Electrode material production and processing system based on double screws

A processing system and twin-screw technology, applied in electrode manufacturing, chemical/physical processes, mixers with rotating stirring devices, etc., can solve the problem of uneven contact between powder particles and binders, prone to hard precipitation, batch Poor stability and other problems, to achieve the effect of flexible production plan, conducive to mixing materials and granulation, and short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

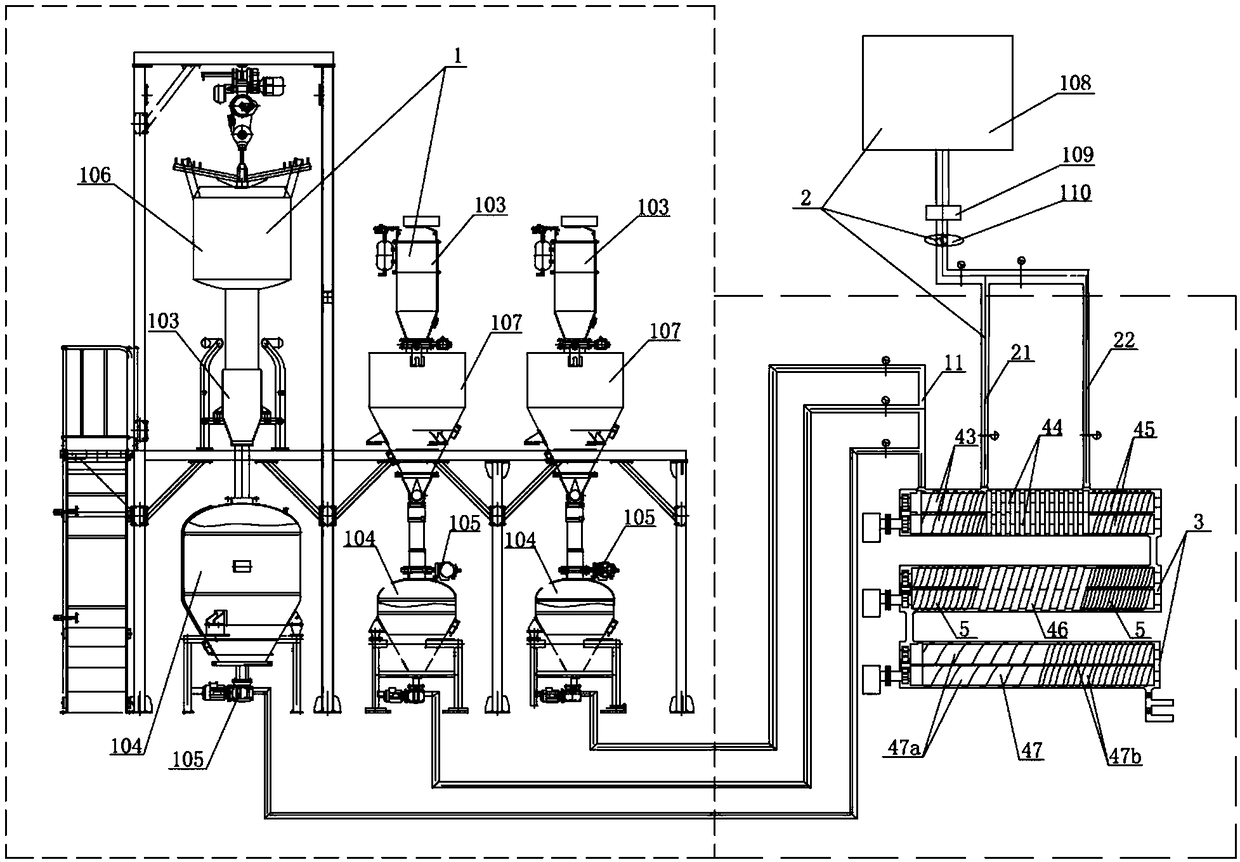

[0036] The invention provides a twin-screw-based electrode material production and processing system, such as figure 1 As shown, it includes a feeding device and a batching stirring device. The material enters the batching stirring device under the action of the feeding device, and is discharged after being stirred and mixed by the batching stirring device. The batching and stirring device is provided with two discharge pipes 6, and the discharge pipe 6 is provided with two slurry outlet switches 61. During normal use, the slurry flows to the transfer tank through the first discharge pipe. When the formula needs to be replaced At the same time, the final slurry flows to the temporary storage tank through the second discharge pipe, and it is convenient and quick to change the formula during the production process.

