Cutting-off process for high-quality Bundy tubes

A high-quality, Bondi tube technology, applied in the field of mechanical processing, can solve the problems of easy generation of waste, poor straightening effect, low efficiency of Bondi tube, etc., to avoid waste, improve straightening treatment efficiency, and improve cutting efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

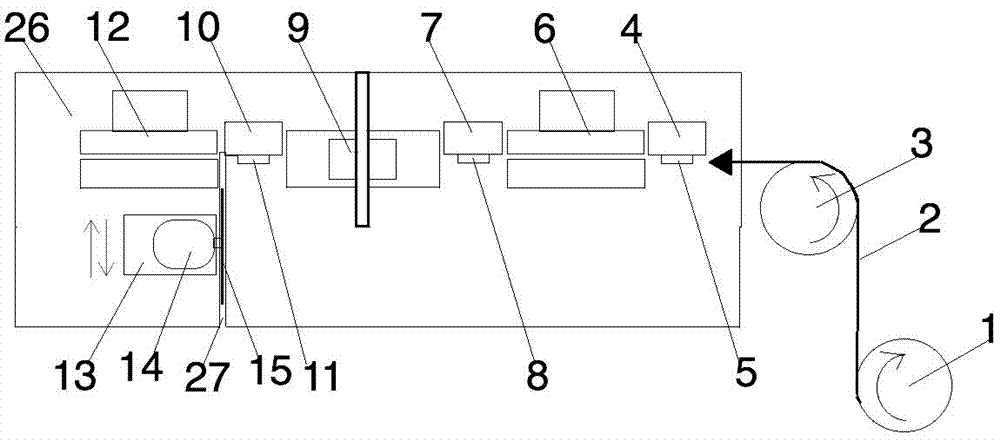

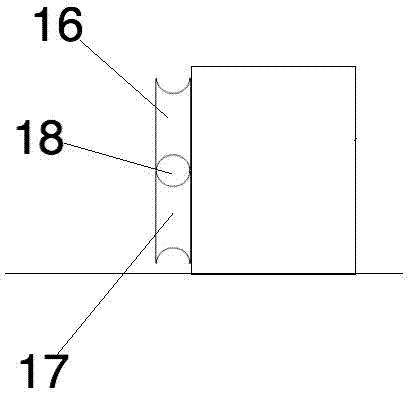

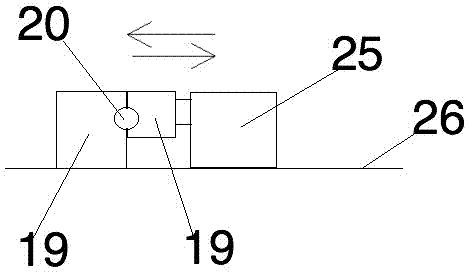

[0027] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0028] like Figure 1-5 Shown: This embodiment is a high-quality Bondi tube cutting process, including the following steps:

[0029] (1) Unwinding correction: The Bondi tube 2 wound on the I-shaped reel 1 is corrected and guided by the correction wheel 3 and then enters the first conveying wheel group 5. The controller controls the first servo motor 4 to drive the first conveying The wheel set 5 transports the first section of the Bondi tube with the preset conveying length to the horizontal straightening device 6 and then stops; the Bondi tube 2 is in the process of correcting and guiding the correction wheel 3, forming a The force of the anti-clockwise bending can effectively counteract the clockwise winding force of the Bondi tube 2 on the I-wheel spool 1, so as to further straighten the straightness of the Bondi tube 2.

[0030] (2) Horizontal str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com