Patents

Literature

113results about How to "Adjust the pressing force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

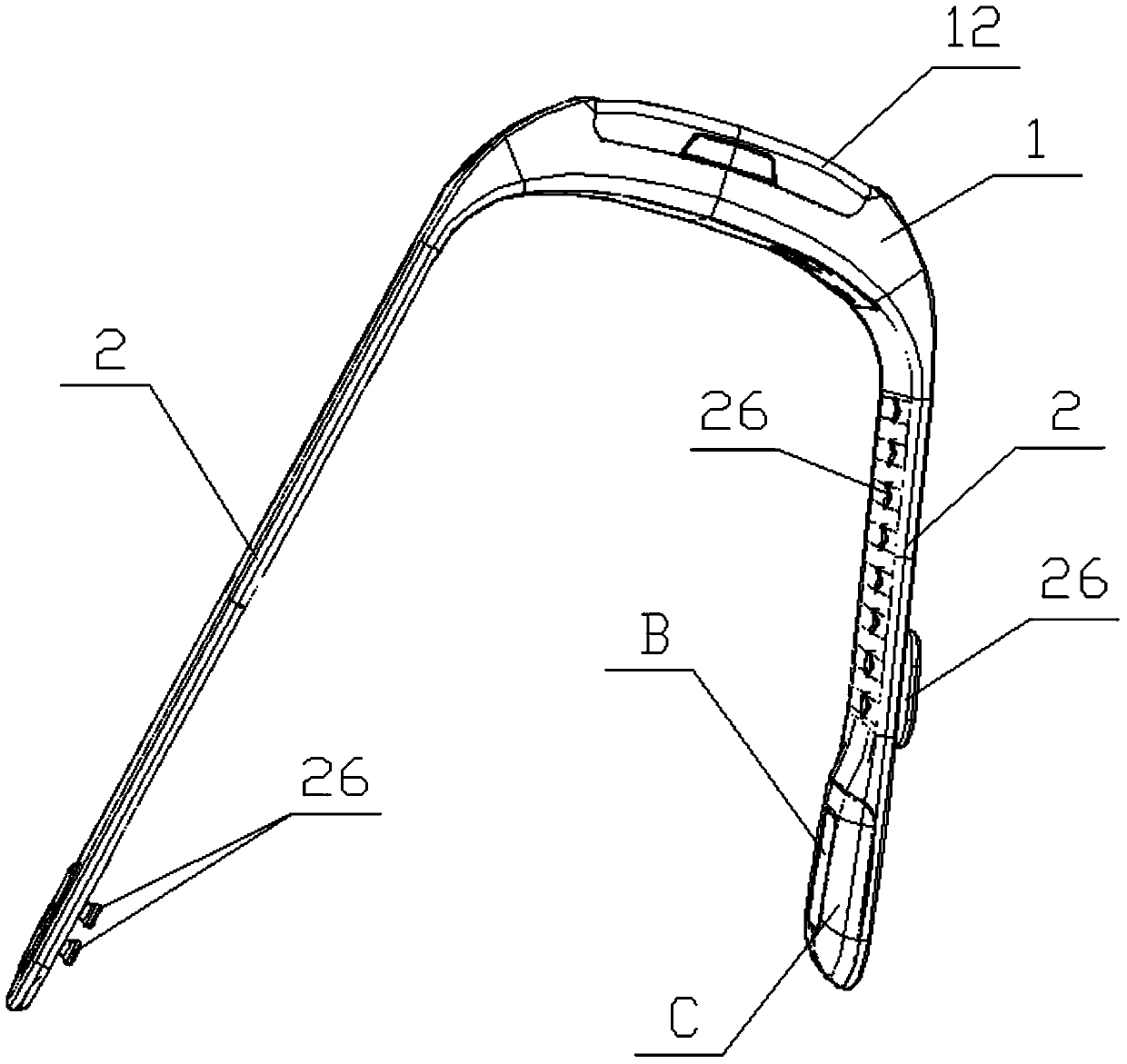

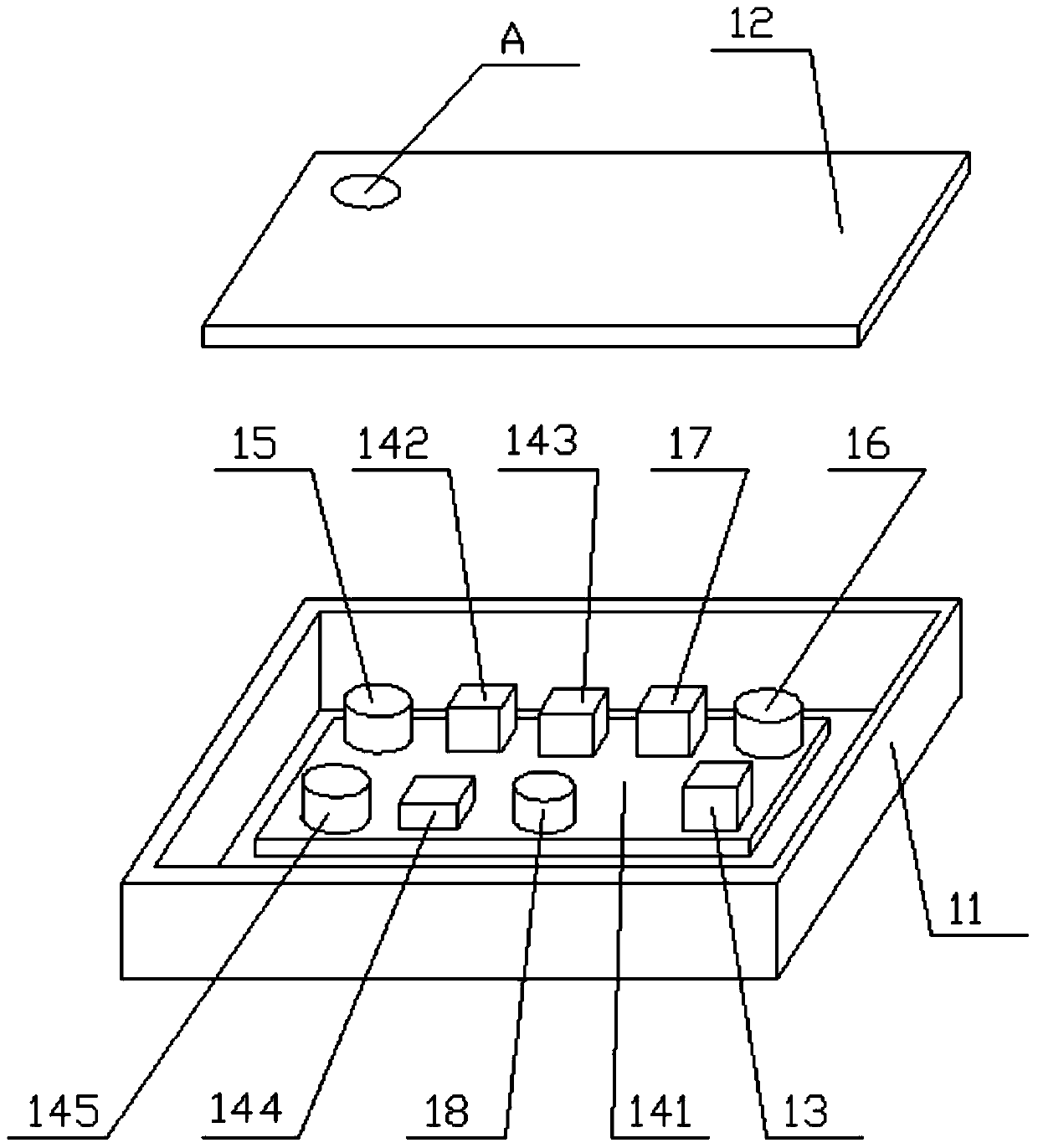

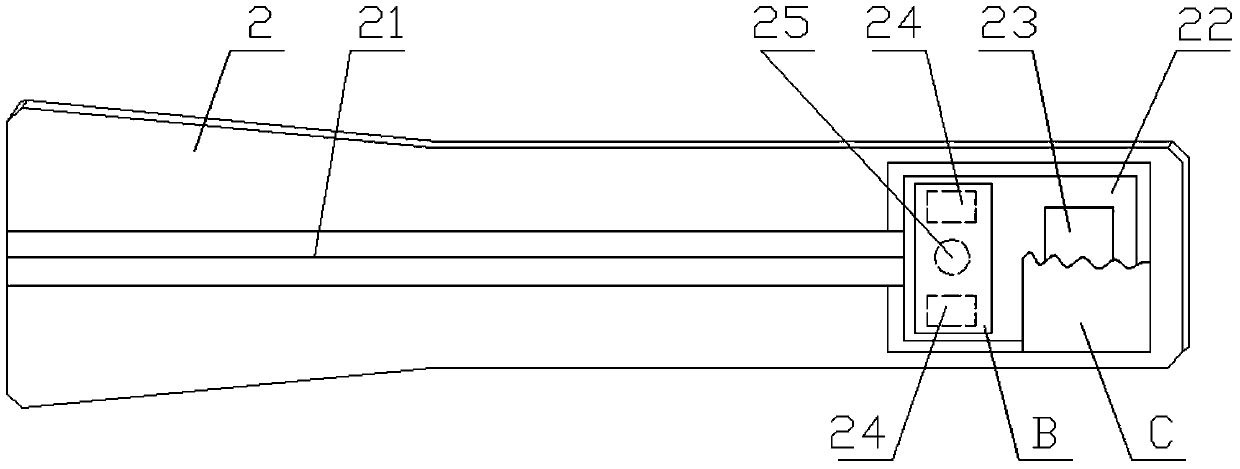

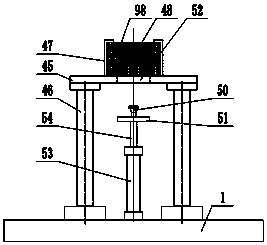

Bracelet capable of collecting multi-parameter health indexes

InactiveCN104000571AImprove accuracyObvious pulseDiagnostic recording/measuringSensorsHealth indexAnalog signal processing

The invention discloses a bracelet capable of collecting multi-parameter health indexes. The bracelet comprises a body and a wrist strap. The body comprises a shell body, a displaying screen, a power supply, a clock part and a main control system. The displaying screen, the power supply, the clock part and the main control system are arranged in the shell body. The main control system comprises a main printed board, a microprocessor, a storage, an analogue signal processing chip and a Bluetooth transmission device. The microprocessor, the storage, the analogue signal processing chip and the Bluetooth transmission device are arranged on the main printed board. An infrared temperature sensor, an alarming device, a gravitational acceleration sensor for step counting and a charging connector are arranged on the main printed board. A flexible connecting wire cable, a measuring printed board, a body surface temperature sensor, a photosensitive sensor and a light source are arranged on the wrist strap. The body surface temperature sensor, the photosensitive sensor and the light source are integrated on the measuring printed board. A tensioning device is arranged on the wrist strap. The bracelet is small and light, wearing and using are convenient, various health parameters can be monitored accurately, human body parameters are collected near the Neiguan point under a wrist of a palm side, the number of blood vessels under the wrist is large, pulsation is obvious, and accordingly the accuracy of data testing and obtaining through the bracelet is greatly improved.