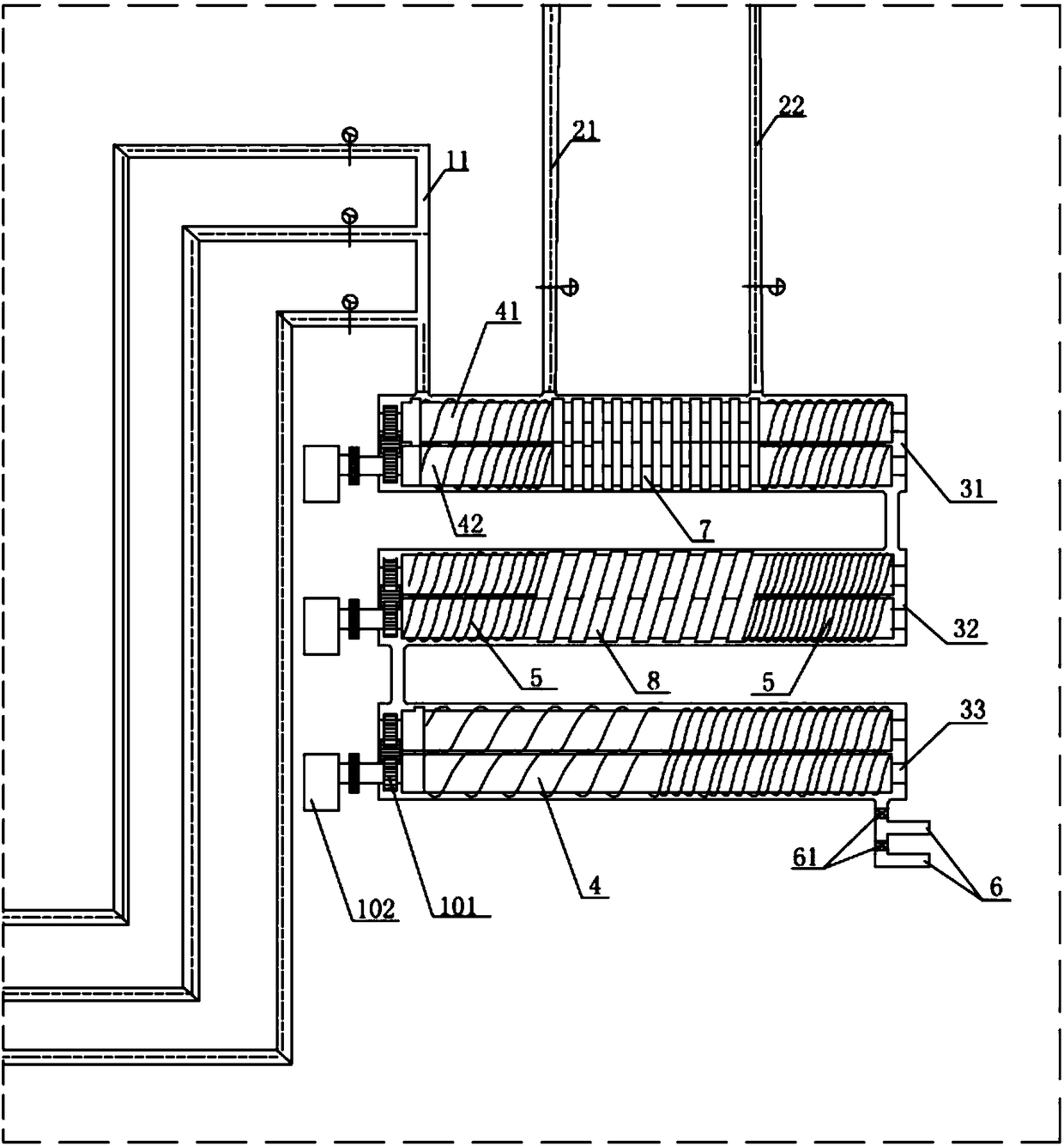

[0037] Such as figure 2 As shown, the batching stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com