Bean-straightening-facilitated rotary-drum-cleanable green soybean extruder

A technology for cleaning drums and bean machines, which is applied in food processing, cleaning methods and utensils, and cleaning methods using tools, etc., can solve the problems of difficulty in meeting consumers' consumption needs, unfavorable labor costs, and complicated operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

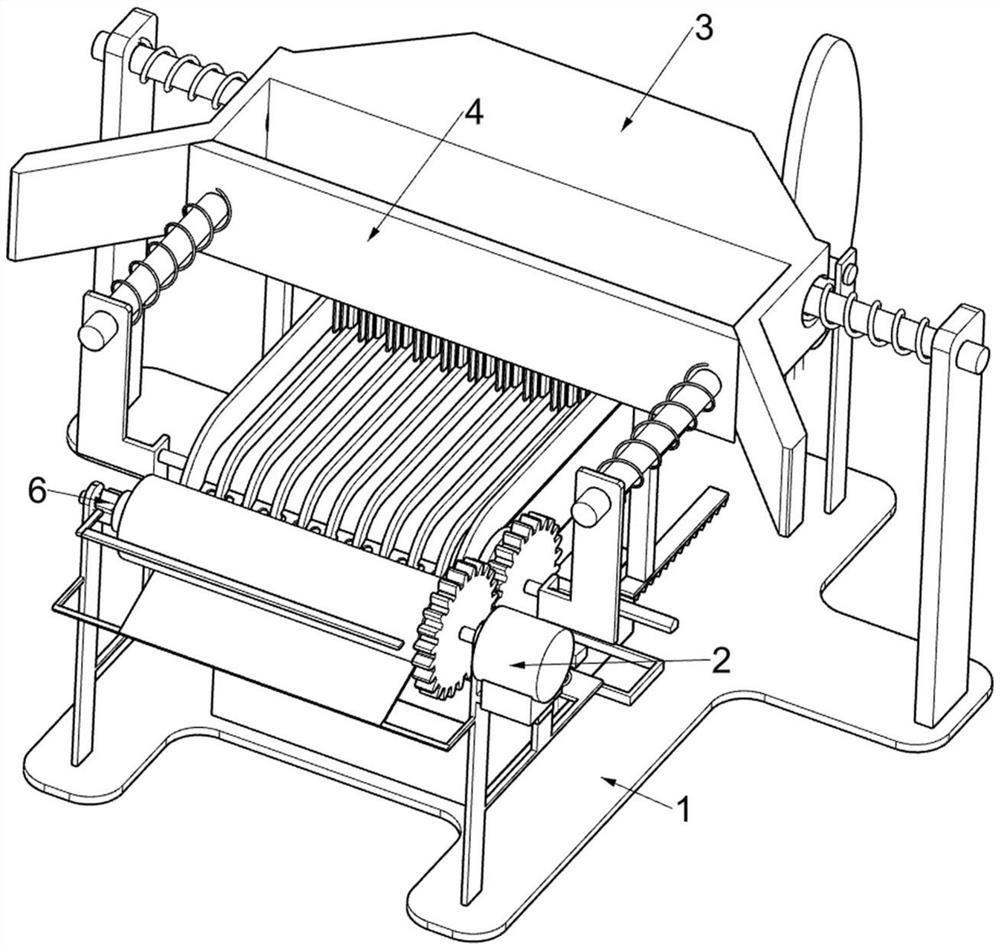

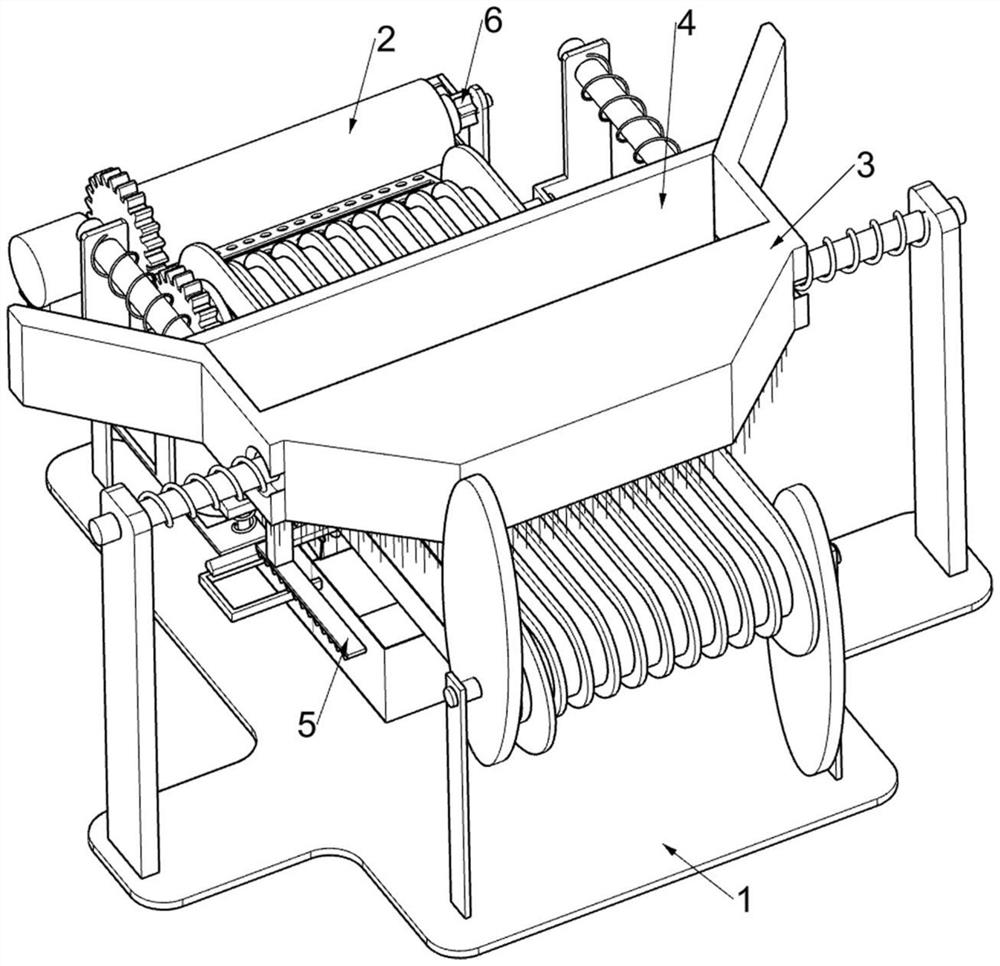

[0024]An easy to combat beans and can clean the drums, such asFigure 1-9 As shown, including the bottom plate 1, the squeezed bean mechanism 2, the spread mechanism 3, the pushing mechanism 4, and the jitter screening mechanism 5, is fixed to the bottom plate 1 for the rapid separation of the beans and the bean shell. The spreading mechanism 3 for booting the stacked hair beans is provided on the bottom plate 1 and the soybean mechanism 2 for the pushing mechanism 4 of the messy Mao Tuzhen, and the shake screen is shaken. The mechanism 5 is provided on the bottom plate 1 and the soybean mechanism 2 and is connected to the promotion mechanism 4, and the jitter screening mechanism 5 and the pushing mechanism 4 can fit the adhesive soybean shell on the beans to be separated from the bean.