Owner:CHENGDU ICARETECH

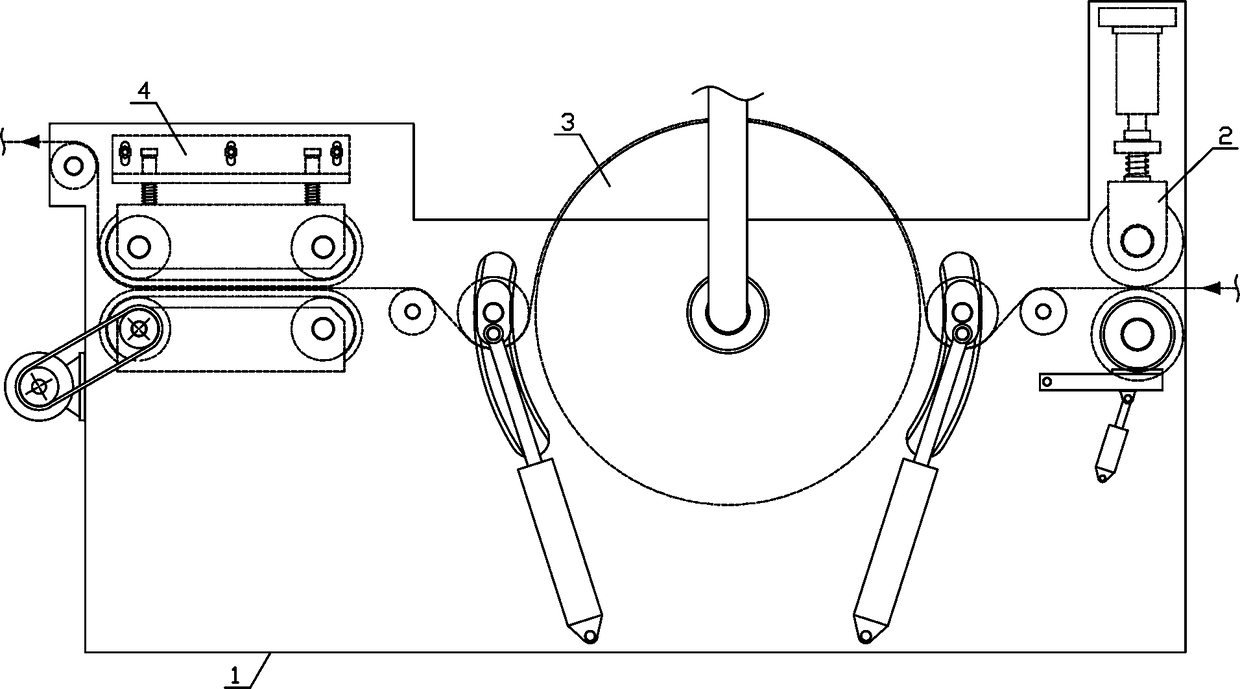

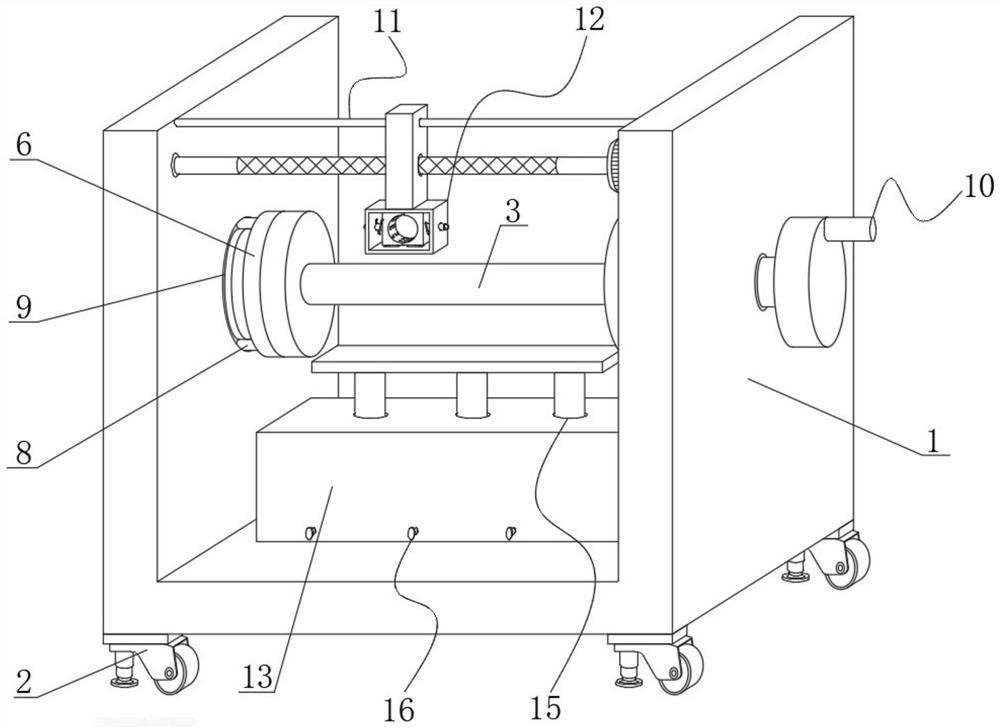

Yarn conveying and pulling mechanism

PendingCN108584532AStable and even stretchingEfficient heatingFilament handlingTextiles and paperYarnHeat conducting

The invention discloses a yarn conveying and pulling mechanism, and belongs to the field of textile processing mechanical equipment. According to the yarn conveying and pulling mechanism, a yarn feeding mechanism, a pulling mechanism and a yarn guide mechanism are arranged on a fixing support in sequence in the horizontal direction. A lower yarn bearing guide roller is connected with the portion,located on the lower side of an upper yarn press guide roller, of the fixing support in a horizontal rotation mode. A shaping rotating drum is connected to the portion, located between a front yarn guide roller and a rear yarn guide roller, of the fixing support in a horizontal rotation mode, and a heat-conducting oil pipe is arranged at the shaft ends of the two sides of the shaping rotating drumin a communicating mode. Pulling guide plates are arranged in pulling guide grooves in a sliding mode in the circular arc direction, and the pulling guide grooves are formed in the two sides of the shaping rotating drum. One end of one pulling rotating roller and the same end of the other pulling rotating roller are connected to the pulling guide plates on the two sides of the fixing support in arotating mode correspondingly. A yarn discharging guide roller is connected to the portion, located on one side of an adjusting support, of the fixing support in a horizontal rotation mode. The yarnconveying and pulling mechanism is reasonable in structural design, can efficiently and accurately convey yarn, and can conduct stable pulling shaping on the yarn section by section in the conveying process, the degree of automation of yarn processing is improved, and the requirements of production and usage are met.

Owner:嘉兴市华益股份有限公司

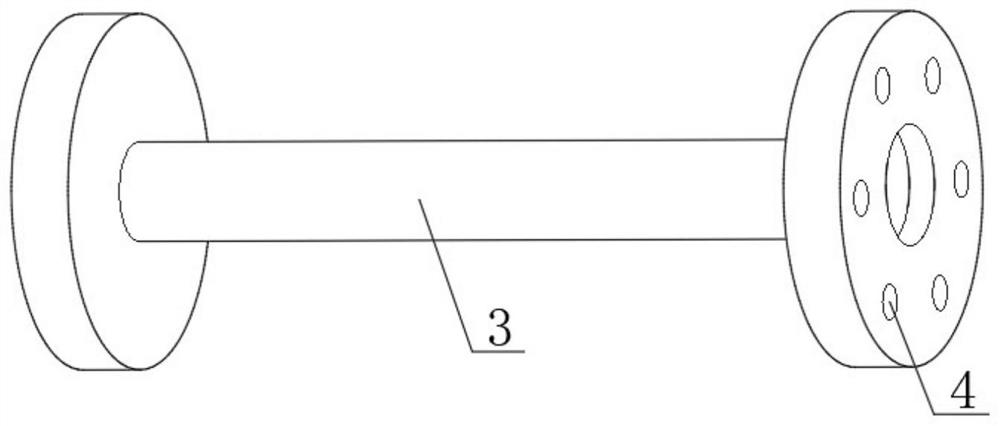

Take-up reel capable of preventing cable from being wound during winding for electric power and electrical engineering and use method thereof

InactiveCN112978482AAvoid tanglesAvoid the situationFilament handlingElectric machineryControl theory

The invention discloses a take-up reel capable of preventing a cable from being wound during winding for electric power and electrical engineering and a use method thereof, and belongs to the technical field of electric power and electrical engineering. The take-up reel comprises a take-up frame, wherein a set of self-locking universal wheels are installed on the bottom surface of the take-up frame, and a take-up reel body is arranged in the take-up frame; the left side surface and the right side surface of the take-up reel body are each provided with a set of limiting holes, a first motor is fixedly embedded in the left side surface of the take-up frame, the output end of the first motor is fixedly connected with a first clamping plate, and the right side surface of the first clamping plate is fixedly connected with a set of first limiting blocks. According to the take-up reel, through cooperative arrangement of the take-up frame, the take-up reel body, the first motor, a first clamping plate, a first limiting block, a limiting hole, a wiring mechanism, a cable guiding mechanism and a pressing assembly, the cable can be evenly wound on the outer surface of the take-up reel body, such that the situation that the cable is wound, knotted and loosened during winding can be avoided, and the cable can be prevented from being damaged.

Owner:义乌市勋武电子商务有限公司

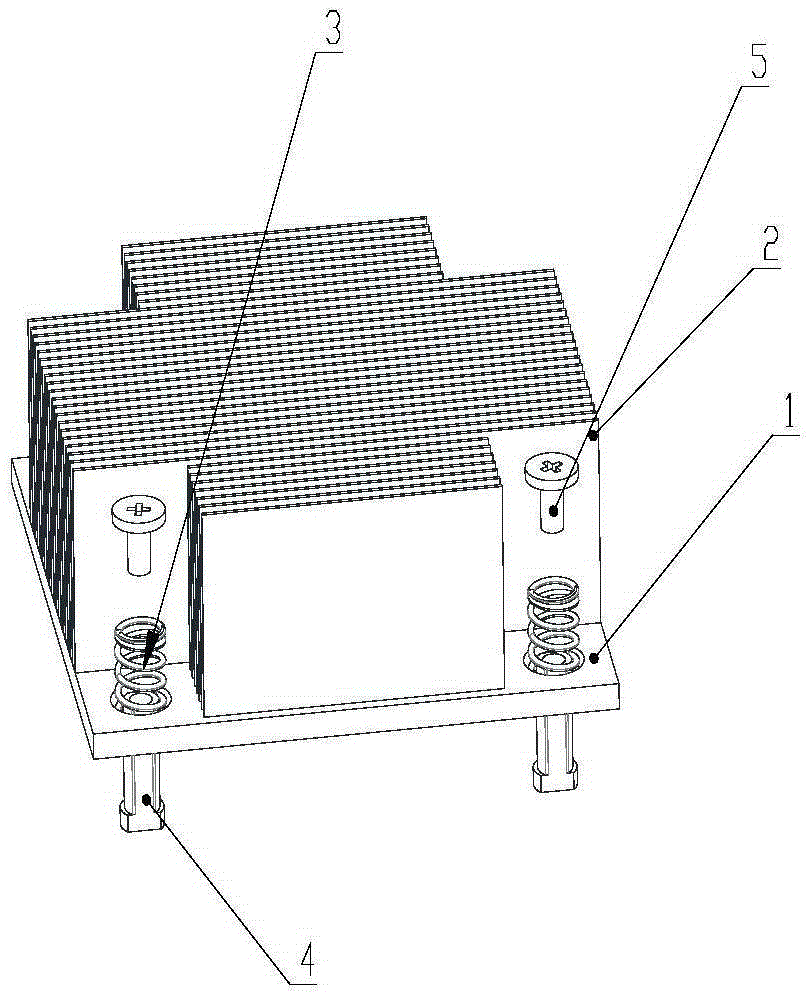

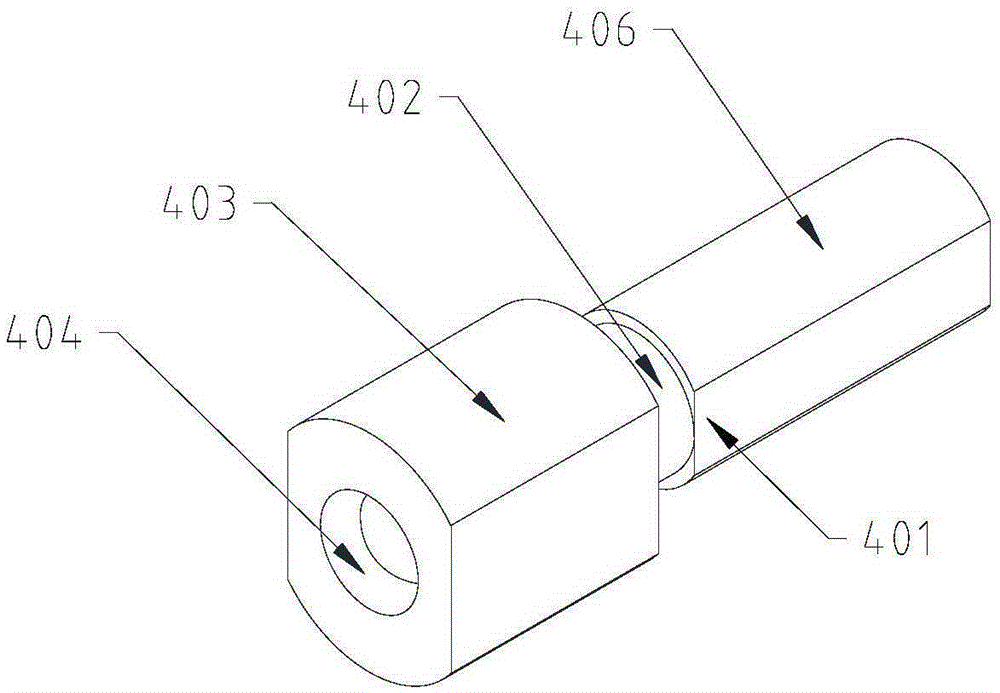

Chip heat radiation assembly and chip circuit board thereof

InactiveCN105280589AImprove reliabilityImprove assembly efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringRadiation effect

The invention discloses a chip heat radiation assembly and a chip circuit board thereof. The heat radiation assembly comprises a base (1), heat radiation fins (2), springs (3), adjusting rod assemblies (4) and locking screws (5). The upper surface (104) of the base (1) is provided with circular holes (102) and special-shaped through holes (101), wherein the depths of the circular holes (102) are smaller than the thickness of the base (1). The lower surface (105) of the base is provided with a base boss (103) for installing a chip. Each adjusting rod assembly (4) comprises a support bar (401) and an adjusting nut (403), the support bar (401) is composed of a polished rod (406) and a threaded rod (402), the adjusting nut (403) is internally provided with a threaded through hole (405), and the threaded rod (402) is provided with external threads screwed with an inner threaded hole (404). The height of each adjusting nut (403) is smaller than the sum of heights of the chip and the base boss (103), and the locking screws (5) are screwed into the threaded through holes (405). The invention can improve the heat radiation effect and the assembly reliability.

