Patents

Literature

30results about How to "Good straightening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

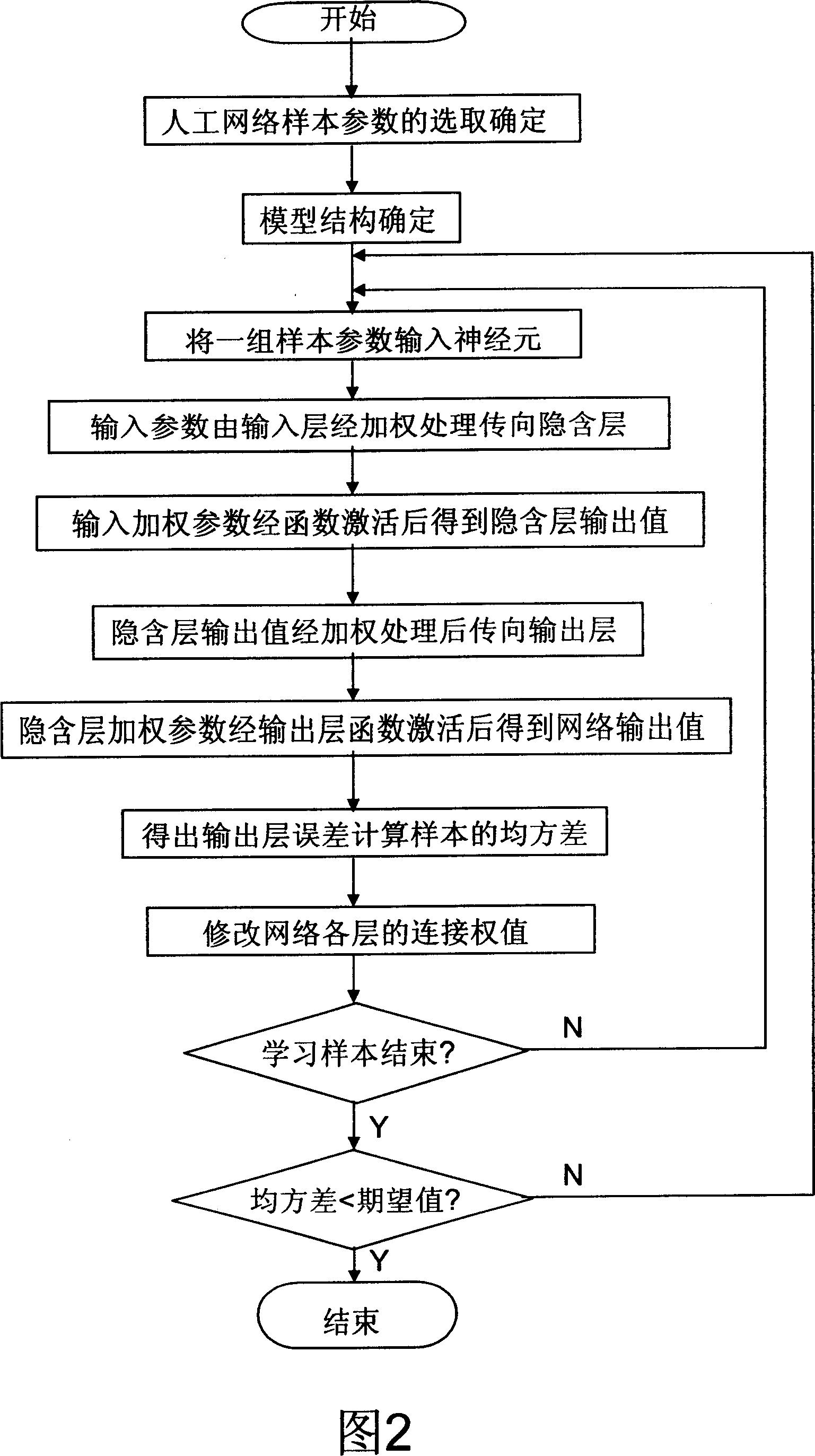

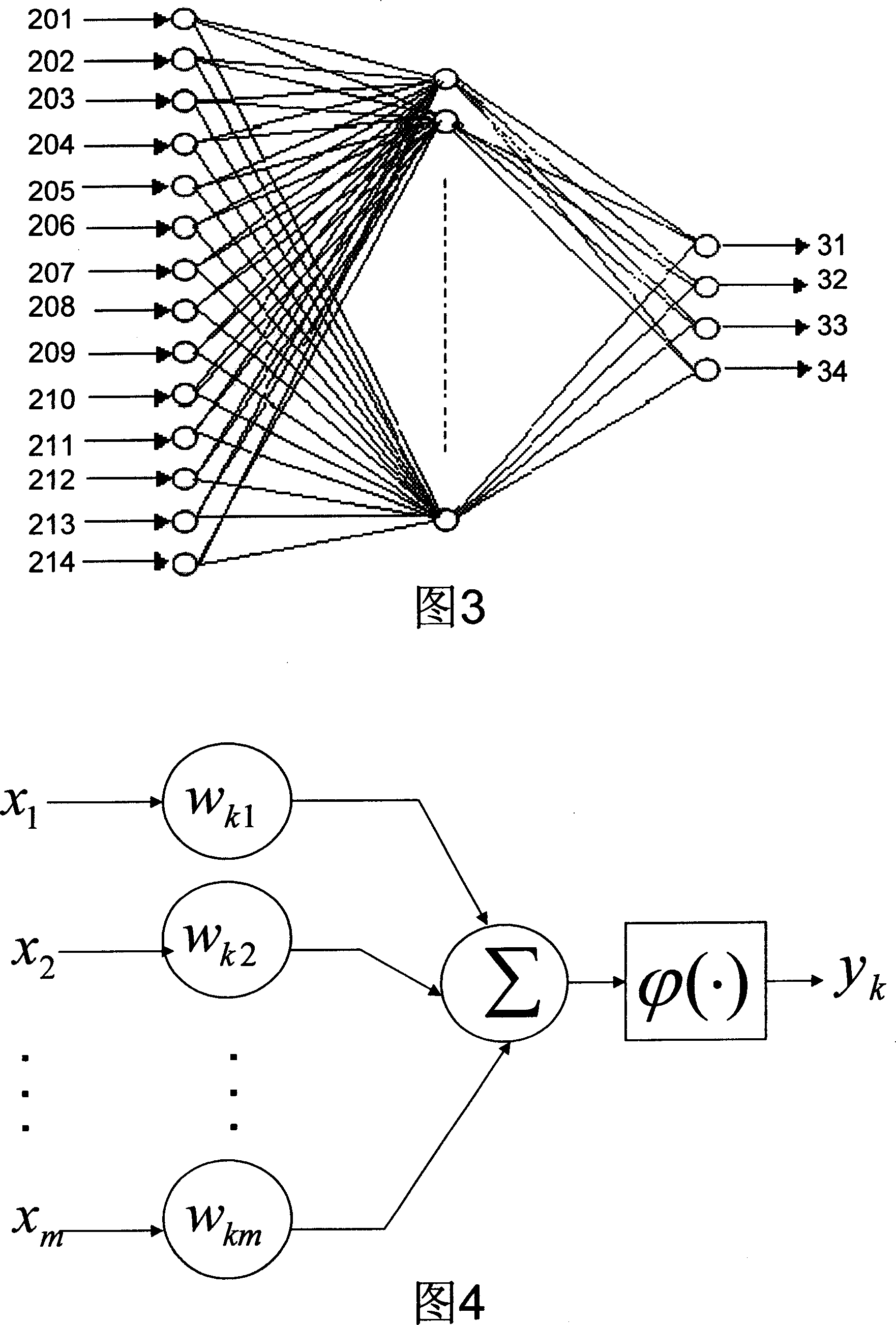

Processing parameter setting method of tension straightening machine set correct roller

ActiveCN101097581AGood straightening effectImprove straightening effectSpecial data processing applicationsBack propagation neuralNerve network

The invention discloses a kind of setting method for processing parameter of correct roller of withdrawal straightening stands based on spot measured data and analysis result, and the shape of steel sheet at the export of withdrawal straightening stands is good as standard, and it chooses the relative data with representation as the training sample parameter of artificial nerve network, and combines the characteristics of withdrawal straightening stands to choose the skilled and general reversing transmission nerve network. The good operation experience is converted into mathematical model to build the setting method for processing parameter under different steel rule and material. The invention can overcome the problems that the setting of processing parameter of traditional spot withdraw is short of theory, and the result is not ideal, and the invention fits for the production characteristics, it has good withdraw effect and satisfy the requirement for producing the production with high quality.

Owner:BAOSHAN IRON & STEEL CO LTD +1

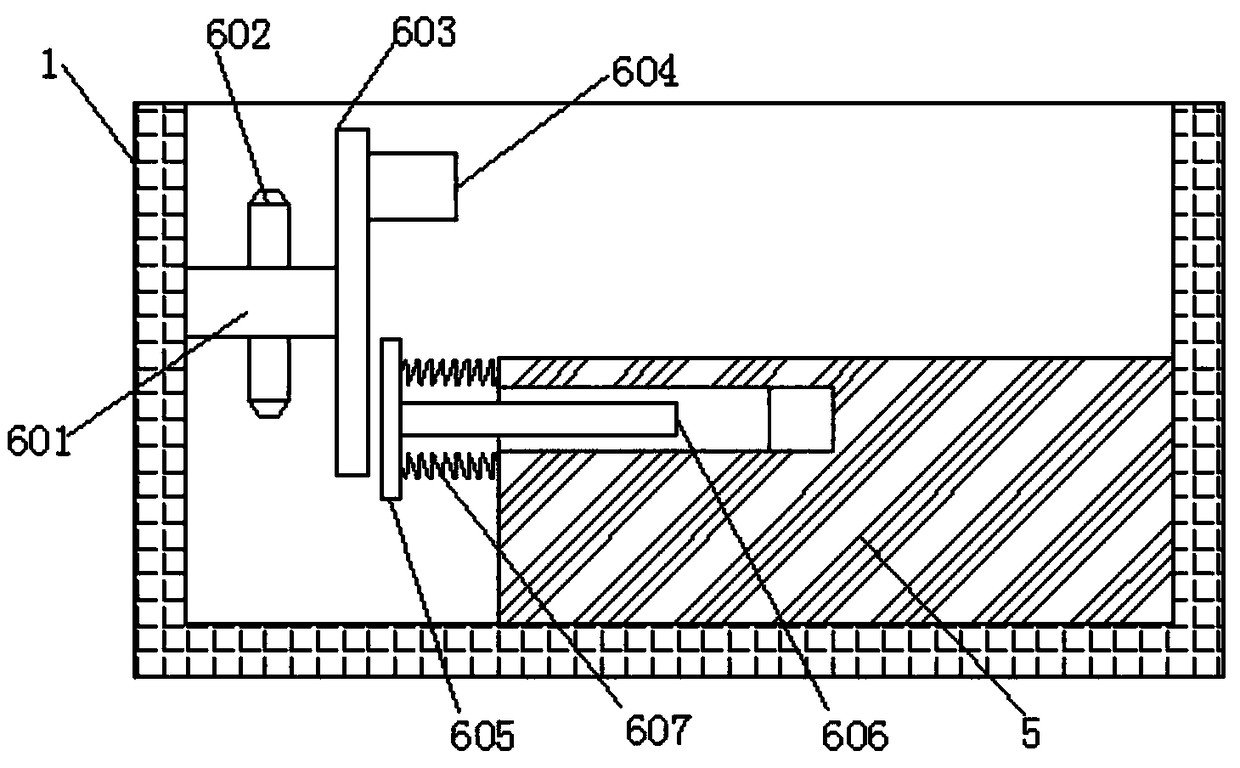

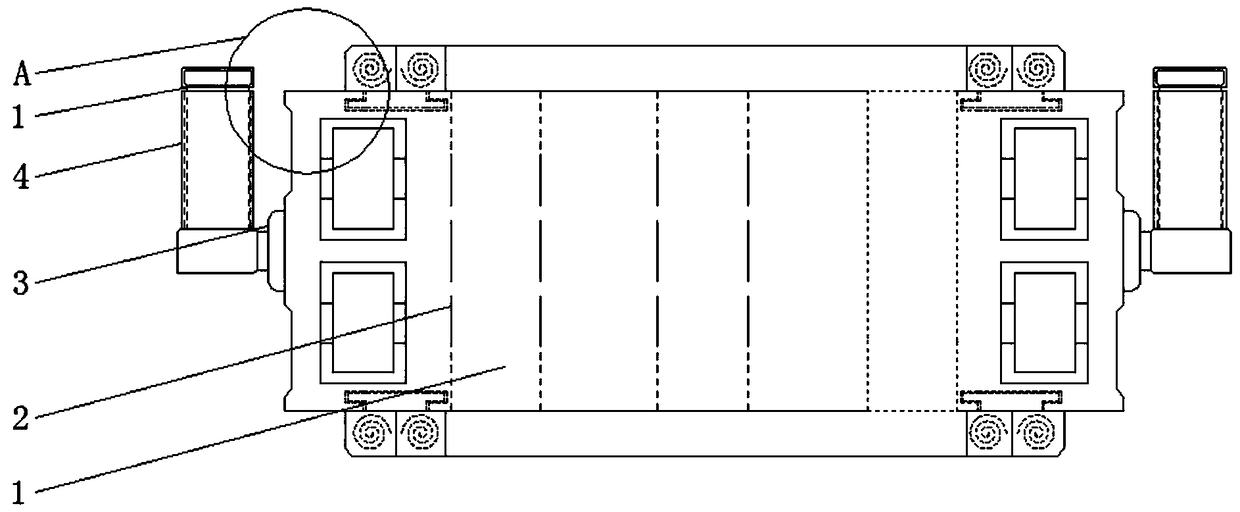

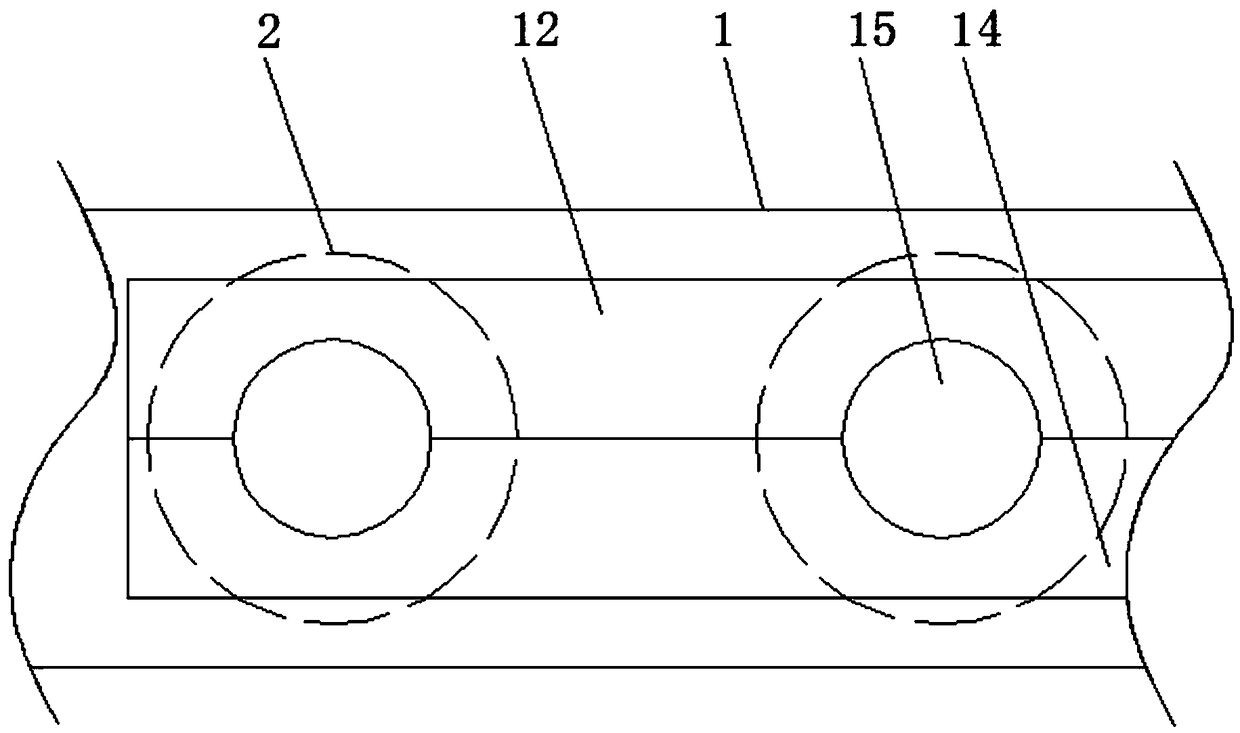

Steel bar straightening and cutting equipment for construction site

The invention discloses steel bar straightening and cutting equipment for a construction site. The equipment comprises a fixed box, a first roller and a second roller, the lower end of the fixed box is fixedly connected with a support, the two ends of the first roller and the two ends of the second roller are rotationally connected to the inner side wall of the fixed box correspondingly, and a first gear is fixedly connected to the outer side wall of the first roller in a sleeving mode. After a steel bar is straightened through a third roller and a fourth roller, the steel bar is straightenedagain through the first roller and the second roller, so that a good straightening effect is achieved, meanwhile, the steel bar can be driven to move, and manual delivery is not needed; an annular rack moves up and down, then a pressing block is driven to strike the steel bar up and down in a reciprocating mode, and longitudinal steel bar straightening is carried out; an extrusion block is used for repeatedly extruding a connecting block, so that a connecting plate transversely strikes the steel bar, and transverse steel bar straightening is carried out; and a cutting mechanism is added so that cutting can be carried out by controlling the movement of a cutting motor up and down through an electric telescopic rod.

