Straightening machine for manufacturing air-tight door

A straightening machine and airtight door technology, applied in the direction of manufacturing tools, feeding devices, positioning devices, etc., can solve the problems of low efficiency, time-consuming and labor-intensive efficiency of I-beams, and achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is attached Figure 1-10 The application is described in further detail.

[0044] The so-called straightening machine is a machine used to straighten shaft parts. Through straightening, the ideal straightness requirements or rotation accuracy requirements can be obtained to ensure that the parts can meet the assembly accuracy or obtain the minimum cutting process in the next process. margin.

[0045]The I-beam includes a web, and side plates are provided at both ends of the web, and the side plates are parallel to each other and perpendicular to the web.

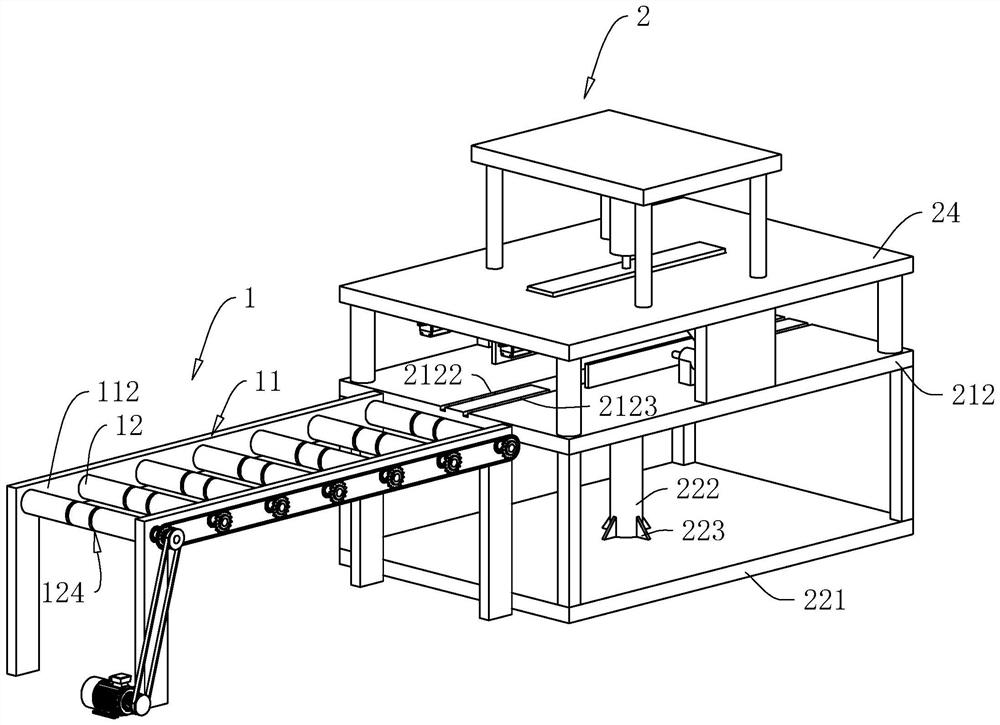

[0046] The embodiment of the present application discloses a straightening machine used for manufacturing airtight doors. refer to figure 1 A straightening machine for airtight door manufacturing includes a transmission mechanism 1 and a straightening mechanism 2 arranged in sequence, and the straightening mechanism 2 is close to one end of the transmission mechanism 1 .