Owner:GUANGXUN SCI & TECH WUHAN

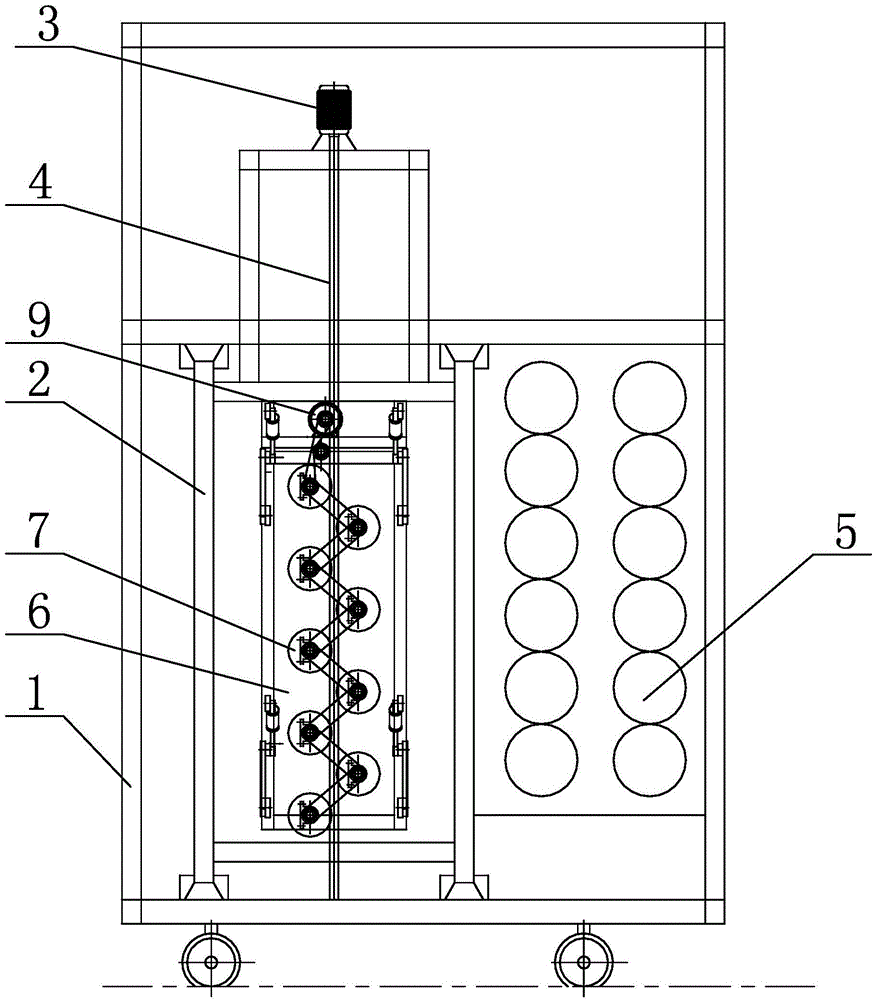

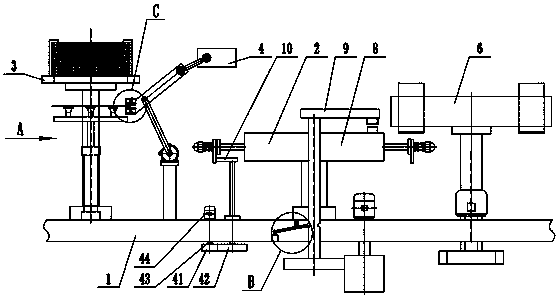

Dust collection type putty grinding device

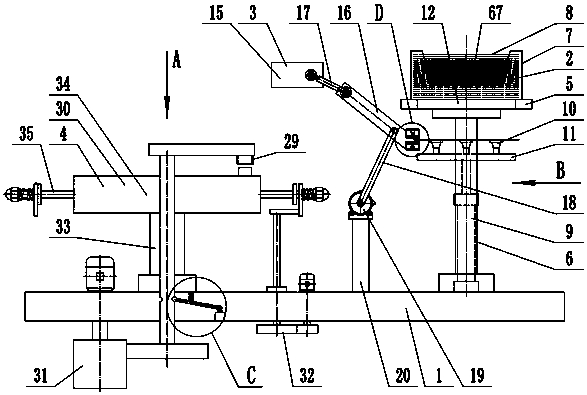

ActiveCN104084858ARealize all-round grindingAdjust the pressing forceGrinding carriagesGrinding bedsEngineeringMoving frame

The invention discloses a dust collection type putty grinding device which comprises a trolley capable of moving transversely. The trolley is provided with a vertical moving frame and a first driving mechanism driving the vertical moving frame to vertically move. A grinding assembly, a blowing mechanism and a dust collection cover are installed on the vertical moving frame, wherein the blowing mechanism is located on one side of the grinding assembly, and both the grinding assembly and the blowing mechanism are together covered with the dust collection cover. A dust removing device is connected to the rear portion of the dust collection cover through a dust collection air pipe. The grinding assembly comprises a supporting body installed on the vertical moving frame. The supporting body is provided with a plurality of rotatable grinding heads and a second driving mechanism, wherein the grinding heads are located on the front end face of the supporting body, and the second driving mechanism drives the grinding heads to rotate. According to the dust collection type putty grinding device, putty on the side of the trolley can be automatically ground, the grinding strength is adjustable, the ideal grinding effect can be achieved, and labor is greatly saved. In addition, when the dust collection type putty grinding device is used for putty grinding, almost no dust is discharged, no pollution is produced to the environment, and no negative effects are produced on the body health of workers.

Owner:安徽中车浦镇城轨交通运维科技有限公司

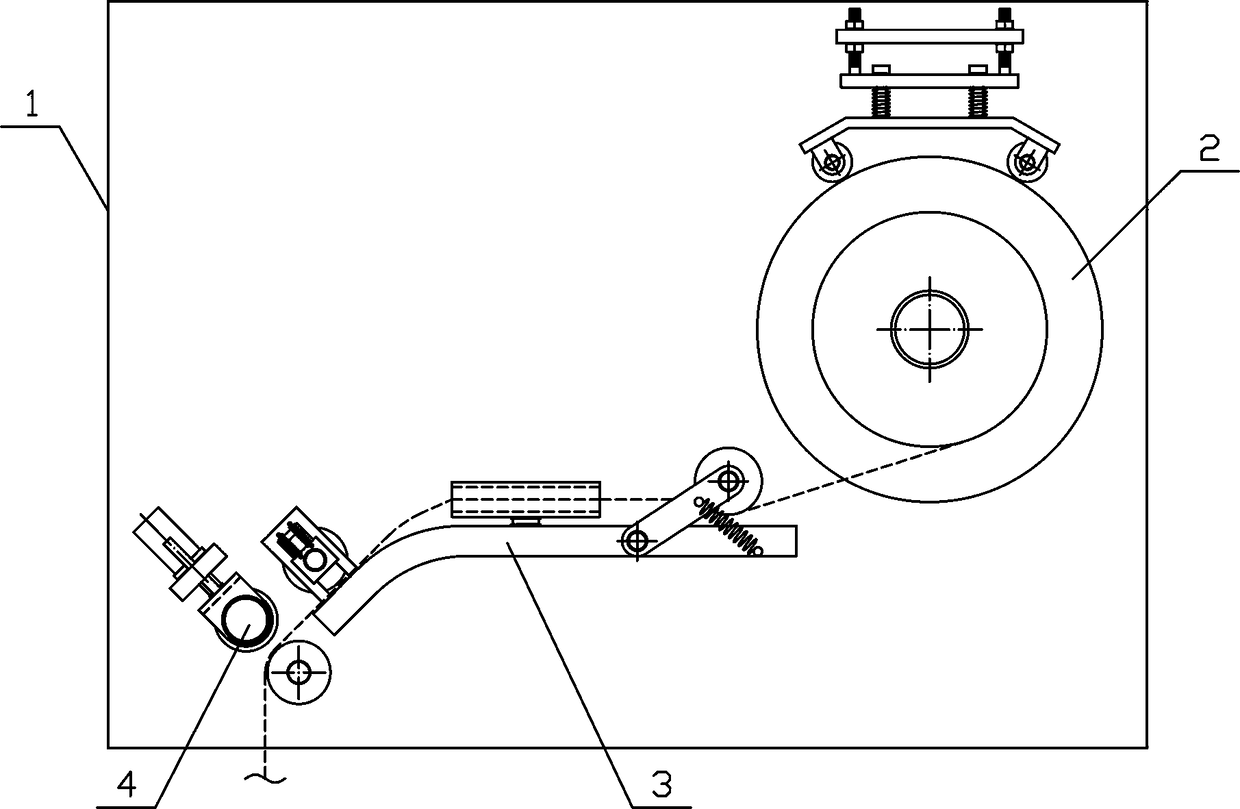

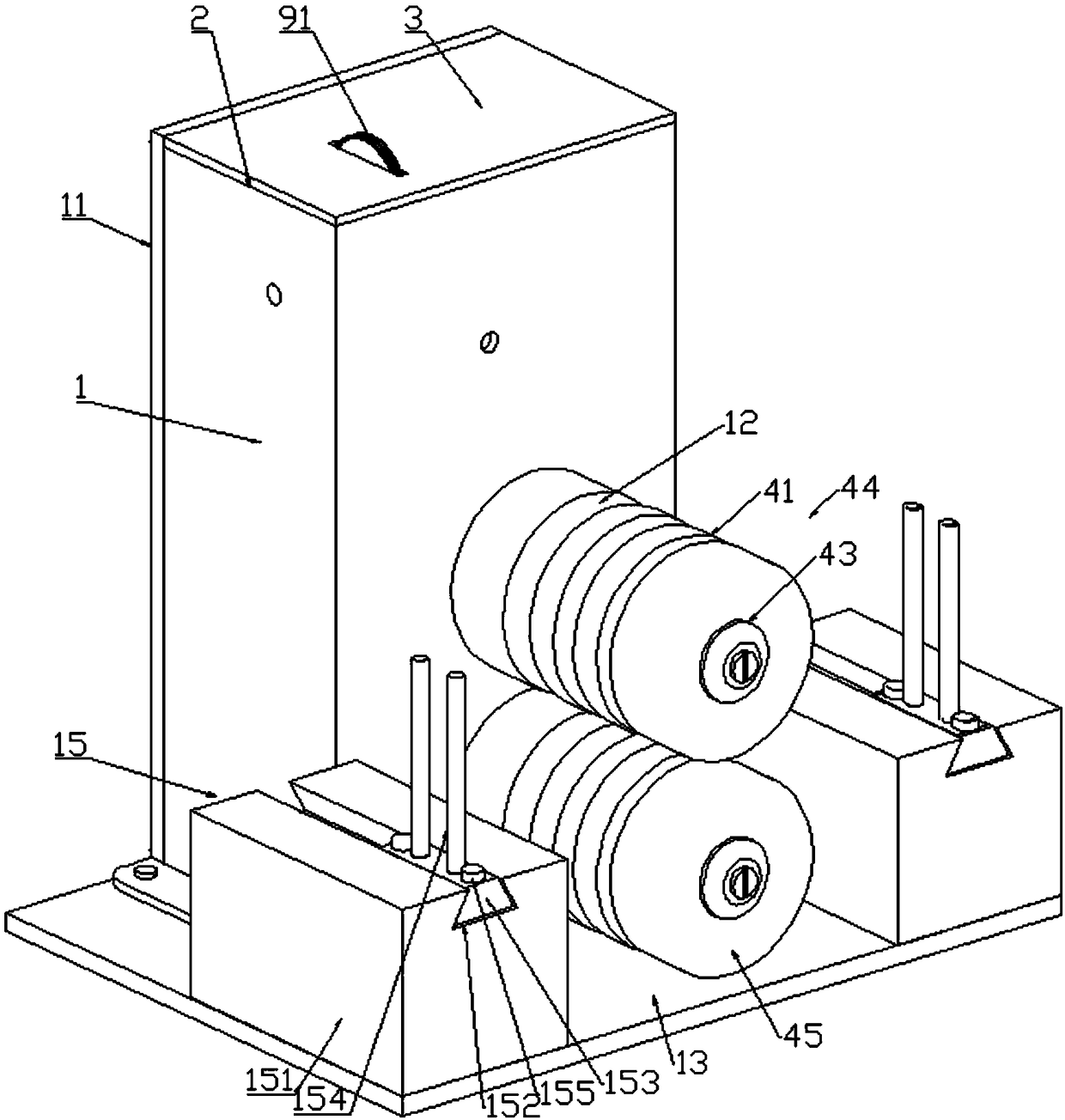

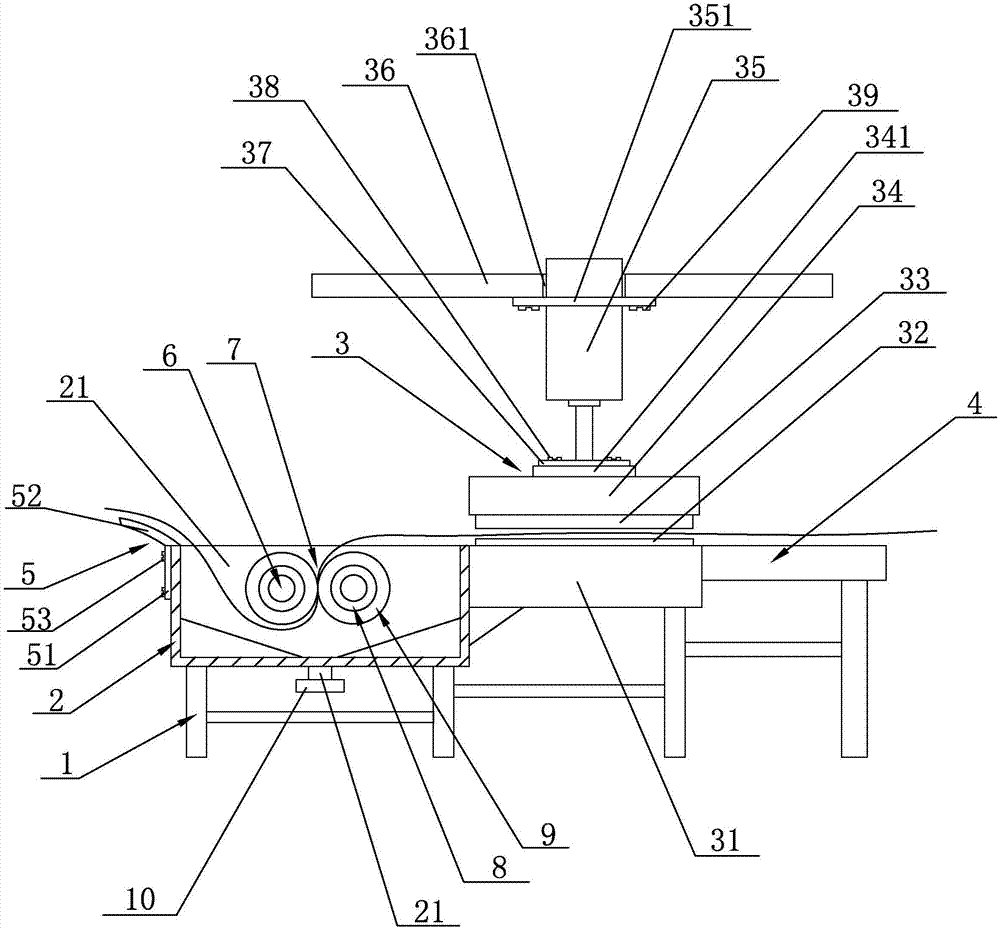

Linen strip damping unwinding mechanism

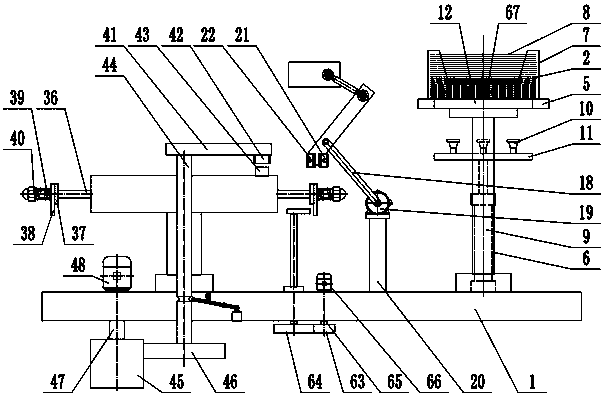

InactiveCN108861854AStable unwindingSmooth transmissionFilament handlingCircular discMechanical equipment

