Straightening device based on metal bent wire machining

A technology for bending and wire rods, applied in the field of straightening devices, can solve the problems of wire rods falling off, poor straightening effect, and easy to bend, etc., and achieve the effects of easy use, good straightening effect, and enhanced fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

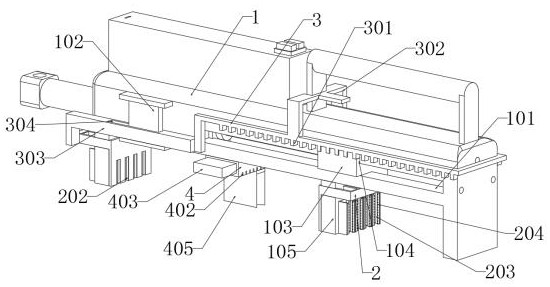

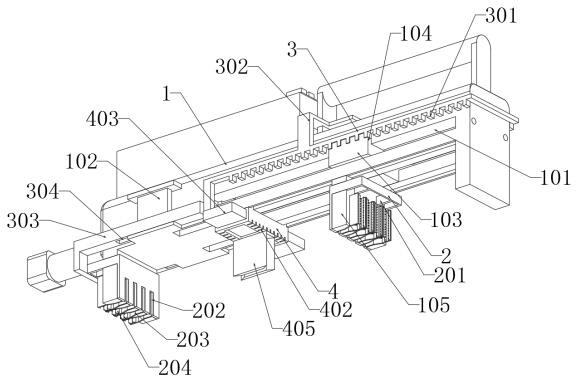

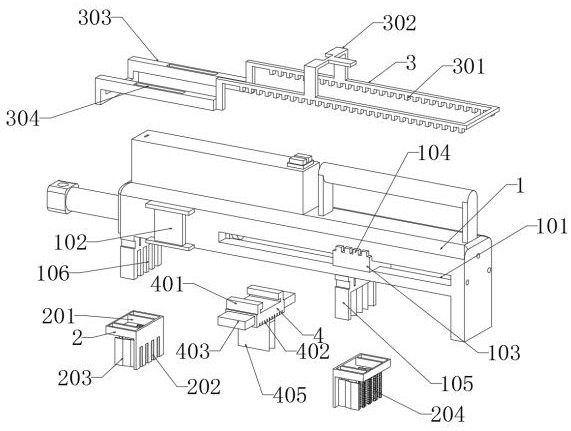

[0029] Example 1: as attached figure 1 to the attached Figure 10Shown: The present invention provides a straightening device based on metal bending wire processing, including a main body 1; the main body 1 is an L-shaped structure, and an electric push rod is installed inside the left end of the main body 1, which is used to generate power to push the moving part 103 , so that the moving piece 103 can drive the bottom piece 105 at the right end to displace together, so that the bottom piece 105 at the right end drives the wire to straighten, and a battery is provided above the left end of the main body 1, which is used to provide power for the electric push rod. The main body 1 There is a handle above the right end of the main body, so that the device can easily control the displacement, the volume is more compact, and it is more convenient to use. There are L-shaped grooves on both sides of the bottom of the main body 1, which are used to embed the ejector rod 401, so that t...

Embodiment 2

[0034] Embodiment 2: When the hardness of the straightened wire rod is relatively high, and the wire rod can be straightened at one time, it is not necessary to install the sliding member 4, so that the device can complete the straightening operation at one time, and at the same time, the work efficiency can be improved.

Embodiment 3

[0035] Embodiment 3: When encountering a thicker wire or when both ends of the wire are greatly bent, the wire can be directly embedded into the clamping plate 203, so that the wire can be directly contacted and fixed with the clamping block 202, so that the device can be used more easily. Convenient.

[0036] When using: When the device needs to be used, the device can be moved manually by using the handle, and then the position of the moving part 103 can be adjusted according to the length of the wire, and then the wire that needs to be straightened is embedded between the splints 203. A plurality of metal wires are placed, so that the device can straighten a plurality of wires. After the wires are embedded, they can contact the clamping block 202 first, so that the clamping block 202 can initially fix it, and then control the moving rod 3 to move down , so that the block 301 can be inserted into the rectangular groove of the connecting plate 104, and then connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com