Machining system for chain with firm structure

A processing system and solid technology, applied in the direction of metal chains, etc., can solve the problems of hidden safety hazards, easy disconnection at the interface, high energy consumption, and achieve the effect of ensuring processing quality, consistent cutting length and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0056] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

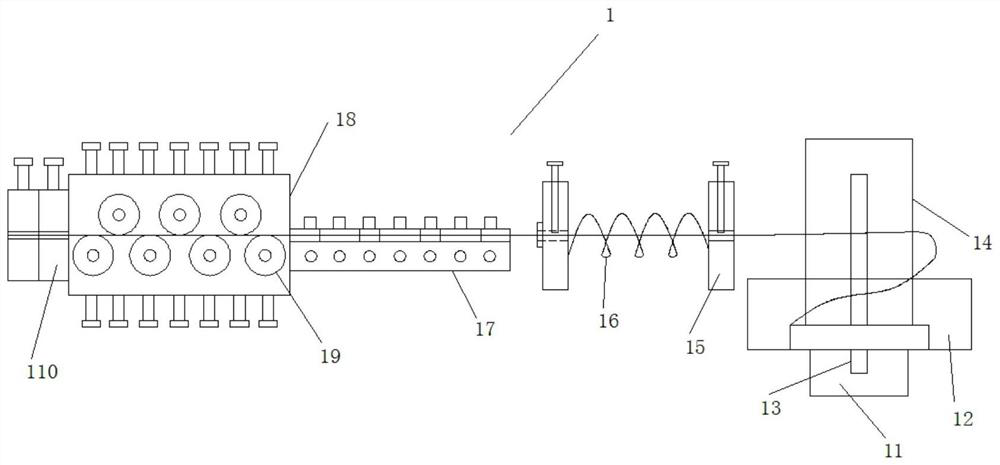

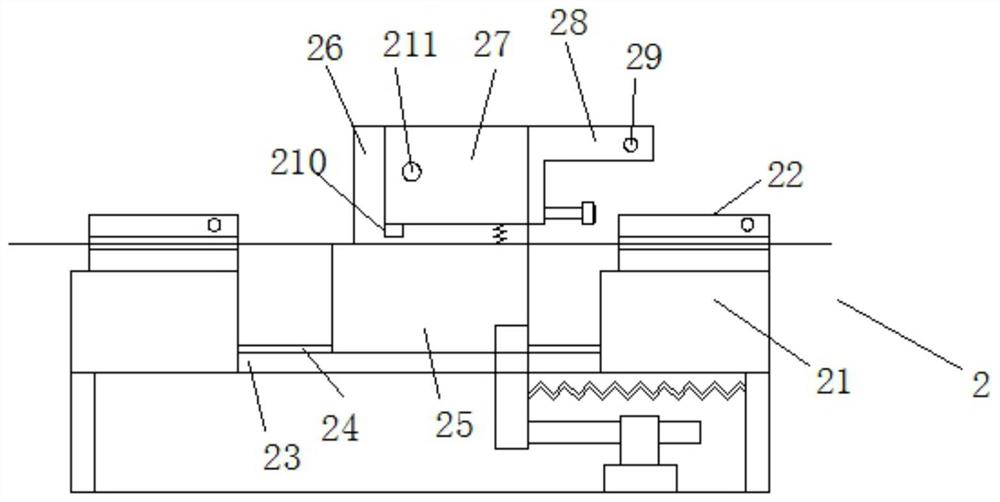

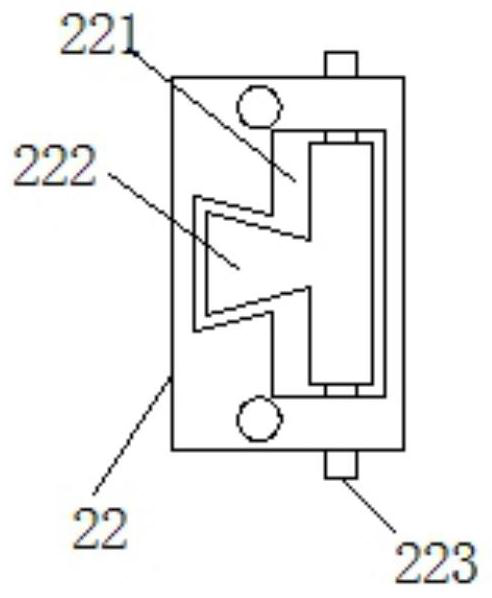

[0057] Such as Figure 1-Figure 10 As shown, this specific embodiment adopts the following technical solutions: including unwinding and straightening device 1, conveying device 2, shearing device 3, bending device 4 and linkage driving device 5, conveying device 2, shearing device 3 and bending The devices 4 are each driven via a linked drive 5 .

[0058] Such as figure 1 As shown, the unwinding and straightening device 1 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com