The invention discloses a linen strip damping unwinding mechanism and belongs to the field of textile processing mechanical equipment. An unwinding mechanism body of the linen strip damping unwindingmechanism is vertically arranged on one side of the upper portion of a fixed bracket. A strip pulling mechanism is arranged on the position, on the lower side of a strip conveying mechanism, of the fixed bracket. A roll-bearing rotary roller is horizontally and fixedly arranged in the middle of one side of a rotating disc. The two sides of the lower portion of a damping bracket are symmetrically and rotationally connected with damping rotary wheels correspondingly. A feeding press roller is horizontally arranged on one side of the upper portion of a strip conveying bracket. A strip guiding channel is horizontally formed in a strip guiding sleeve. The two ends of a strip-guiding press roller are rotationally connected to strip-pressing guiding plates on the two sides of the strip conveyingbracket correspondingly. A material-pulling rotary roller is horizontally and rotationally connected to a lifting bracket. A strip-bearing rotary roller is horizontally and rotationally connected to the position, on the lower side of the material-pulling rotary roller, of the fixed bracket. The linen strip damping unwinding mechanism is reasonable in structural design, linen strips can be stably and accurately unwound and conveyed efficiently, conveniently and rapidly, the unwinding and conveying efficiency and quality of the linen strips are improved, and the needs of production and use are met.

Owner:于星杰

Plastic thin film laminating machine

The invention provides a plastic thin film laminating machine. The plastic thin film laminating machine comprises a rack, a first unwinding roller, a second unwinding roller, a pair of laminating rollers, a gluing mechanism, a traction mechanism and a winding mechanism. The first unwinding roller and the second unwinding roller are rotatably connected to the rack, the laminating rollers are rotatably arranged at the position, between the gluing mechanism and the traction mechanism, of the rack, the winding mechanism comprises a transfer base and a winding roller, the two ends of the winding roller are provided with winding rotating shafts, one end of the rack is provided with a C groove allowing the winding rotating shafts to transversely slide in, the transfer base is provided with a supporting structure for supporting the winding rotating shaft to rotatably adjust the height of the winding roller, and a driving motor, a driven shaft, a winding shaft sleeve and a gear assembly are arranged on one side of the rack. The supporting structure in the winding mechanism can adjust the height of the U supporting part, the winding rotating shaft can be aligned with a shaft hole of a driven shaft, and the driven shaft drives the winding roller to rotate more stably.

Owner:浙江天畅塑胶有限公司

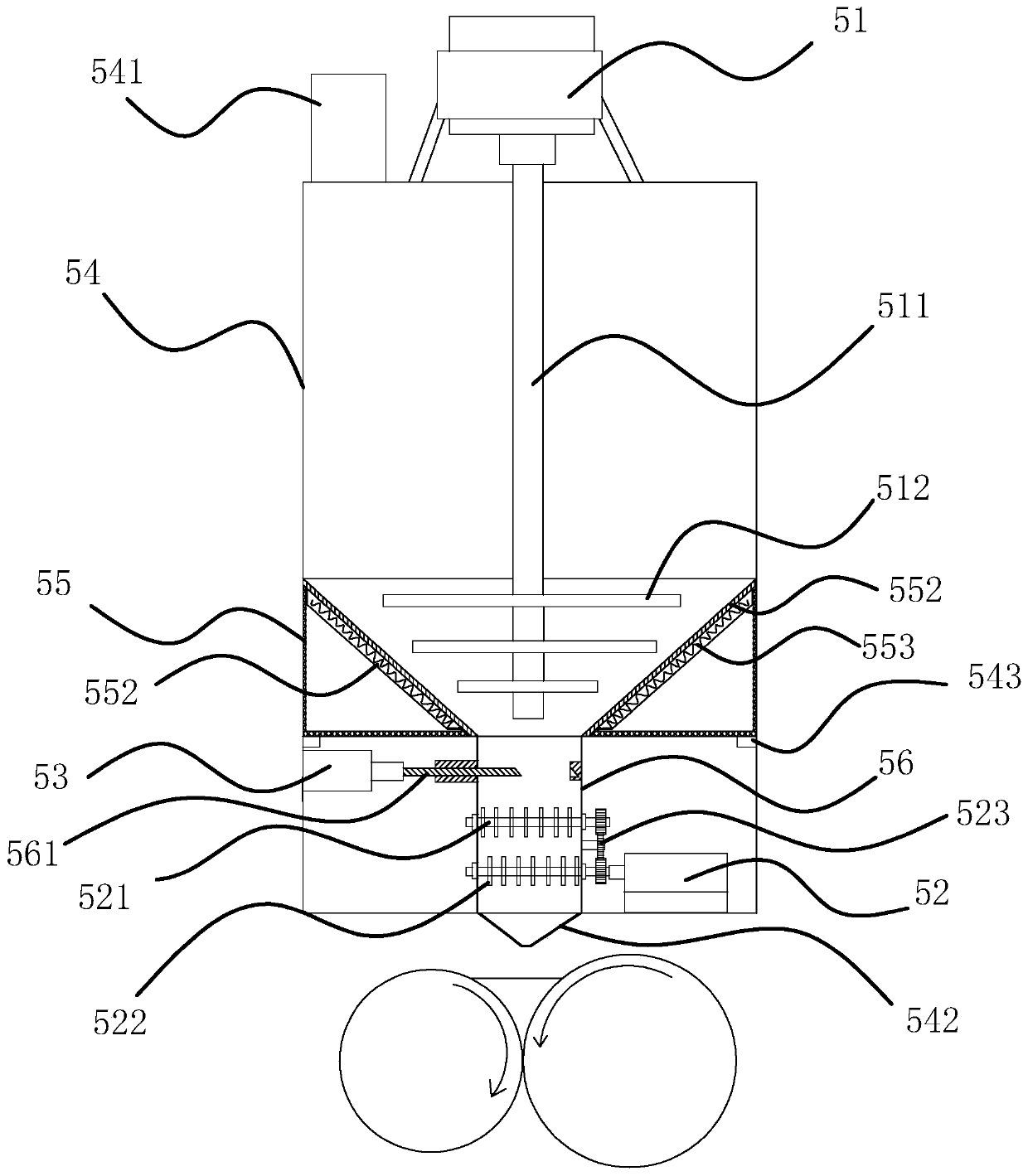

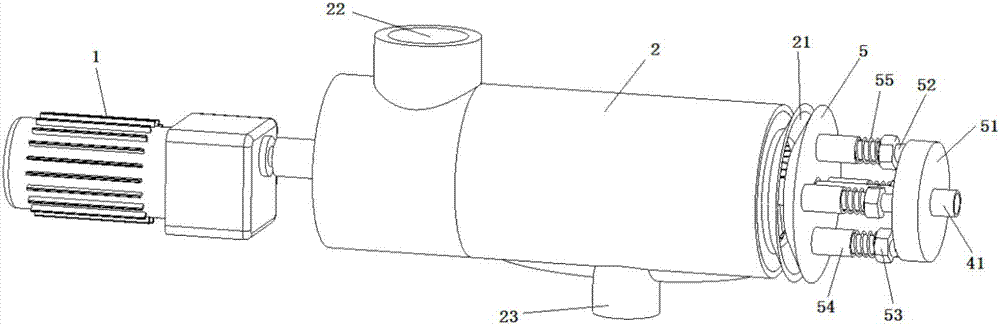

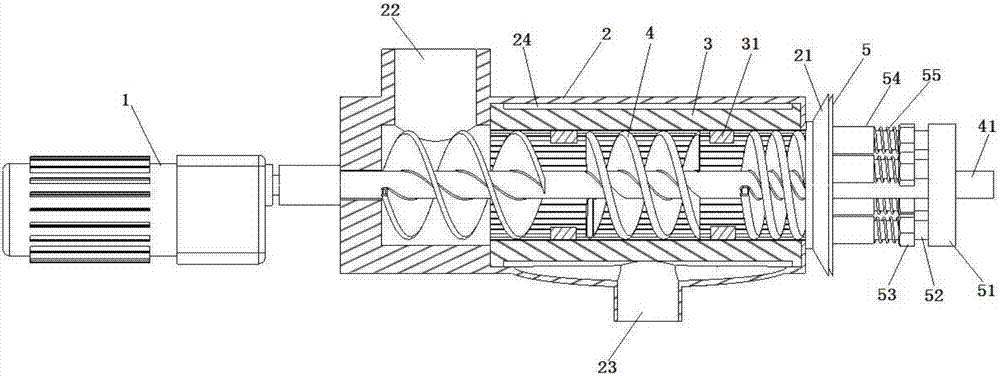

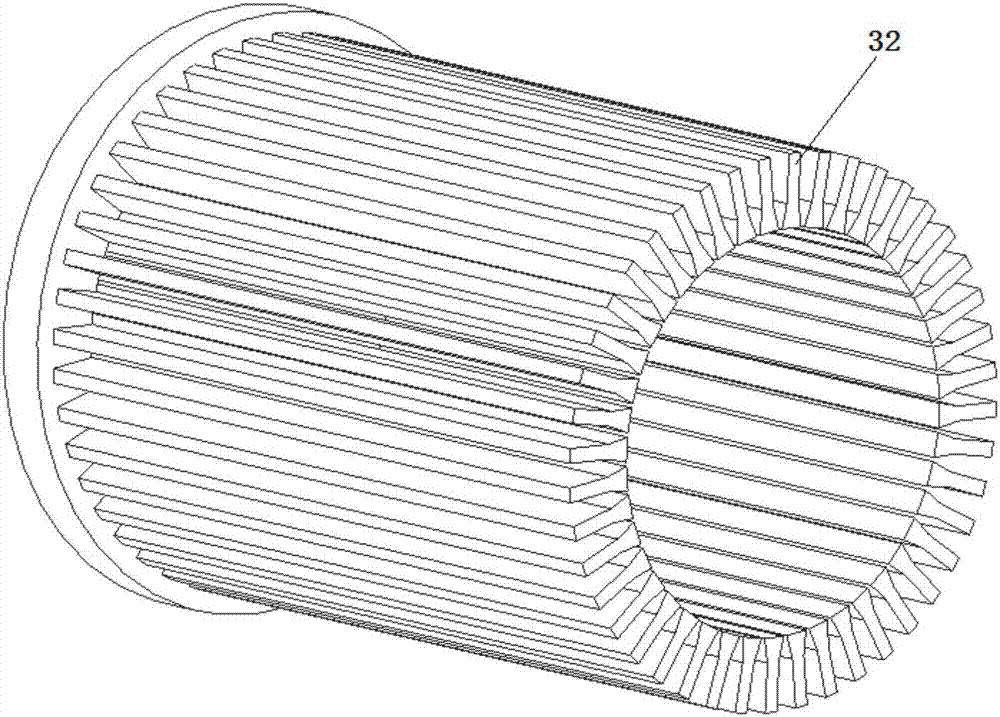

Spiral extrusion type excrement solid-liquid separation device capable of controlling solid humidity

The invention discloses a spiral extrusion type excrement solid-liquid separation device capable of controlling the solid humidity, and relates to an excrement solid-liquid separation device. The device aims at solving the problems that an existing excrement solid-liquid separation device is high in maintenance cost and long in separation time, separated-out solid is high in moisture content, accordingly, the microorganism reaction environment cannot be effectively controlled, and a screen net type solid-liquid separation device is likely to be blocked. The device is composed of a motor, a separator shell, a screen drum, a packing auger and a discharge outlet compression cover. A packing auger shaft of the packing auger is provided with multiple spiral blades. The thread distance of each spiral blade is gradually reduced from the side of the closed end of the separator shell to the side of a conical opening of the separator shell. The screen drum is composed of multiple wedge-shaped strip plates distributed at equal intervals. The inner wall of the screen drum is provided with multiple blocking teeth. The device is stable in operation, solves the problem that blockage is likely to be caused, can control the humidity of solid waste, can meet the requirements of fungi for living environment to enable fungi to be in the optimal fungus living and growth conditions, and is applicable to excrement solid-liquid separation.