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

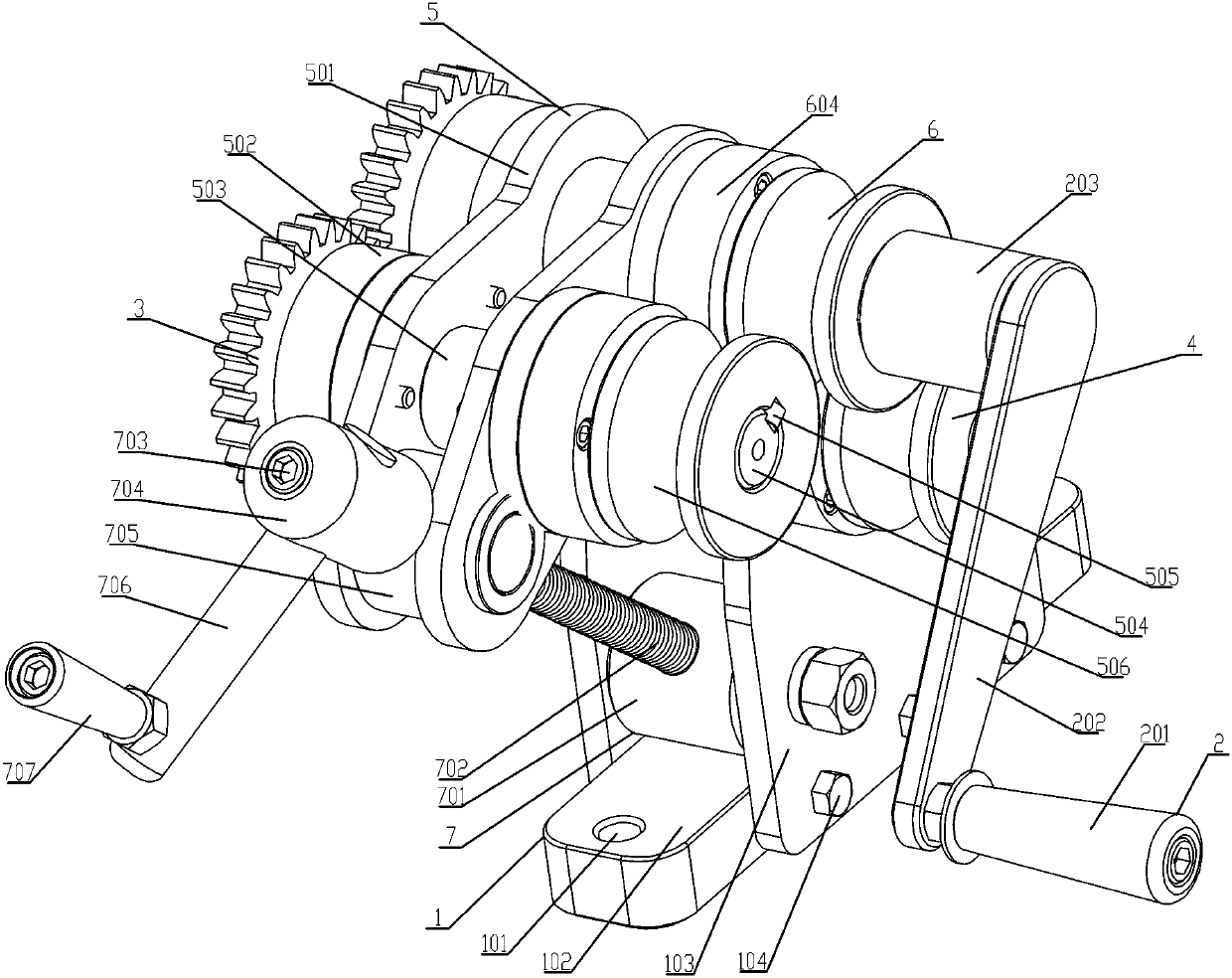

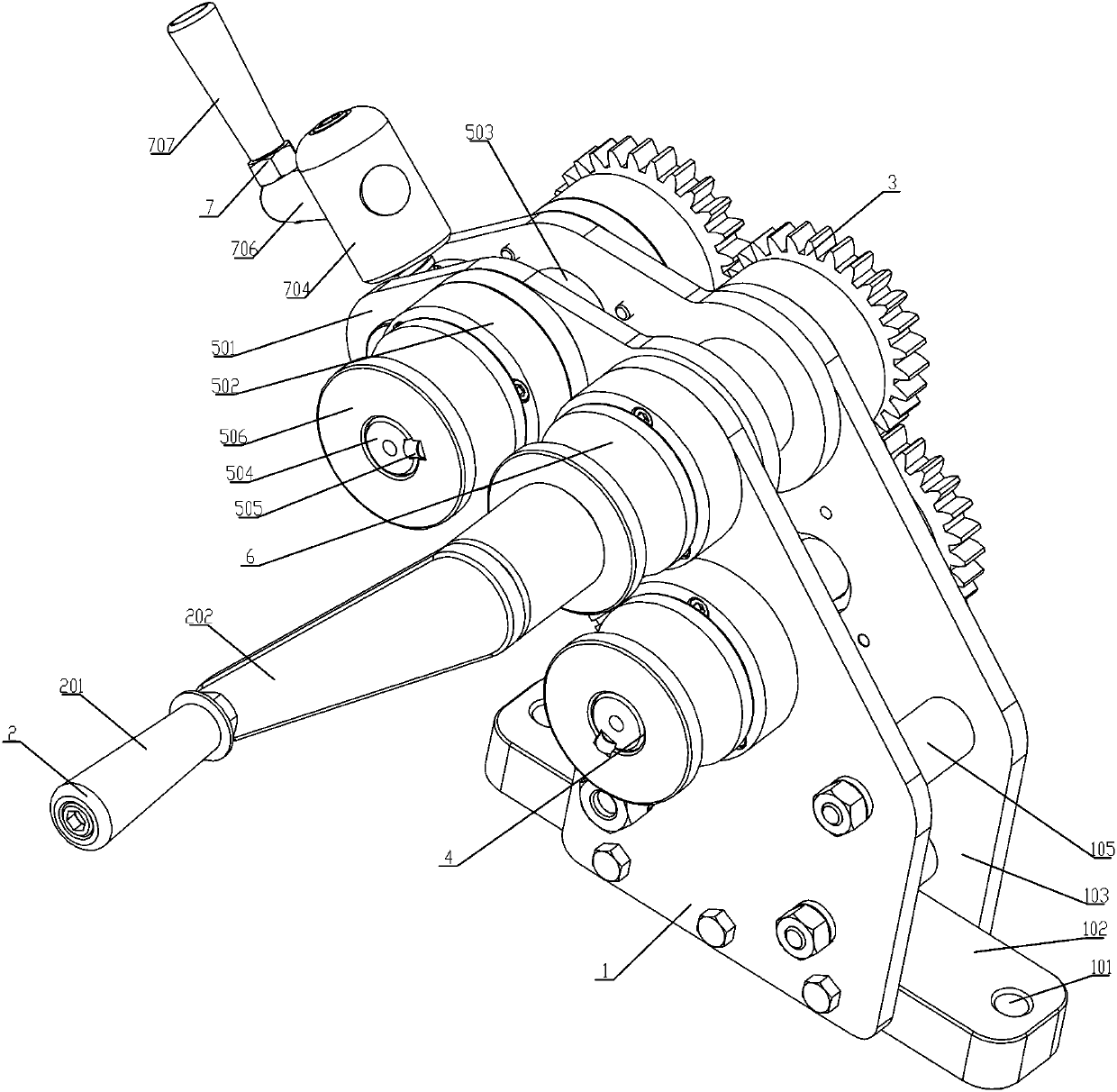

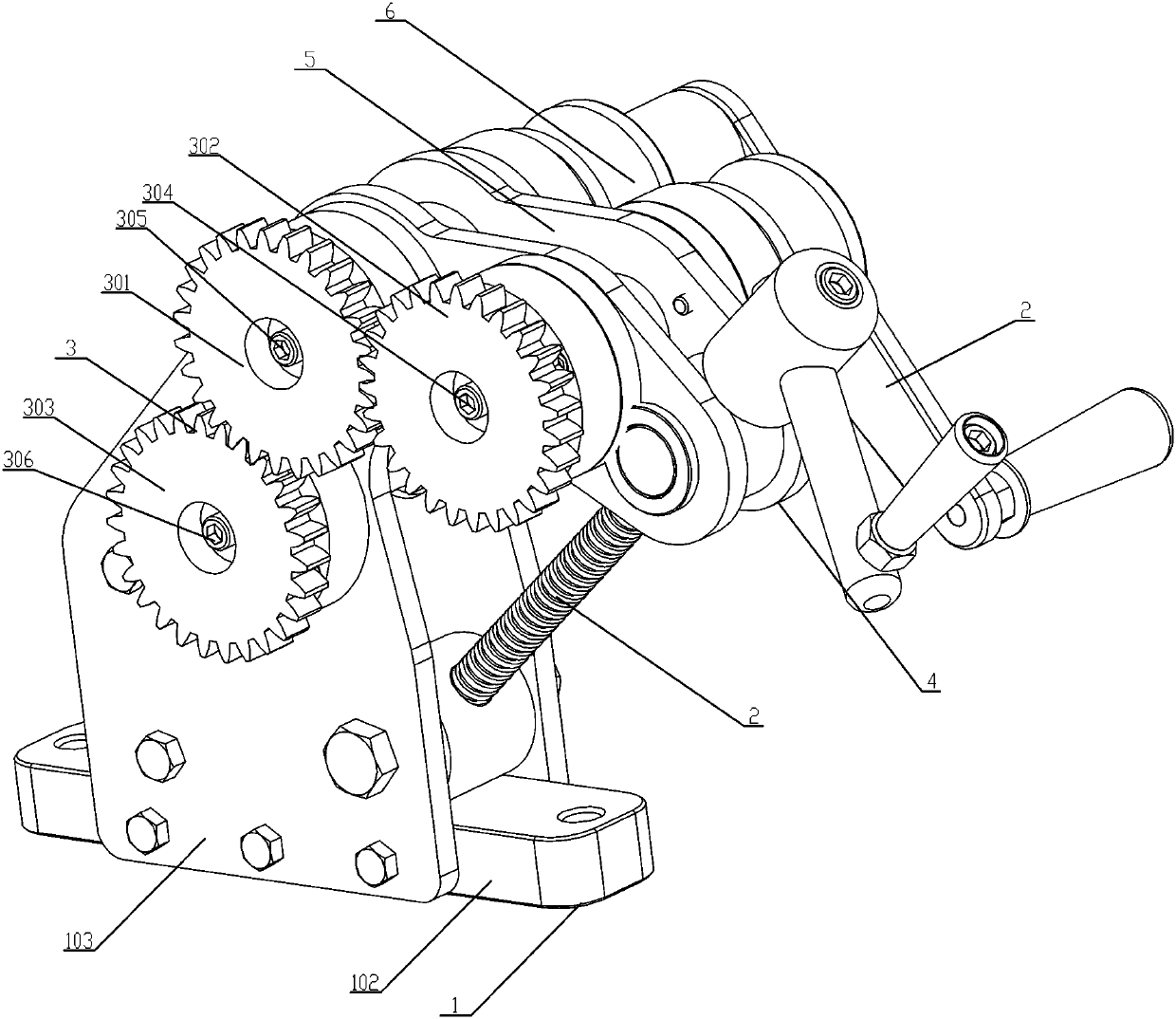

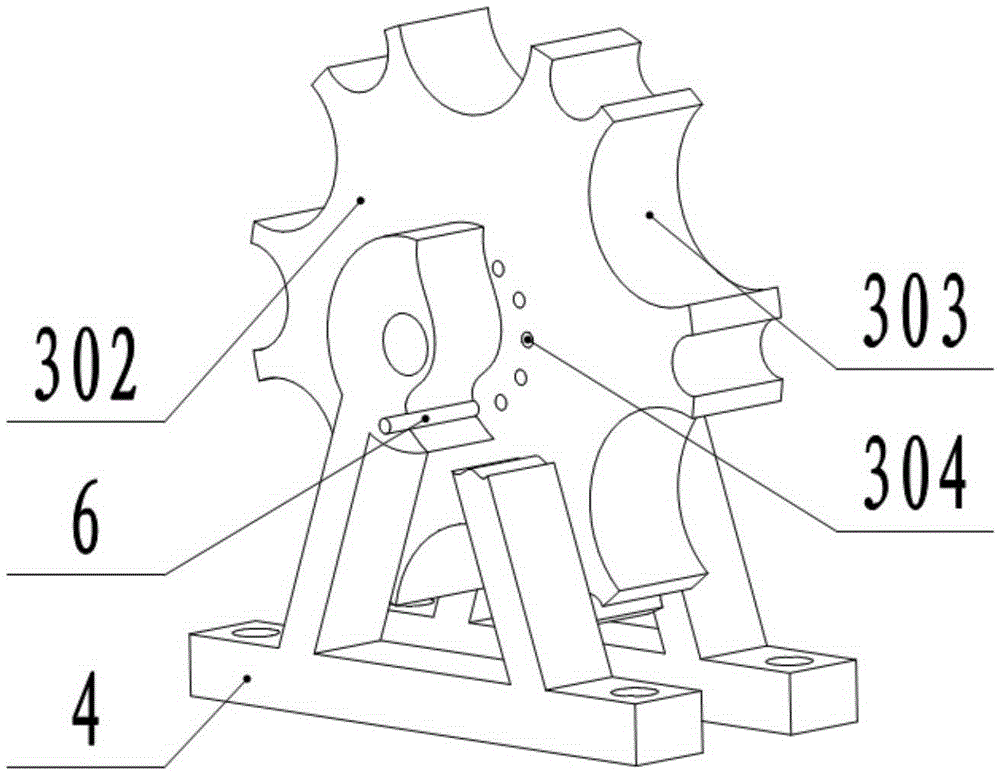

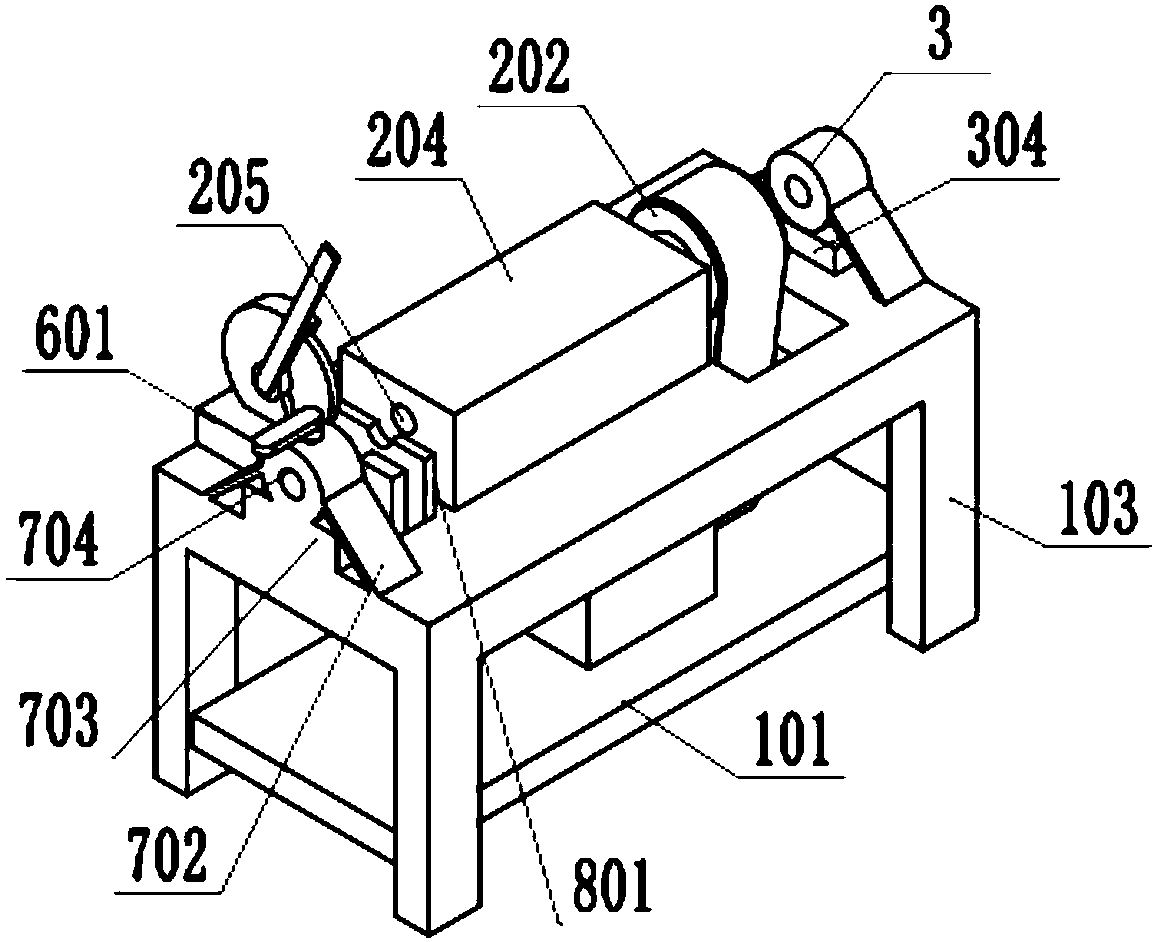

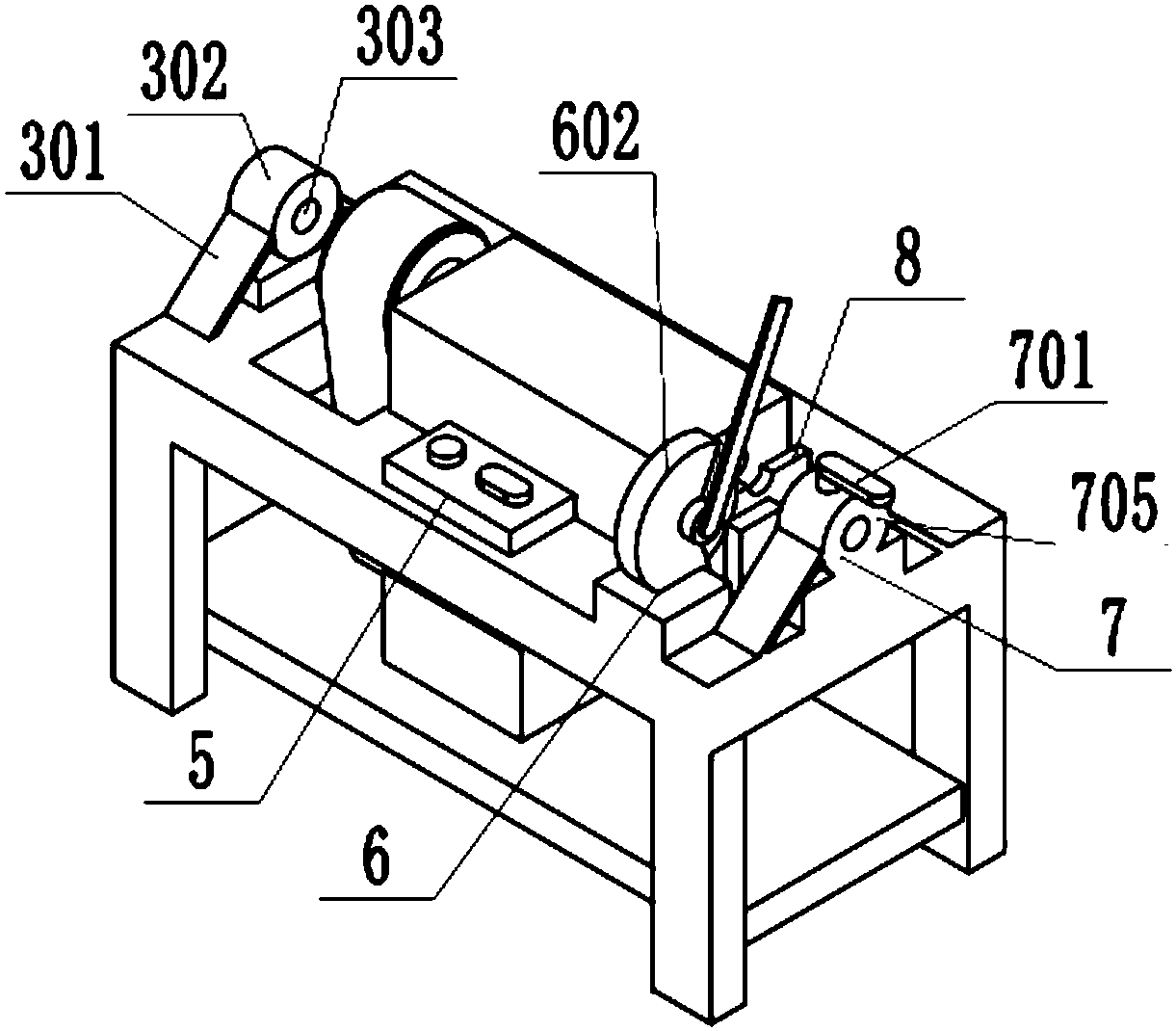

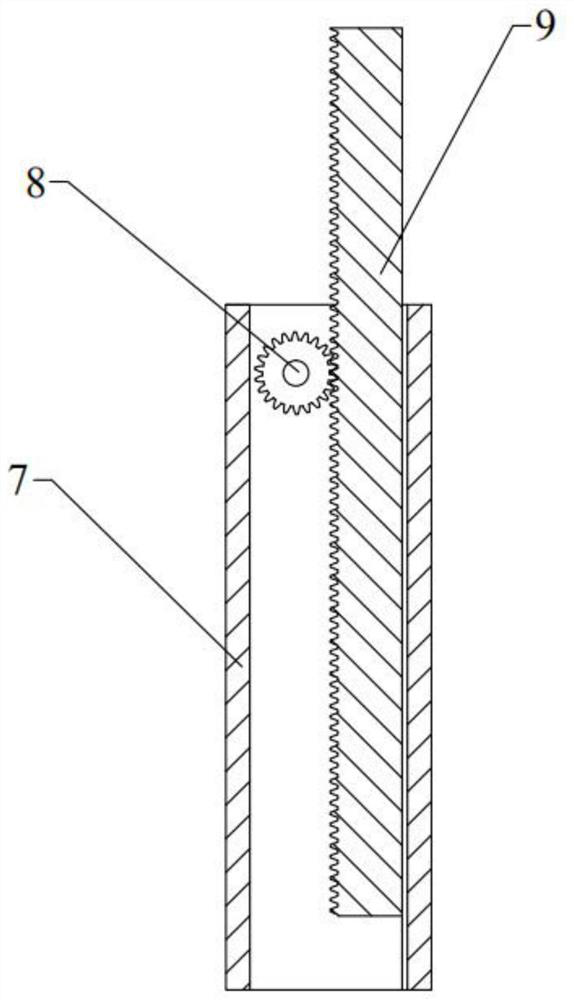

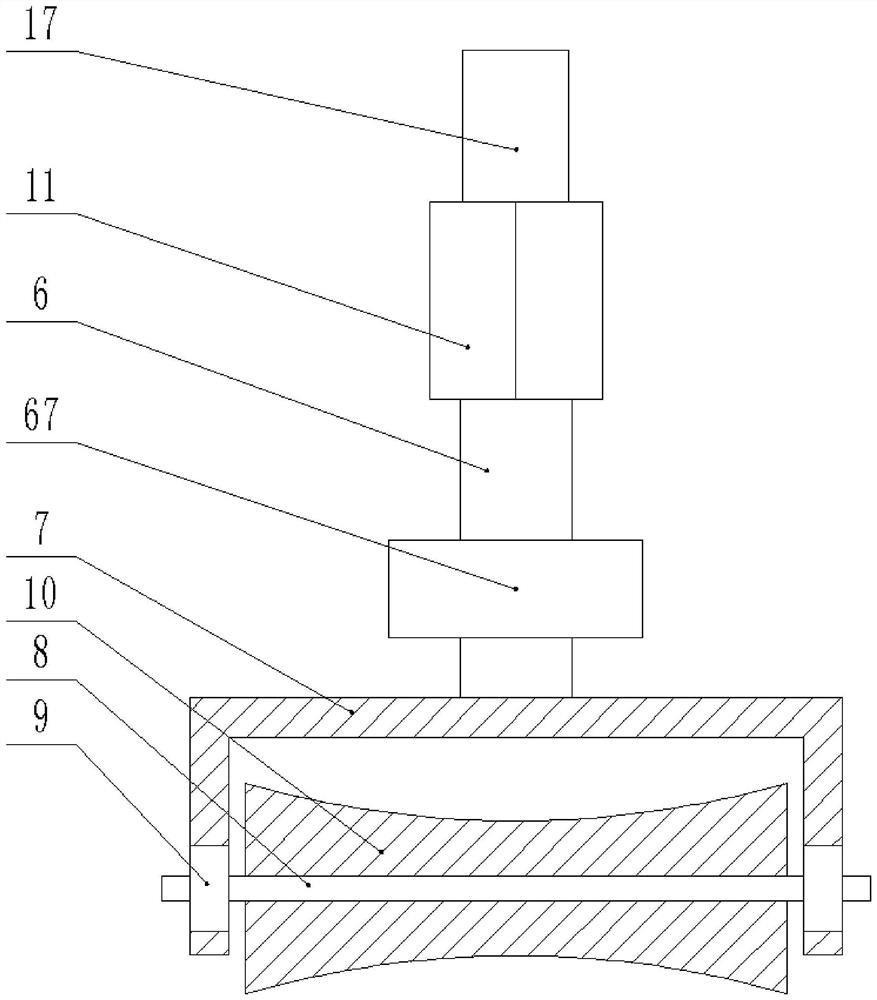

Straightening device based on screw compression adjustment and using method

The invention provides a straightening device based on screw compression adjustment and a using method. A bottom compression roller structure is supported and mounted between rack vertical plates of arack structure; a top compression roller structure is supported and mounted at the tops of the rack vertical plates, and the top compression roller structure is matched with the bottom compression roller structure; a power mechanism for driving the main shaft to rotate is mounted on the main shaft where the top compression roller structure is located in a matched manner; a swing compression roller mechanism is mounted on the main shaft where the top compression roller structure is located in a running fit manner; a screw type swing arm adjusting mechanism used for adjusting the rotating angleof the swing compression roller mechanism and the rack structure is installed between the swing compression roller mechanism and the rack structure. Gear transmission mechanisms used for driving thebottom compression roller structure, the top compression roller structure and the swing compression roller mechanism to rotate synchronously are installed at the other ends of main shafts of the bottom compression roller structure, the top compression roller structure and the swing compression roller mechanism. According to the straightening device, the rotating angle between the straightening compression rollers can be adjusted in a screw transmission mode, then the pressing force in the straightening process is adjusted, and the optimal straightening effect is achieved.

Owner:CHINA THREE GORGES UNIV

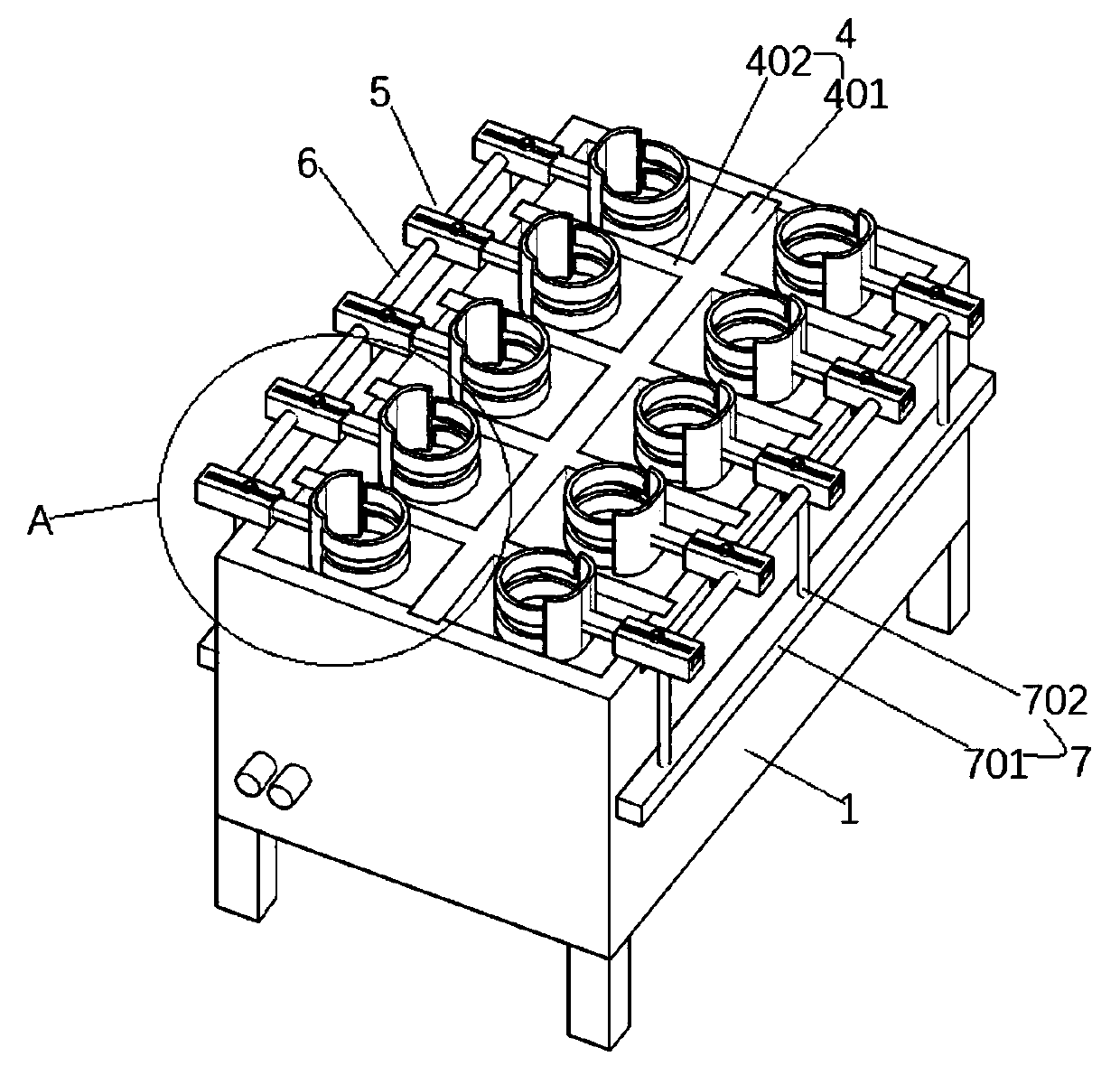

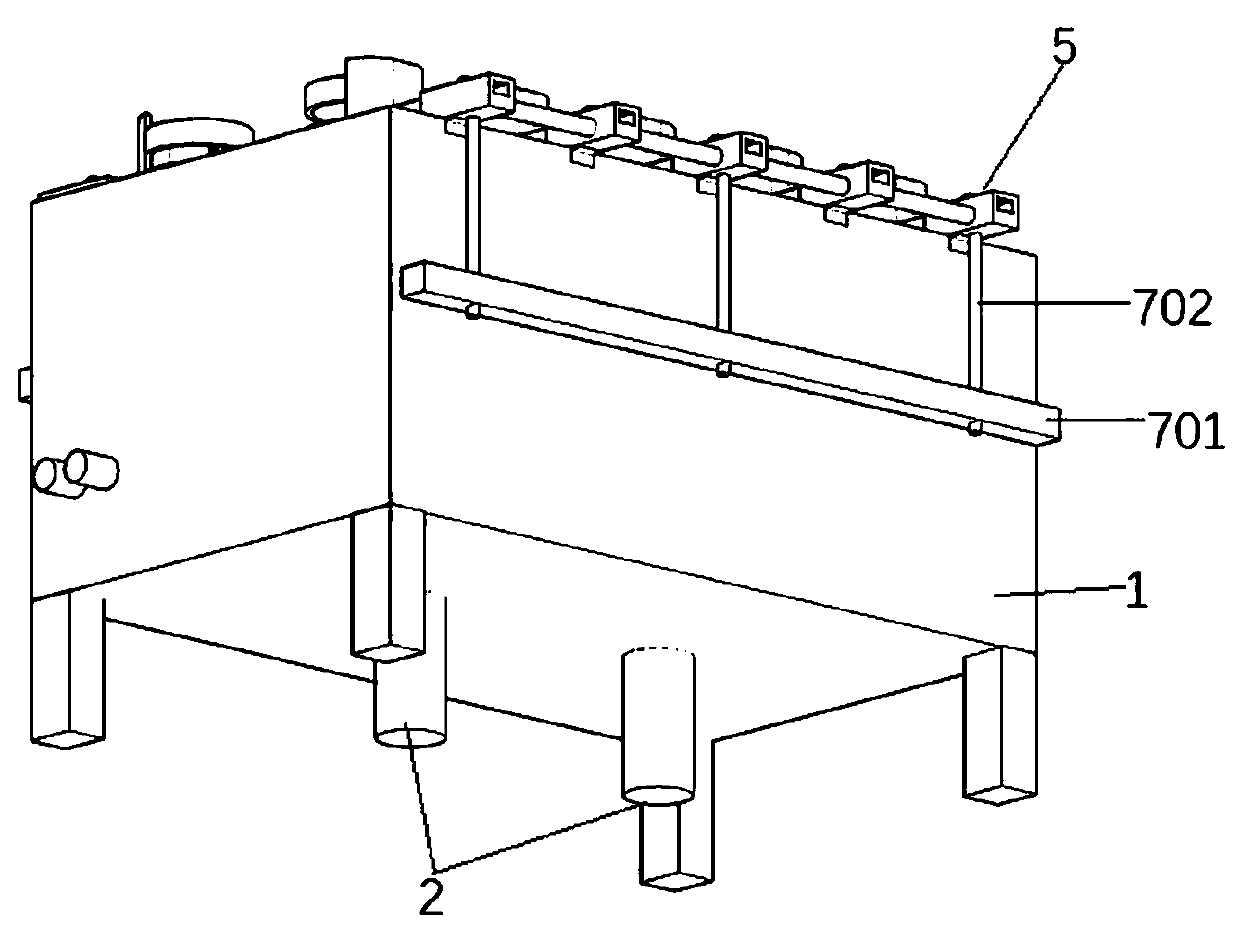

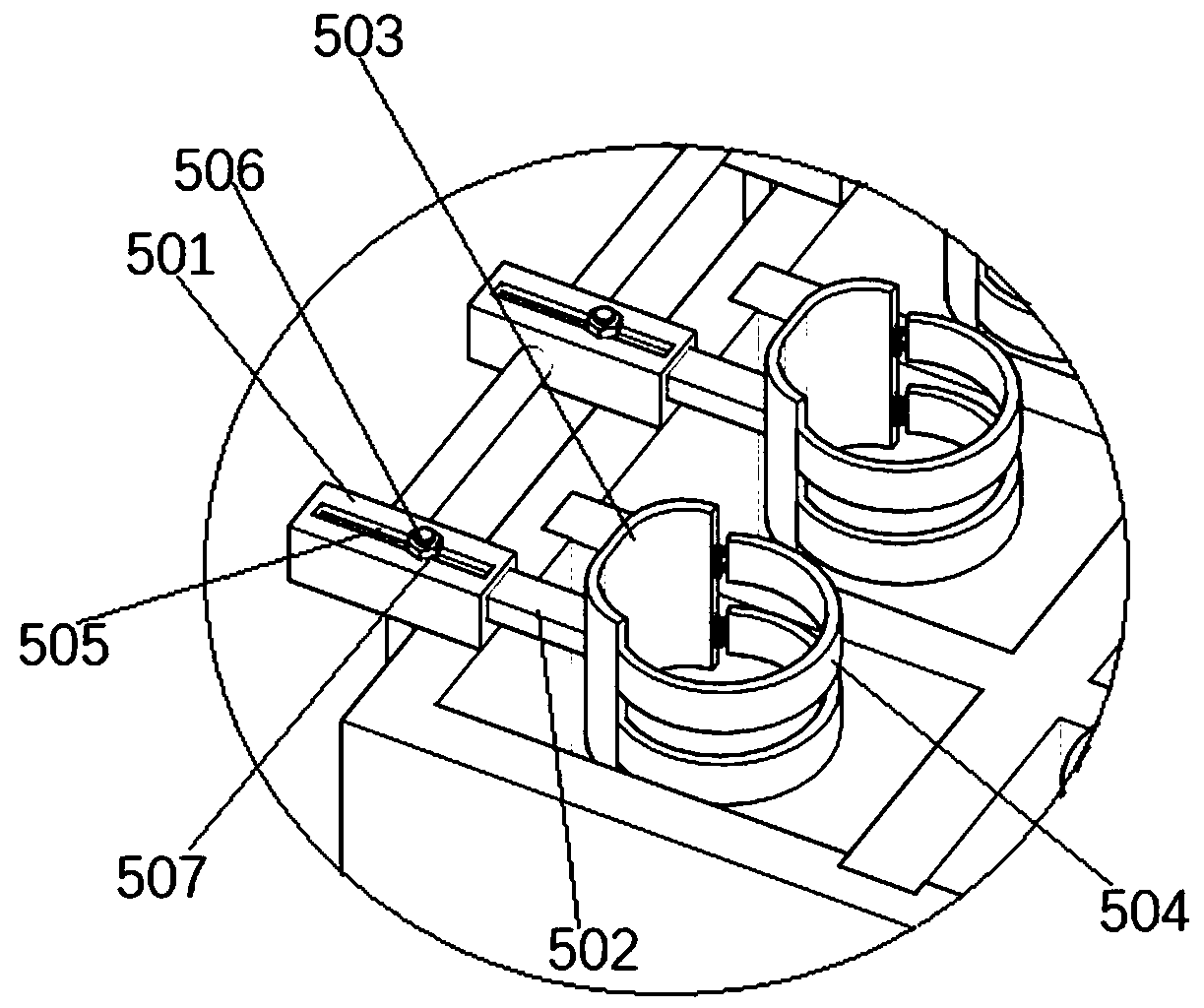

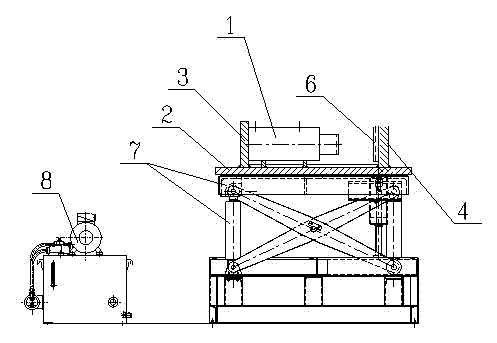

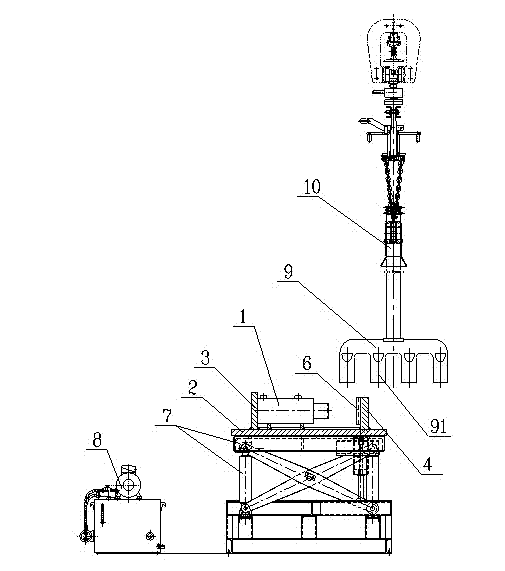

Forestry engineering seedling culture device

InactiveCN111264236AImprove operational efficiencyImprove straightening effectCultivating equipmentsTree rootForest industry

The invention relates to the technical field of forestry devices, in particular to a forestry engineering seedling culture device. The forestry engineering seedling culture device comprises a water tank, a lifting mechanism arranged in the water tank, a pore plate connected with the top of the lifting mechanism, a seedling accommodating mechanism arranged on the upper end face of the pore plate and an adjustable seedling straightening mechanism arranged at the upper end of the water tank; the upper end of the seedling accommodating mechanism is positioned in the water tank when the lifting mechanism is completely contracted; and the lower end of the seedling accommodating mechanism is positioned outside the water tank when the lifting mechanism completely extends out. According to the forestry engineering seedling culture device, the adjustable seedling straightening mechanism is simple in structure and convenient to mount and dismount, when the adjustable seedling straightening mechanism is used together in cooperation with a supporting mechanism, the device is high in structural stability and convenient to use, component parts are convenient to maintain and replace, and the device is high in straightening efficiency and extremely good in straightening effect; after seedlings are cultivated, the seedlings are moved out from the side faces, the operation is rapid, tree roots and trunks are hardly damaged, and the survival rate of the transplanted seedlings is greatly increased; and the device is convenient to maintain.

