Steel bar straightening and bending machine

A technology of bending machine and straightening mechanism, which is applied in the field of steel bar straightening and bending machines, can solve the problems of reducing the straightening effect and achieve good straightening effect and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

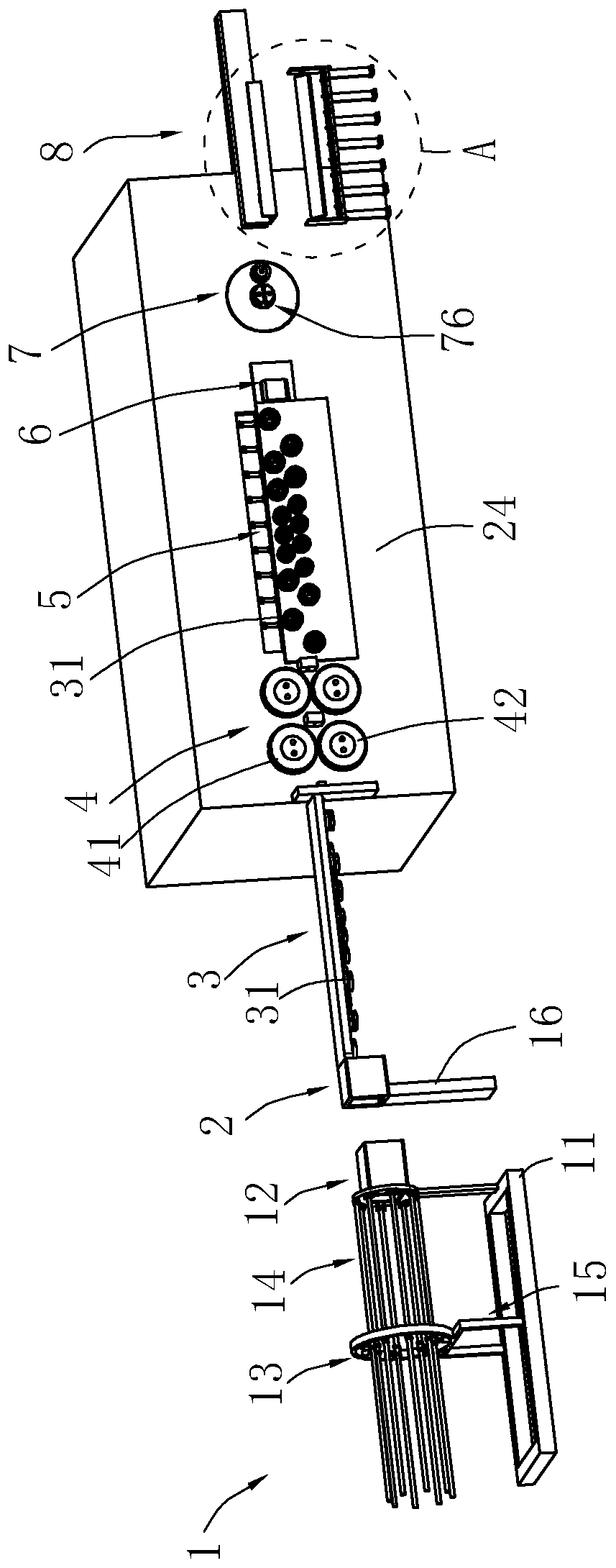

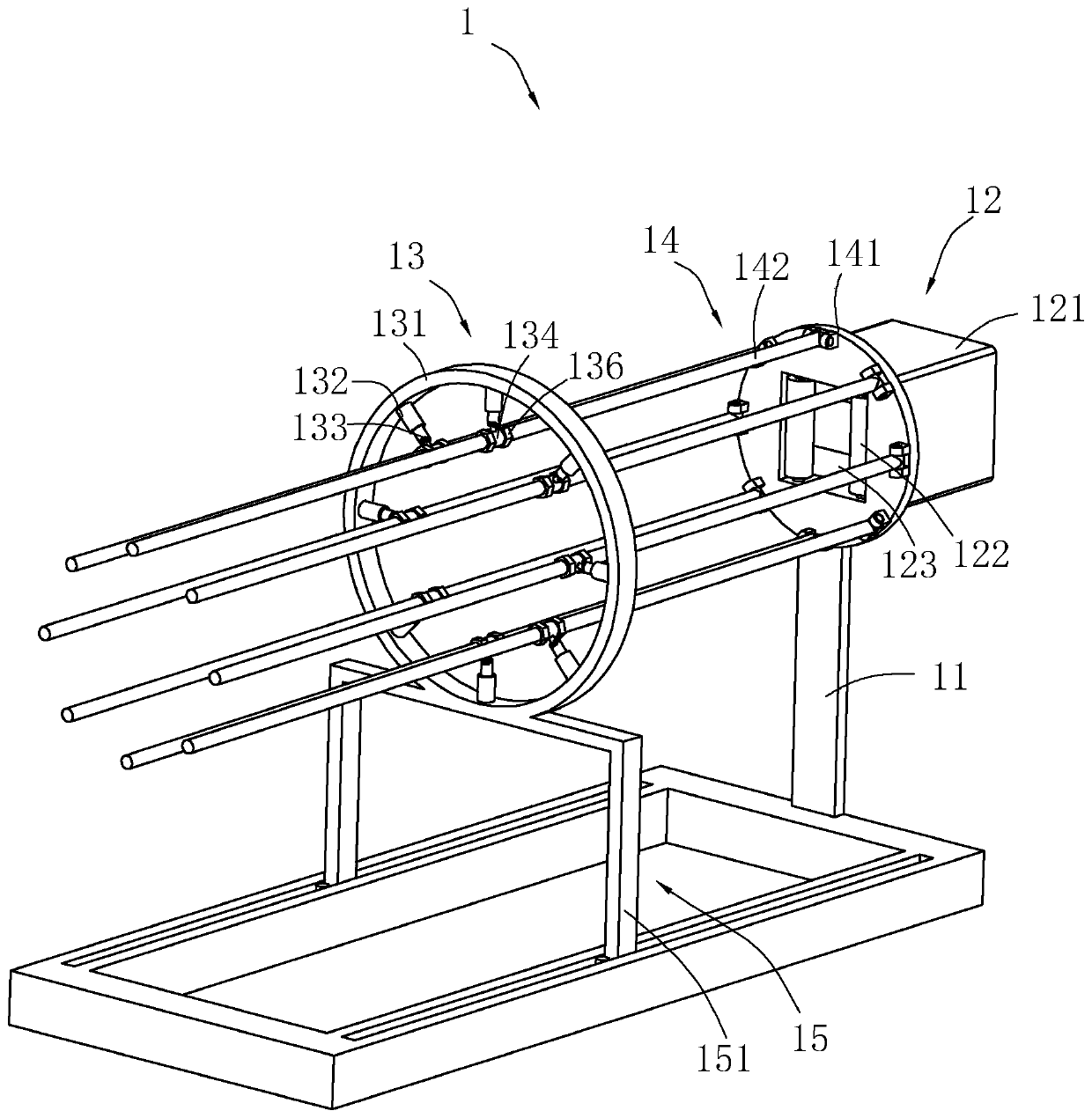

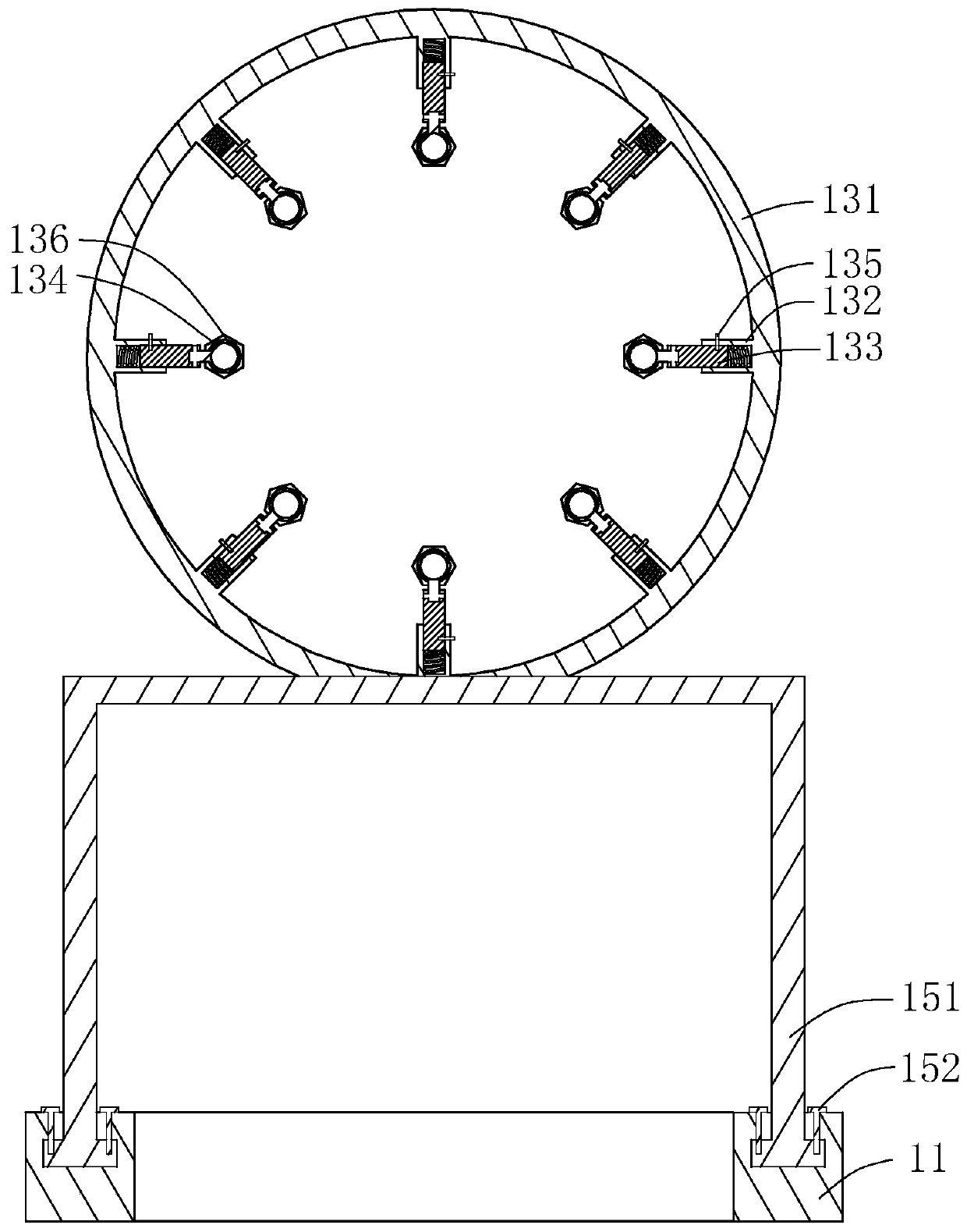

[0041] refer to figure 1 , is a steel bar straightening and bending machine disclosed in this embodiment, the first presetting mechanism 1, the second presetting mechanism 2, the horizontal straightening mechanism 3, the feeding mechanism 4, the vertical Straightening mechanism 5, cutting mechanism 6, bending mechanism 7 and transmission mechanism 8. The steel bar is transmitted through the feeding mechanism 4, and first enters the first presetting mechanism 1 and the second presetting mechanism 2 for presetting processing, so that the spiral steel bar can be extended into the horizontal straightening mechanism 3 and the vertical straightening mechanism 5. Perform straightening processing, through the mutual cooperation of the transmission mechanism 8 and the bending mechanism 7, so as to perform bending processing on the steel bars and realize the blanking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com