Processing parameter setting method of tension straightening machine set correct roller

A technology of process parameters and setting methods, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as unsatisfactory effects and lack of theoretical guidance, and achieve good tension and straightening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

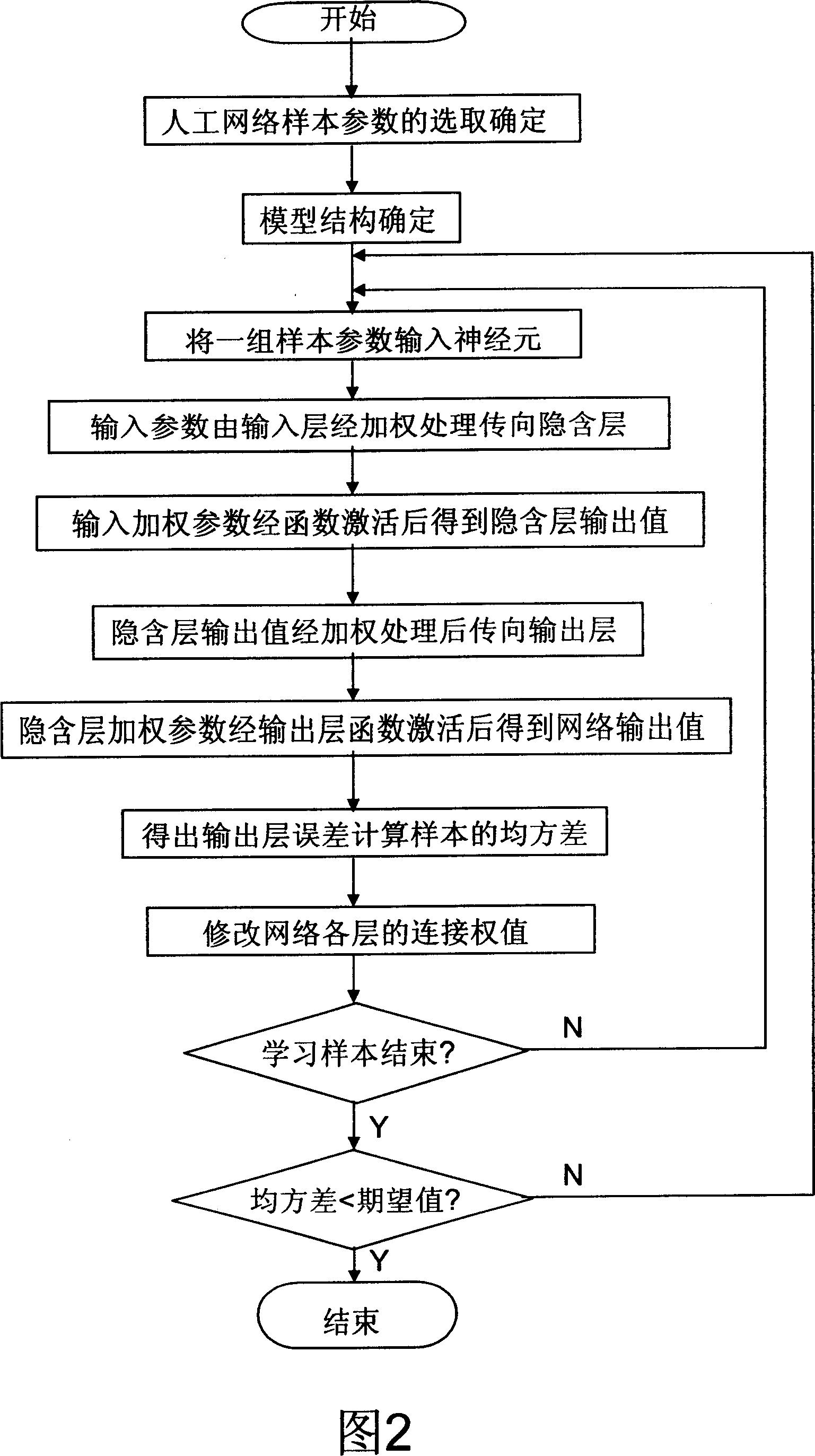

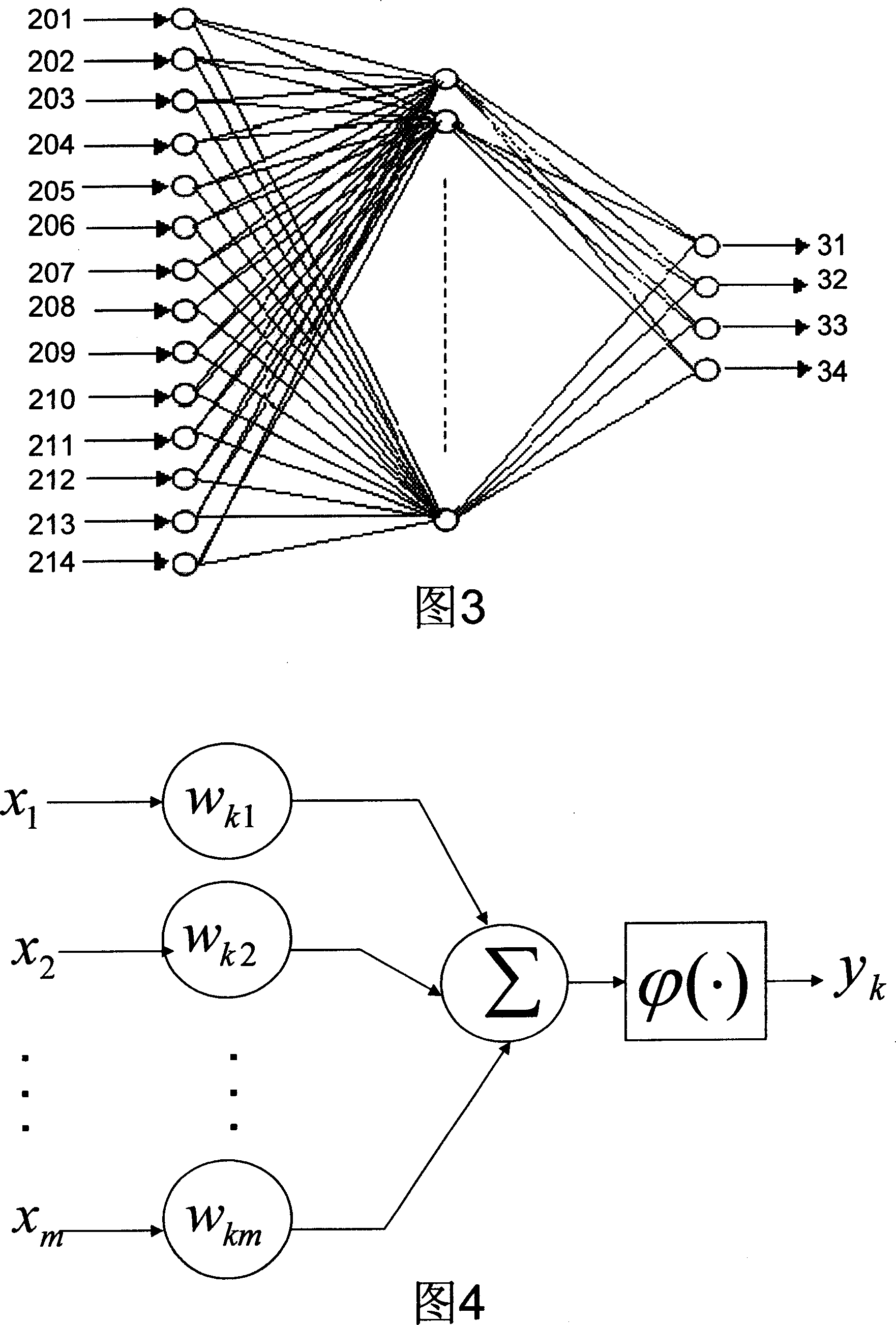

[0039] Please refer to FIG. 2 , the process parameter setting method of the straightening roll of the tension leveling machine unit of the present invention is mainly based on the multi-layer feed-forward neural network structure of the back propagation learning method to set the parameters of the straightening roll. In fact, the method of the present invention has selected the comparatively mature and commonly used BP neuron network structure in the artificial neuron network tool. .

[0040] Method of the present invention is specified as follows:

[0041] First of all, the training sample parameters of the artificial neural network are selected and determined, and the relevant data of the steel plate to be corrected are selected, including the wave shape data of the strip steel, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com