Owner:令狐荣钢

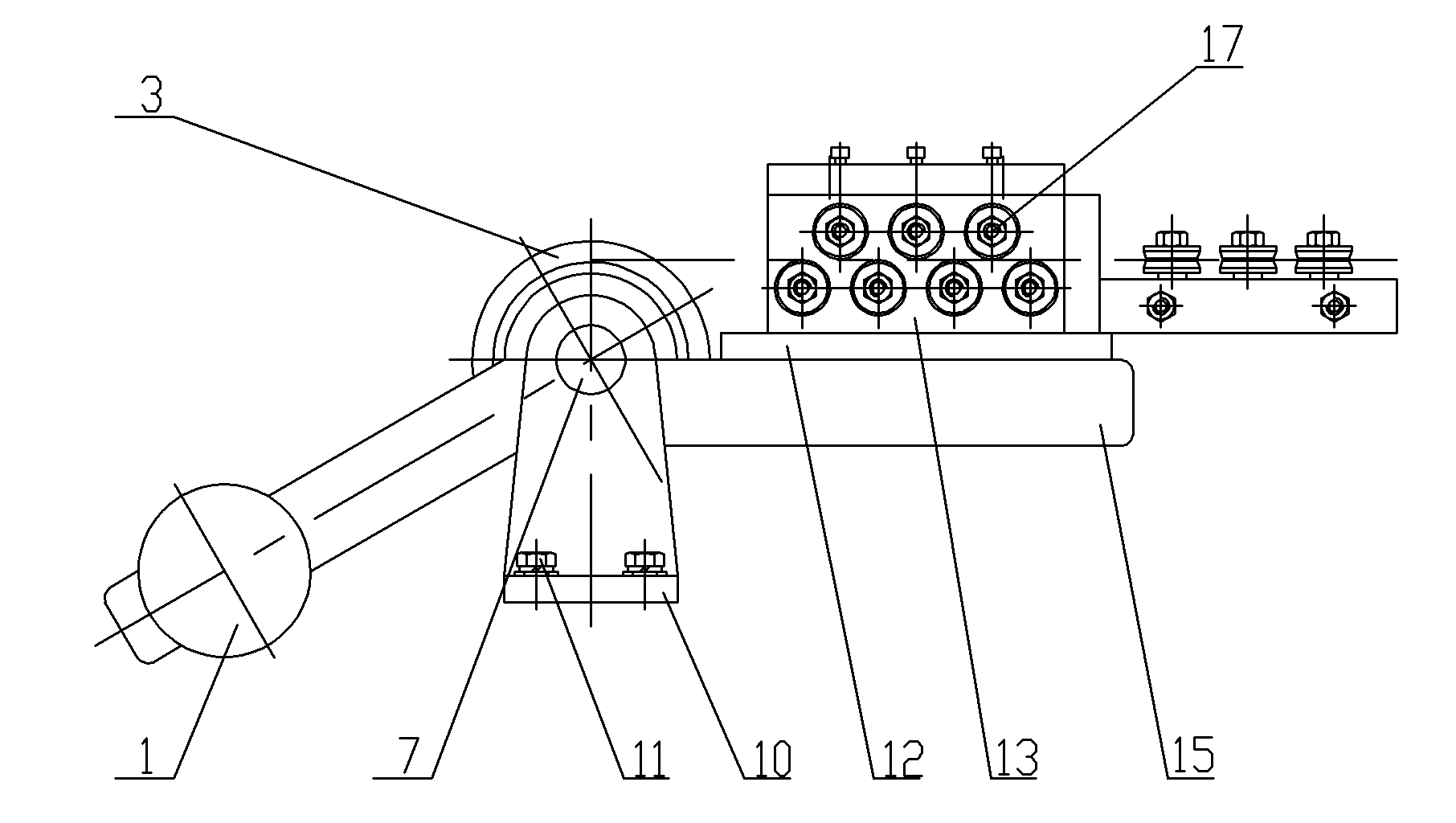

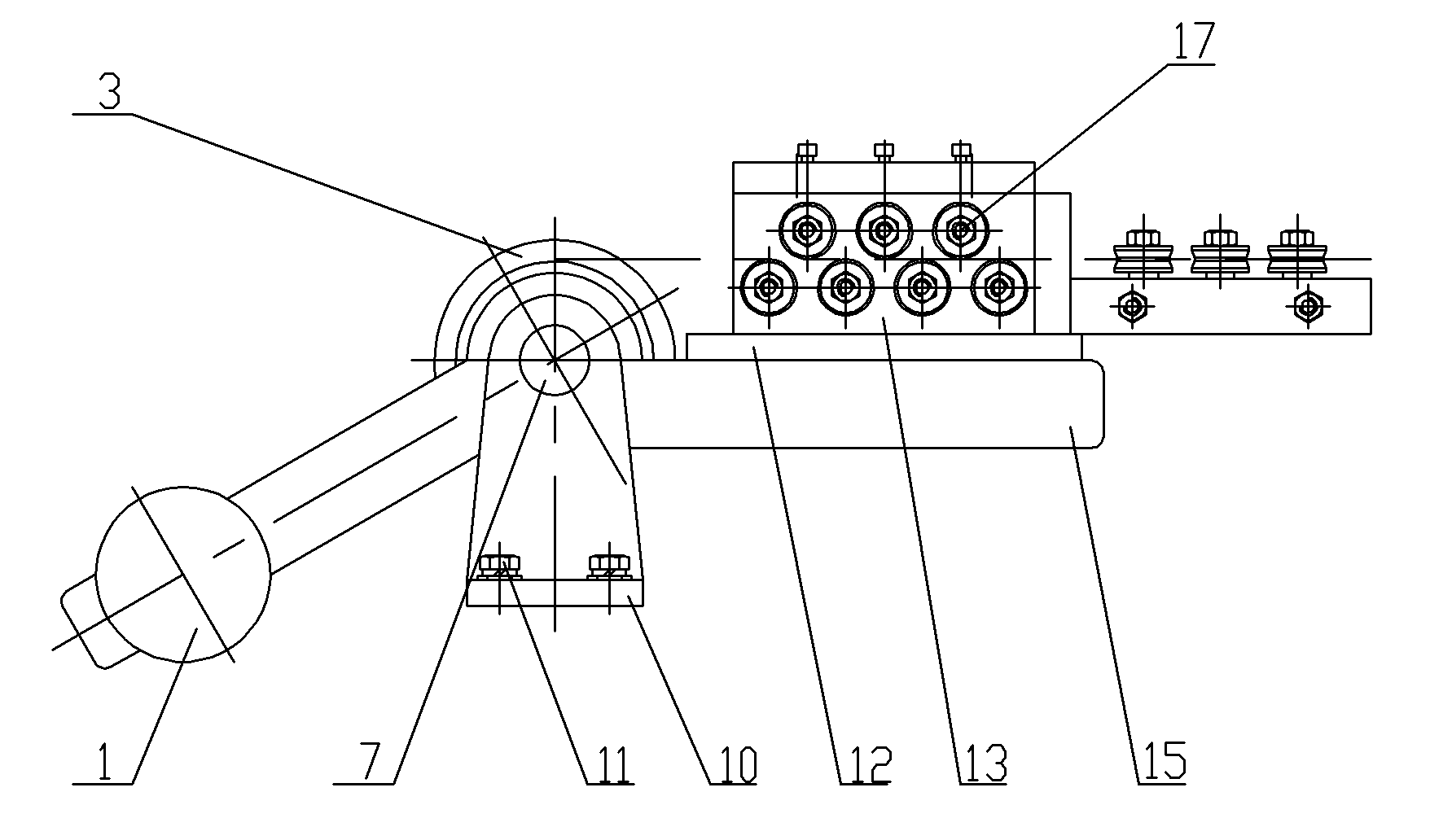

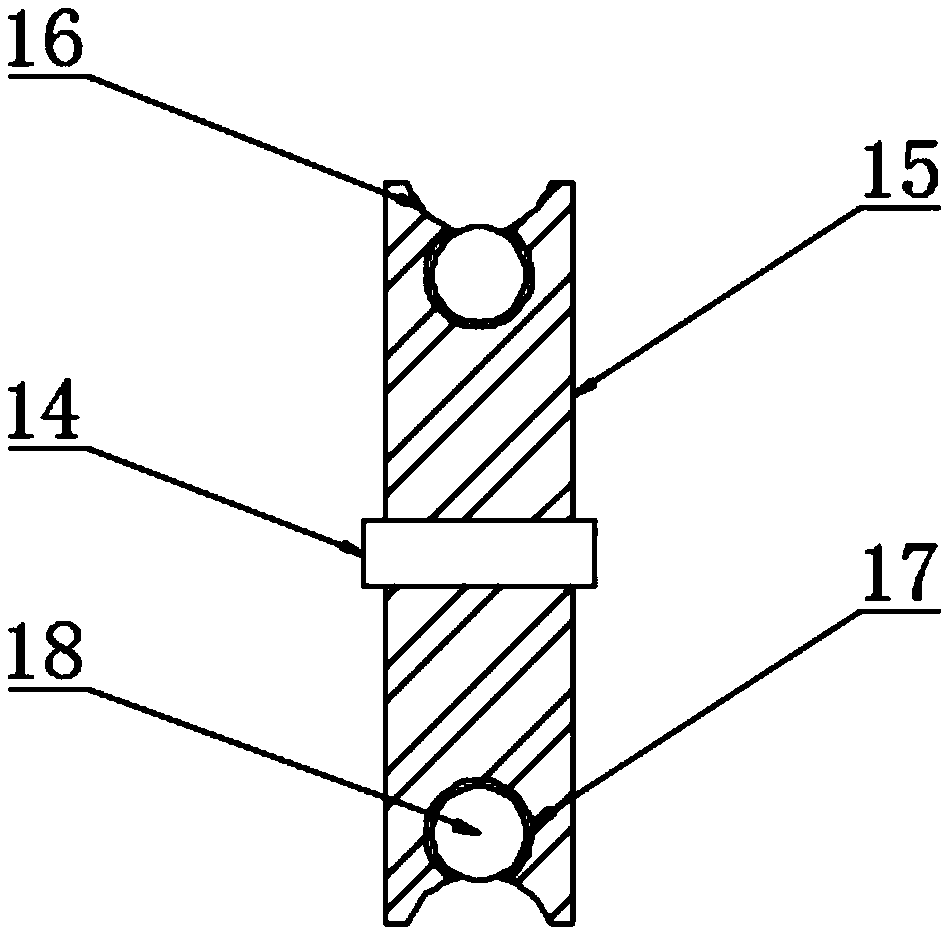

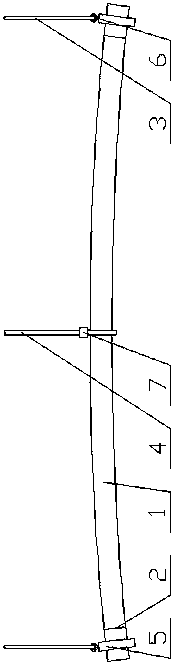

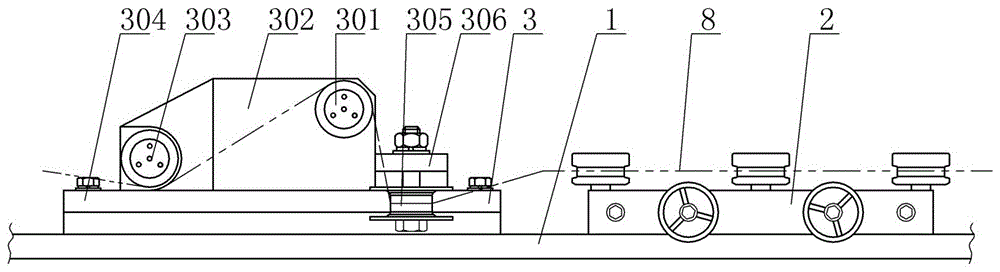

Straightening counterweight device arranged on trunk type take-up machine

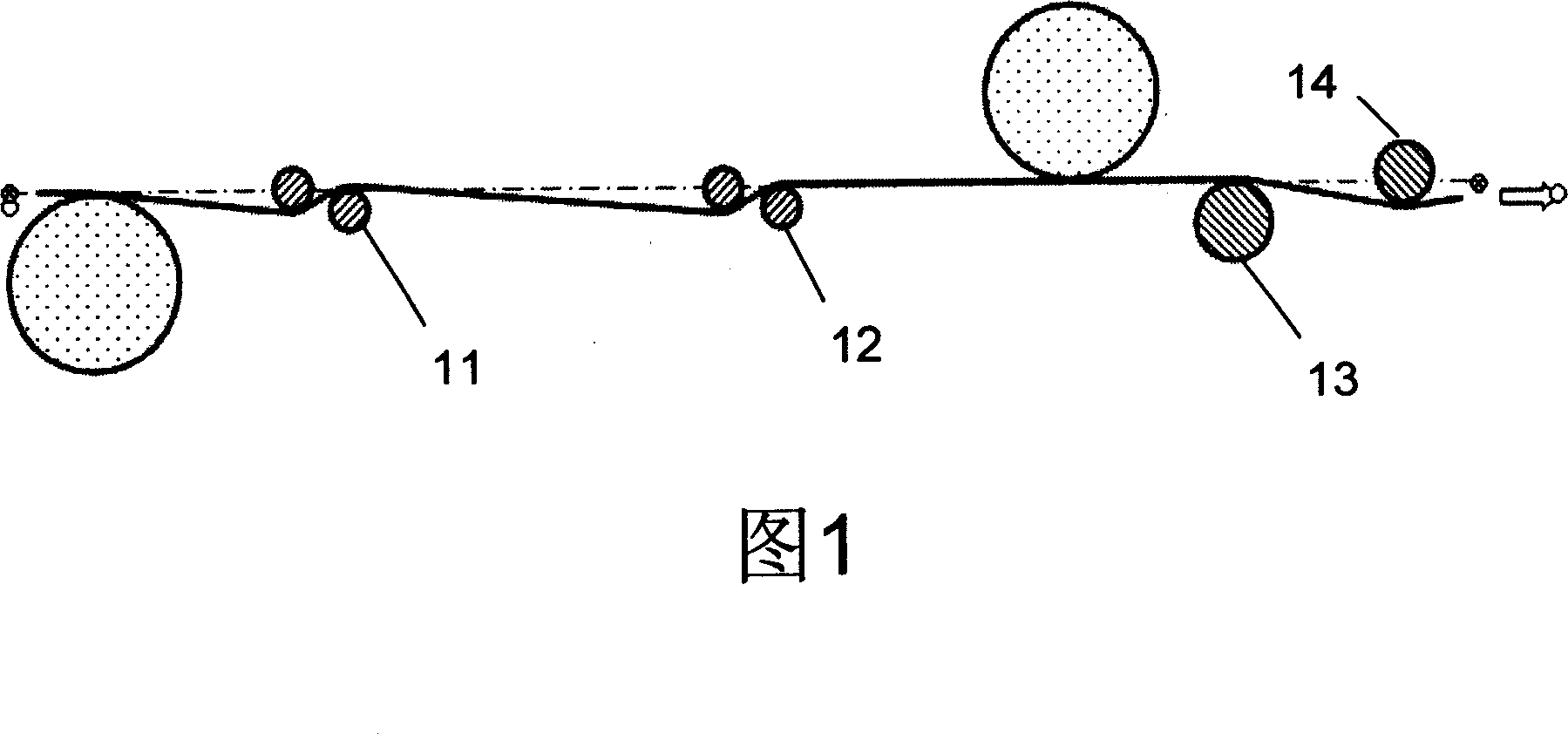

InactiveCN102310115AEasy to adjustGood straightening effectWire straightening devicesAgricultural engineeringEngineering

The invention relates to a straightening counterweight device arranged on a trunk type take-up machine. The device is characterized in that a shaft is arranged at the upper end of a bracket; a sleeve is arranged at the middle part of the shaft; second bearings are arranged at the two ends of the shaft respectively; a first bearing is arranged on the sleeve, and a wire-through wheel is sheathed on the first bearing; a level is arranged on the bracket through the shaft and the second bearing; a counterweight block is mounted at one end of the level, and a support plate is mounted at the other end of the level, and a straightener is arranged on the support plate. The straightener comprises a longitudinally arranged fixing plate and a horizontally arranged fixing plate, and seven straightening pulleys are distributed in two rows on the fixing plates through wheel shafts and a third bolt in a staggered manner; a second bolt is arranged at the bottom of the bracket; the second bearing is fixed with the shaft through a bearing retainer ring; a retainer ring used for a hole is arranged between the first bearing and the wire-through wheel; and the counterweight block is arranged at one end of the level through a first bolt. The straightening counterweight device adopts a level mechanism, so that the straightener can be adjusted conveniently, and a good straightening effect can be reached.

Owner:WUXI PINGSHENG SCI & TECH

Steel pipe straightening device

InactiveCN106623505AAxial Straightness ImprovementReasonable structureArchitectural engineeringSteel frame

The invention discloses a steel pipe straightening device. The steel pipe straightening device comprises a load bearing platform and a rotary frame; supporting columns are installed at the upper end of the load bearing platform; a steel frame is fixedly connected to the upper ends of the supporting columns; first telescopic rods are installed at the lower end of the steel frame; a row of upper pressing rollers are connected to the lower ends of the first telescopic rods; second telescopic rods are installed at the upper end of the load bearing platform; a row of lower pressing rollers are connected to the upper ends of the second telescopic rods; telescopic rod bodies distributed uniformly are fixedly installed in an inner cavity of the rotary frame, and pressing roller bodies are arranged at the lower ends of the telescopic rod bodies; the two sides of the rotary frame are provided with through holes; a transverse rod is connected into the through holes in a sleeved mode; supporting rods are fixedly connected to the two ends of the transverse rod; a belt wheel is rotationally connected to the middle of the rotary frame through a belt; and a motor is rotationally connected to the belt wheel. The steel pipe straightening device is reasonable in structure, convenient, practical and better in straightening effect.

Owner:CHONGQING HUICHANG STEEL PIPE MFG CO LTD

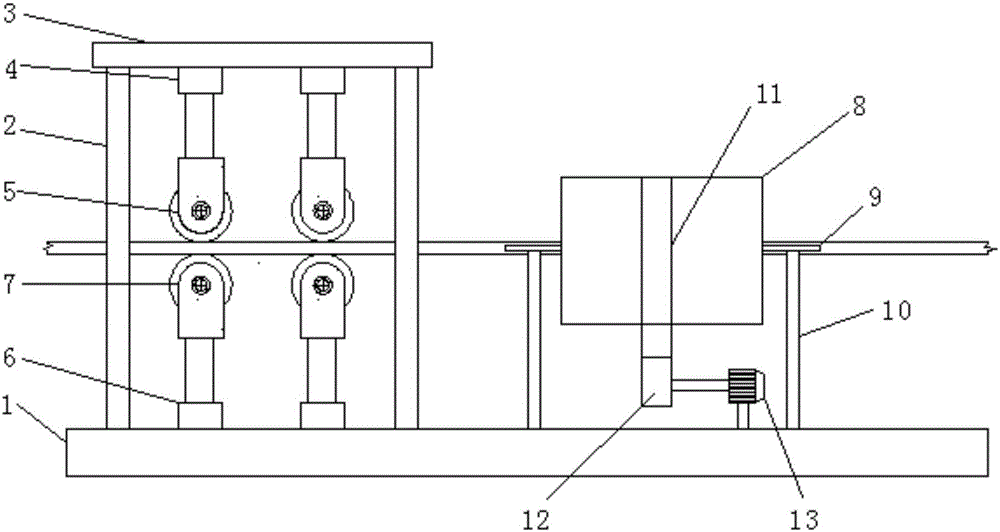

Special-shaped wire straightening device

The invention discloses a special-shaped wire straightening device. The special-shaped wire straightening device comprises a fixed bottom plate, a wire guide plate is installed at one end of the fixedbottom plate, and a supporting column is installed at the other end of the fixed bottom plate; a straightening wheel set and a wire pressing roller are sequentially arranged between the wire guide plate and the supporting column; the wire guide plate is provided with a wire guide hole for a special-shaped wire penetrating through, and a wire guide groove for supporting the special-shaped wire isformed in the upper end of the supporting column; the wire guide hole and the guide groove are located on the same horizontal line, and the special-shaped wire enters a straightening device body fromthe wire guide hole and leaves the straightening device body from the wire guide groove; and the straightening wheel set is used for straightening the special-shaped wire in the left and right direction; and the wire pressing roller is used for straightening the special-shaped wire in the up and down direction. The special-shaped wire straightening device can straighten the special-shaped wire online to facilitate the next processing of the special-shaped wire. During the straightening process, the wire shape of the special-shaped wire can be effectively maintained, and the straightening effect is good.

Owner:JIASHAN JIANGNAN MACHINERY & ELECTRICAL INSTR LTD

Numerical control reinforcing steel bar hoop bending machine

InactiveCN104438955ATwo-way straightening speed is fastGood straightening effectEngineeringSteel bar

The invention relates to a numerical control reinforcing steel bar hoop bending machine which comprises a machine frame, a cutting motor, a rear straightening plate, a front straightening plate and a cutting mechanism. The cutting motor is installed on the lower portion of the machine frame, the cutting mechanism is arranged on the upper portion of the cutting motor, a hoop bending mechanism is disposed on one side of the cutting mechanism and is connected with the rear straightening plate through a mechanical device, a pressing drive device is disposed on one side of the rear straightening plate and is connected with a wire pulling device through a transmission shaft, and the wire pulling device is provided with a wire pulling rod. According to the numerical control reinforcing steel bar hoop bending machine, a drive structure is reasonable, stability is good, vibration is little, and market prospects are wide.

Owner:QINGDAO HOSEN HEAVY IND

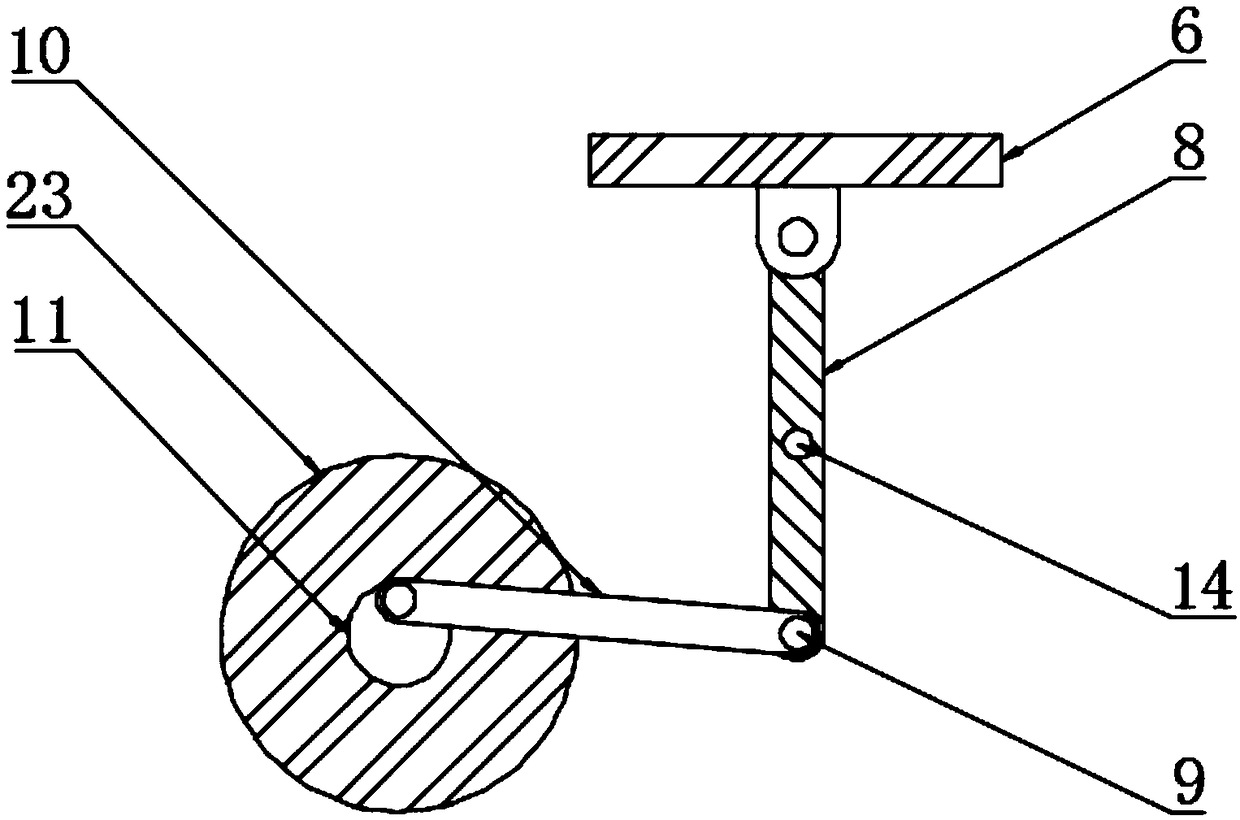

Multifunctional steel bar straightening device and method

The invention discloses a multifunctional steel bar straightening device and method. The multifunctional steel bar straightening device comprises a machine body, a traction belt is arranged in the machine body, positioning holes are formed in both sides of the traction belt, and rollers are arranged in the traction belt. Fixed frames are disposed at the two ends of the rollers, a movable plate isdisposed at the bottom of the fixed frames, sliding grooves are formed in both sides of the movable plate, and a linkage plate is disposed at the bottom of the movable plate. The top of the linkage plate is movably connected with the movable plate. A rotating shaft is disposed in the linkage plate, and the rotating shaft is fixedly connected with the linkage plate. According to the multifunctionalsteel bar straightening device and method, through the arrangement of a rotating wheel, a transmission rod and the linkage plate, when a motor drives the rotating wheel to rotate, the transmission rod can rotate the linkage plate back and forth around a fixed rod, so that the movable plate is enables to slide back and forth in the sliding grooves, a steel bar can spirally move forward in the device during the work of the device, not bending phenomenon is caused when the steel bar is straightened by the device, and the straightening effect of the steel bar is better.