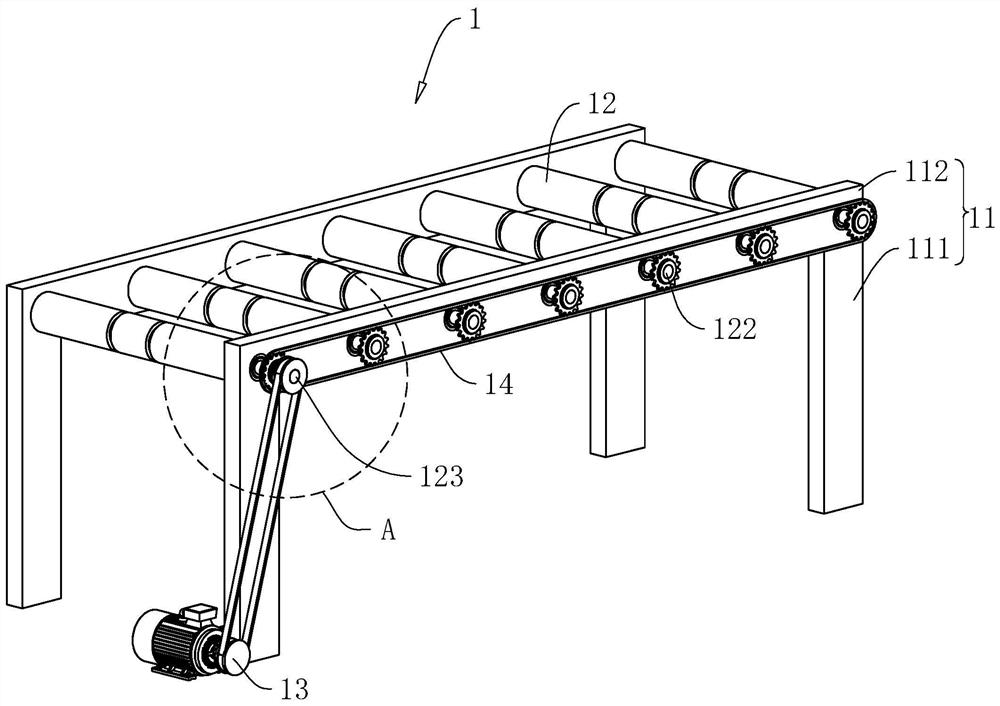

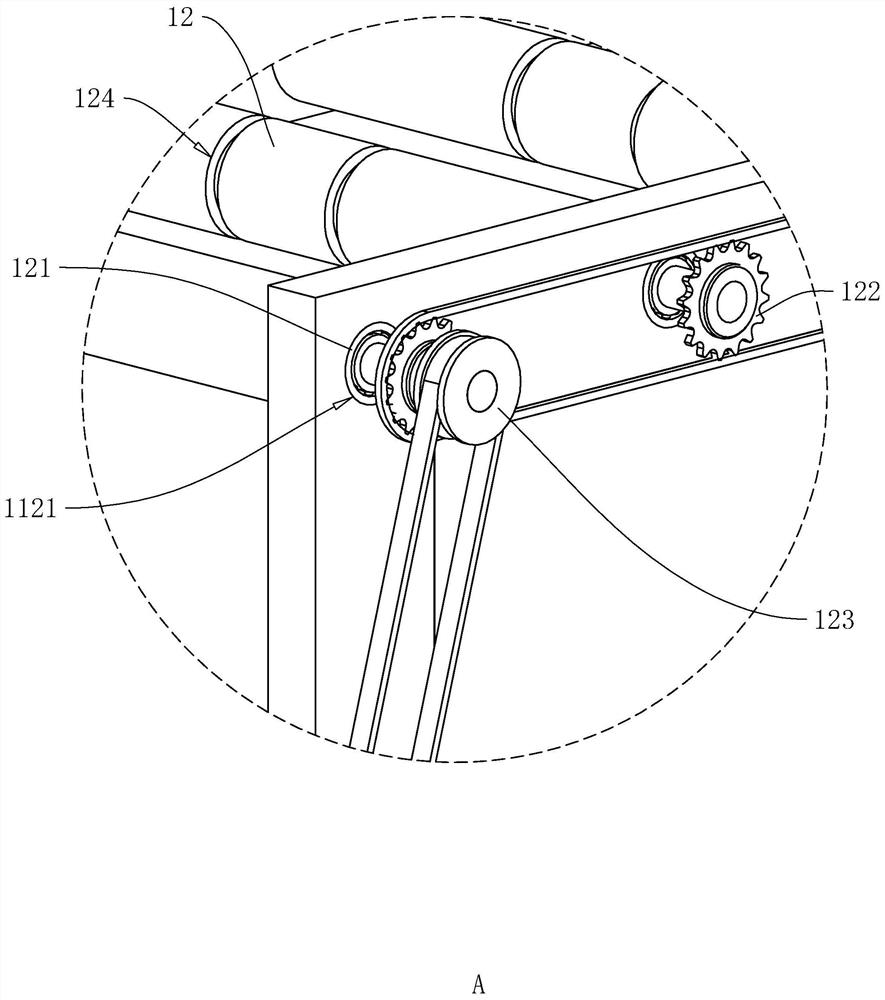

[0047] refer to figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com