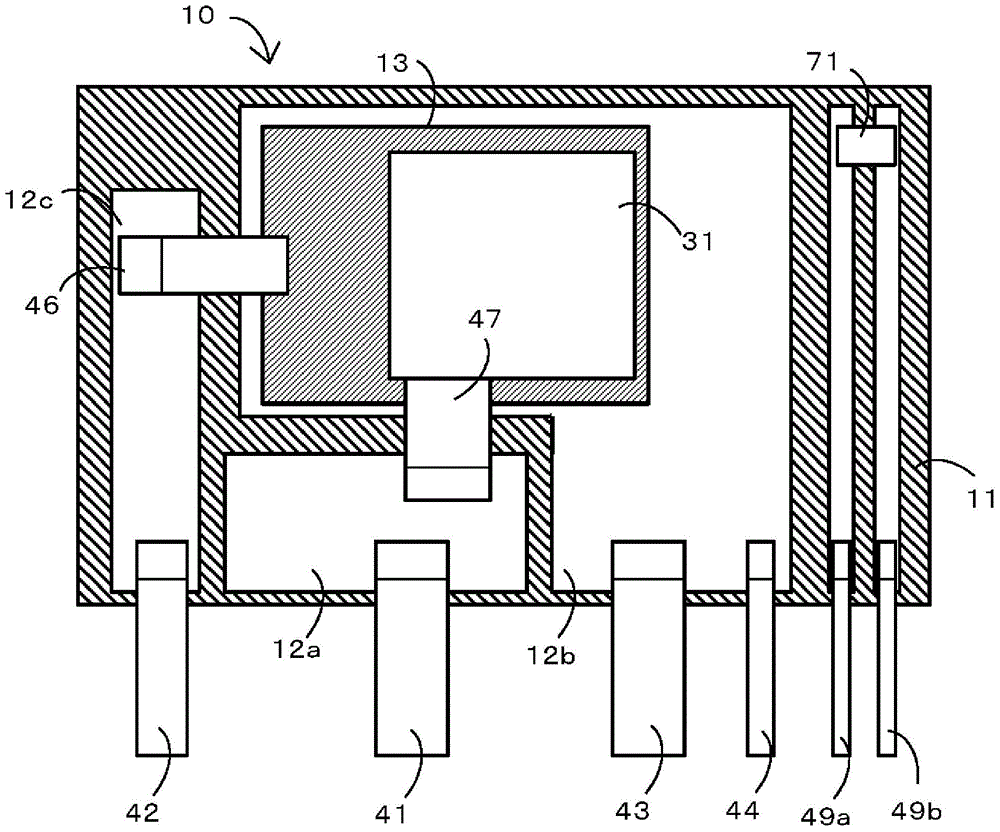

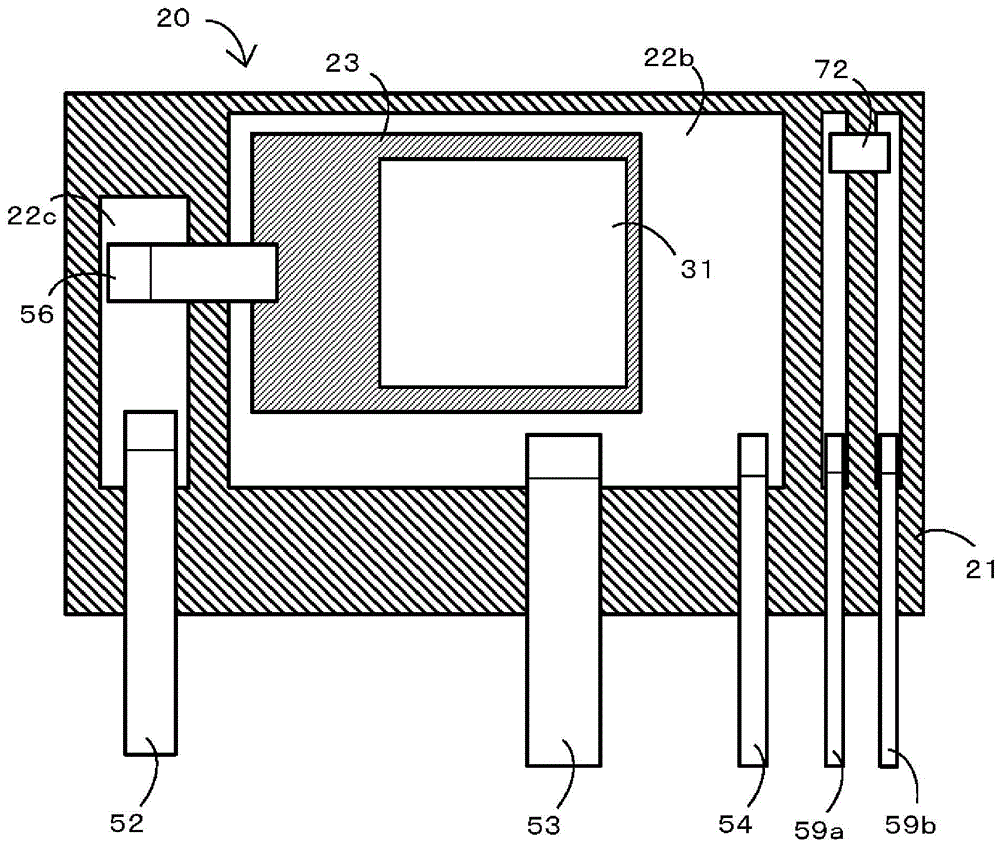

[0053] Such as figure 2 As shown, the first mem...

no. 2 Embodiment approach

[0081] Next, a second embodiment according to the present invention will be described.

[0082] Such as Figure 7 As shown, the second embodiment relates to an electronic device including the semiconductor module 100 described in the first embodiment and a heat sink 200 provided with a concave portion 210 into which the semiconductor module 100 is inserted. The size of the recess 210 is consistent with the size of the semiconductor module 100 . Therefore, as long as the semiconductor module 100 is inserted into the concave portion 210 , the semiconductor module 100 is fixed to the heat sink 200 .

[0083] In the second embodiment, other configurations are slightly the same as those in the first embodiment. In the second embodiment, a detailed description of the same parts as those in the first embodiment will be omitted.

[0084] The inside of the concave portion 210 of the cooling plate 200 may also be coated with a lubricant made of silicon grease or the like, and the sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com