Winding mechanism

A technology of winding mechanism and winding wheel, which is applied in the field of cable storage devices, can solve the problems of unfavorable cable winding efficiency and labor intensity of operators, and achieve a good straightening effect and reduce the gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

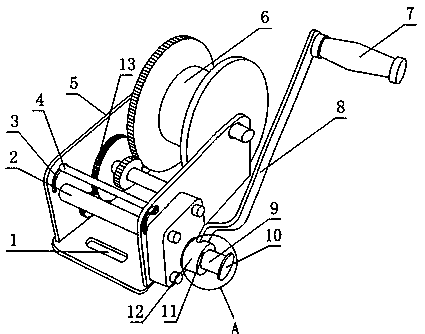

[0025] Such as figure 1 with figure 2 , A winding mechanism, including a frame 5 and a reel 6 arranged on the frame 5, the frame 5 is also provided with a reel brake for braking the reel 6 to rotate around its axis Mechanism and cable leveling mechanism;

[0026] The cable leveling mechanism includes a fixed rod 2 and a movable rod 4 which are arranged on the frame 5 and whose axes are parallel to each other, and the distance between the movable rod 4 and the fixed rod 2 is linearly adjustable;

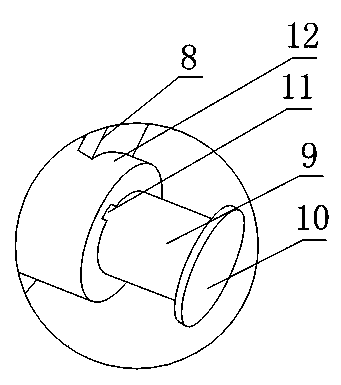

[0027] The reel brake mechanism includes a gear train 13 and a rocker 8. One end of the rocker 8 is fixed at the front end of the gear train 13, and the rear end of the gear train 13 meshes with the reel 6 in gear teeth. Series 13 is a reduction drive gear train;

[0028] The gear train 13 also includes a driving wheel rod 9, the gear at the front end of the gear train 13 is fixed on the driving wheel rod 9, the connecting end of the rocker 8 and the gear train 13 is also fixedly connecte...

Embodiment 2

[0031] This embodiment is further limited on the basis of embodiment 1, such as figure 1 with figure 2 In order to facilitate linear adjustment of the distance between the movable rod 4 and the fixed rod 2, the frame 5 includes a bottom plate and two side plates respectively fixed on different sides of the bottom plate, and each side plate is provided with an arc hole 3. Both ends of the movable rod 4 are respectively located in an arc-shaped hole 3, and the movable rod 4 is fixedly connected with the frame 5 through a nut.

[0032] In order to facilitate the fixation of the frame 5 of the present invention, and to facilitate winding and winding, the bottom plate is also provided with at least two bottom plate bolt holes 1, and the bottom plate bolt holes 1 are waist-shaped holes. The adoption of the bottom plate bolt hole 1 as a waist-shaped hole is intended to reduce the requirement of the present invention for the dimensional accuracy of the connecting bolt of the mounting se...

Embodiment 3

[0035] This embodiment is further limited on the basis of embodiment 1, such as figure 1 with figure 2 , In order to prevent excessive friction damage to the outer layer of the cable when the cable passes through the gap between the fixed rod 2 and the movable rod 4, the fixed rod 2 and the movable rod 4 both include a rigid part and a sleeve provided on the inner side The wear-resistant part on the rigid part, the rigid part is metal, and the wear-resistant part is elastic rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com