Owner:青岛哈工程正和环保科技有限公司

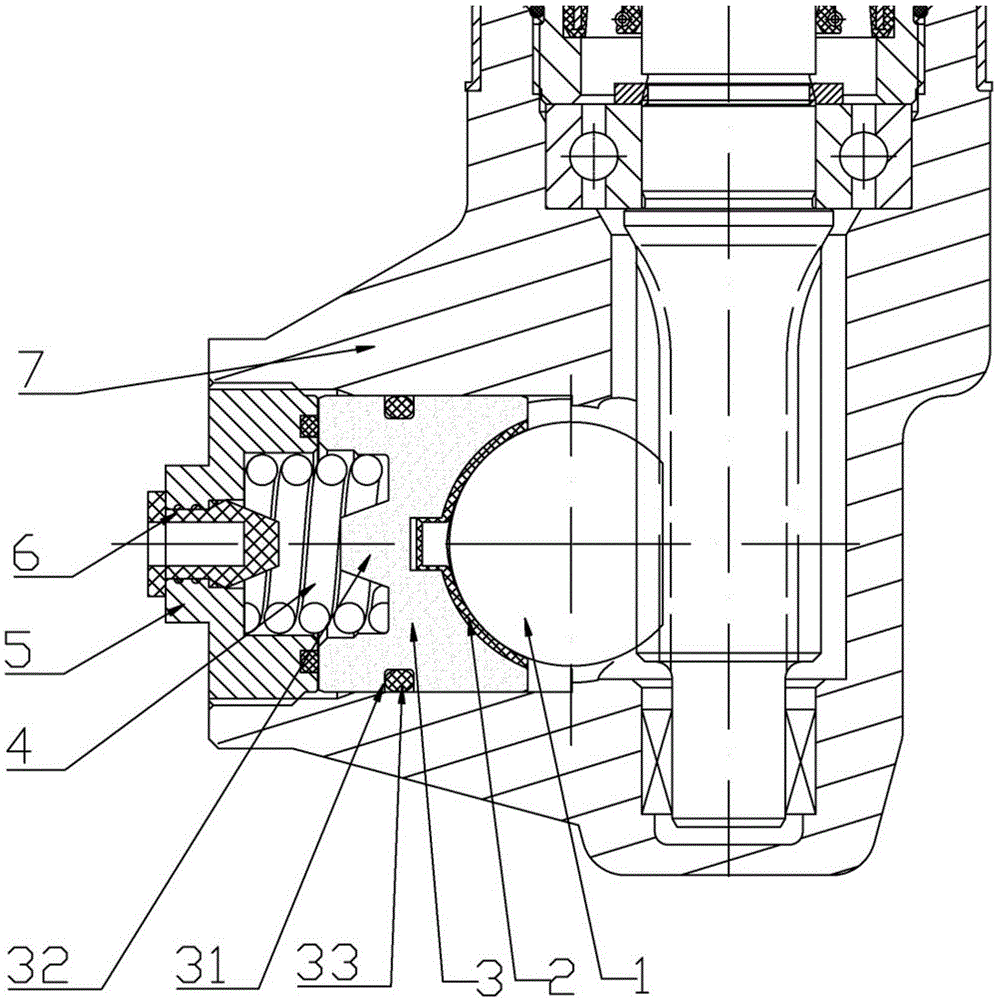

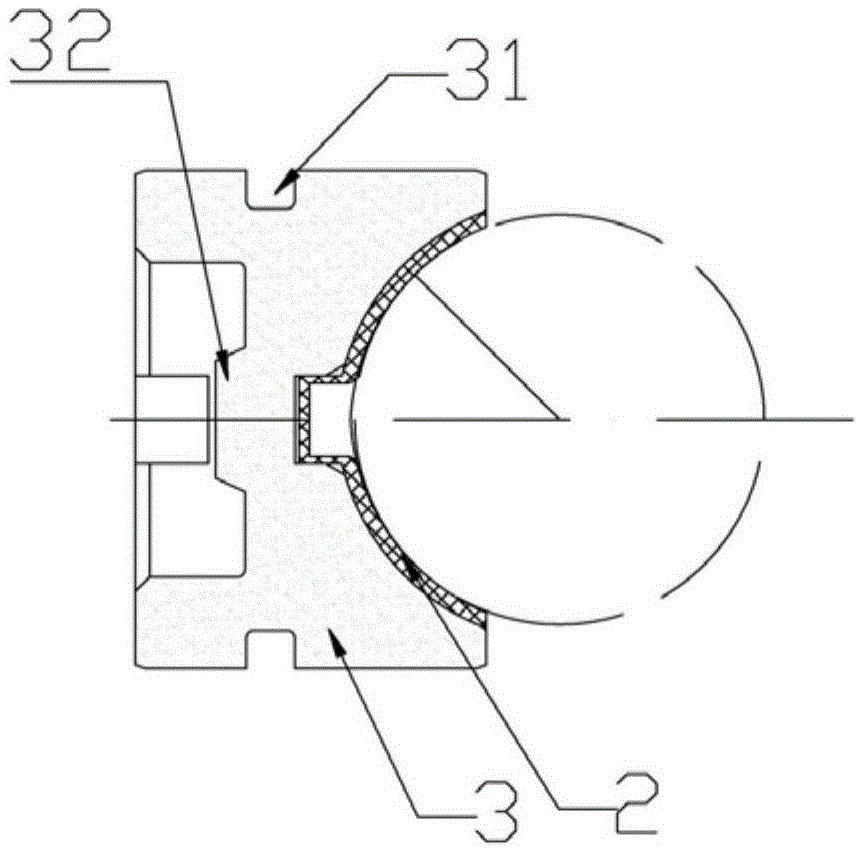

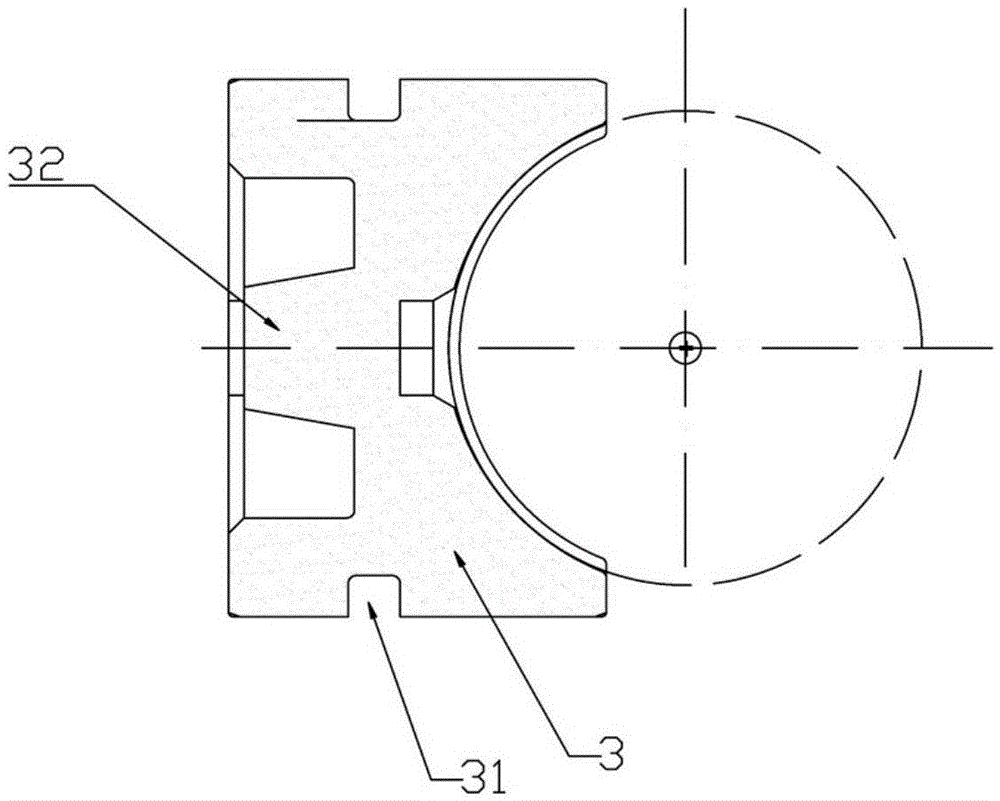

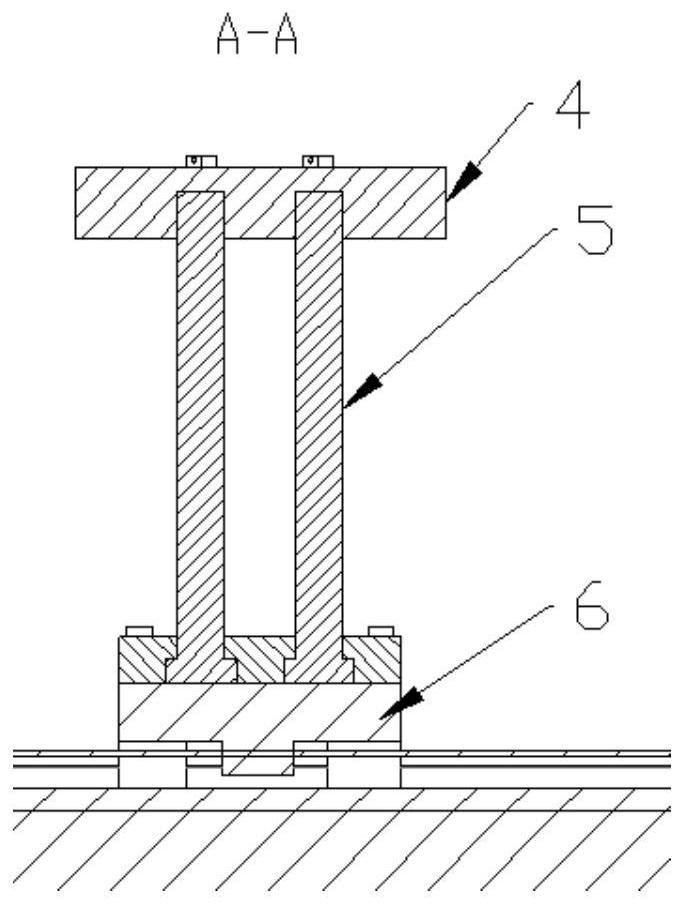

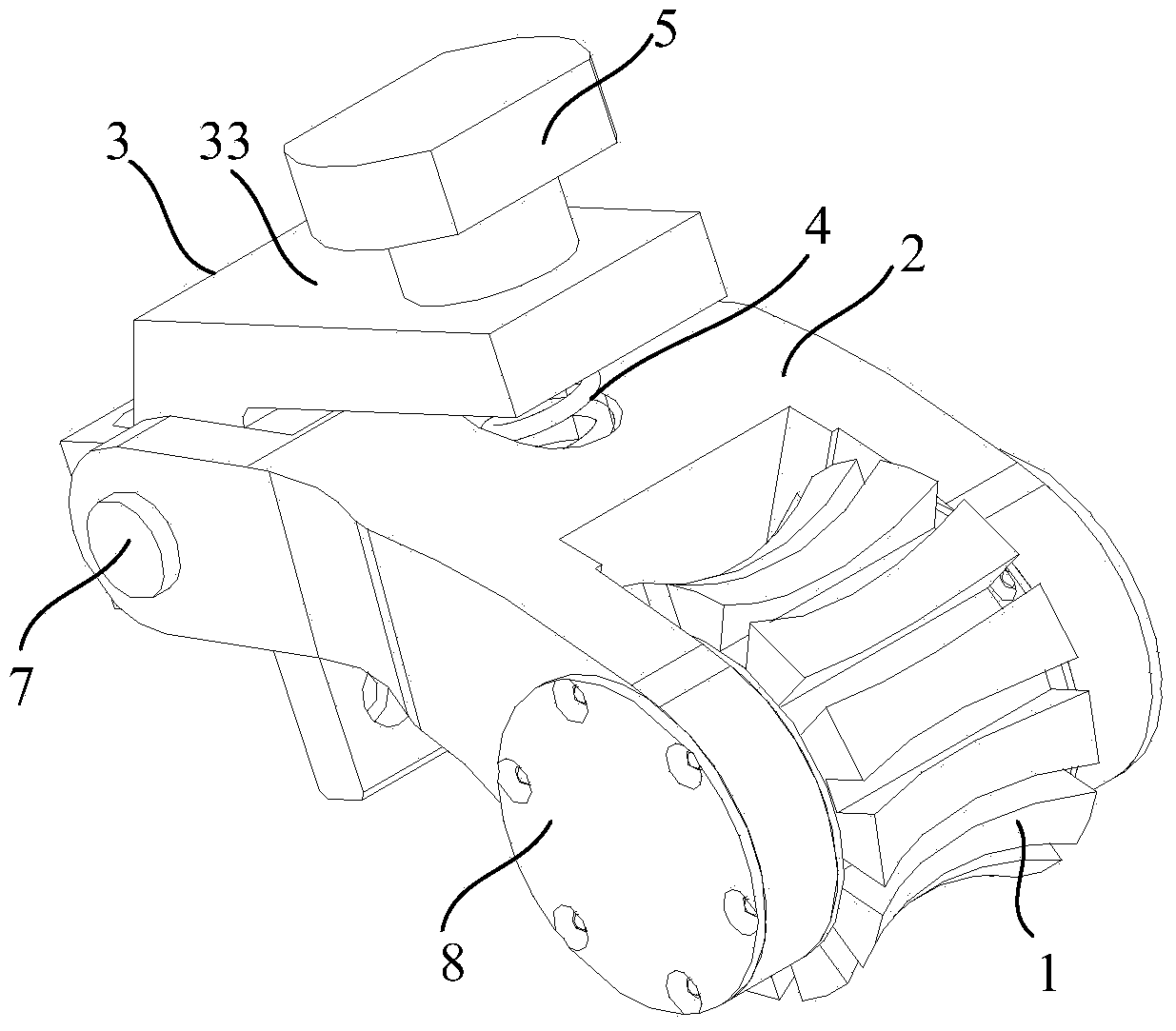

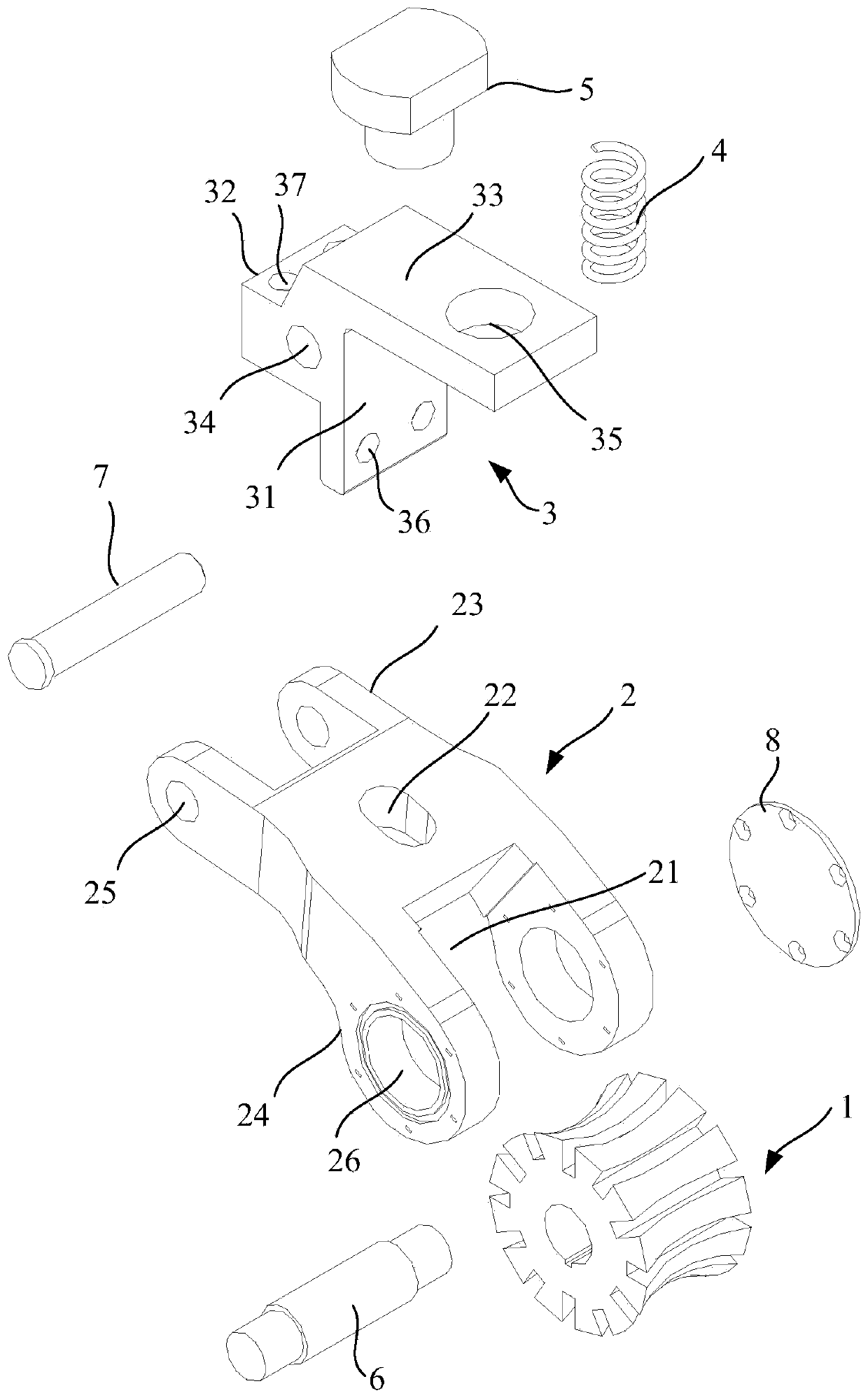

Pressure-adjustable steering gear rack compaction structure

InactiveCN105564494AIncrease contact areaReduce frictionMechanical steering gearsLubricationIn degree

The invention discloses a pressure-adjustable steering gear rack compaction structure. The pressure-adjustable steering gear rack compaction structure comprises a gear, a rack (1), a supporting pressure block (3), an arc-shaped pressure sheet (2), a pressure cover (5) and a spring (4), wherein the gear and the rack (1) are engaged with each other and mounted in a housing (7); the supporting pressure block (3) compacts the rack (1) and one end, opposite to the rack (1), of the supporting pressure block (3) is arc-shaped; the arc-shaped pressure sheet (2) is arranged between the supporting pressure block (3) and the rack (1), and an oil tank which stores a lubrication medium is arranged on one side, in contact with the rack (1), of the pressure sheet (2); the pressure cover (5) compacts the supporting pressure block (3) and is in threaded connection with the housing (7); and the spring (4) is arranged between the pressure cover (5) and the supporting pressure block (3). The deformation degree of the spring (4) is changed by changing the screw-in degree of the pressure cover (5), so that the compaction force is adjusted, the area of contact with the rack (1) is enlarged, the friction is reduced, the abrasion of the rack (1) is reduced, and the service life of a steering gear is prolonged; and the compaction force of the spring (4) is adjusted through a sealing screw (6).