Owner:大连绿云科技有限公司

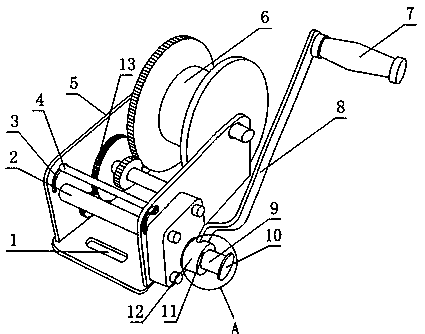

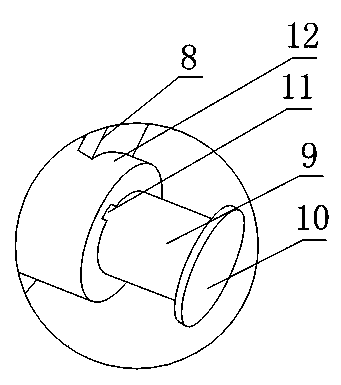

Winding mechanism

The invention discloses a winding mechanism. The winding mechanism comprises a machine frame and a winding wheel, wherein the machine frame is provided with a winding wheel brake mechanism and a cable straightening mechanism, the cable straightening mechanism comprises a fixing rod and a moving rod, the distance between the fixing rod and the moving rod is linearly adjustable, the winding wheel brake mechanism comprises a gear train and a rocking bar, the gear train is a reduction drive gear train, the gear train further comprises a drive wheel rod, a gear at the front end of the gear train is fixed on the drive wheel rod, a sleeve is fixedly connected with the connection end of the rocking bar and the gear train, a through hole for the drive wheel rod to penetrate through is formed in the sleeve, a key groove is formed in the side face of the through hole, a key matched with the key groove in keying mode is arranged on the drive wheel rod, and the key is parallel to the axis of the drive wheel rod. The winding mechanism is simple in structure, and is high in winding and unwinding efficiency, automatically completes straightening and reshaping work of a cable and obtains good reshaping effects during the winding and unwinding process, and furthermore facilitates use life extension of the cable and safety of operating personnel.

Owner:SICHUAN TIANWEI ELECTRONICS

Steel pipe straightening device

The invention provides a steel pipe straightening device. The steel pipe straightening device comprises a machine frame, a straightening plate, a straightening mold, a base and a handle. The straightening plate is hinged to the machine frame, a groove hole and adjusting holes are formed in the straightening plate, the groove hole is located in the center of the straightening plate, and the adjusting holes are symmetrically distributed in the two sides of the groove hole. The straightening mold comprises an upper mold wheel and a lower mold wheel, the upper mold wheel and the lower mold wheel are symmetrically arranged up and down, the upper mold wheel is connected with the straightening plate, and the lower mold wheel is rotationally connected with the base. The handle is located at one end far away from the machine frame and fixedly connected with the straightening plate. According to the steel pipe straightening device in the technical scheme, the mold is divided into an upper part and a lower part, and straightening is carried out in a pressure straightening manner; the size of the mold is adjustable, and the steel pipe straightening device is suitable for straightening different-specification steel pipes; and the lever principle is used, the structure is simple, operation is convenient, and the straightening effect is obvious.

