Device and method for straightening steel claw

A technology of straightening and steel claws, which is applied in the field of straightening devices, can solve the problems of low frequency of use, large floor space, and high equipment investment, and achieve the effects of reducing equipment costs, small floor space, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

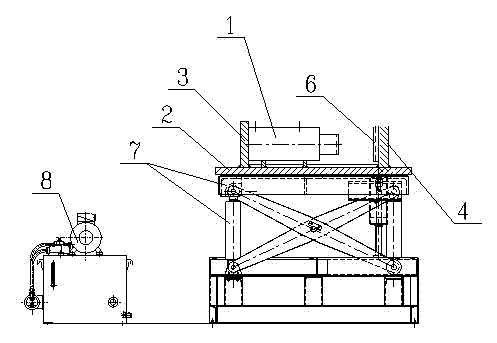

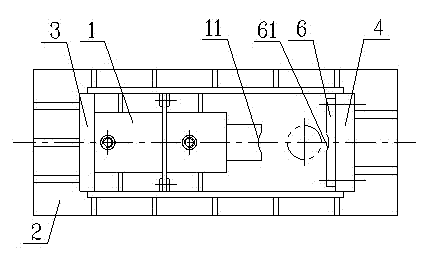

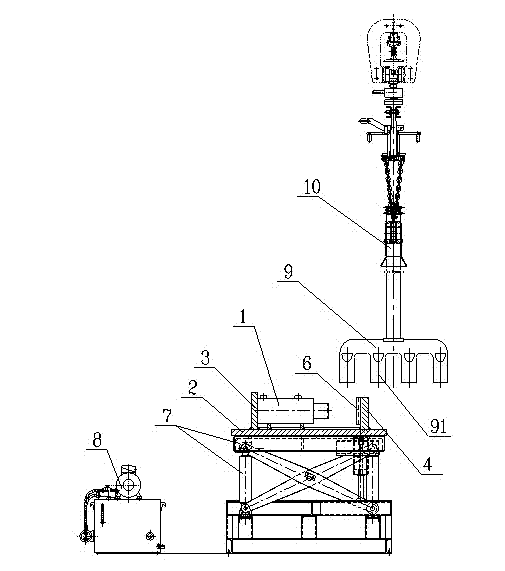

[0016] refer to figure 1 , figure 2 and image 3 , said a kind of steel claw straightening device comprises jack 1, lifting platform 7, hydraulic station 8 and base plate 2, and lifting platform 7 is a scissor type hydraulic lifting platform, jack 1 is a hydraulic jack, jack 1 and lifting platform 7 The power input end is connected with the power output end of the hydraulic station 8 . The lower end of the base plate 2 is fixed on the lifting end of the upper end of the lifting platform 7, a vertical plate 3 is fixed vertically on one side of the upper end of the base plate 2, and a straightening plate 4 is vertically fixed on the other side of the base plate 2 opposite to the vertical plate 3. 3 and the straightening plate 4 are parallel to each other. The jack 1 is arranged between the vertical plate 3 and the straightening plate 4, the base of the jack 1 is fixed on the surface of the vertical plate 3, and the straightening plate 4 is located on the telescopic path of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com