Owner:WUHU STERLING STEERING SYST

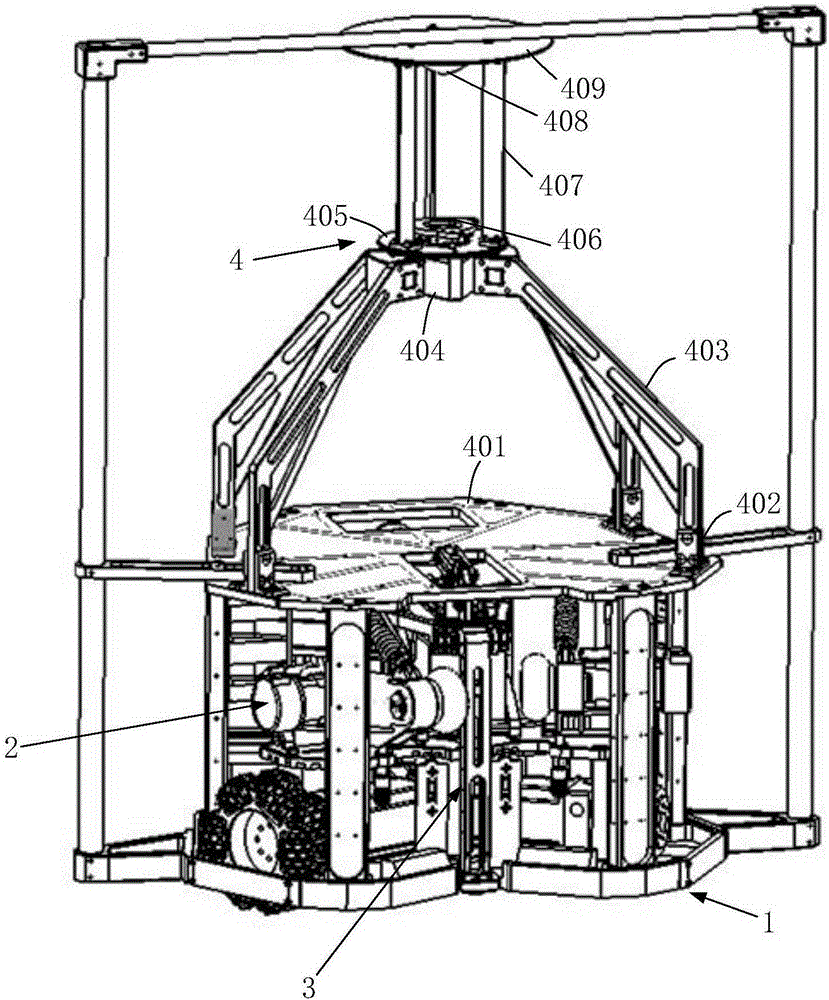

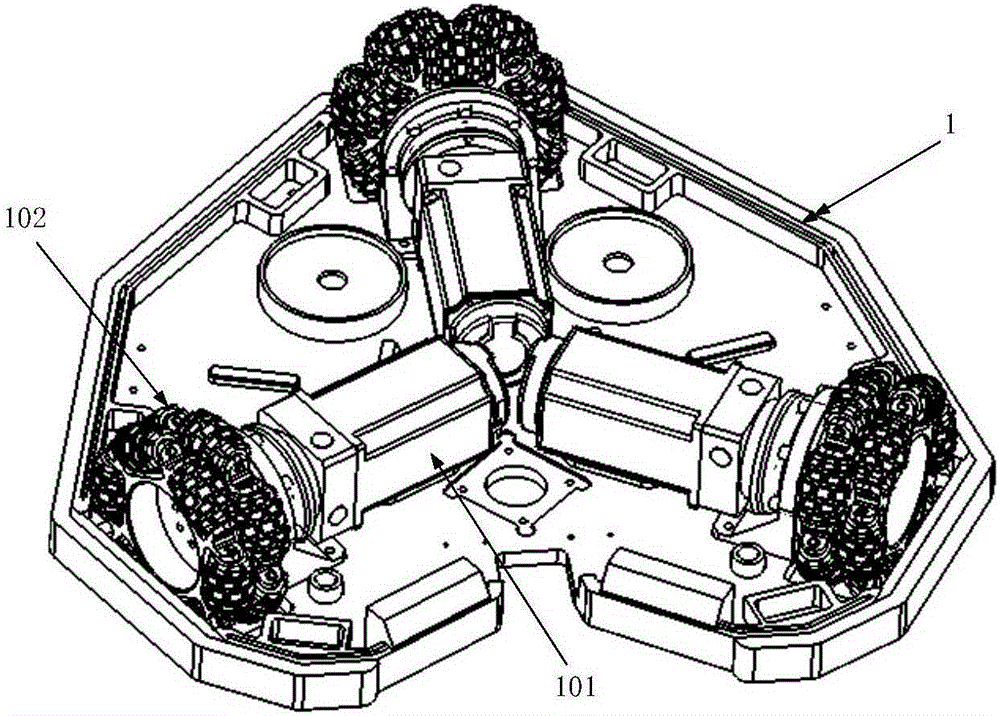

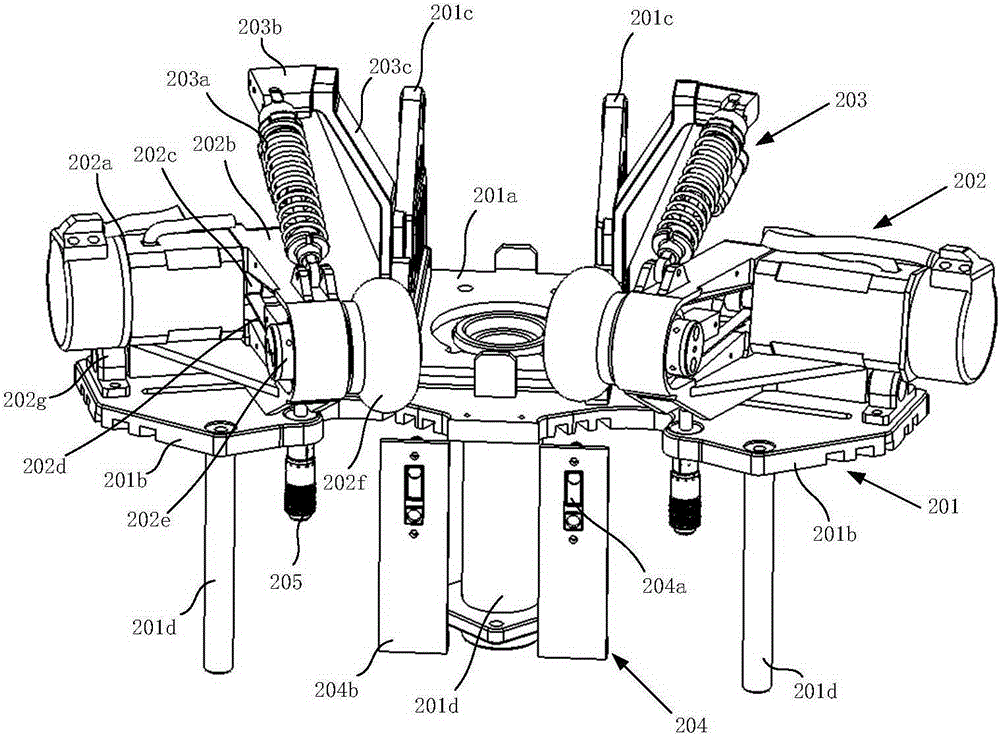

Modularized football robot

InactiveCN105148528AReasonable useEasy to assemble and disassembleSelf-moving toy figuresSoccer robotControl system

The invention discloses a modularized football robot which comprises an all-direction moving underframe, a dribbling device, a ball kicking device and a top-layer visual device. The all-direction moving underframe is used for moving of the robot, the dribbling device, the ball kicking device and the top-layer visual device are mounted on the all-direction moving underframe, the dribbling device drives two rollers to rotate from front to rear through a motor to enable a football to be fitted with the rollers all the time, the ball kicking device is mounted on the upper portion of the dribbling device, and a ball hitting rod is controlled to swing back and forth through an electromagnet to quickly move forwards to push the football to move; up-down position of the ball hitting rod driven by the motor is adjustable, so that adjusting of different shooting angles is realized; the top-layer visual device is positioned on the uppermost portion, and image information on a reflection mirror site is collected and transmitted to a control system through a camera to determine a target position of the next step. The modularized football robot has the advantages that the all-direction moving underframe is of a modularized structure, so that space is utilized reasonably; the modularized football robot is convenient to mount and demount and compact in structure.