Owner:天津市晟方庆宇科技发展有限公司

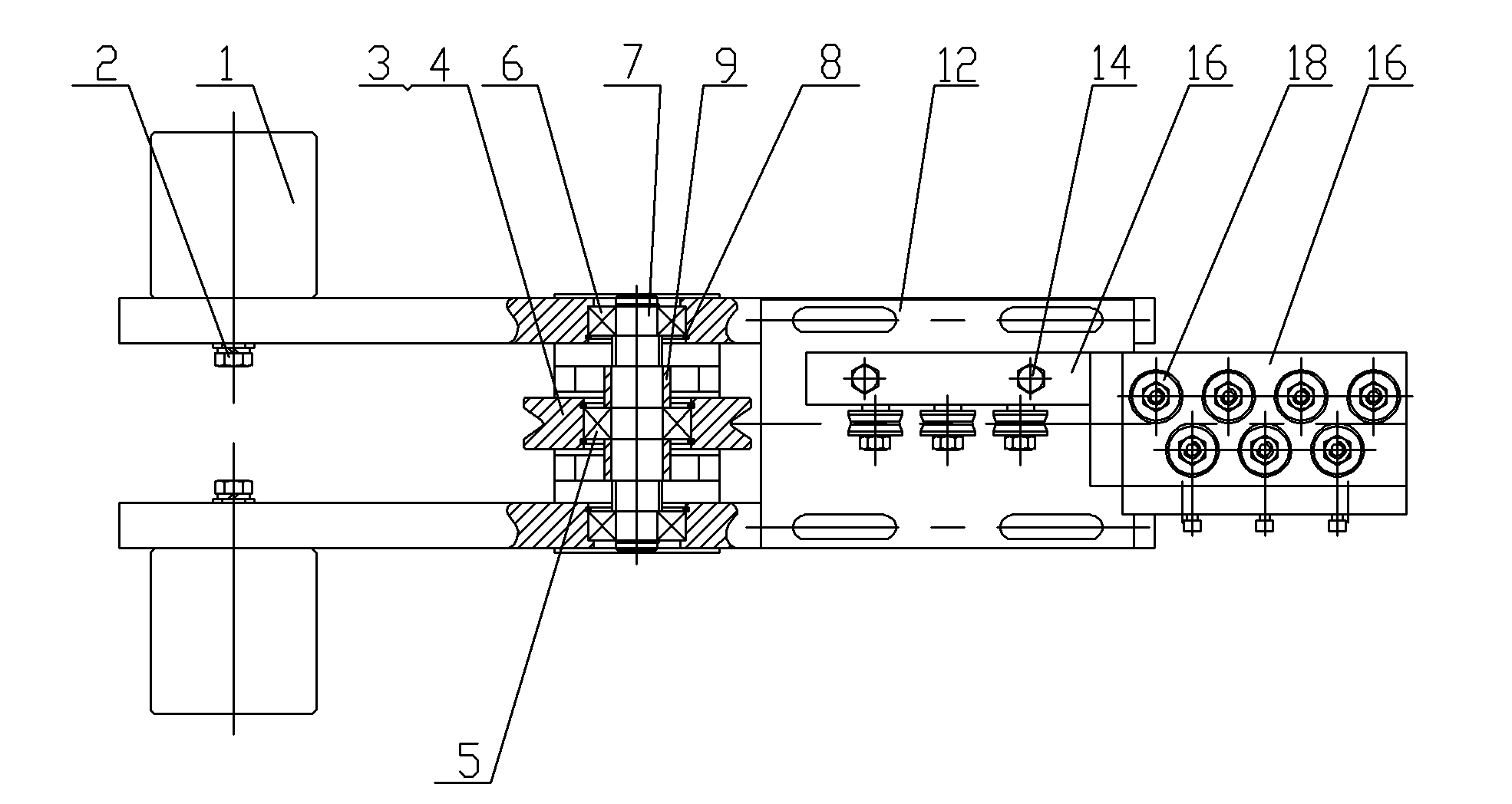

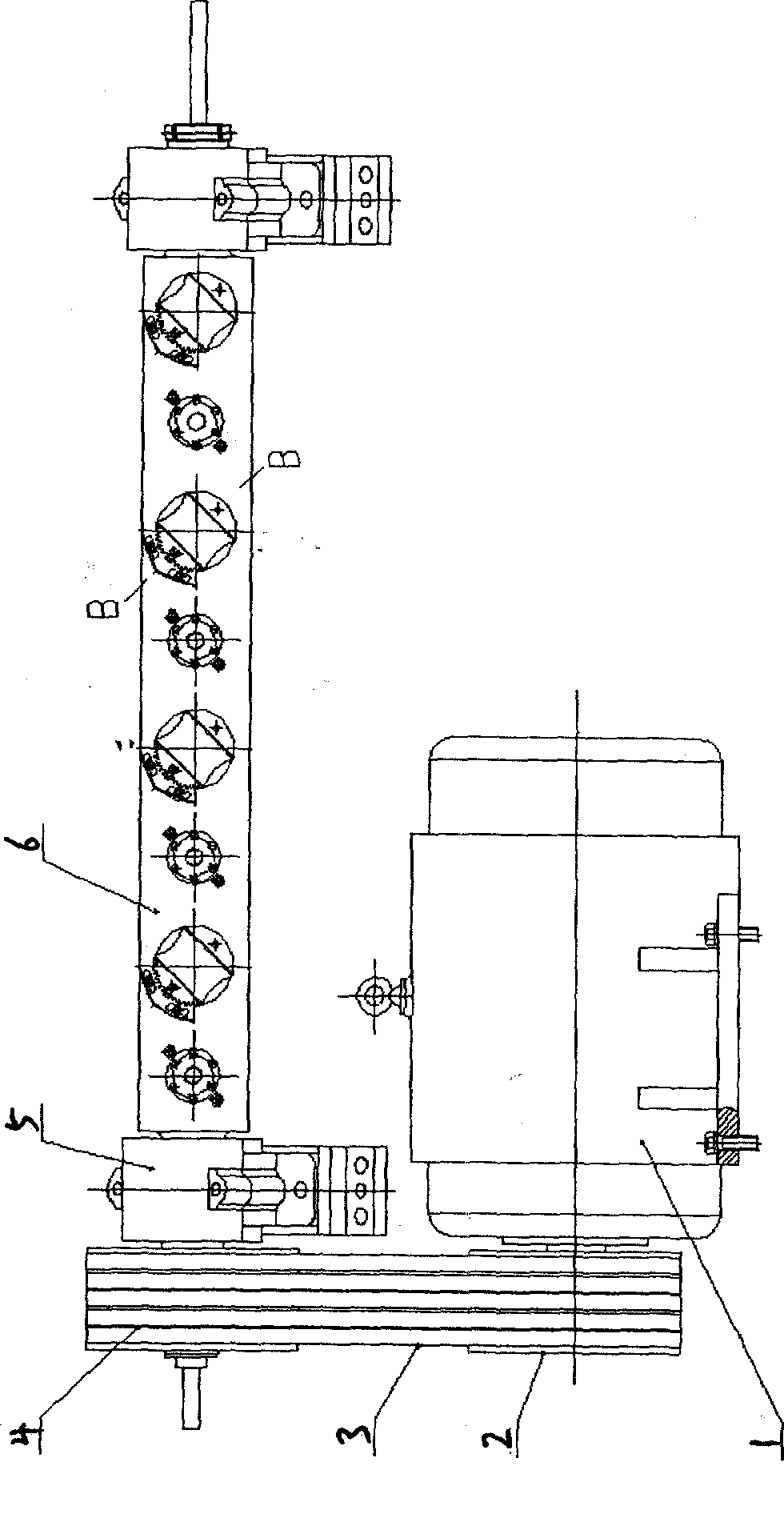

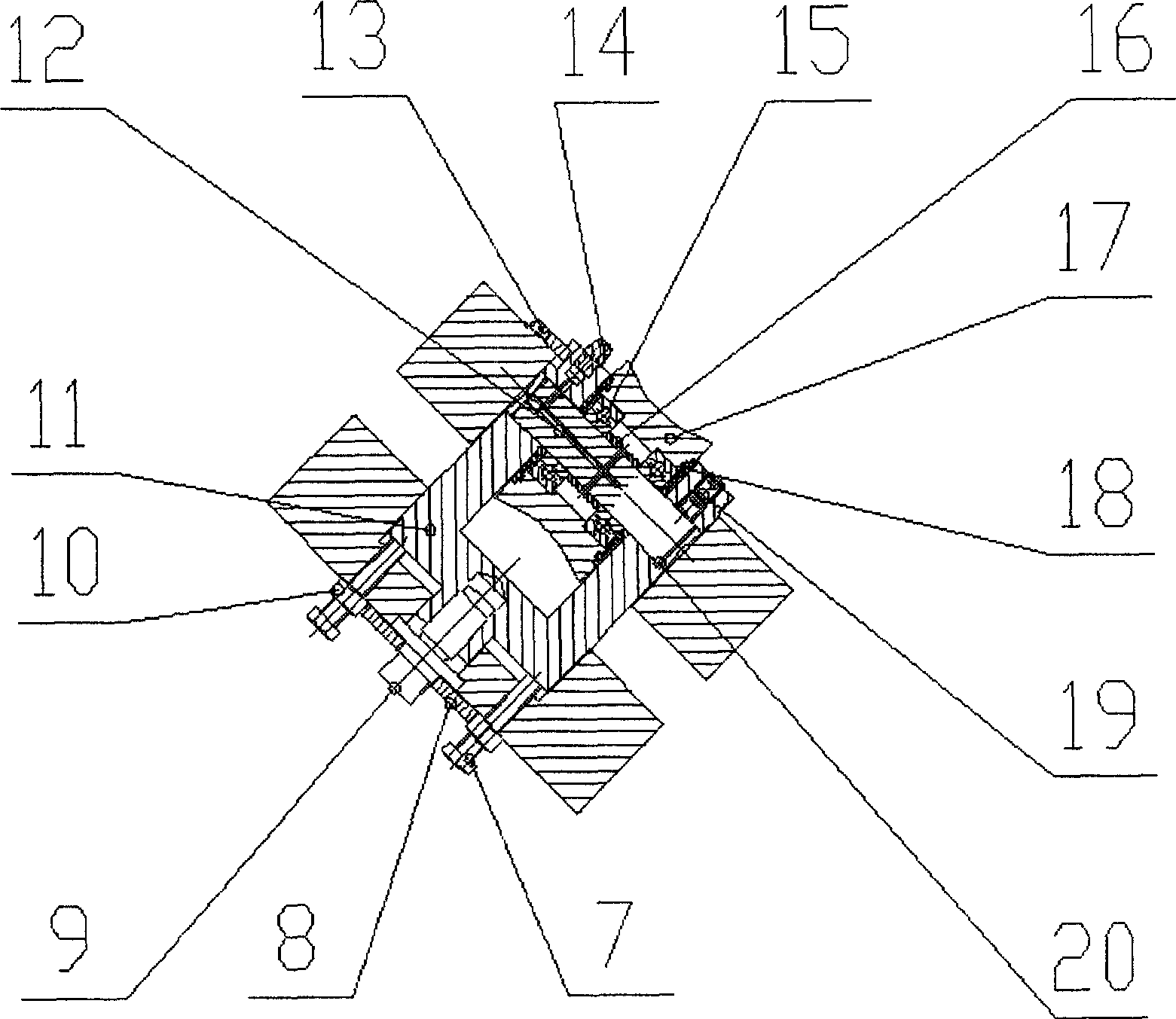

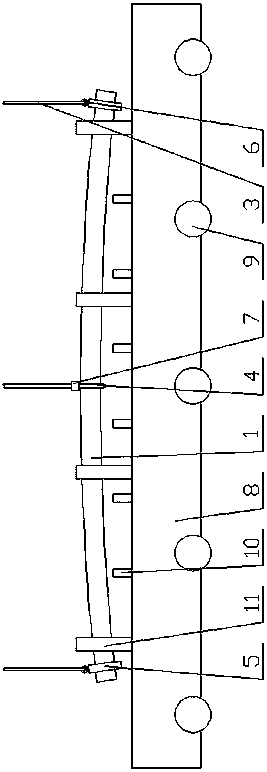

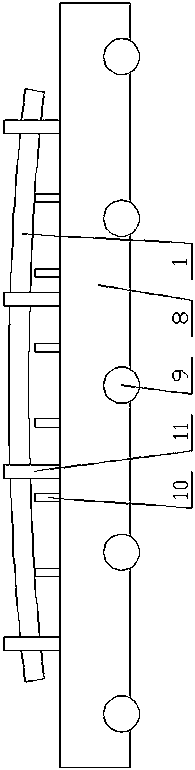

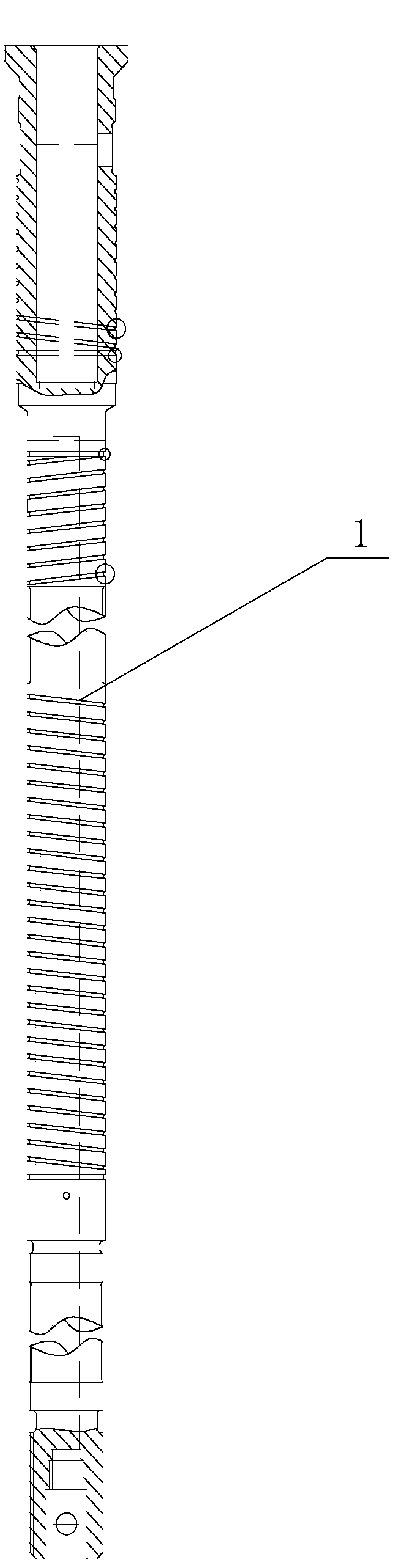

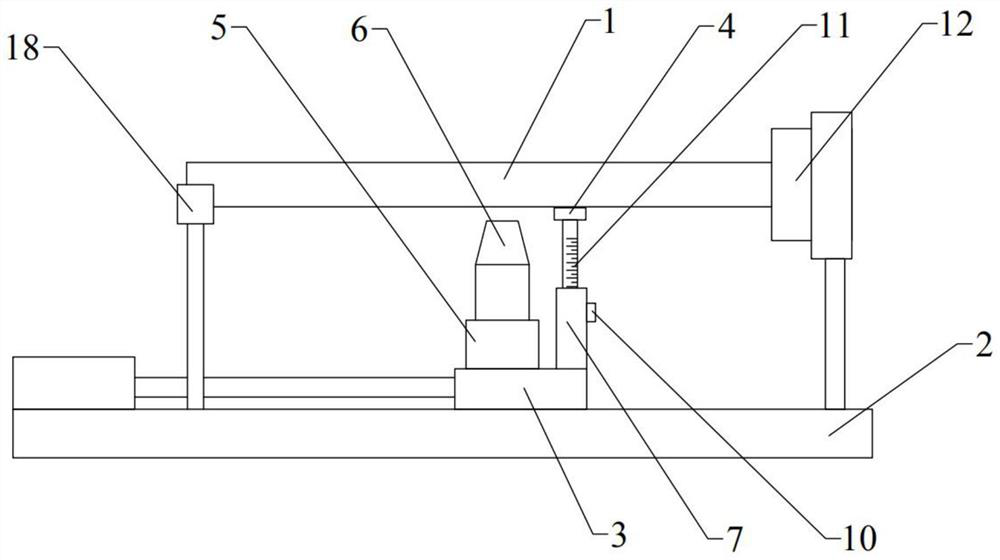

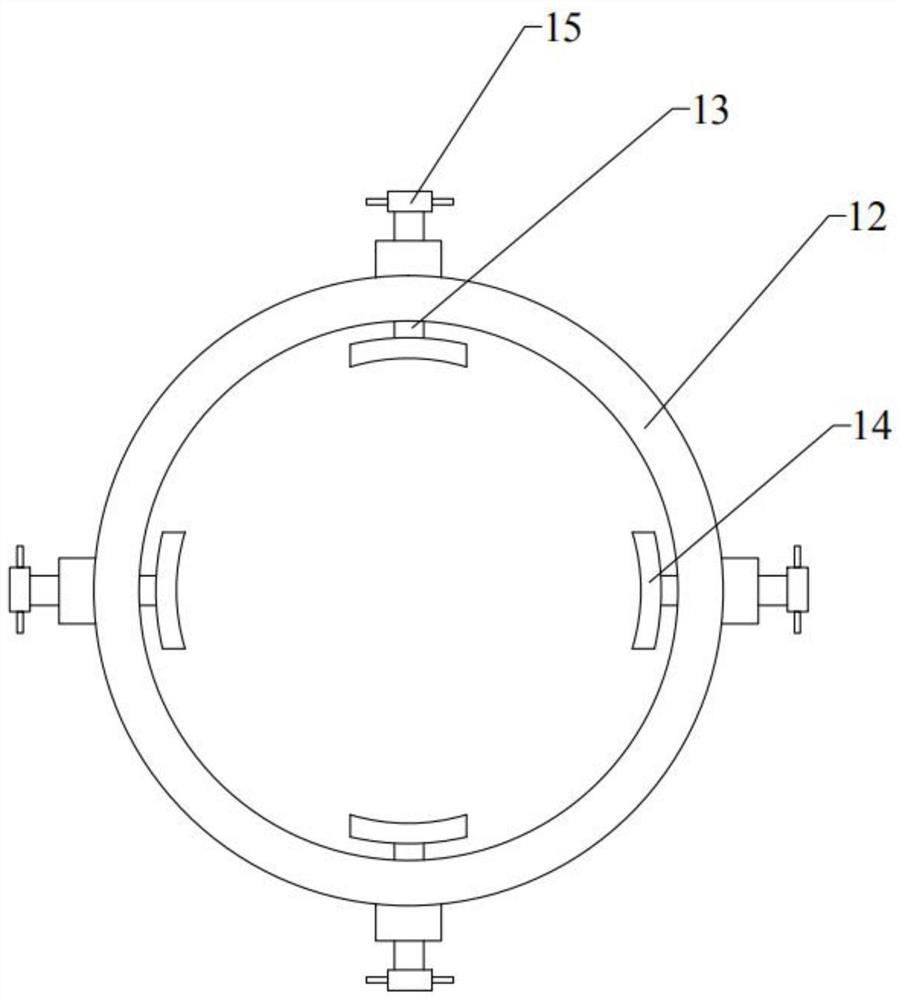

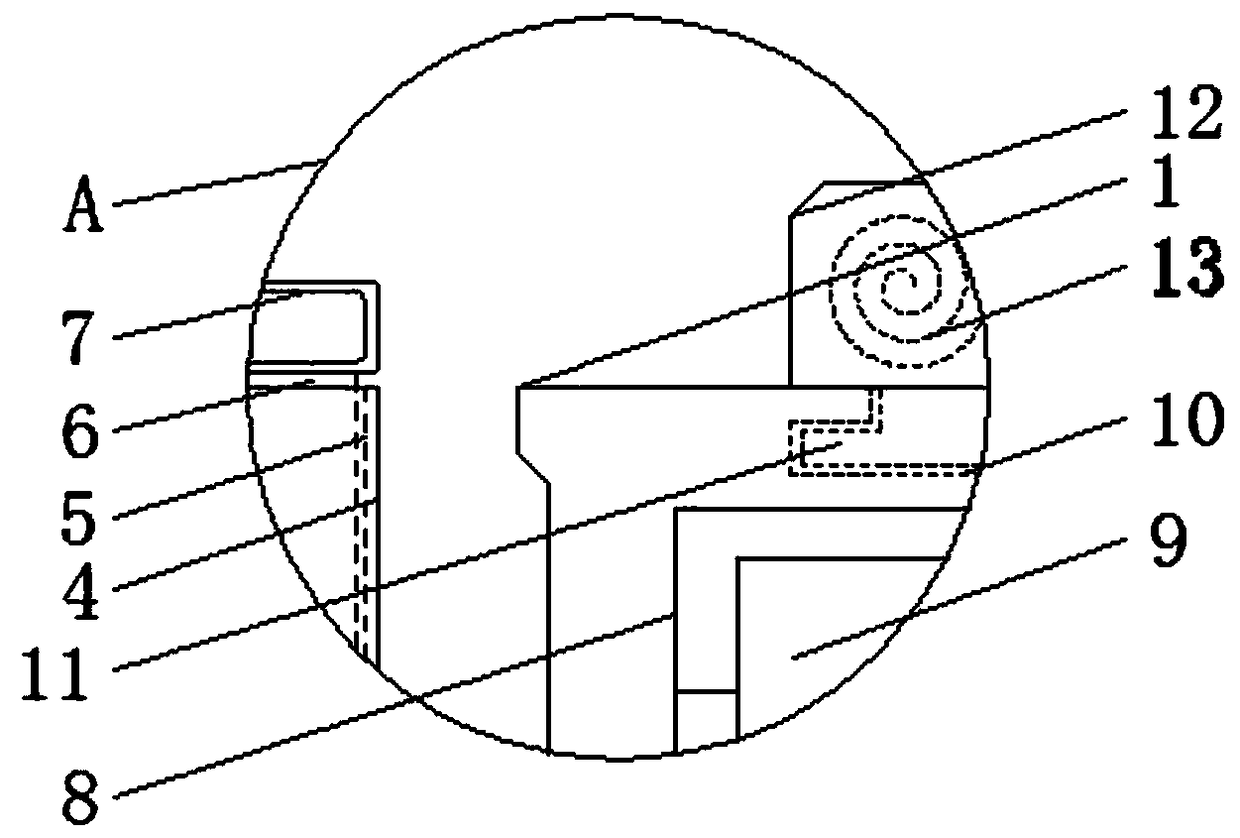

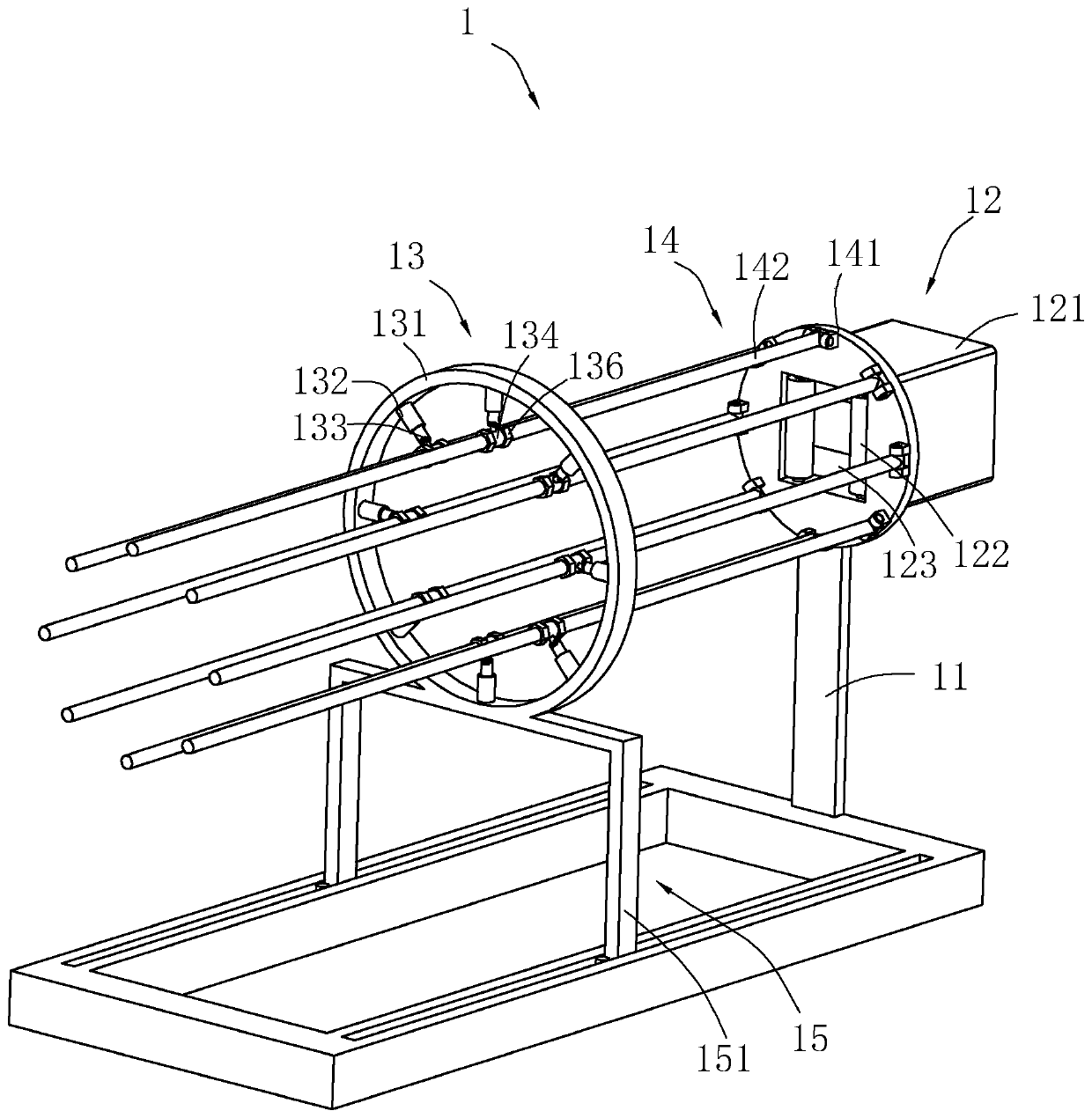

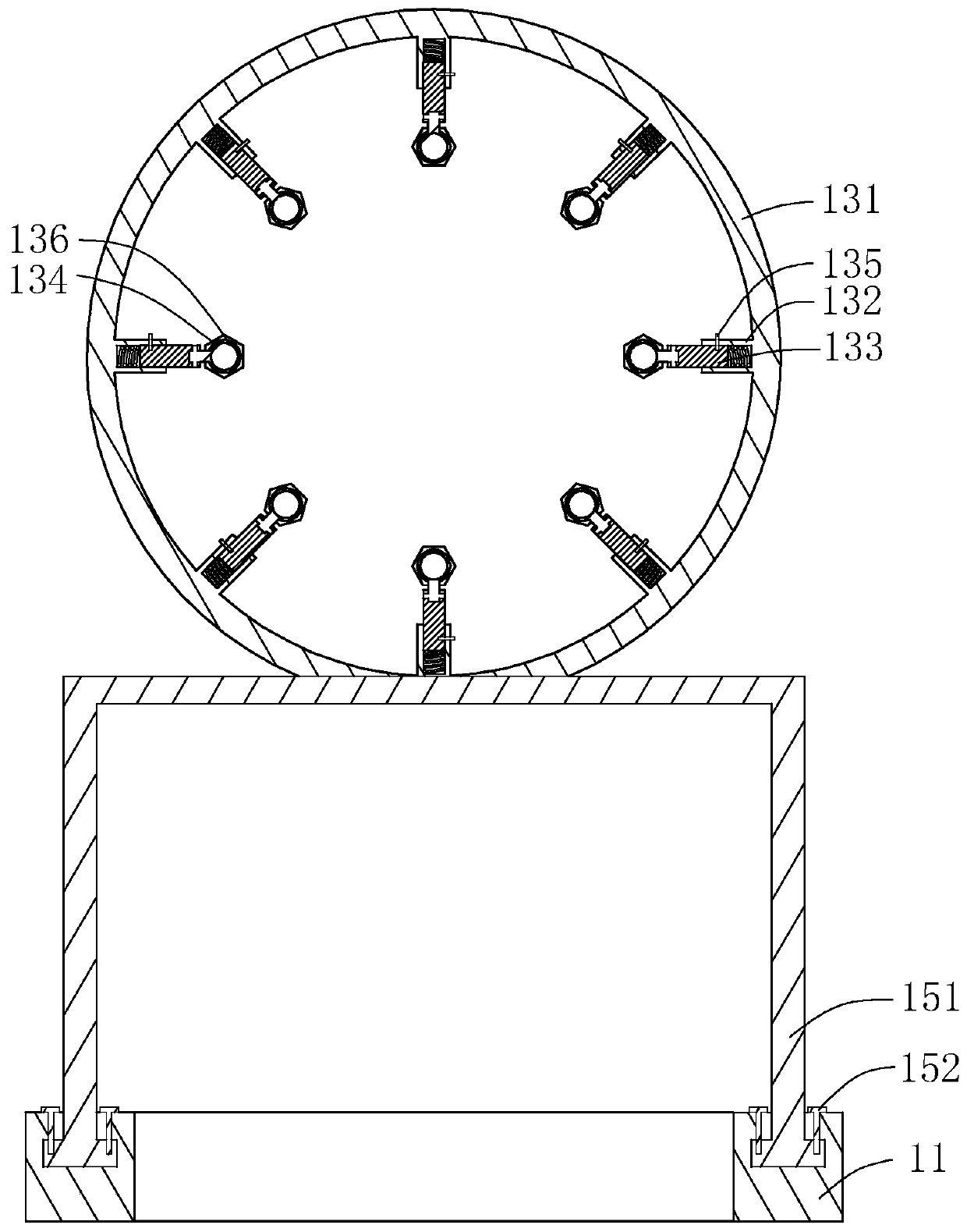

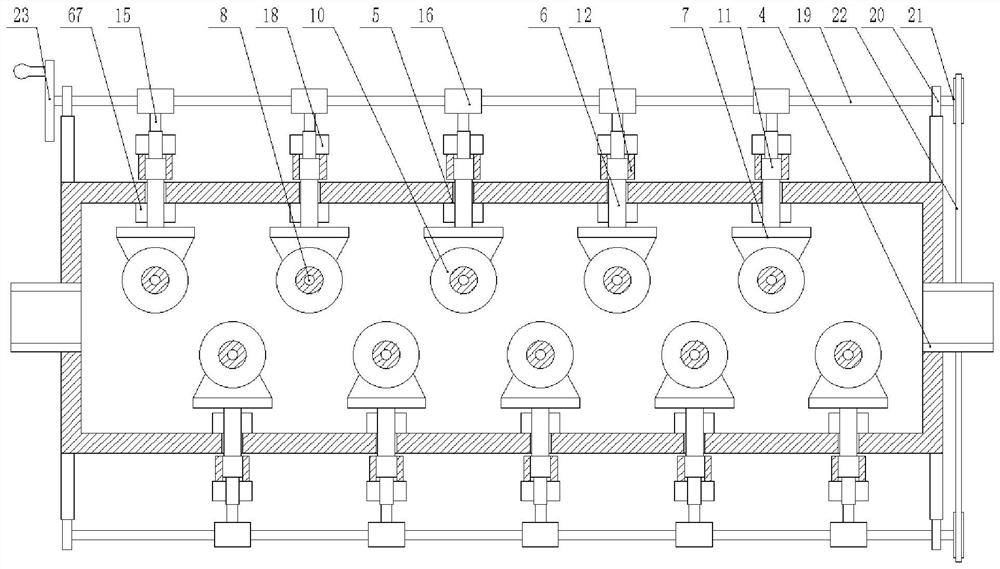

Rotating-hoop web-roll type straightener of a straightening cutting machine and straightening method thereof

The invention relates to a rotating-hoop web-roll type straightener of a straightening cutting machine and a straightening method thereof. The straightener consists of a motor, a motor belt wheel, a belt, a rotating hoop belt wheel, a bearing stand, a rotating hoop, a locking bolt, a gland bush, an adjusting screw mandril, a lock nut, a roller frame, a roller shaft, a dental plate, an oil nozzle, a bearing, a sleeve, a hyperboloid straightening roll, a close cover, a locking screw and a check ring; one side of the motor is provided with the motor belt wheel; the rotating hoop belt wheel is arranged above the motor belt wheel; the belt is sleeved on the periphery of the motor belt wheel and the rotating hoop belt wheel; the bearing stand is arranged on one side of the rotating hoop belt wheel; two ends of the rotating hoop are provided with the bearing stand; the middle part of the rotating hoop is horizontally provided with at least one mounting hole, and the middle part of the lateral surface of the rotating hoop is provided with at least one observation window; and the mounting hole is provided with a straightening roll component. The mounting angle of the straightening roll can be conveniently adjusted by the dental plate, the rolling reduction of the straightening roll can be conveniently adjusted by the adjusting screw mandril, and the locking bolt is locked after the position of the straightening roll is adjusted. When working, the straightening roll rotates along with the rotating hoop at a high speed and also rotates around the axes of the straightening roll.

Owner:LUOYANG TIHOT RAILWAY MACHINERY MFG

Annealing self-weight straightening method for P5 alloy steel continuous casting round billet

The invention discloses an annealing self-weight straightening method for a P5 alloy steel continuous casting round billet. The annealing self-weight straightening method for the P5 alloy steel continuous casting round billet comprises the steps that the two ends of the round billet are lifted up, and the round billet is rotated to enable a bent portion to face upwards through a lifting rope arranged in the middle of the round billet; and then the round billet is put on a trolley type annealing furnace, the soaking time is prolonged when annealing is conducted, it is guaranteed that the cooling speed of the trolley type annealing furnace is within the range from 25 DEG C / h to 35 DEG C / h, and when the temperature reaches 200 DEG C, the round billet is taken out of the furnace and air-cooledto the room temperature. According to the annealing self-weight straightening method for the P5 alloy steel continuous casting round billet, the bent round billet achieves automatic straightening under the action of the self weight through an annealing technology, no additional straightening technology is needed, the saw cutting scrap amount of the P5 continuous casting round billet is decreased,the cost is reduced, and the production efficiency is improved.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

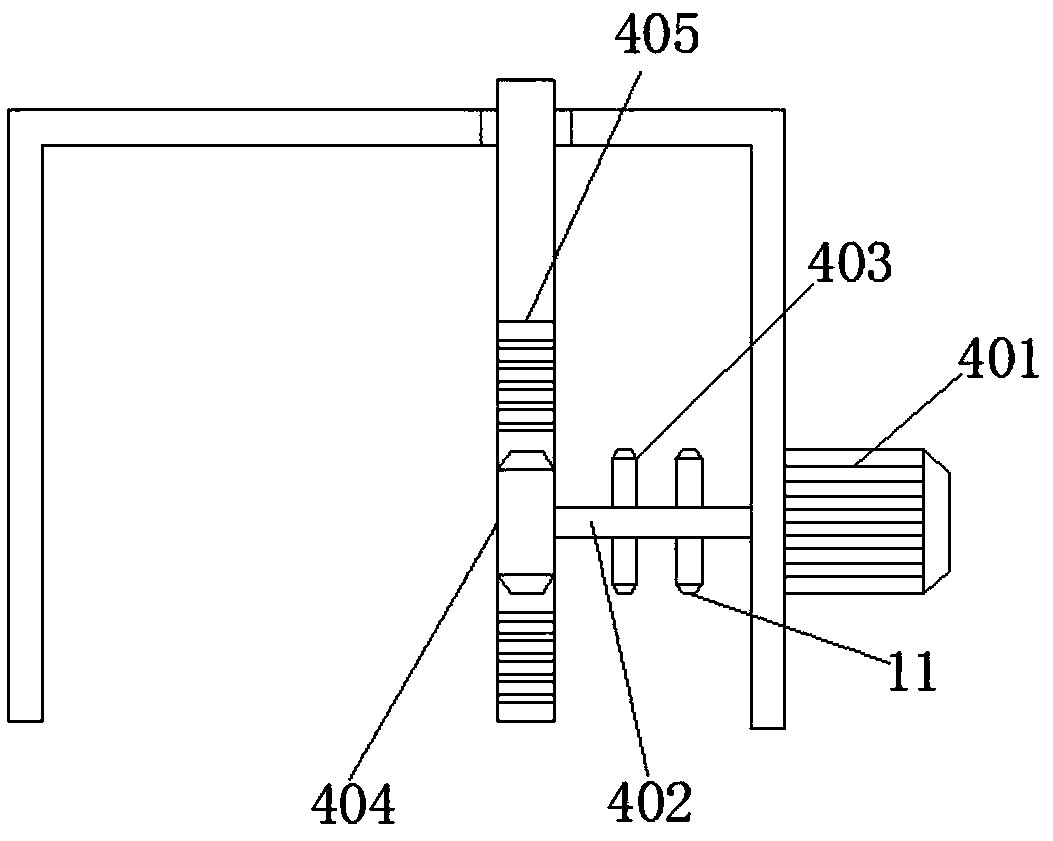

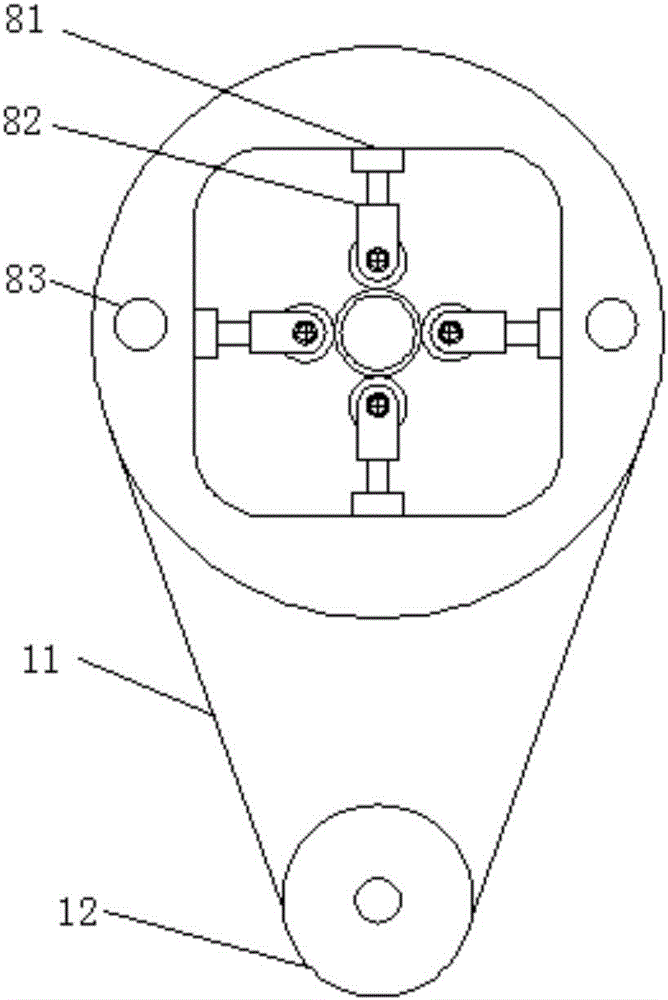

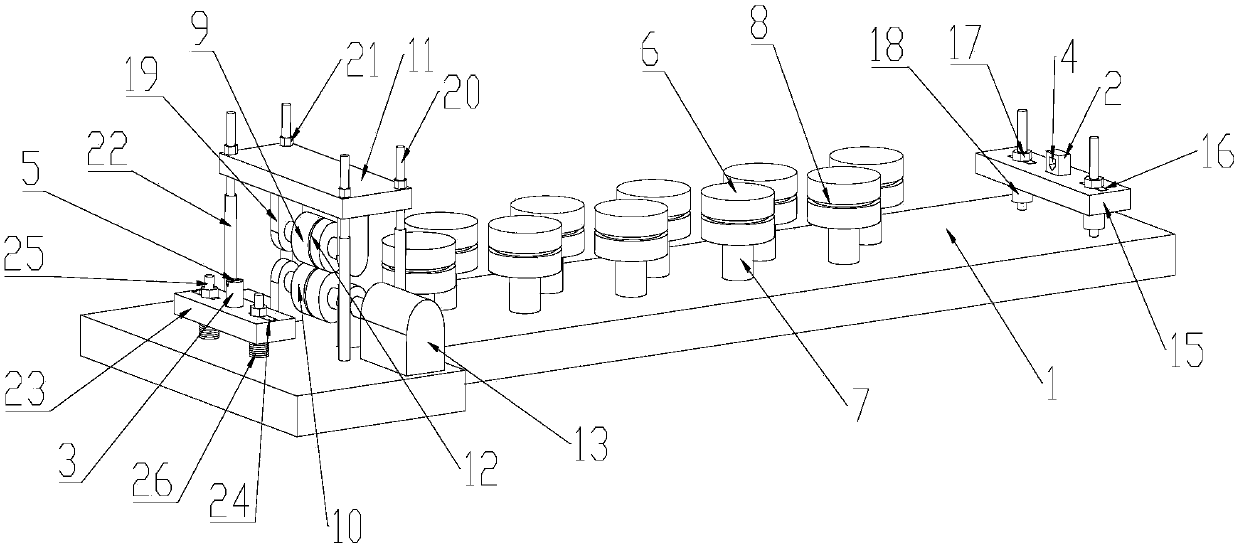

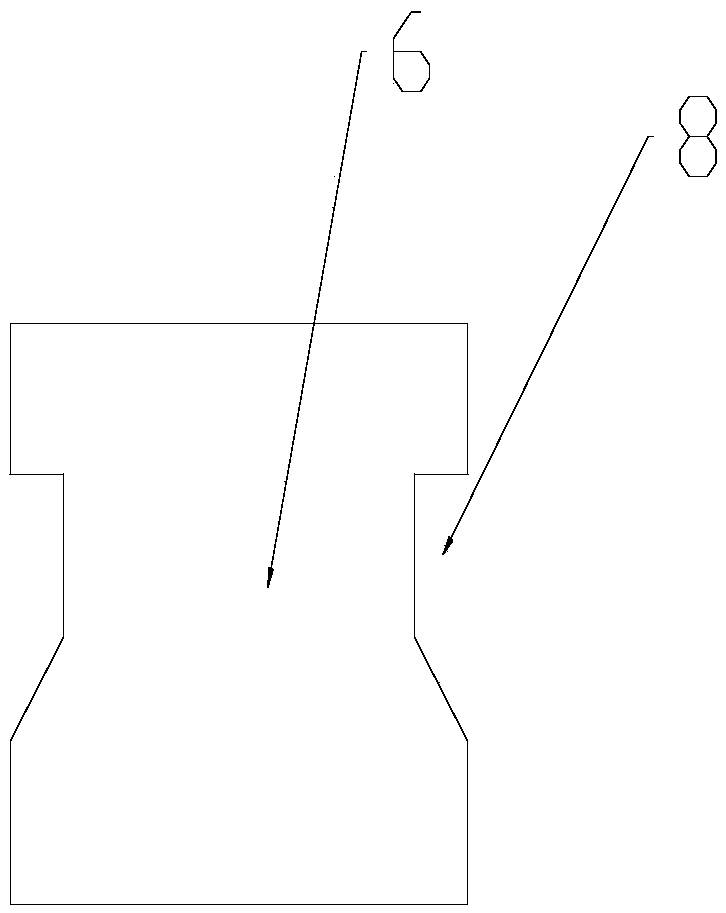

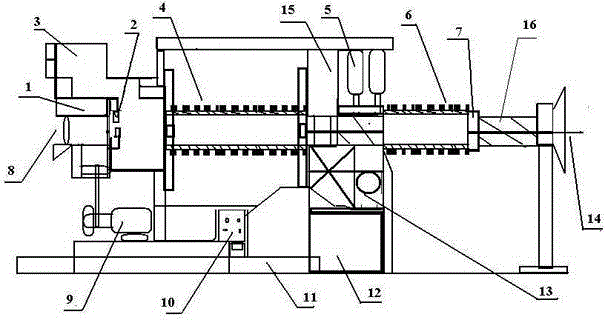

Special reinforcing steel bar straightening and cutting-out integrated equipment for constructional engineering

The invention discloses special reinforcing steel bar straightening and cutting-out integrated equipment for constructional engineering. The special reinforcing steel bar straightening and cutting-outintegrated equipment is composed of a base, a straightening machine and a cutting machine, wherein the straightening machine is fixedly connected with the base. A motor used for providing rotating torque is arranged on the lower portion of the base, the motor is fixedly connected with the base, and the motor is rotatably connected with the straightening machine arranged on the surface of the baseand used for straightening reinforcing steel bars through a belt; and the straightening machine is fixedly connected with the base, and the cutting machine used for cutting the reinforcing steel barsis arranged on one side of the straightening machine. A cutting device is arranged on a crate, after straightening work is completed, the reinforcing steel bars can be directly cut out according to working requirements, the operating time is greatly saved, the operating efficiency is improved, and meanwhile the problem that secondary bending of the reinforcing steel bars is caused in the later subsequent carrying process is effectively solved.

