Crystal marking machine

A marking machine and crystal technology, which is applied to power transmission devices, printing, transfer materials, etc., can solve the problems of insufficient movement of the marking position of the picture frame, increase the workload of operators, and affect the overall appearance of the product, so as to increase the fixed effect. , Simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

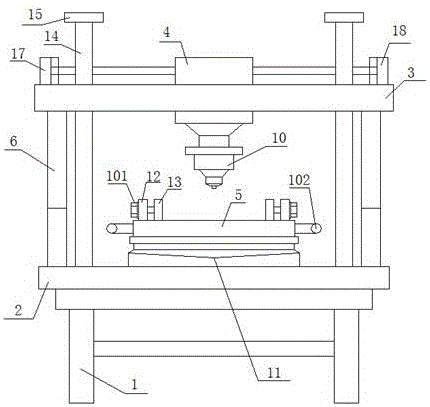

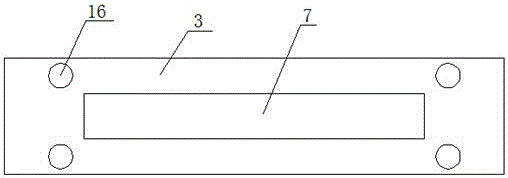

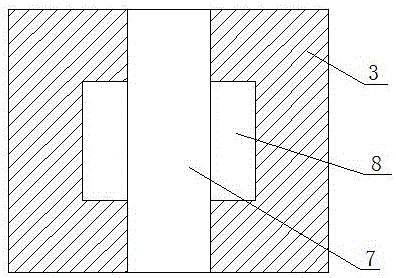

[0016] refer to figure 1 , figure 2 , image 3 and Figure 4 A crystal marking machine, including a frame 1, a support plate 2, a beam 3 and a moving block 4, the support plate 2 is fixed on the frame 1, and two hydraulic lifting rods are symmetrically arranged on the support plate 2 6. The crossbeam 3 is erected on the upper ends of the two hydraulic lifting rods 6, and the crossbeam 3 is provided with a moving groove 7 which is convenient for the moving block 4 to slide left and right, and the crossbeam 3 on both sides of the chute 7 is provided with a chute 8. The moving block 4 is provided with a slider 9 that slides in cooperation with the chute 8, the lower part of the moving block 4 is provided with an infrared marking head 10, and the middle part of the upper part of the support plate 2 is provided with a rotating mechanism 11. A workbench 5 is fixed on the output end of the upper part of the rotating mechanism 11, and two fixed plates 12 are arranged symmetrically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com