Owner:BEIJING INFORMATION SCI & TECH UNIV

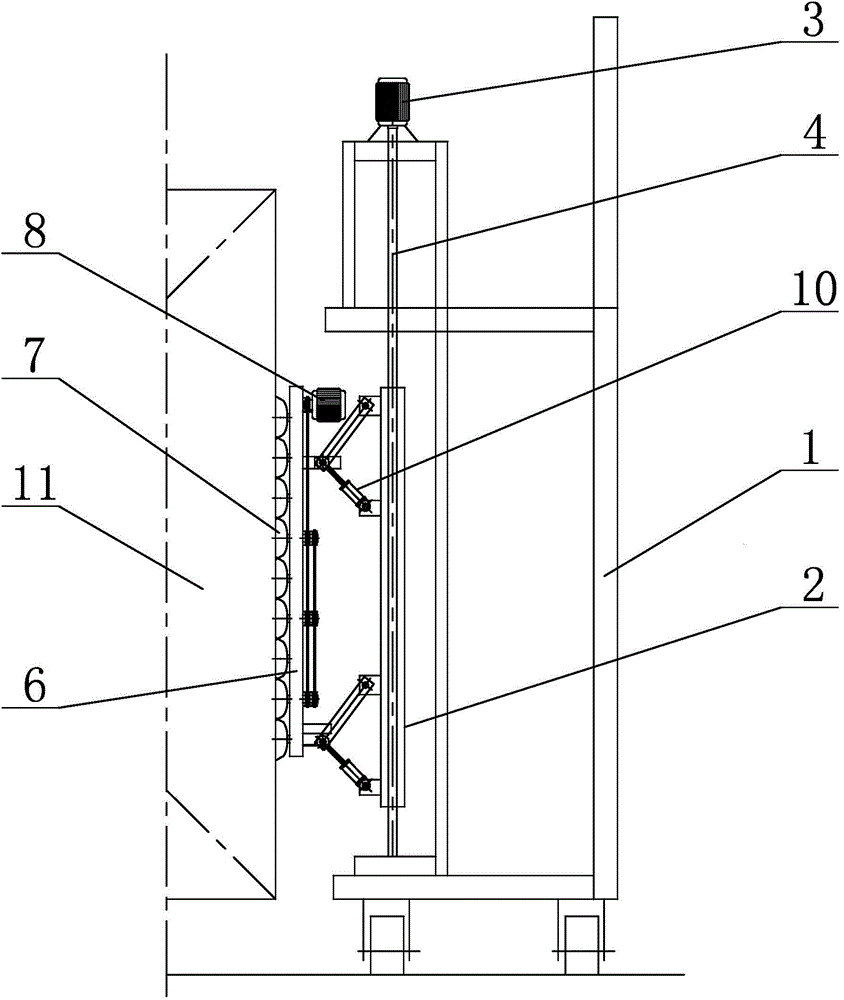

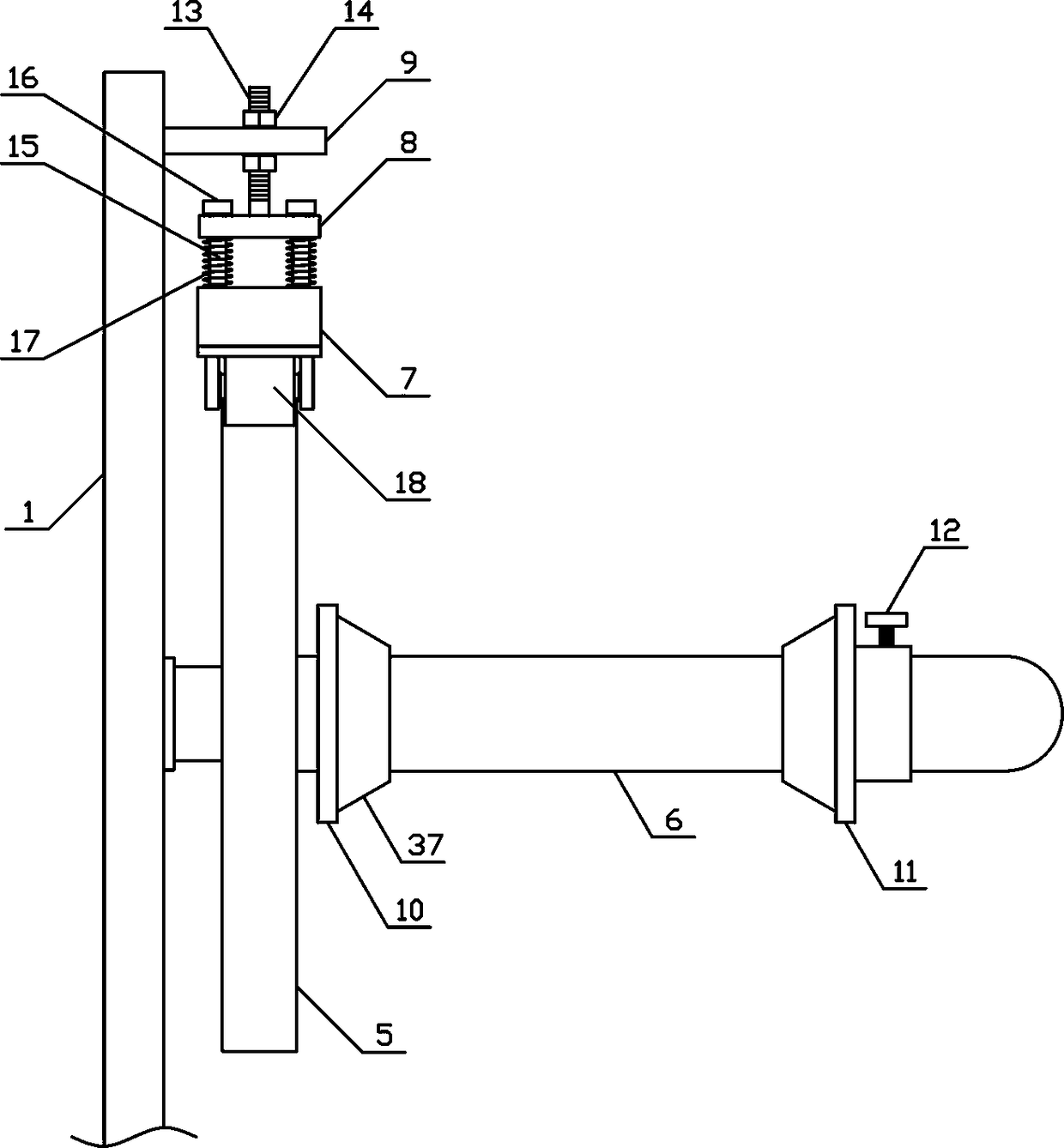

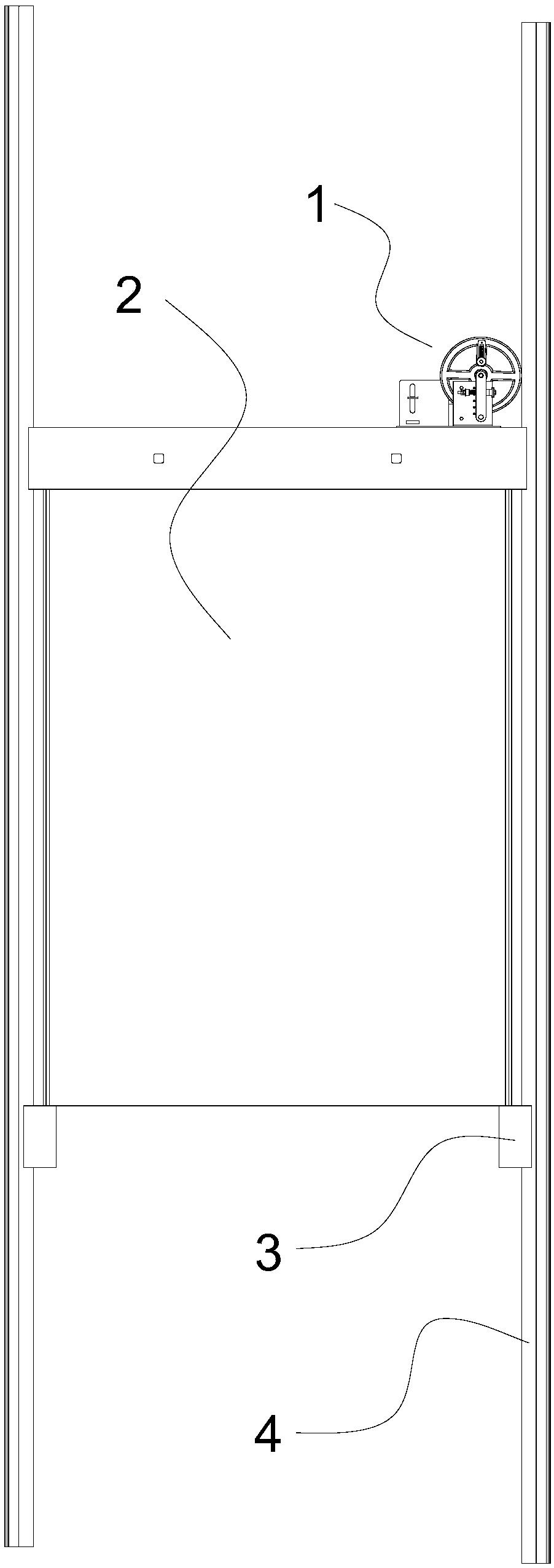

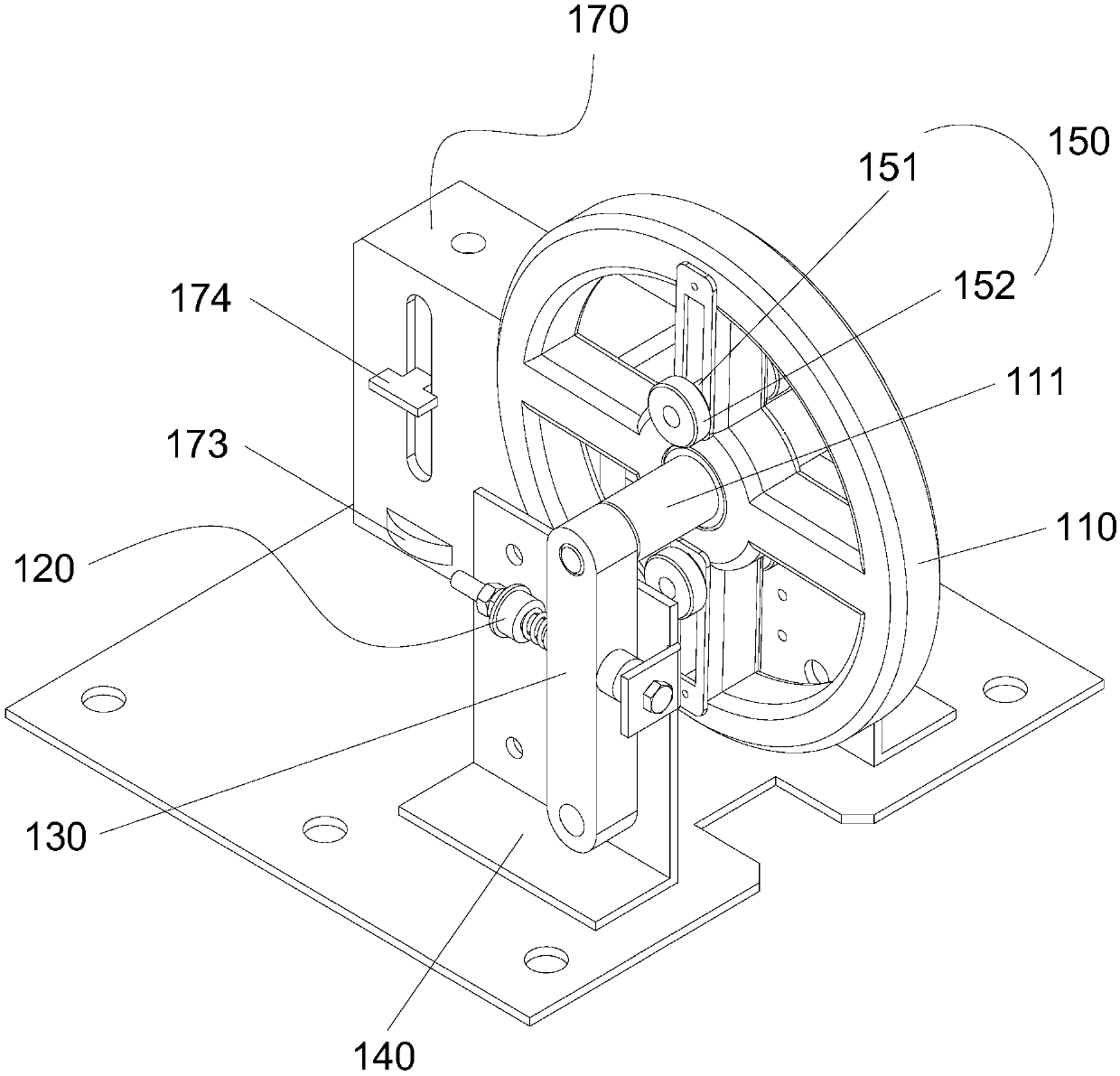