Owner:韩为国

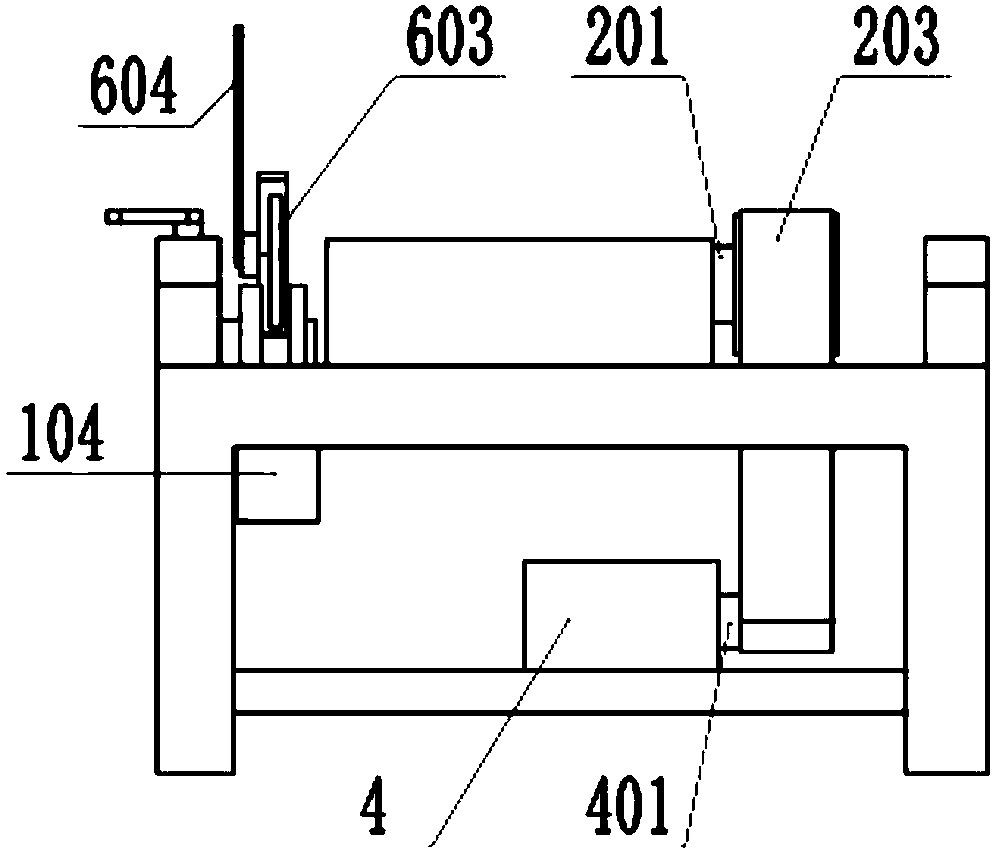

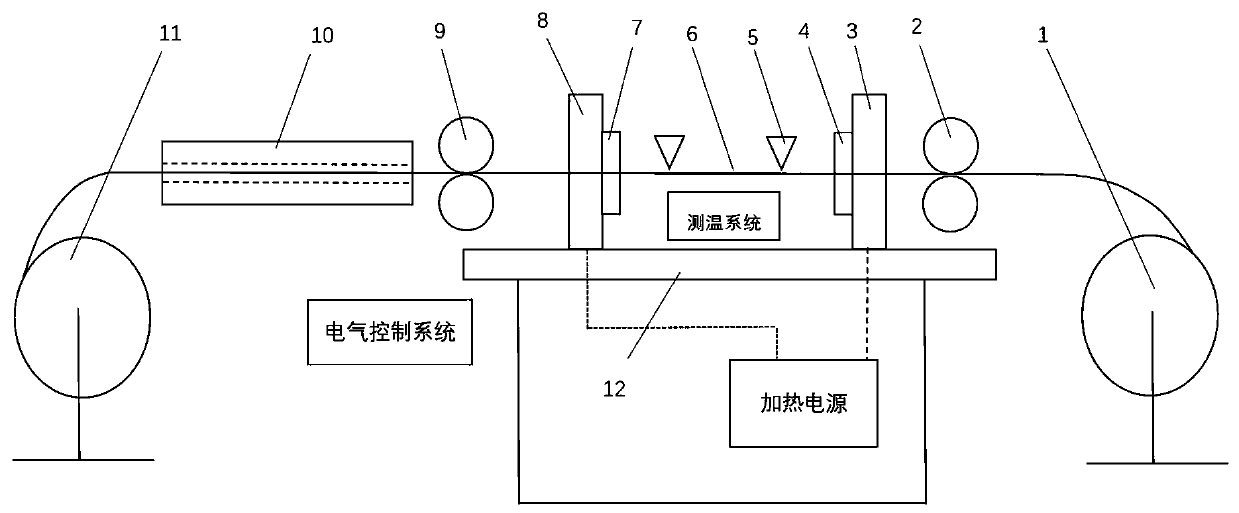

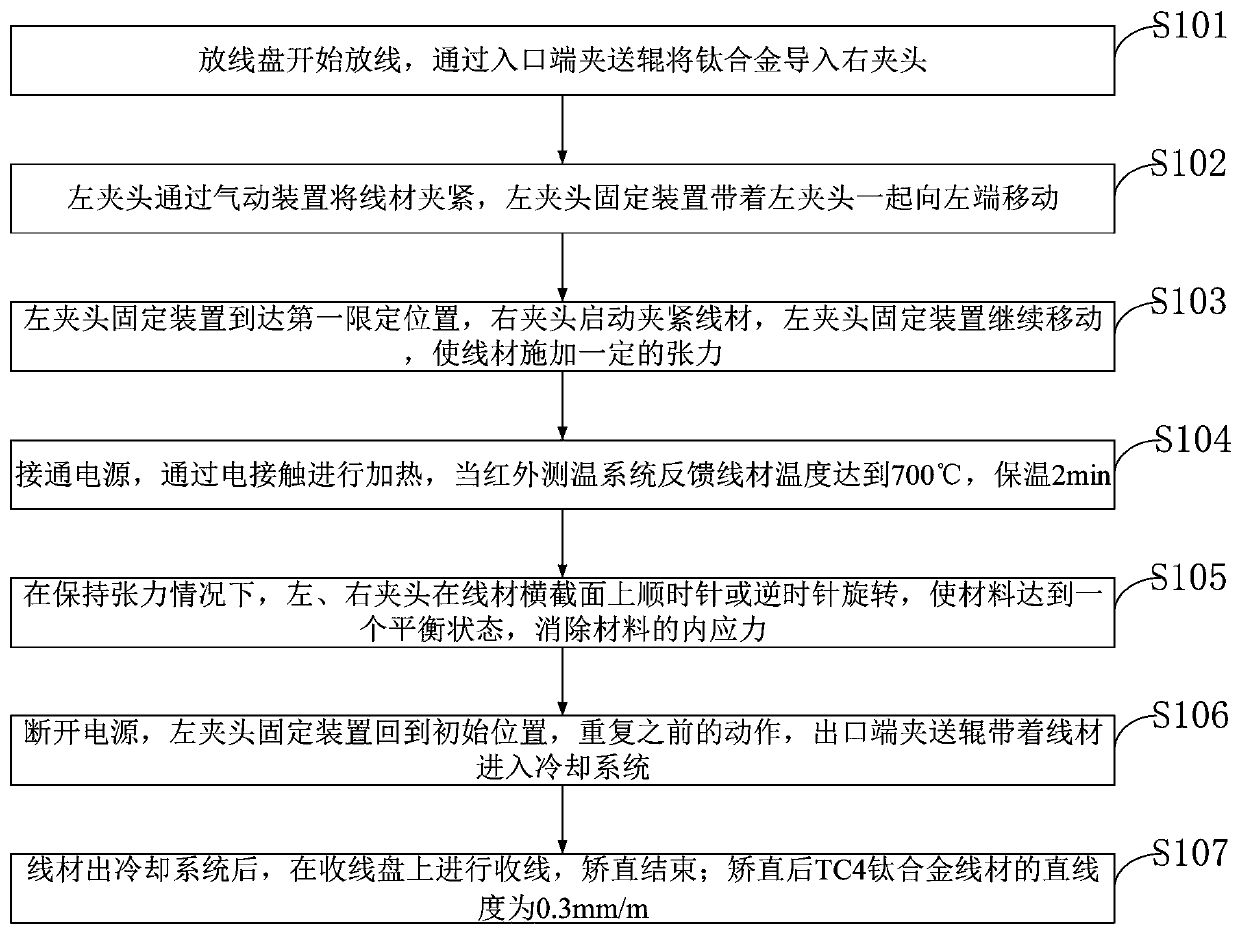

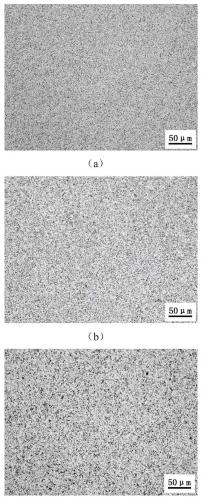

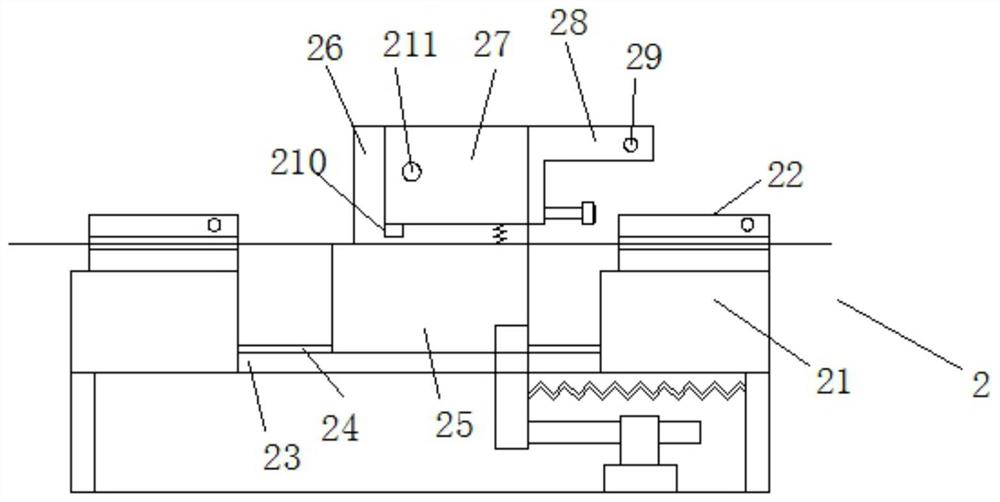

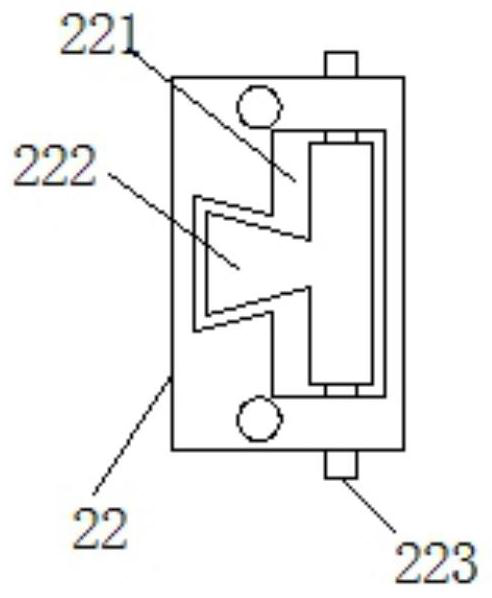

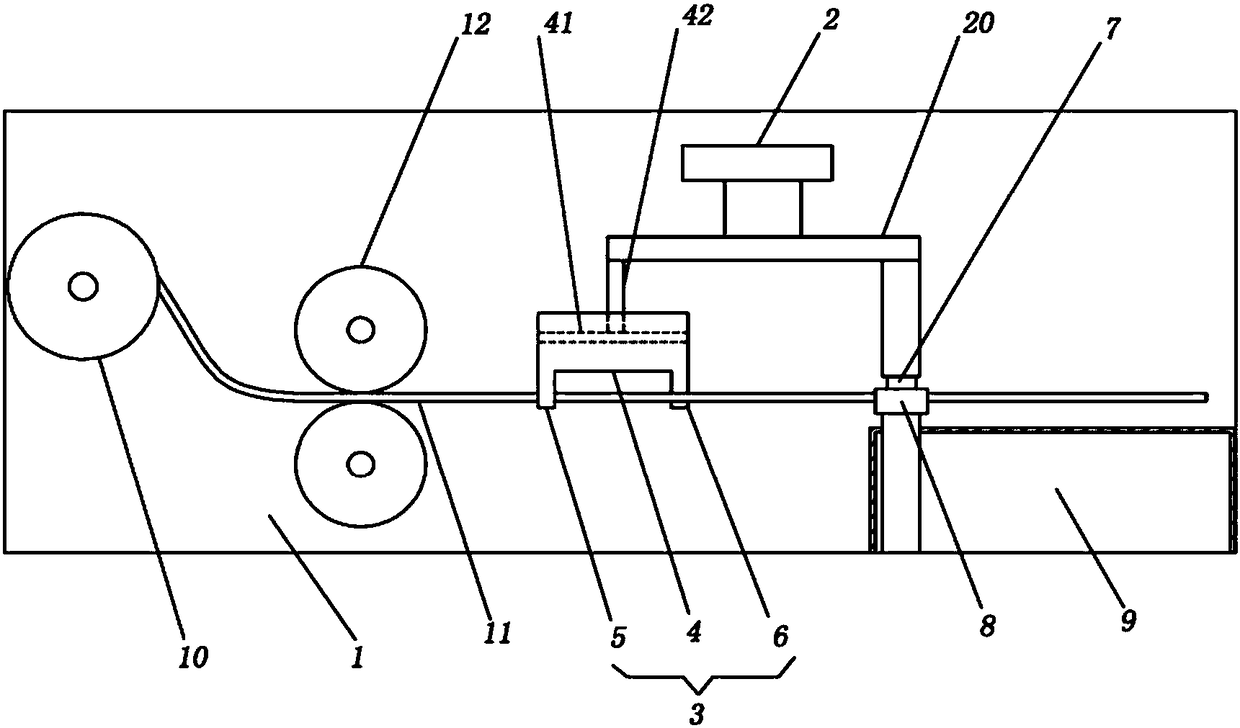

Alloy wire straightening method and system and application

InactiveCN111390062ASolve the problem of low straightening efficiencyYield limit reachedWire rodStructural engineering

The invention belongs to the technical field of titanium alloy wires, and discloses an alloy wire straightening method and system and an application. Feeding is performed by a feeding device, and an alloy wire is stably led into a right clamping device through an inlet pinch roller device; a left clamping and fixing device pulls the alloy wire out of the right clamping device through a left chuck,moves to the left end, and stops at a first limited position; when the left clamping and fixing device reaches the first limited position, a right chuck begins to clamp the alloy wire; the left clamping and fixing device continues to move leftward, so that the alloy wire has a certain tension; the alloy wire is heated to straightening temperature, and the temperature is fed back by a temperaturemeasuring system; the left and right chucks carry the alloy wire to rotate clockwise or counterclockwise on the cross section to eliminate internal stress of the alloy material. The straightened titanium alloy wire has good straightening effect, and straightness is smaller than or equal to 0.5 mm / m. The method and system can straighten a plurality of wires simultaneously, and are simple and convenient to operate and have high production efficiency.

Owner:西安圣泰金属材料有限公司

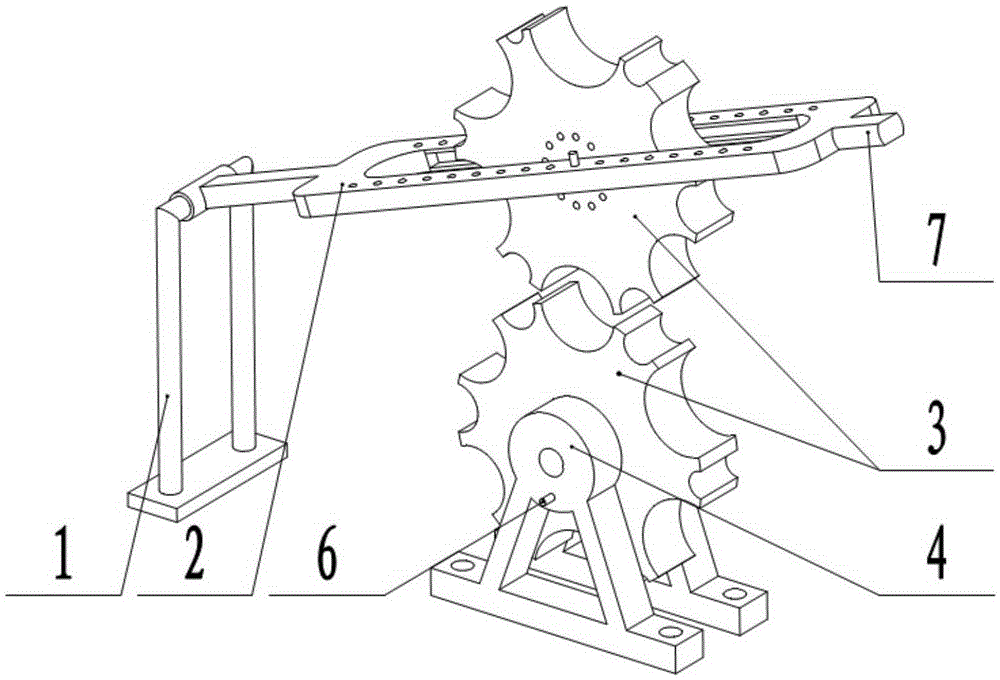

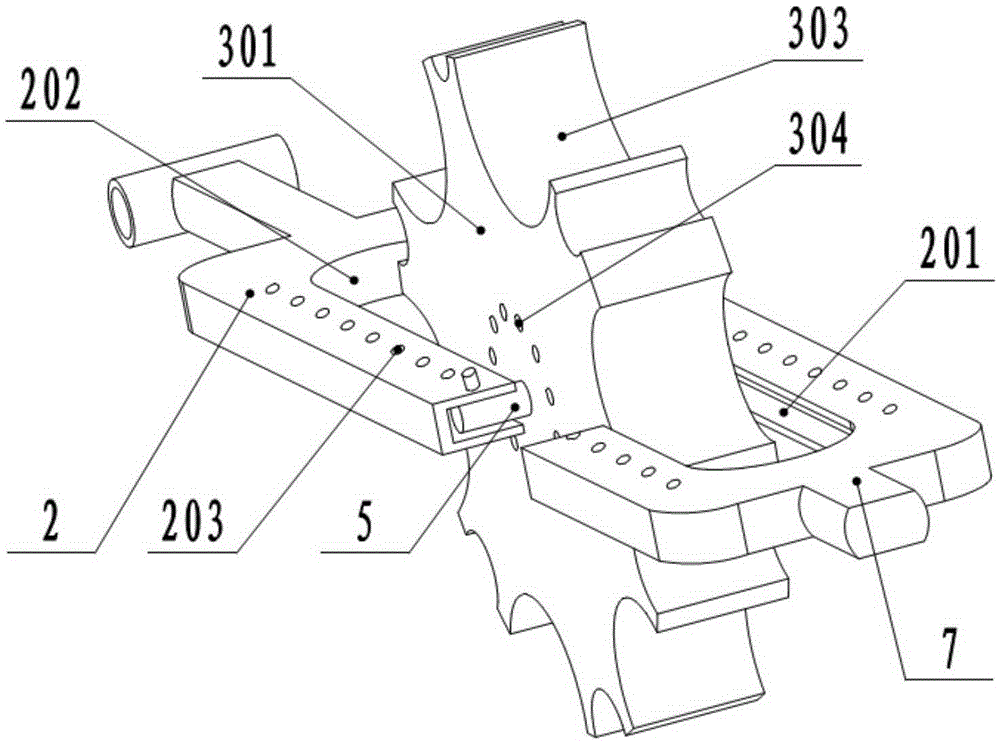

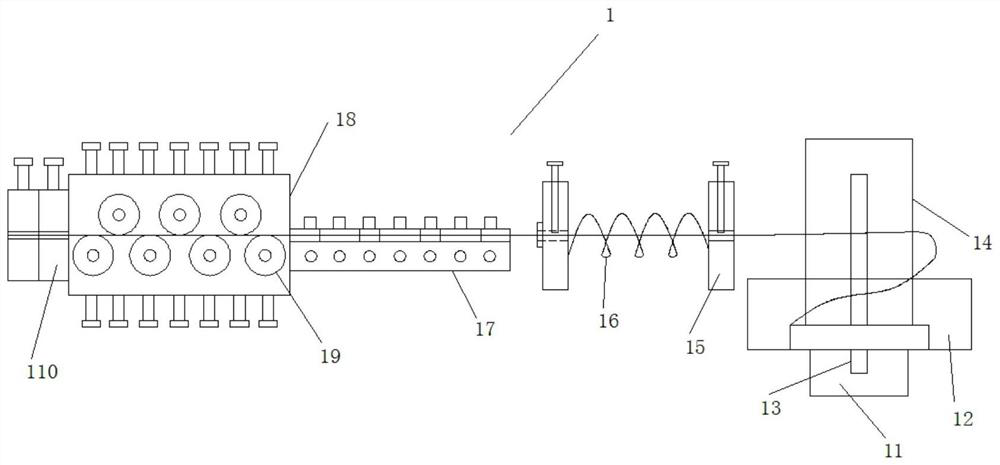

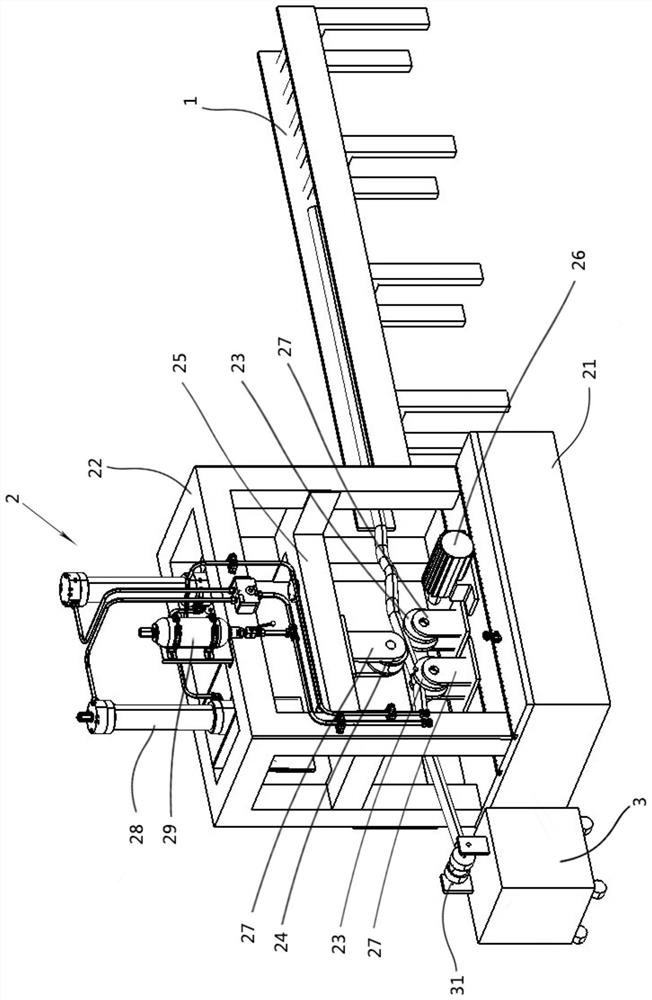

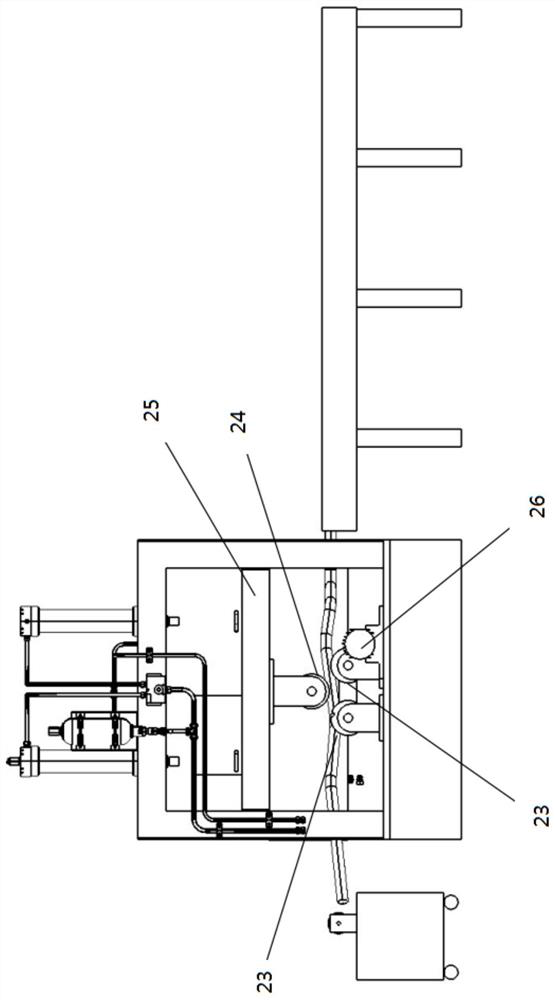

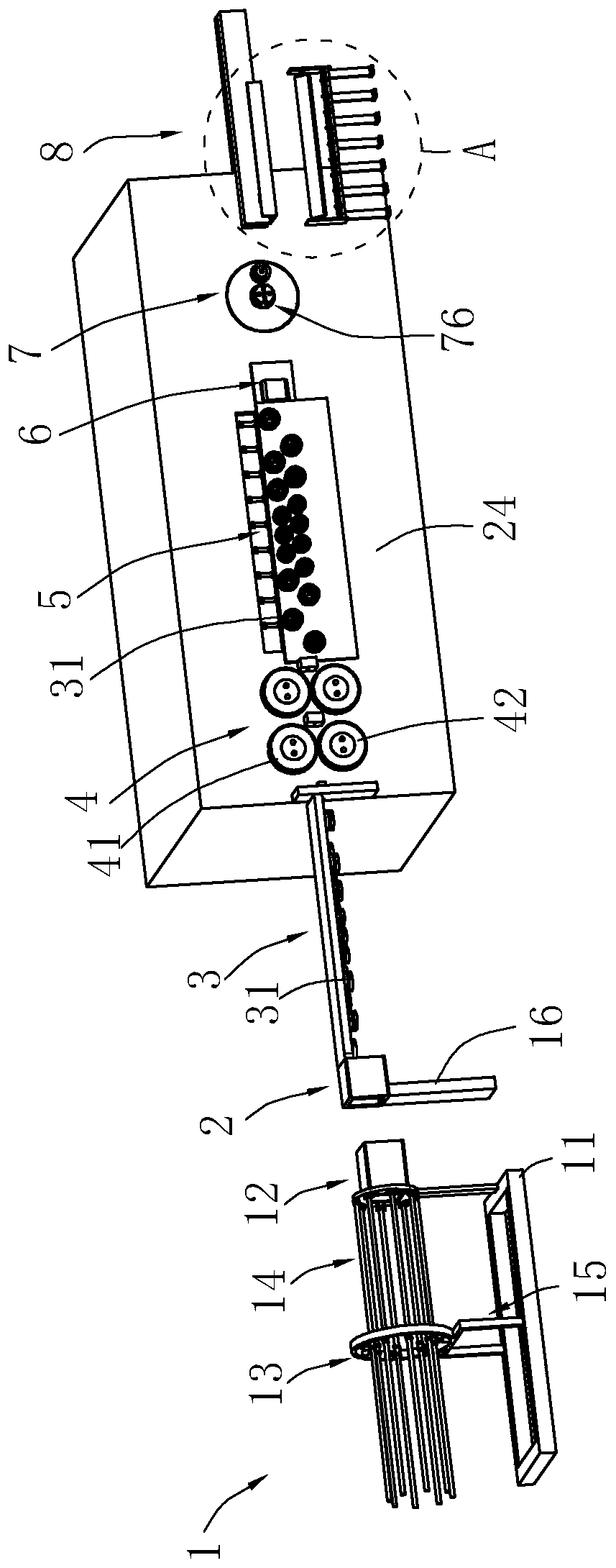

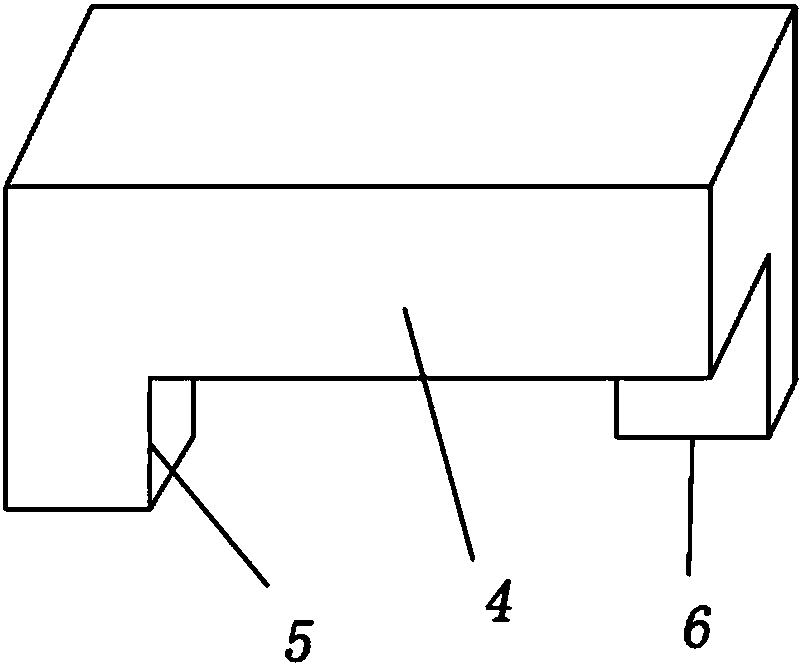

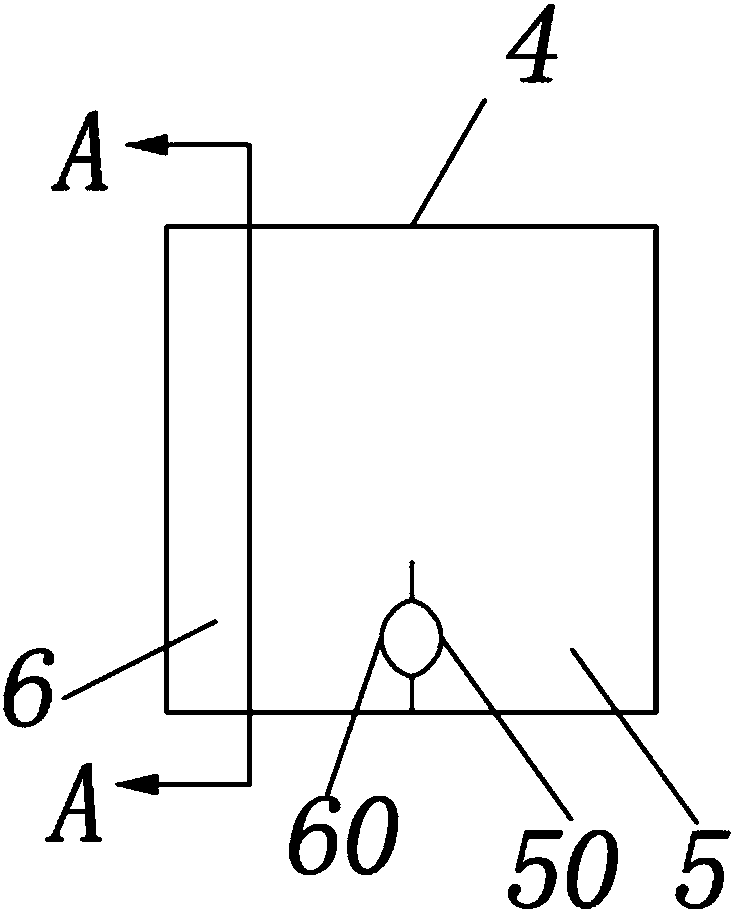

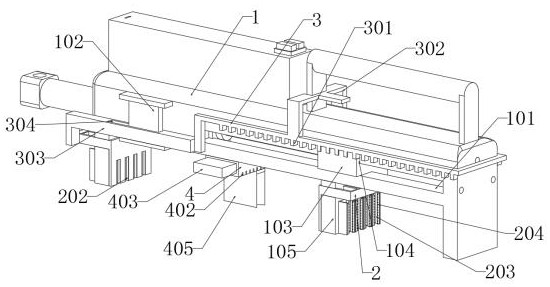

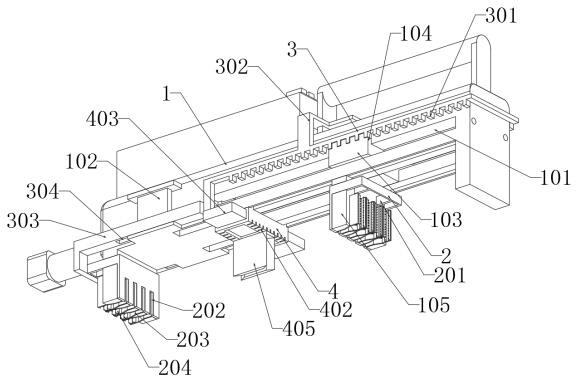

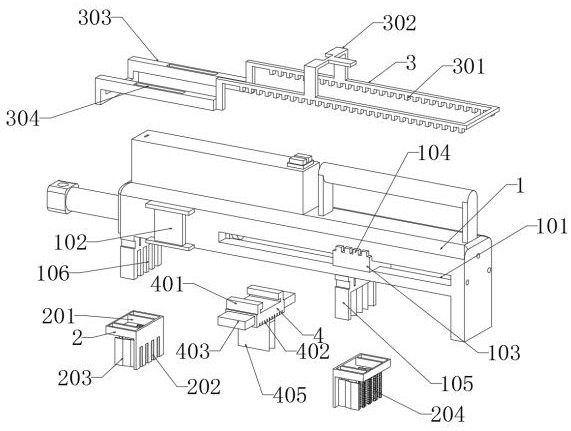

Machining system for chain with firm structure

PendingCN113560462AGood straightening effectConsistent cut lengthMetal chainsManufacturing engineeringMachining system

The invention discloses a machining system for a chain with a firm structure, and relates to the technical field of chain machining. An unwinding and straightening device is arranged at an input end of a conveying device, a shearing device is arranged at an output end of the conveying device, the shearing device is arranged on one side of a bending device, the conveying device, the shearing device and the bending device are driven by a linkage driving device, an unwinding mechanism drives steel wire coils to rotationally unwind, unwound steel wires enter a straightening mechanism after being guided by a guiding mechanism and then enter a straightening arrangement mechanism from the straightening mechanism, the arranged steel wires are conveyed to the shearing device through a moving seat of the conveying device, and after the shearing device shears the steel wires, the steel wires are bent and machined into the chain through the bending device. The machining system has the advantages that the chain with the firm structure can be machined, fabric cannot be scratched at a connector of the chain, the chain can be effectively fixed during conveying, the shearing lengths of the steel wires are consistent, linkage driving is realized by a plurality of mechanisms, the production efficiency is high, and the production cost is low.

