Integrated steel bar rust removing and straightening equipment for bridge construction

A steel bar straightening device and straightening technology, applied in metal processing equipment, grinding/polishing equipment, machine tools designed for grinding the rotating surface of workpieces, etc. Single function and other problems to achieve better results, ensure health and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

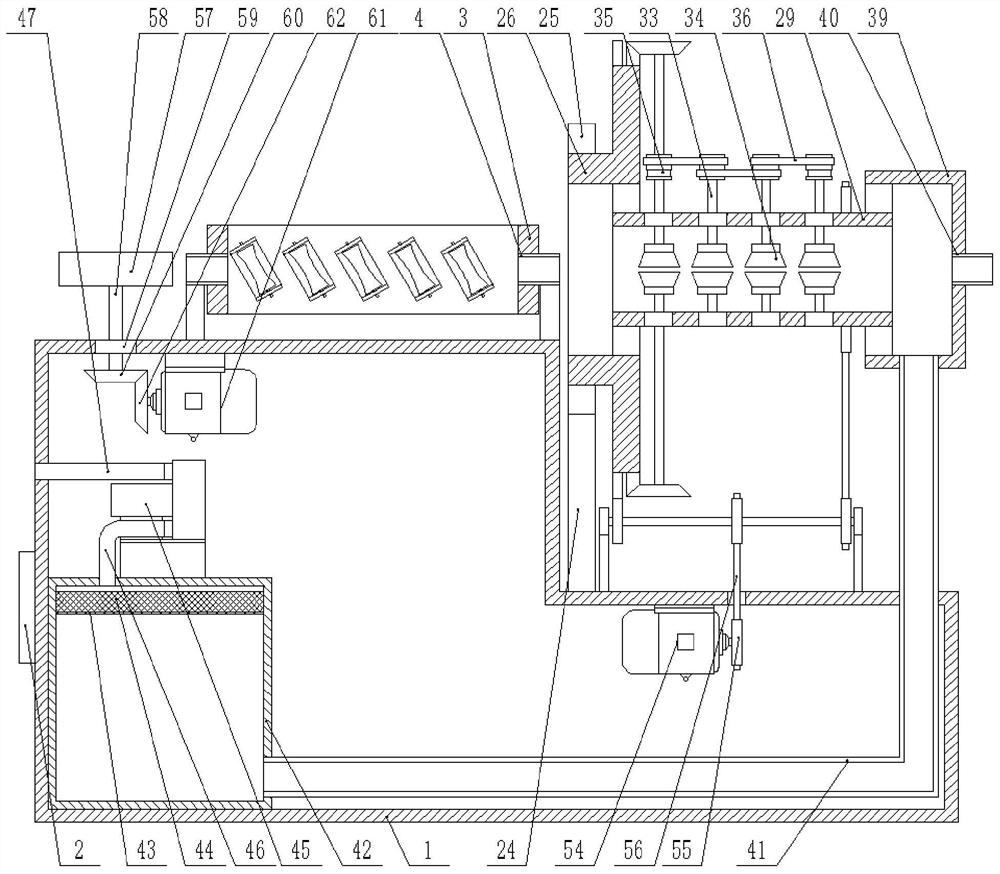

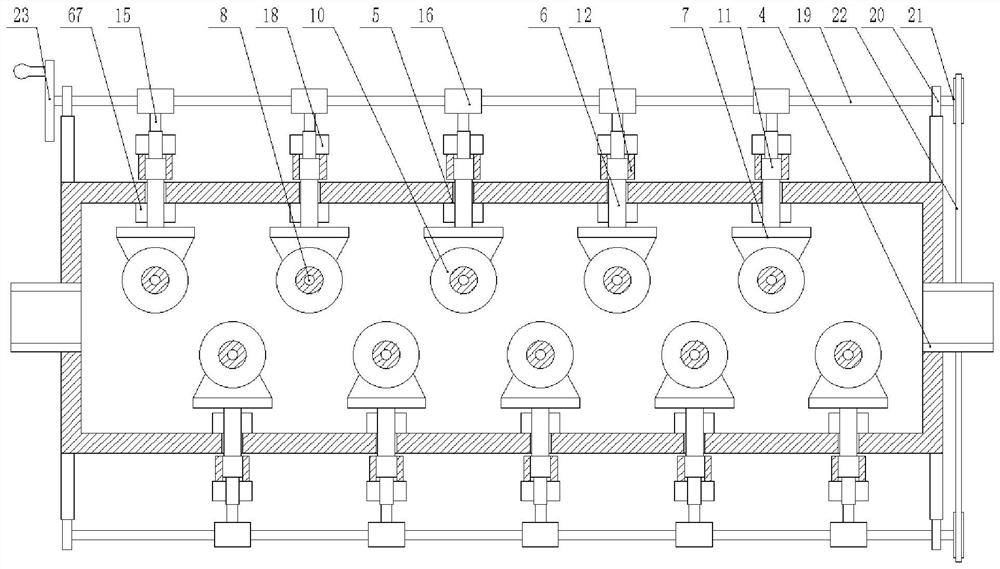

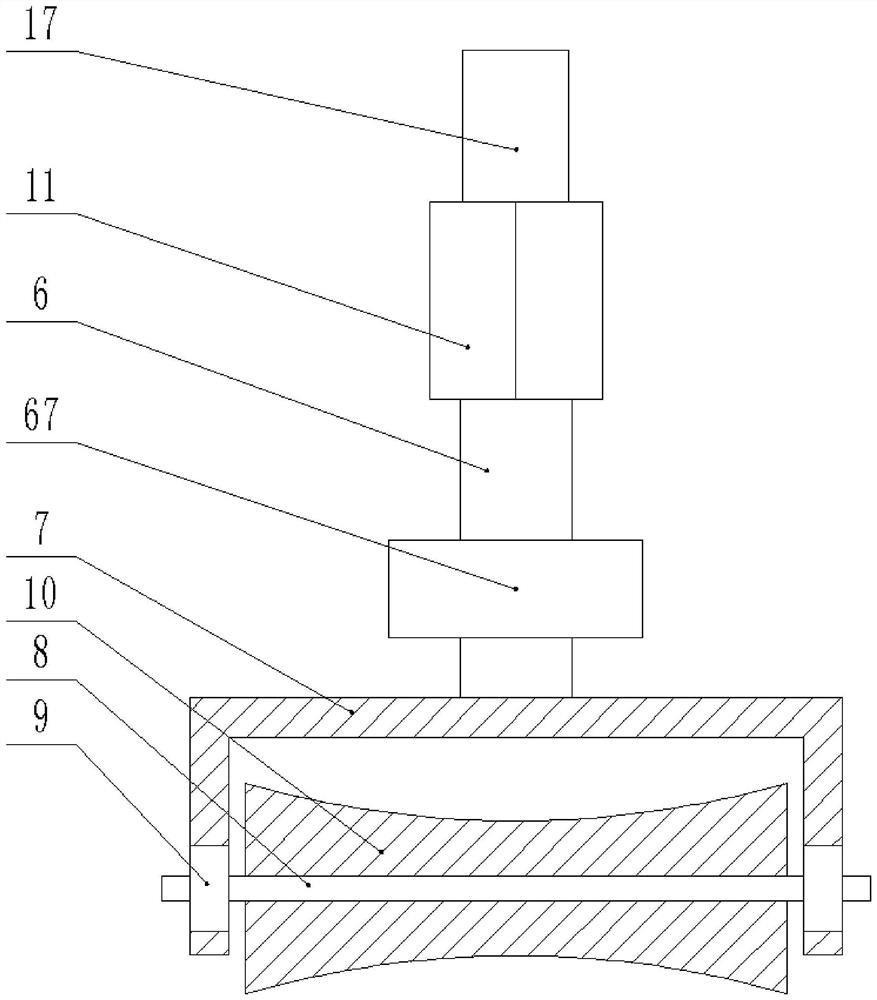

[0029] The present invention will be specifically described below with reference to the drawings. Figure 1-8 Indicated.

[0030] In this apparatus, the device is powered by power supply with the external power source connection, the external power source is electrically connected to the controller 2, the pump 45, the variable frequency motor 54, the speed reducer 61, and the electric cylinder 63, and the model number of the controller 2 is FX3GE- The 40mt / ESS model of the PLC controller, the control signal output of the controller 2 controls the operation of the entire device by the transistor 2, the control signal output of the controller 2, and the electric cylinder 63, respectively, respectively.

[0031]The founding point of this program is the structural design of the adjustment steel-reinforced, combined with attachment. figure 1 Attachment figure 2 Attachment image 3 Attach Figure 4 , Including the upper side of the casing 1, a collision frame 3 is provided, and the reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com