Full-automatic stepless speed self-adapting winding technology

A stepless speed regulation and self-adaptive technology, applied in coil manufacturing and other directions, can solve problems such as uneven lines, easy torsion of lines, and inability to control the flatness of lines.

Active Publication Date: 2015-12-16

CHONGQING WANGBIAN ELECTRIC GRP CORP

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The winding machine includes a take-up mechanism and a take-up mechanism. Only improving the take-up mechanism can only solve the problem of winding tension, but it cannot control the flatness of the line; , the lines are easily twisted, resulting in uneven lines

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0025] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

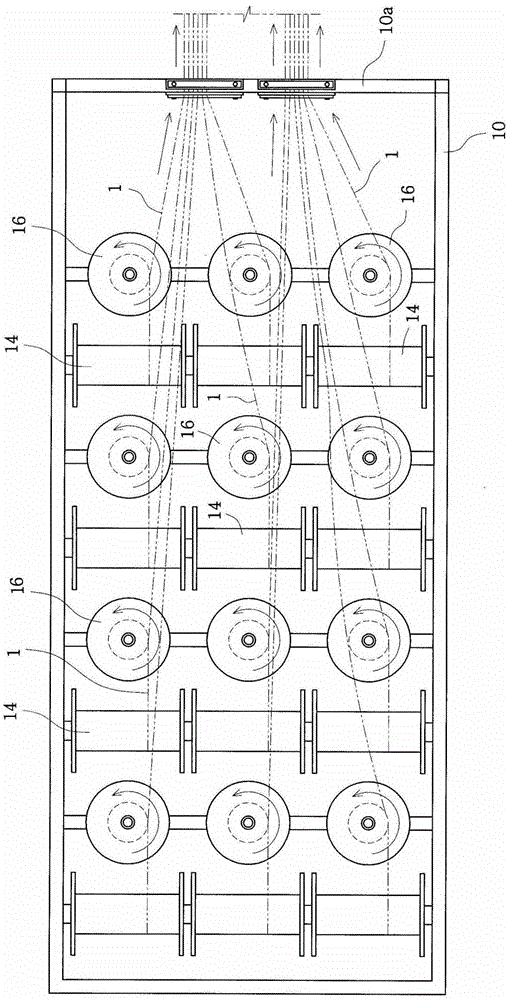

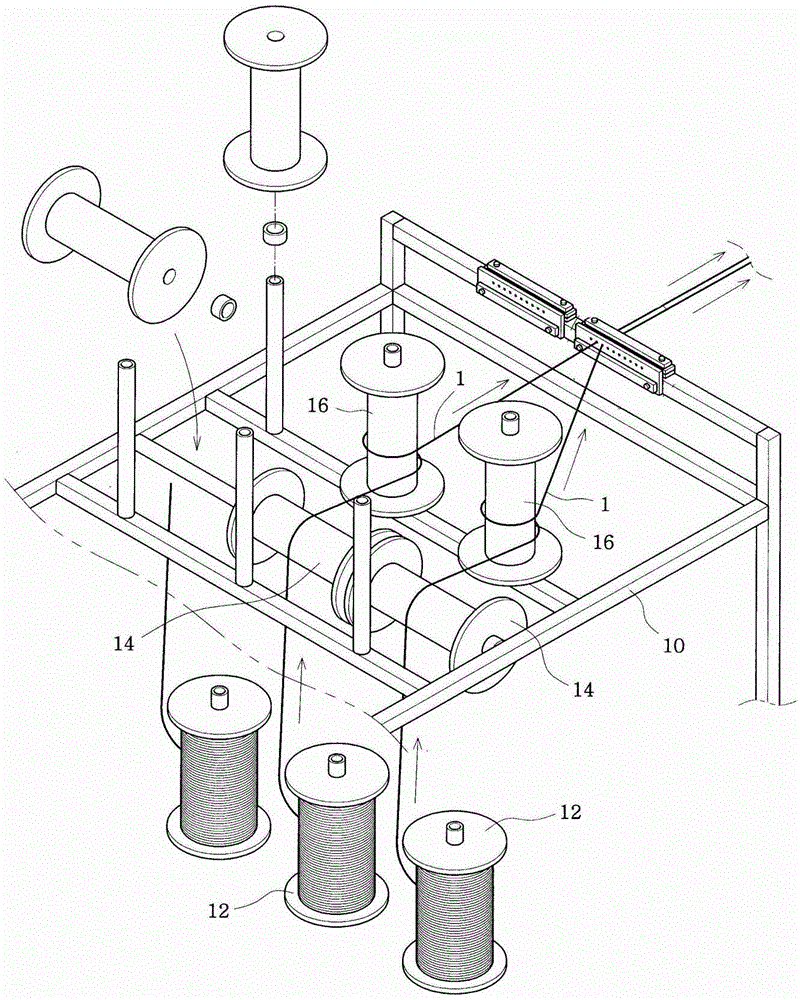

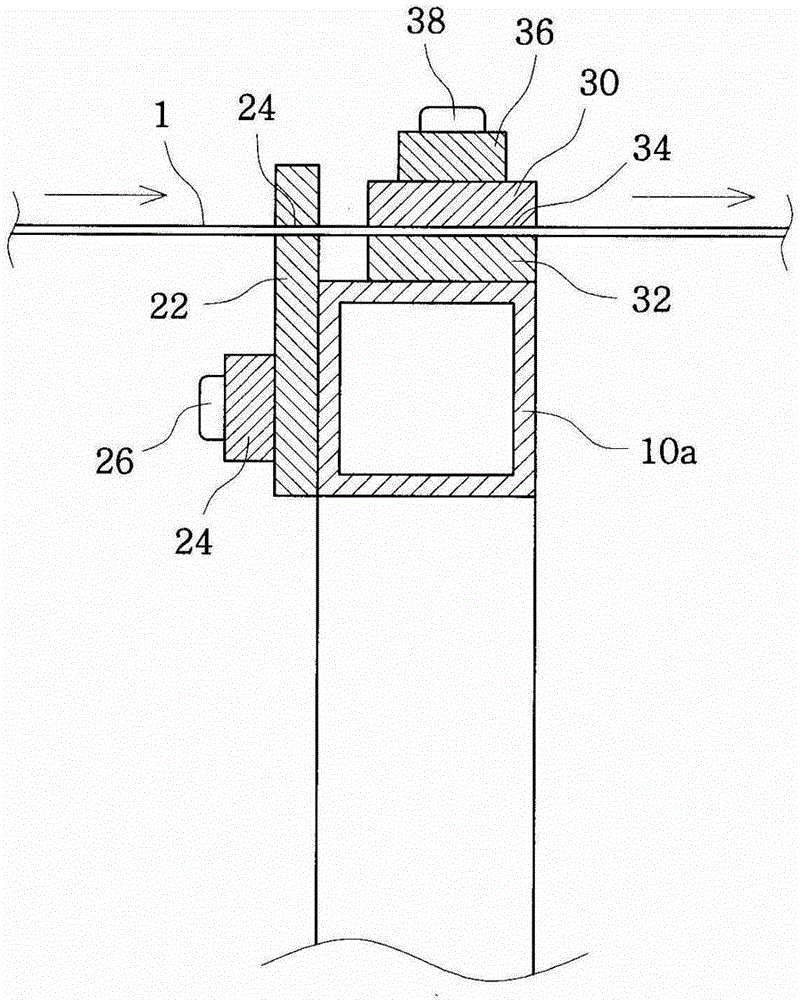

The invention discloses a full-automatic stepless speed self-adapting winding technology for a power transformer coil used in a transformer manufacturing industry. The full-automatic stepless speed self-adapting winding technology comprises the following steps: (a) line adjustment, enabling a line to sequentially pass through a guide wheel and a guide block, and connecting the line to a take-up reel; (b) line checking, starting a motor on a take-up mechanism, pulling the line on a pay-off mechanism gradually, enabling the line to pass through the guide block and to wind the take-up reel through guide of the guide wheel, and sliding the guide block to a proper position on a rack or adjusting a line hole into which the line penetrates until the deflection angle of the line from the guide block is less than 30 degrees; and (c) line winding, after checking the line, locking the guide block on a determined position through a lock mechanism, and restarting the motor. According to the full-automatic stepless speed self-adapting winding technology, the technical defect that the line flatness cannot be controlled in the prior art is overcome; and the full-automatic stepless speed self-adapting winding technology capable of automatically adjusting the line flatness is provided.

Description

technical field [0001] The invention relates to a fully automatic stepless speed regulation self-adaptive winding process for power transformer coils used in the transformer manufacturing industry. Background technique [0002] In the prior art, such as the "automatic winding machine for high-voltage coils of power transformers" disclosed in Chinese patent CN972455159 on July 28, 1999, the working principle of the automatic winding machine for high-voltage coils of power transformers is as follows, under the control of computer programs, The motor drives the take-up shaft to rotate through the magnetic powder clutch. The take-up reel is installed on the take-up shaft. Through the magnetic powder clutch, the motor realizes equal torque output to ensure constant tension of the line when taking up the line. Moreover, the above-mentioned whole frame responsible for taking up the wire is slidably connected with the base, so that the winding position of the take-up reel can be cha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01F41/06

Inventor 杨德文

Owner CHONGQING WANGBIAN ELECTRIC GRP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com