Owner:如皋市淇奥五金制品有限公司

Valve rod bending and deforming straightening process

InactiveCN108856367AGood straightening effectImprove straightening efficiencyMetal working apparatusEngineeringRoom temperature

The invention relates to a straightening process, in particular to a valve rod bending and deforming straightening process and belongs to the field of machining. The valve rod bending and deforming straightening process aims to solve the problems that an existing valve rod bending and deforming straightening method is long in period, unstable in deforming control and large or small in deforming changing, and multi-time repeated pressing of a high point is needed. The valve rod bending and deforming straightening process includes the steps that firstly, a valve rod needing to be restored is installed on a grinding machine, the two ends of the valve rod are tightly ejected with centres, a grinding machine is started, the bouncing and deforming quantity of the valve rod is inspected, and a high point on the valve rod is marked with a marking pen; secondly, the valve rod is freely placed on the ground, and the high point marked in the first step faces upwards; thirdly, a gas welding deviceis adopted, and the high point of the valve rod is heated; and fourthly, the valve rod is naturally cooled to room temperature, then the valve rod is installed on the grinding machine, the two ends of the valve rod are ejected tightly with the centres, the grinding machine is started, the bouncing and deforming quantity of the valve rod is inspected, and if valve rod straightening is not in place, the steps from the first step to the third step are repeated.

Owner:HARBIN TURBINE

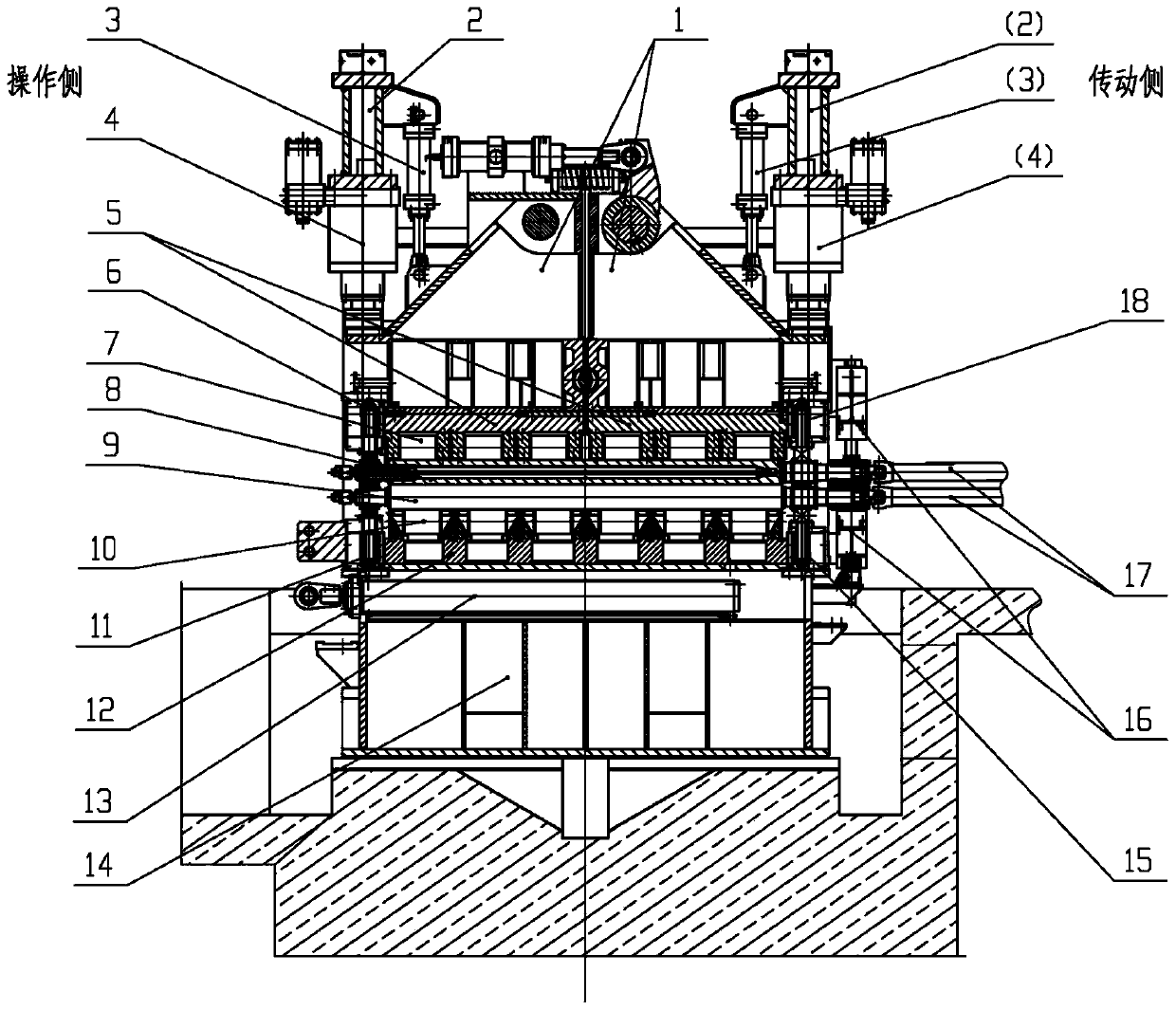

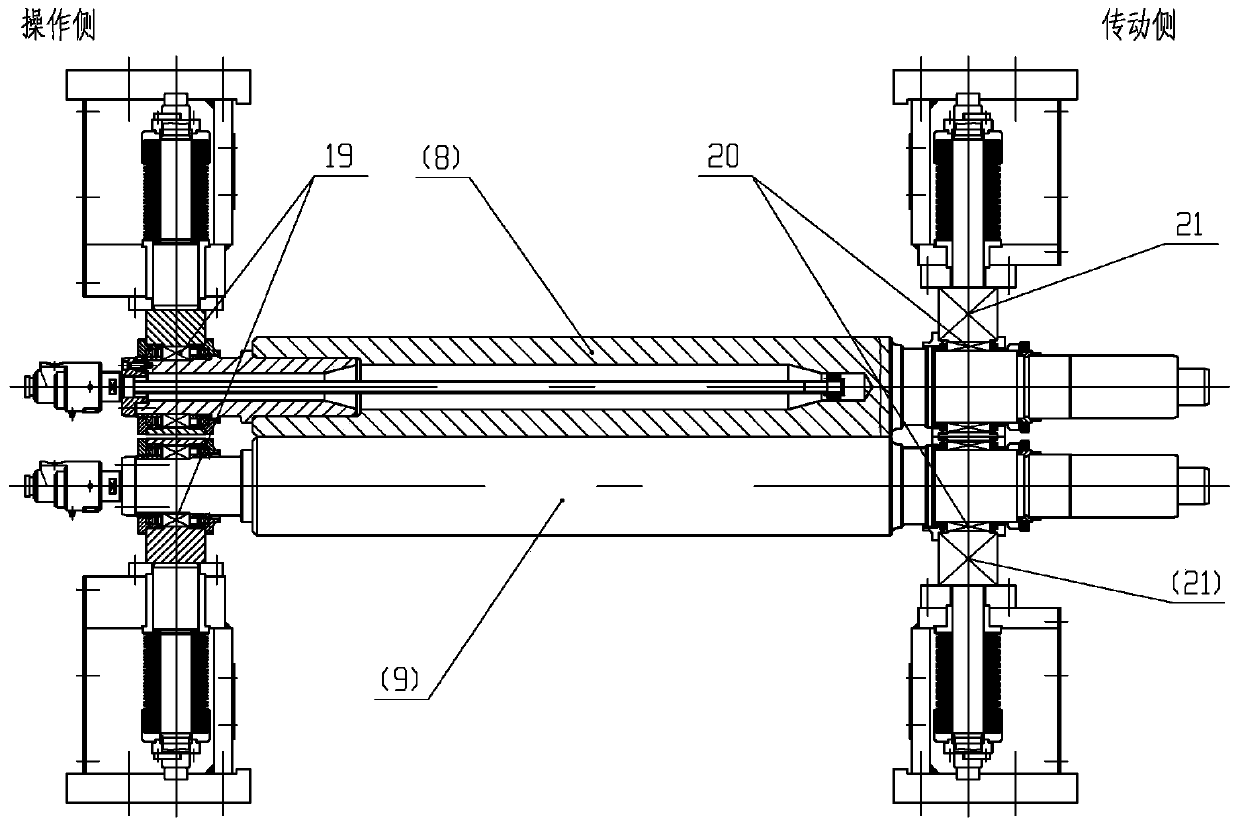

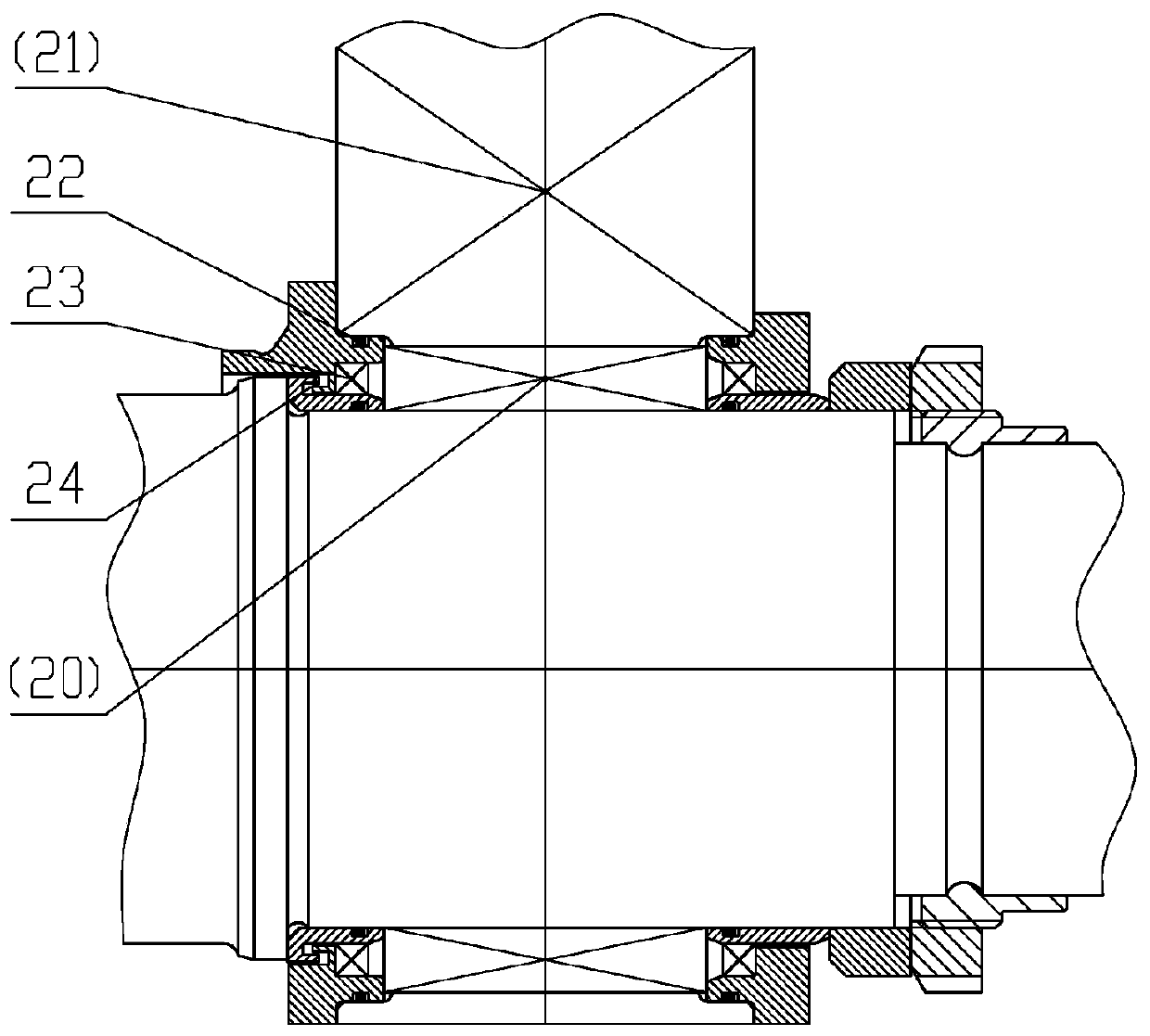

Hot straightening machine

PendingCN110877064AChange the fragile status quoChange the straightening effectMetal rolling arrangementsNeedle roller bearingWork roll

The invention belongs to the field of steel rolling, and relates to a hot straightening machine. The hot straightening machine comprises a memorial archway, a pressing-down roll-bending device, a balancing device, a pressing-down AGC cylinder, an upper roll box, a lower roll box, an upper roll box clamping device, a lower roll box clamping deice, a shaft connecting bracket, a transmission device and a roll changing device; and a needle bearing, or a cylindrical roller bearing or a sliding bearing mechanism is adopted by a transmission side of a working roll system. According to the hot straightening machine, the situation that a straightening plate cannot meet the product quality requirements due to the too large roll diameter, or a straightening roller / a universal joint is prone to beingdamaged to affect production due to the too small roll diameter is broken through; and the current situations that the roll diameter of the hot straightening machine is too large, the straightening plate cannot meet the product quality requirements, or the roll diameter is too small, and the straightening roller / the universal joint is prone to being damaged are completely changed, under the condition of reliable and normal production and covering the specification range of the straightening plate, the straightness of plate straightening is obviously improved, the product quality is obviously improved, the straightening effect is more obvious for plates, especially for wide, thin and high-strength plates, and thus the potential and great benefit effect is brought.

Owner:CISDI ENG CO LTD

Optical wand straightening device

PendingCN112250285AMeet straightening needsSave human effortGlass reforming apparatusOpticsLinear drive

The invention provides an optical wand straightening device. The optical wand straightening device comprises a base; a clamping mechanism used for clamping one end of an optical wand and a rotation driving device used for driving the clamping mechanism to rotate are arranged above one end of the base; a straightening platform is further arranged on the base in a sliding mode; one end of the straightening platform is connected with a linear driving device; the straightening platform is positioned below the optical wand, and the sliding direction of the straightening platform is parallel to thelength direction of the optical wand; a straightening plate is installed at the end, close to the clamping mechanism, of the straightening platform through a height adjusting mechanism, and a flame spray gun is installed at the end, away from the clamping mechanism, of the straightening platform through a gun rack. The optical wand is driven to rotate through the clamping mechanism and the rotarydriving device, the straightening platform is driven to slide through the linear driving device, the flame spray gun located on the straightening platform heats and softens the light bar firstly, andthen the softened optical wand is straightened and shaped through the straightening plate; the straightening platform slides from one end of the optical wand to the other end of the optical wand to complete straightening of the optical wand, repeated adjustment is not needed, manpower and material resources are saved, and the straightening effect is good.

Owner:久智光电子材料科技有限公司 +1

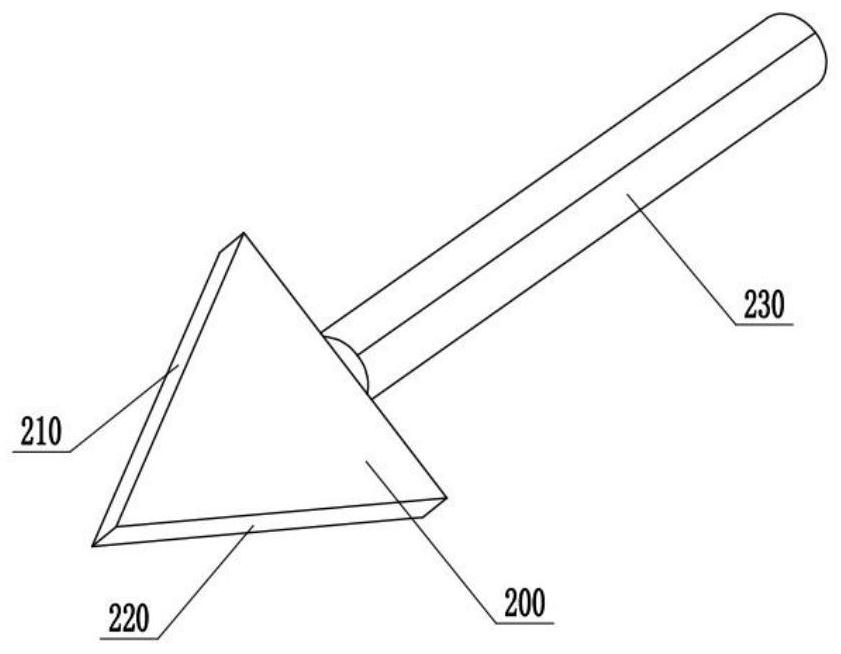

Anti-crowding lead straightening device in diode manufacturing process

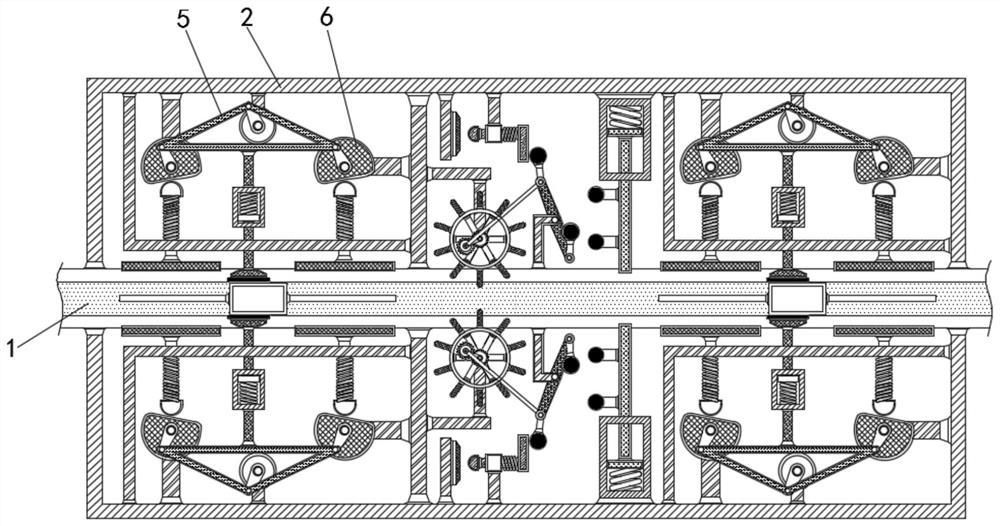

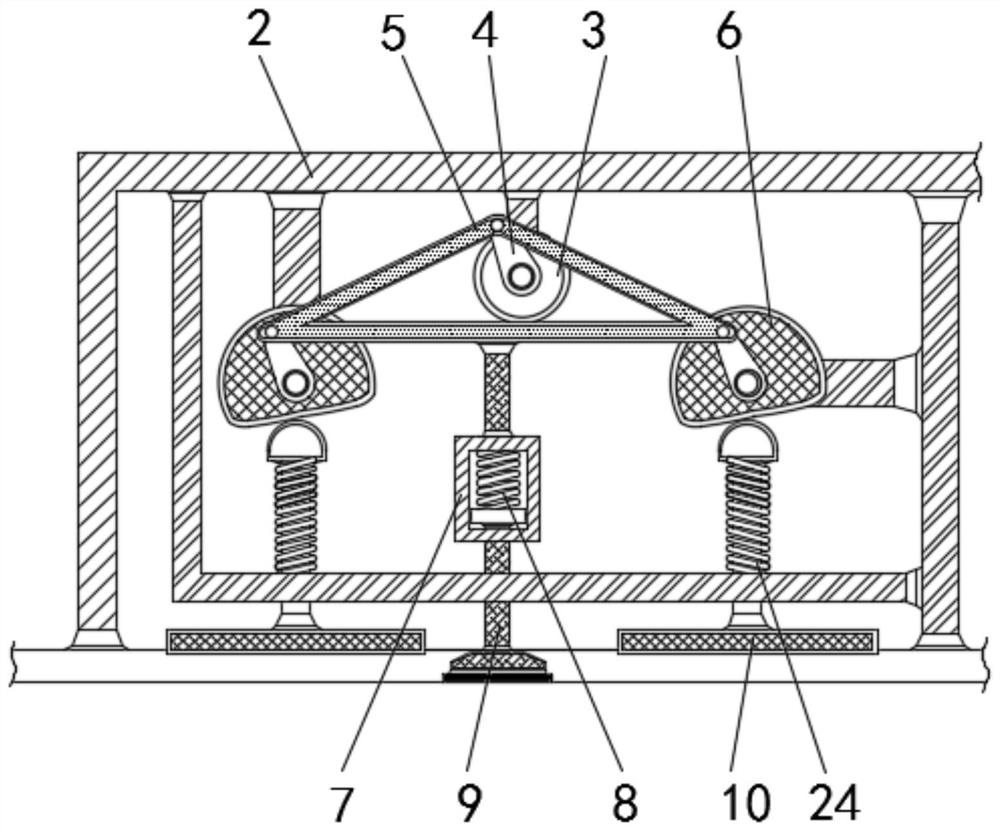

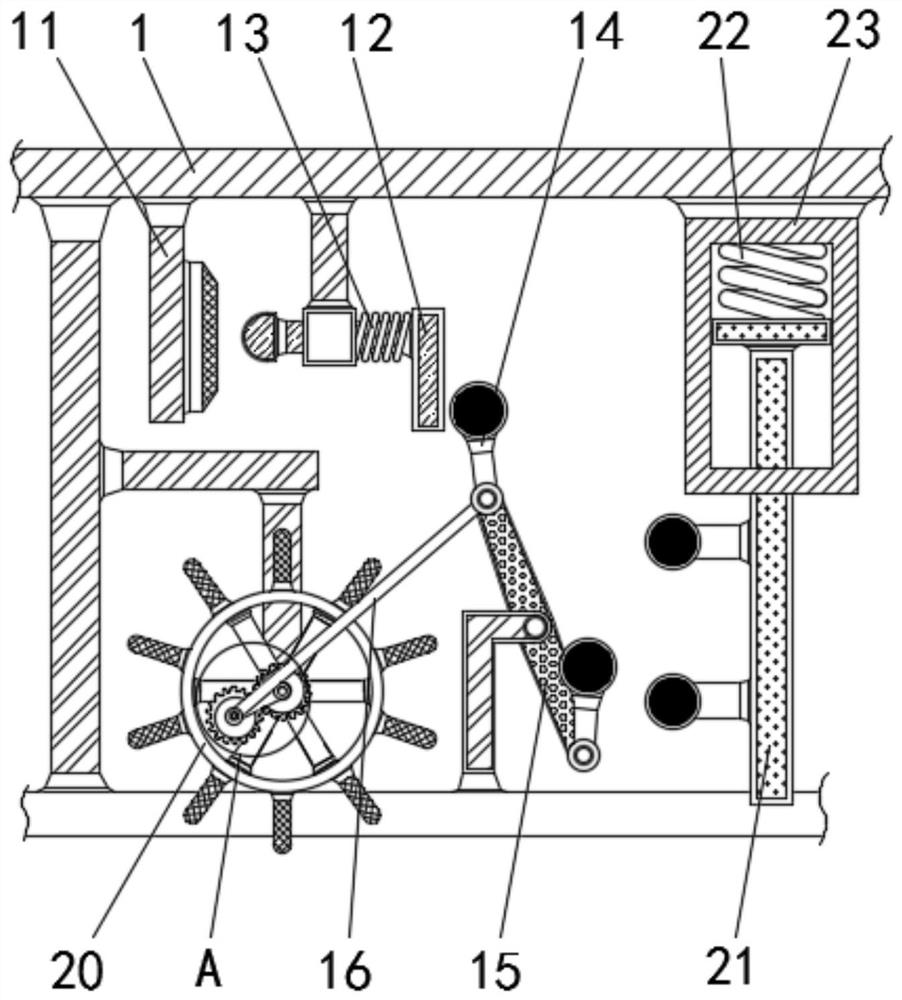

InactiveCN113130358AReduce consumptionSpeed up productionSemiconductor/solid-state device manufacturingSemiconductor devicesDrive wheelCrank

The invention discloses an anti-crowding lead straightening device in a diode manufacturing process. The device comprises a working tape, the upper and lower sides of the working tape are fixedly connected with shells, the inner sides of the shells are connected with driving wheels, the front sides of the driving wheels are fixedly connected with cranks, the front sides of the cranks are rotatably connected with triangular frames, and cams are arranged on the left and right sides of the right sides of the triangular frames. According to the anti-crowding lead straightening device in the diode manufacturing process, the cranks rotate and drive the triangular frames to shake at the same time so that the cams are synchronously driven to rotate, the triangular frames shake and drive conveying rods to synchronously move under the action of connecting blocks so that the conveying rods intermittently drive diodes to move from left to right, and meanwhile, when the cams rotate, straightening rods can move up and down under the action of fourth springs, so that the diode leads are automatically straightened. The structure achieves the effects of reducing manpower consumption and accelerating the production progress.