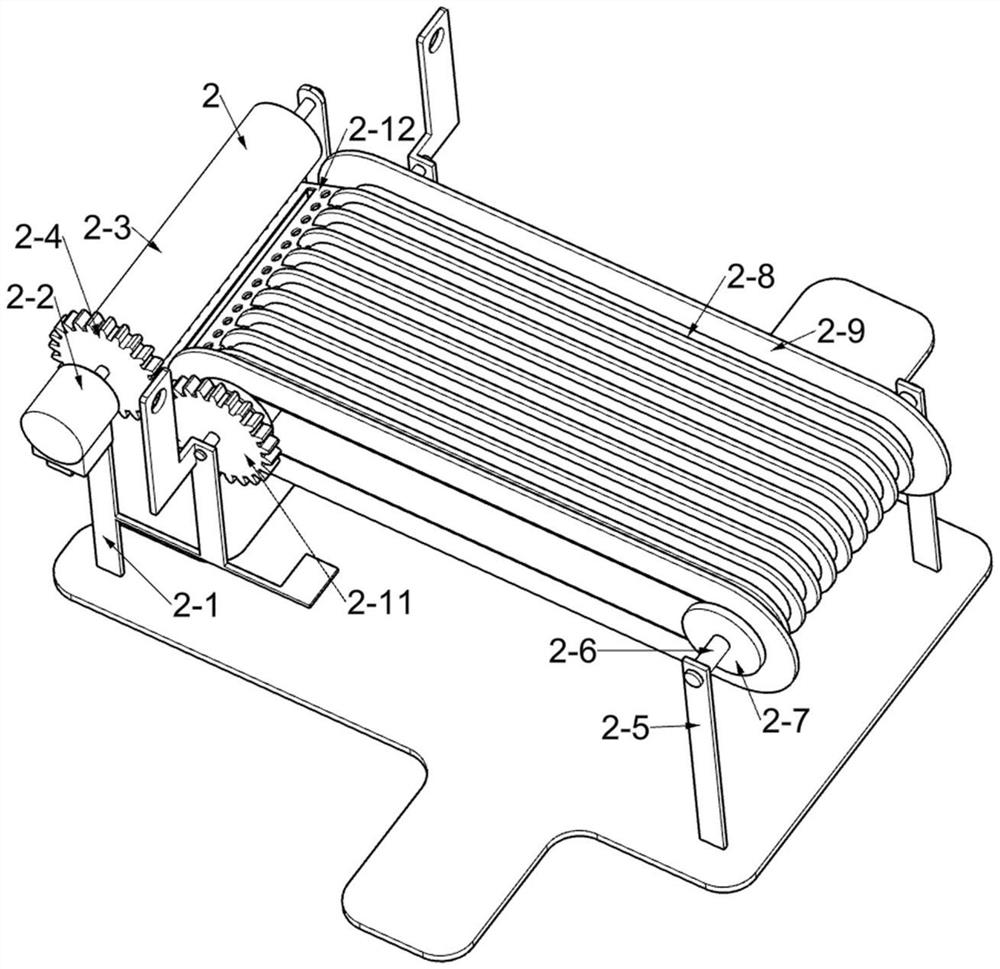

[0025]Specifically, the soybean mechanism 2 includes a first support frame 2-1, a motor 2-2, a drum 2-3, a first gear 2-4, a second support frame 2-5, a rotating shaft 2-6, a rotary wheel 2 -7, conveyo...

Embodiment 2

[0035]On the basis of Example 1, such asFigure 1-2As shown in 8-9, it is also included in the cleaning device 6 for cleaning the bean shell for the drum 2-3, and the cleaning device 6 is provided on another first support frame 2-1, and the cleaning device 6 includes a spline. Turn block 6-1, hollow slider 6-2, spline shaft 6-3 and scraping 6-4, spline transfer block 6-1 with drum 2-3 coaxial setting, hollow slider 6-2 fixed setting At the upper portion of the other first support frame 2-1, the split shaft 6-3 is slidable on the hollow slide rod 6-2 and can be in contact with the spline transfer block 6-1 for the drum 2-3. The adhesive bean shell cleans the clean scraping 6-4 fixed to the spline shaft 6-3.

[0036]Since the drum is pressed for a long time for a long time, some of the shells of some yarans are adhered to the drum 2-3, in order to make the drum 2-3 work more efficiently, the staff can complete the desert operation in the hairpet After cleaning the drum 2-3. The staff firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com