Owner:厦门啸丹贸易有限公司

Furnace discharge robot steel chisel straightening machine

PendingCN113877991AGood straightening effectImprove straightening effectElectric machineryStructural engineering

The invention relates to the technical field of steel machining treatment, and particularly discloses a furnace discharge robot steel chisel straightening machine. The furnace discharge robot steel chisel straightening machine comprises a feeding table, a straightening device and a mateiral guiding table which are sequentially arranged, wherein the straightening device comprises a base, a rack, at least two driving rollers, lower pressing rollers, a lifting support and a motor, the driving rollers are connected to the upper portion of the base in a rolling mode and both connected to the motor, the two driving rollers are in a straight line in the feeding direction and are consistent in height, one lower pressing roller is arranged above the middle position of every two adjacent driving rollers, all the lower pressing rollers are perpendicular to the axis of the feeding direction, at least one lower pressing roller is perpendicular to the horizontal plane, the lower pressing rollers are connected to the bottom of the lifting support in a rolling mode, and the lifting support is driven by a lifting mechanism and is slidably connected into the rack. According to the steel chisel straightening machine, a steel chisel can be straightened from several key directions, the straightening effect meets the material recycling requirement, the problem that the steel chisel is difficult to recycle is solved, cyclic utilization of materials is achieved, resource waste is reduced, and the production cost is reduced.

Owner:涿州泓锲冶金设备有限公司

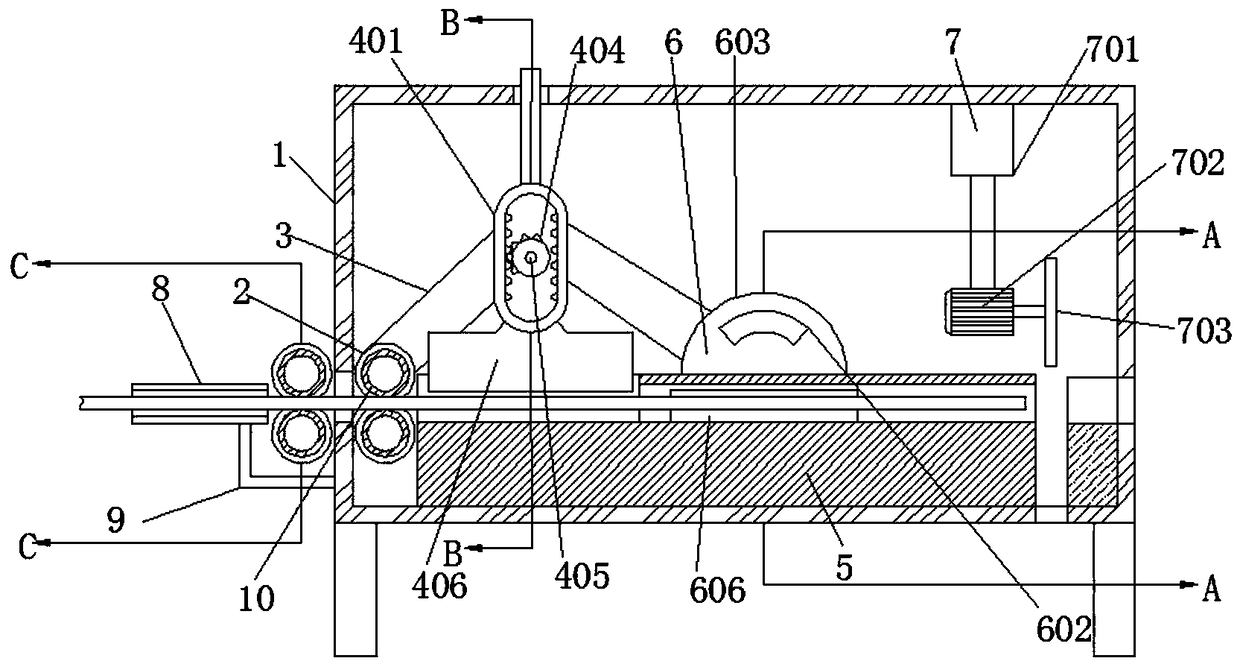

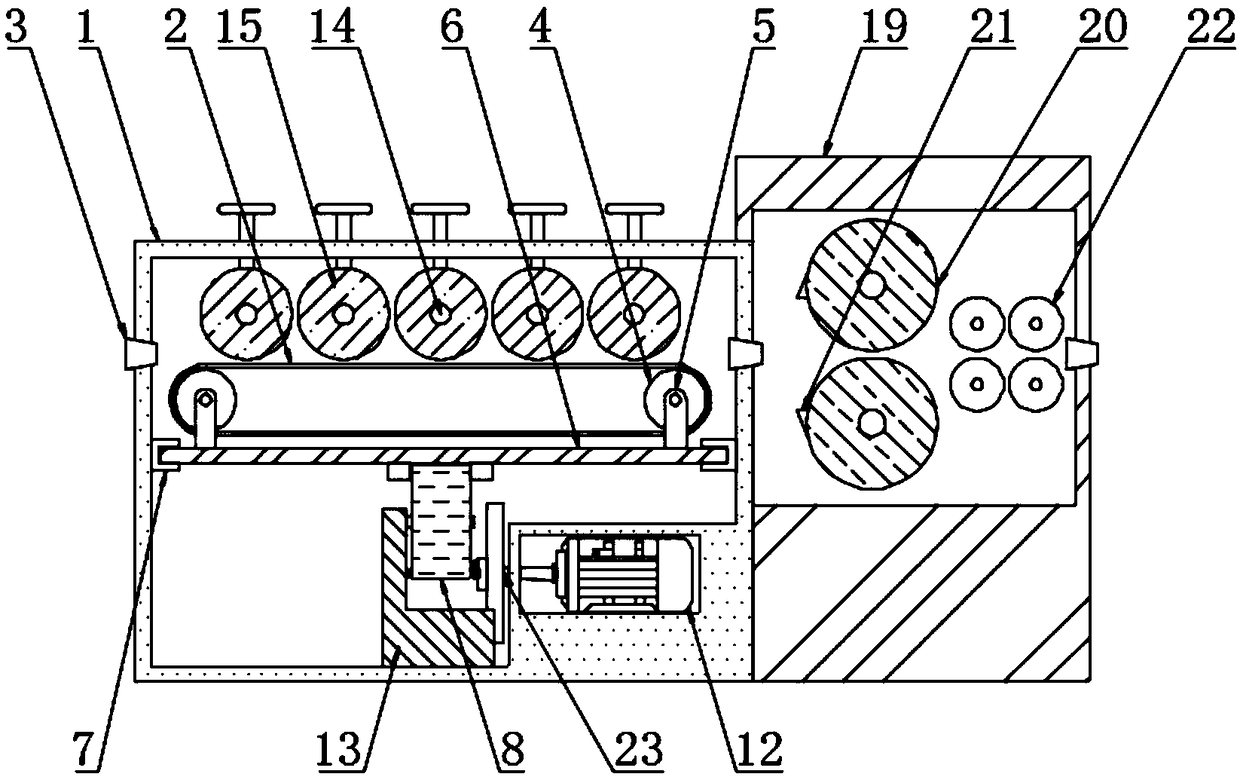

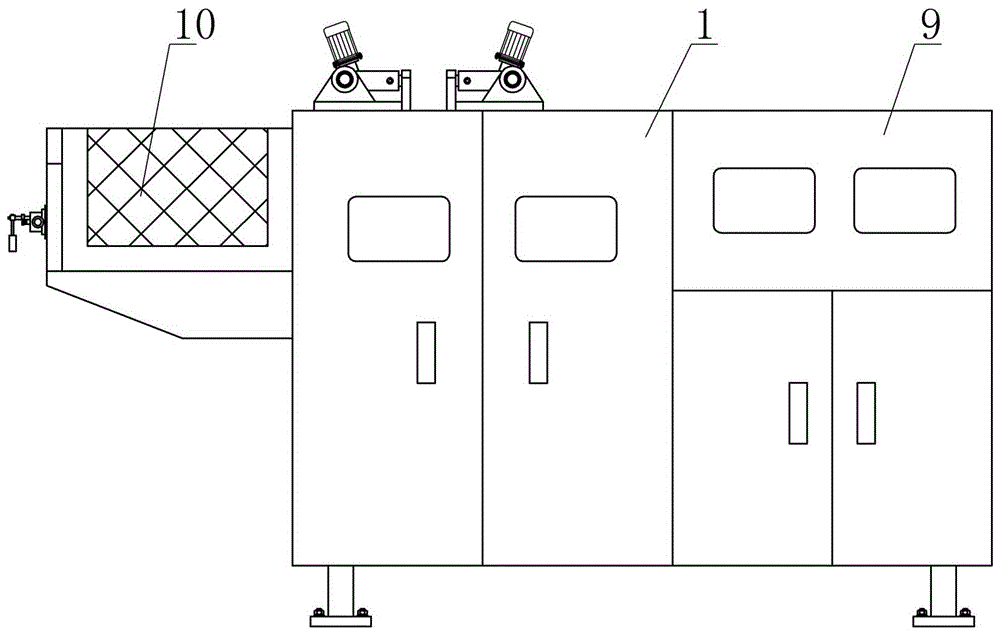

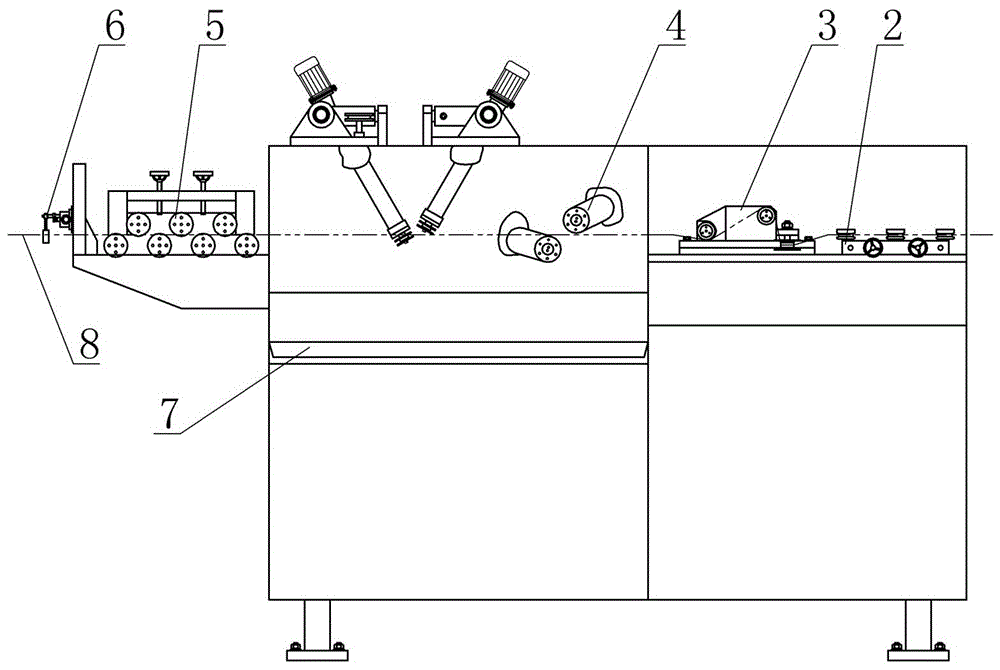

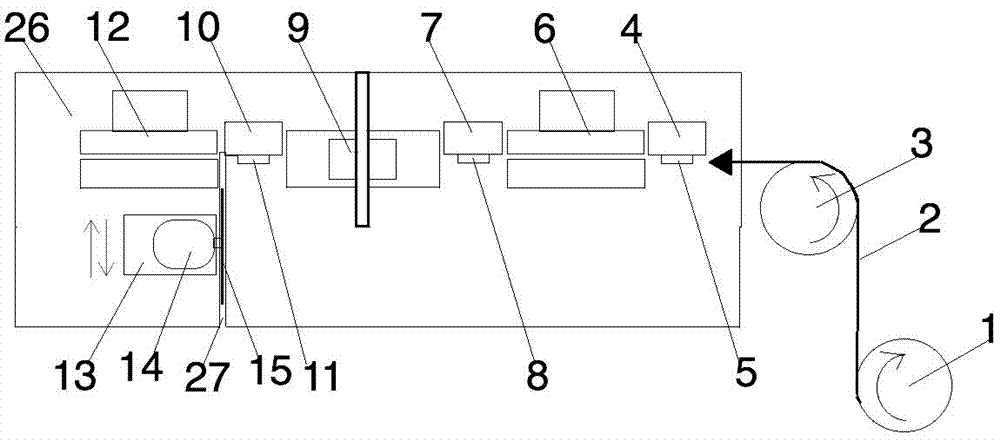

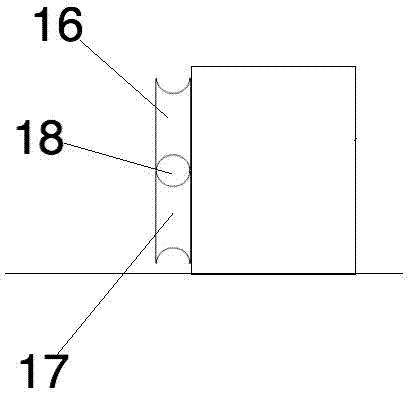

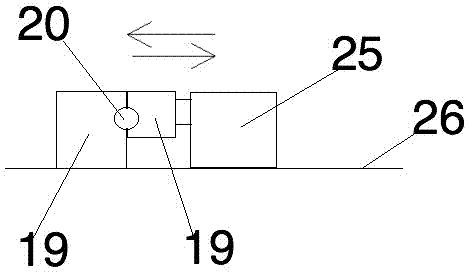

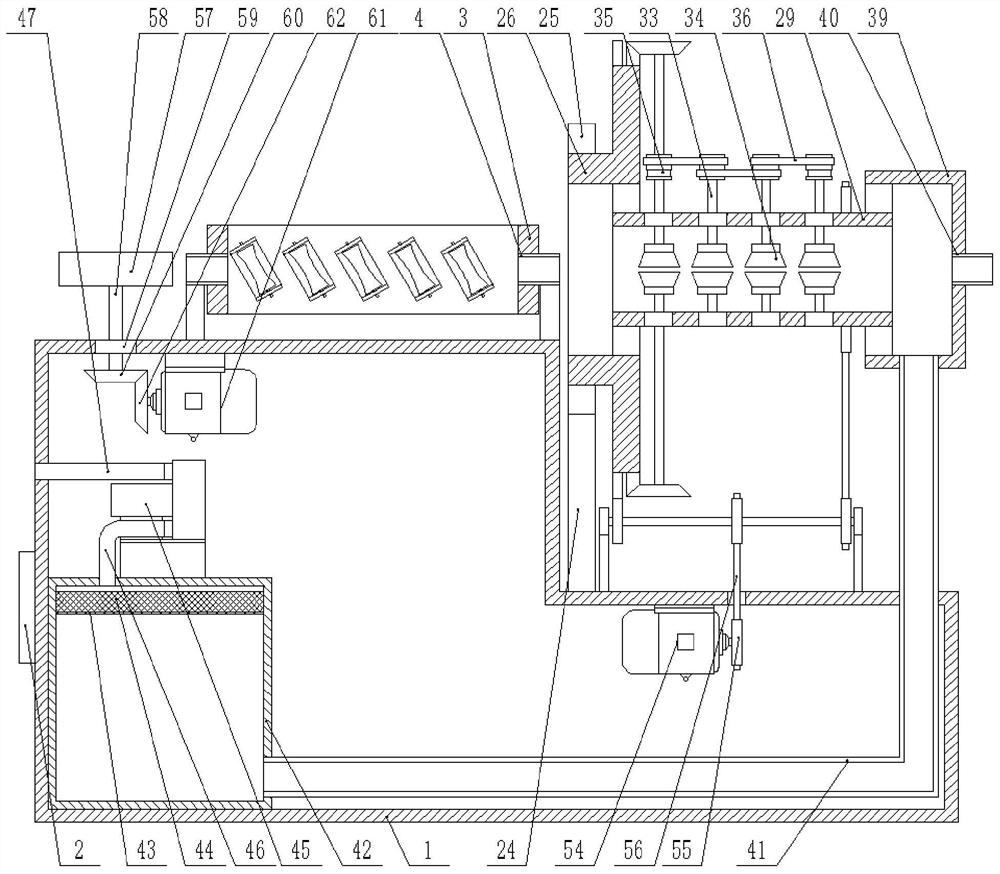

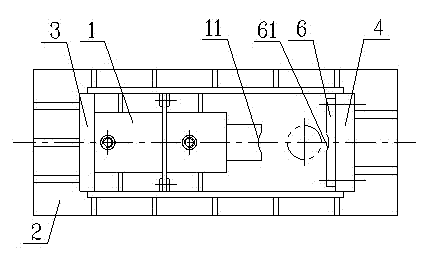

Steel wire electric dephosphorization and mechanical descaling machine for steel cord production

ActiveCN106694615AReduce pollutionHarm reductionWire straightening devicesDirt cleaningElectricityWire rod

The invention relates to a steel wire electric dephosphorization and mechanical descaling machine for steel cord production. The steel wire electric dephosphorization and mechanical descaling machine comprises a box-type machine frame, a descaling device, a dephosphorization device and a straightening device, wherein the descaling device, the dephosphorization device and the straightening device are arranged on the box-type machine frame in sequence. The steel wire electric dephosphorization and mechanical descaling machine further comprises a broken wire detecting device for detecting broken wires; the broken wire detecting device is arranged on the outer side of the box-type machine frame and located at a wire outlet; and the broken wire detecting device and the descaling device are both electrically connected with an electrical control device of steel cords. The steel wire electric dephosphorization and mechanical descaling machine for steel cord production is simple and compact in structure and reasonable in design, surface attachments of wire rods are removed through a mechanical descaling mode, the cleaning effect is improved, the production cost is reduced, and meanwhile, pollution of chemical descaling to the environment and hazards of chemical descaling to human bodies are reduced.

Owner:HENAN HENGXING SCIENCE & TECHNOLOGY CO LTD

Cutting-off process for high-quality Bundy tubes

InactiveCN106903364AImprove straightening processing efficiencyGood straightening effectTube shearing machinesEngineeringMechanical engineering

The invention discloses a cutting-off process for high-quality Bundy tubes. The cutting-off process comprises the following steps: firstly, correcting and guiding the Bundy tubes by using a correction wheel to enter a first conveying wheel set; conveying first sections of Bundy tubes with preset conveying lengths into a horizontal straightening device by the first conveying wheel set to carry out horizontal straightening; then, conveying the first sections of Bundy tubes with the preset conveying lengths into a vertical straightening device by a second conveying wheel set to carry out vertical straightening; next, conveying the first sections of Bundy tubes with the preset conveying lengths into a clamping and fixing device by a third conveying wheel set to carry out clamping and fixing; and finally, cutting off the first sections of clamped and fixed Bundy tubes by using a cutting-off device. By using the cutting-off process, the effect on straightening the Bundy tubes before cutting-off is good, wastes are prevented from being generated, meanwhile, the requirement for rapidly cutting off a mass of Bundy tubes when the mass of Bundy tubes with the same length are required is met, and the cutting efficiency of the Bundy tubes is effectively increased.

Owner:江苏海森电气科技有限公司

Steel bar straightening and bending machine

The invention relates to the technical field of steel bar bending equipment, in particular to a steel bar straightening and bending machine. The machine comprises a first pre-shaping mechanism, a horizontal straightening mechanism, a feeding mechanism, a vertical straightening mechanism, a cutting mechanism, a bending mechanism and a conveying mechanism which are arranged in the conveying direction of steel bars sequentially, wherein the first pre-shaping mechanism comprises a first support frame, a first pre-shaping assembly arranged on the first support frame and used for limiting the bending degree of the steel bars and a second pre-shaping assembly arranged on the first pre-shaping assembly and used for limiting the diameter of a channel defined by the first adjusting assembly; and thefirst adjusting assembly is connected to the first support frame by a first sliding assembly. The machine has better straightening effect.

Owner:上海凯斯特民防设备有限公司

Integrated steel bar rust removing and straightening equipment for bridge construction

ActiveCN113231572AGood straightening effectIncrease straightening speedRevolution surface grinding machinesGrinding/polishing safety devicesRebarRotating drum

The invention discloses integrated steel bar rust removing and straightening equipment for bridge construction. The integrated steel bar rust removing and straightening equipment comprises a box body and a controller installed on the box body, a steel bar conveying driving device is installed at one end of the upper portion of the box body, and an adjustable steel bar straightening device is arranged on one side of the steel bar conveying driving device; and a rotary steel bar rust removing device is arranged at the other end of the upper portion of the box body, and a dust collection device is arranged on one side of the inner lower portion of the box body. According to the integrated steel bar rust removing and straightening equipment, through cooperation of adjusting screw rods and internal thread adjusting cylinders, straightening wheels can be adjusted conveniently, meanwhile, it is guaranteed that the deviation angles of the straightening wheels are the same, the steel bar straightening effect is better, the steel bar straightening speed can be adjusted, and using is convenient; and through the use of an annular boss type rotating disc and a rust removing rotating drum, steel bar rust removing wheels can rotate around a steel bar while rotating, and the rotating direction of the annular boss type rotating disc is opposite to that of the rust removing rotating drum, so that the rotating speed of the steel bar rust removing wheels is higher, and the steel bar rust removing wheels are kept in an efficient working state.

Owner:石淼

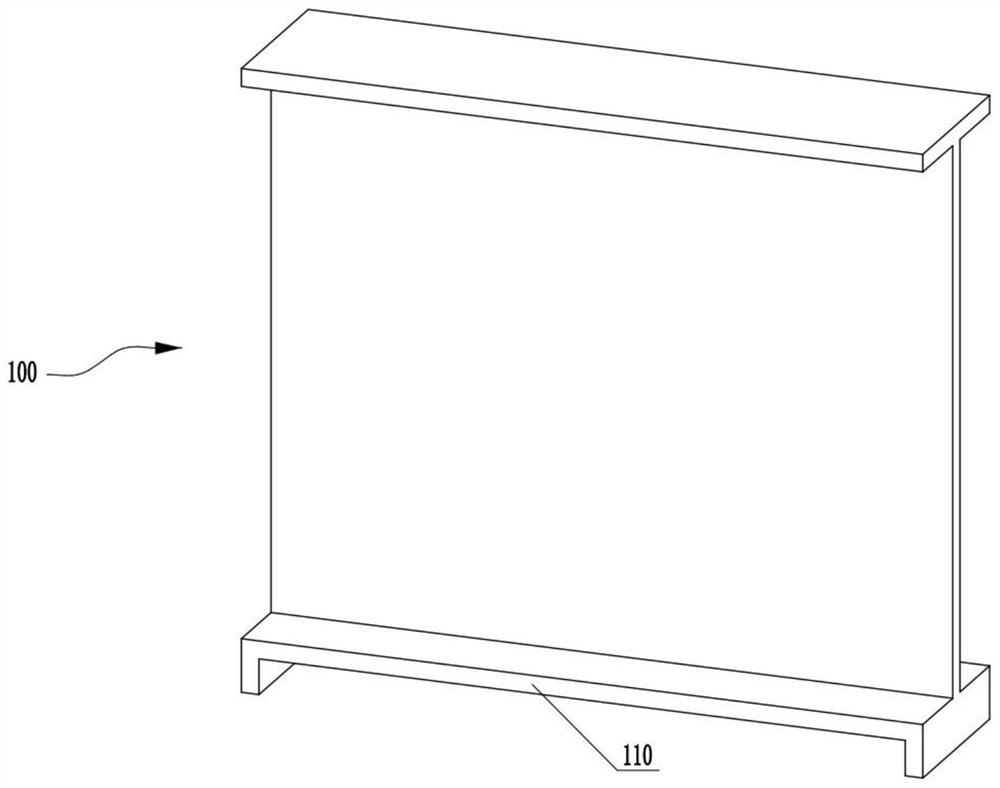

Device and method for straightening steel claw

The invention provides a device and method for straightening a steel claw. The device is used for solving the problems that an existing straightening device is large in occupied floor space and high in device investment, price is over RMB one million, and a steel claw straightening device which is low in use frequency in an anode assembly workshop is over high in cost are solved. The device comprises a jack and a bottom board. A vertical board is perpendicularly fixed to one side of the upper end face of the bottom board and a straightening board is perpendicularly fixed to the other side, opposite to the vertical board, of the bottom board. The jack is arranged between the vertical board and the straightening board. A base of the jack is fixed to the board face of the vertical board and the straightening board is located on a telescopic path of the jack. The device and method are used for industrial electrolysis production and particularly used for straightening the anode assembly steel claw for an electrolytic cell.

Owner:贵阳振兴铝镁科技产业发展有限公司

Repairing tool for bracket crane

InactiveCN108160866AImprove straightening effectPrevent rustLubrication elementsReciprocating motionEngineering

The invention relates to the technical field of repairing and maintaining, and specifically relates to a repairing tool for a bracket crane. The repairing tool for the bracket crane comprises a rack,a pulling mechanism, a power mechanism, a straightening mechanism and a shearing mechanism, wherein the pulling mechanism comprises two conveying rollers for conveying a steel wire rope; the conveyingrollers are rotatably connected to the rack; the power mechanism comprises a moving plate, and a mover for driving the moving plate to linearly reciprocate; the straightening mechanism comprises a straightening cylinder, a piston and a piston rod; the shearing mechanism comprises a supporting part and a shearing blade; the shearing blade is fixedly connected to the moving plate; the supporting part is fixed to the rack; the upper surface of the supporting plate and a center line of a second straightening groove are on the same horizontal plane. The repairing tool is capable of automatically straightening and shearing the steel wire rope.

Owner:河南巨人起重机集团有限公司

Straightening device based on metal bent wire machining

InactiveCN114535460AImprove the fixed effectGood straightening effectStructural engineeringManufacturing engineering

The invention provides a straightening device based on metal bent wire machining, relates to the field of wire machining, and aims to solve the problems that when a wire is straightened, due to the fact that the surface of the metal wire is smooth, the wire is likely to be pulled to be separated and slide down in the pulling process, and the straightening effect is poor due to lack of a follow-up reinforcing and fixing structure. The straightening device comprises a fixing part, a rectangular groove is formed in the top end of the fixing part, the fixing part comprises a clamping plate, the middle position of the clamping plate is of an inclined structure, the clamping plate is fixed to the rectangular groove of the fixing part, and the clamping plate is inserted between the inner plates through the two sides of the outer portion of the groove. During use, a metal wire is embedded between the clamping plates, so that the wire is preliminarily contacted and fixed with the clamping blocks, the moving piece receives power displacement of the electric push rod, then the fixing piece is driven by the clamping blocks to move together, and after the fixing piece moves, the clamping plates deform, the fixing blocks are contacted with the wire, and the clamping plates push the fixing blocks to clamp and fix; therefore, the device achieves the effect of follow-up reinforced fixation.

Owner:徐州百惠模具制造有限公司

Device and method for straightening quartz tube rod

PendingCN114105468ASimple structureEasy to operateGlass making apparatusEngineeringOptical fiber fabrication

The invention belongs to the technical field of optical fiber manufacturing processes, and discloses a device and a method for straightening a quartz tube rod. The device comprises a supporting platform and a straightening body. The supporting platform is located below the quartz tube rod to be straightened. The straightening body is provided with a supporting plane and a grinding end face, the straightening body is located between the supporting platform and the quartz tube rod, the supporting plane is attached to the table top of the supporting platform, and the grinding end face makes contact with the to-be-straightened position of the quartz tube rod and is used for grinding the bending point. The device is simple in structure and convenient to operate, an operator does not need to have operation experience, and a good straightening effect can be achieved.

Owner:JIANGSU HENGTONG OPTICAL FIBER TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com