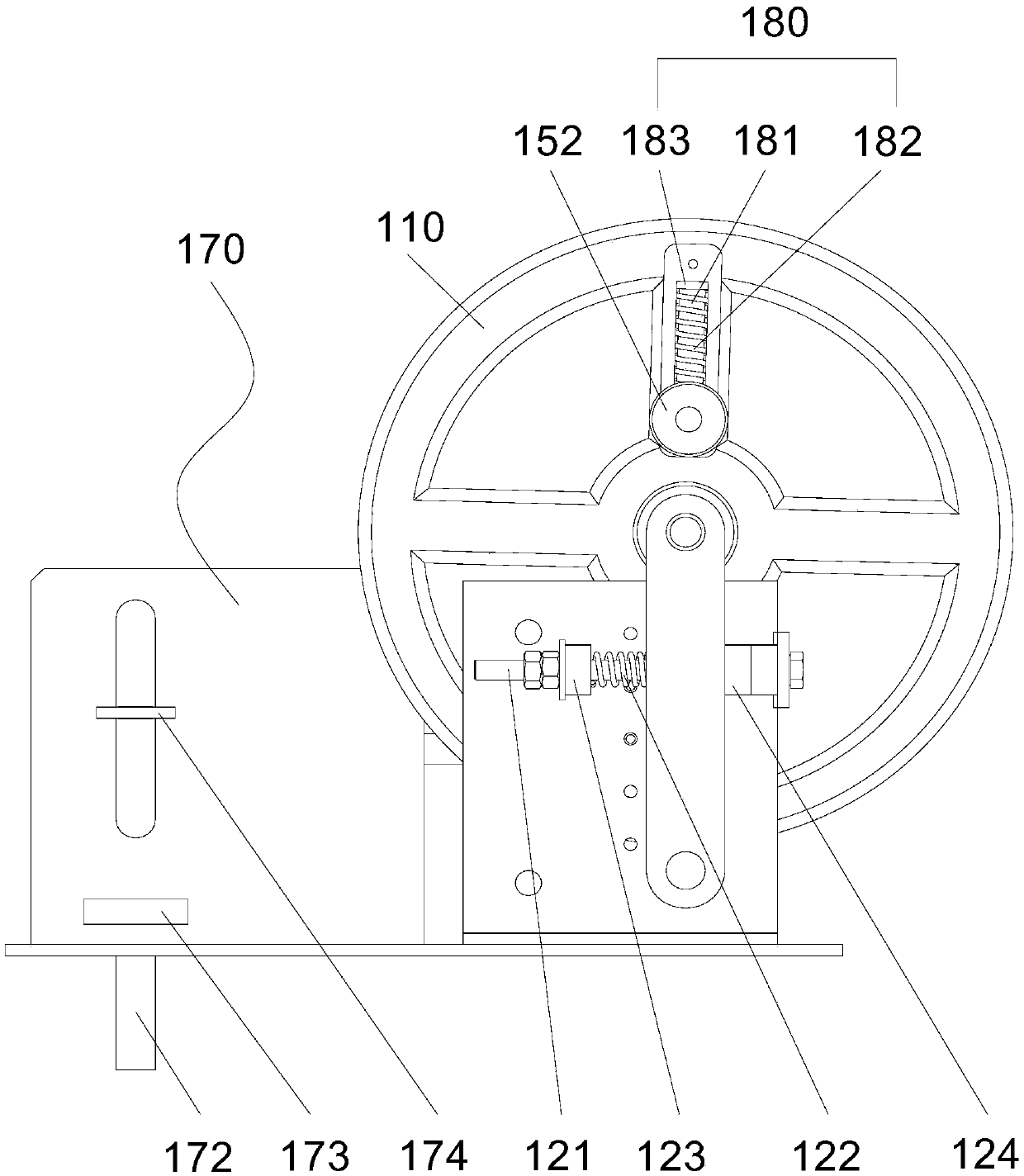

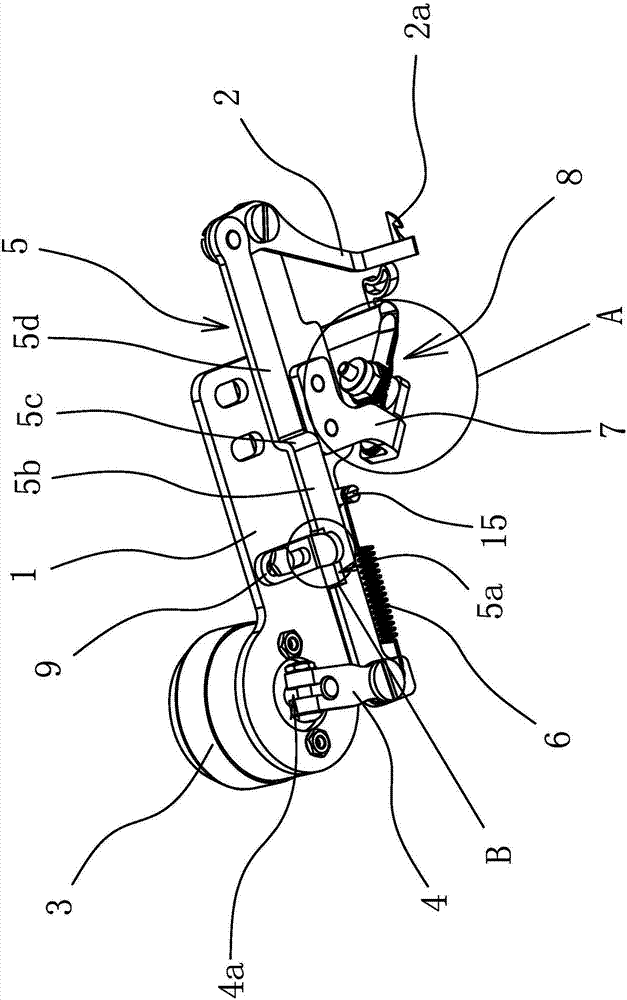

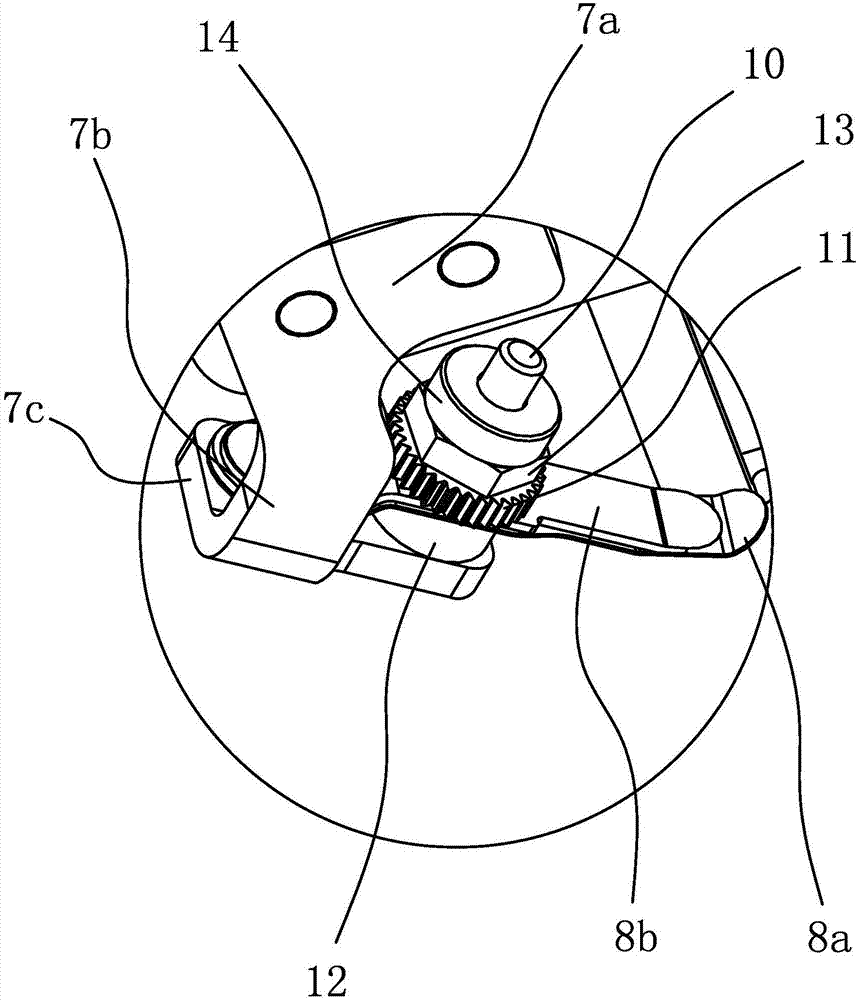

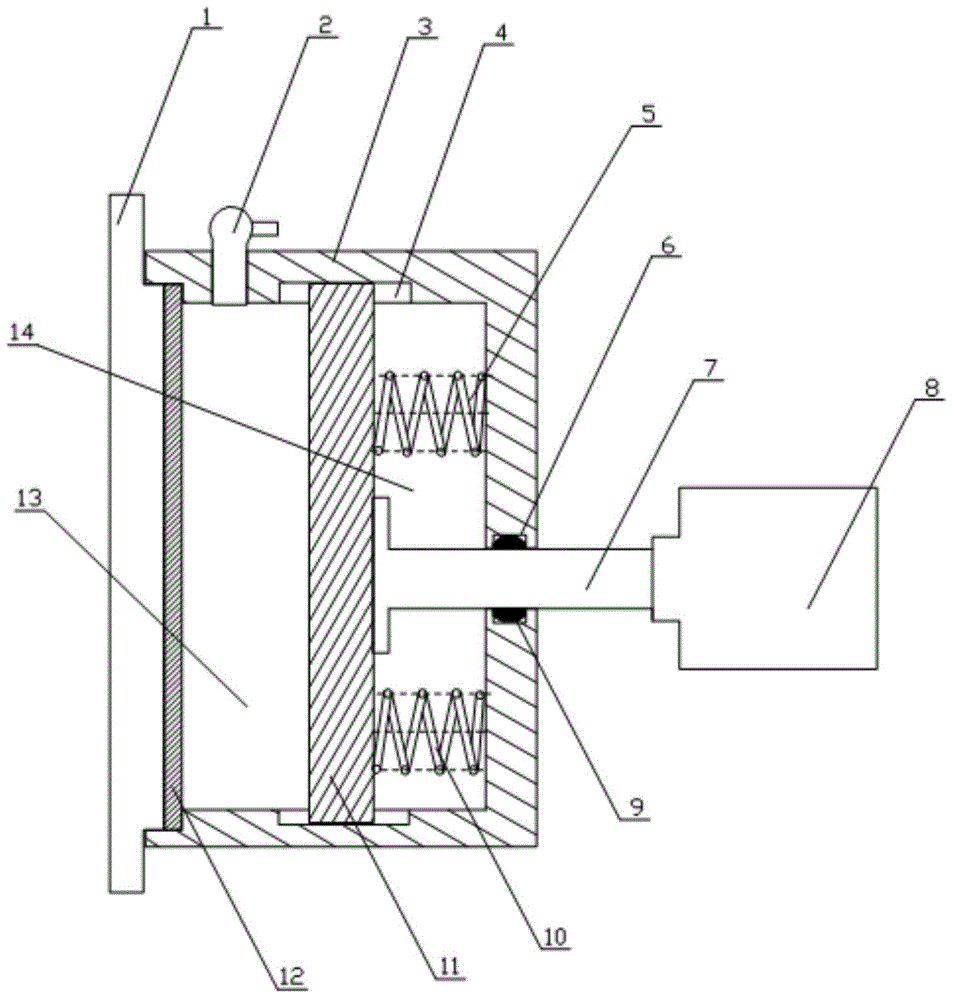

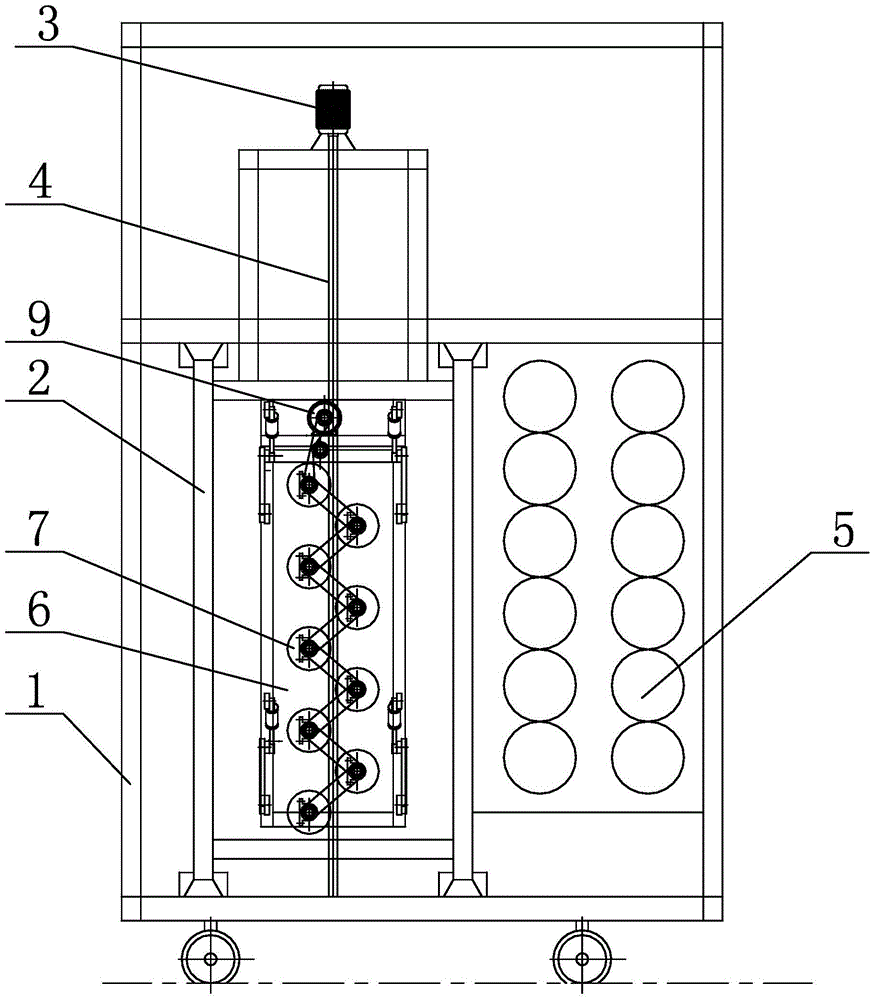

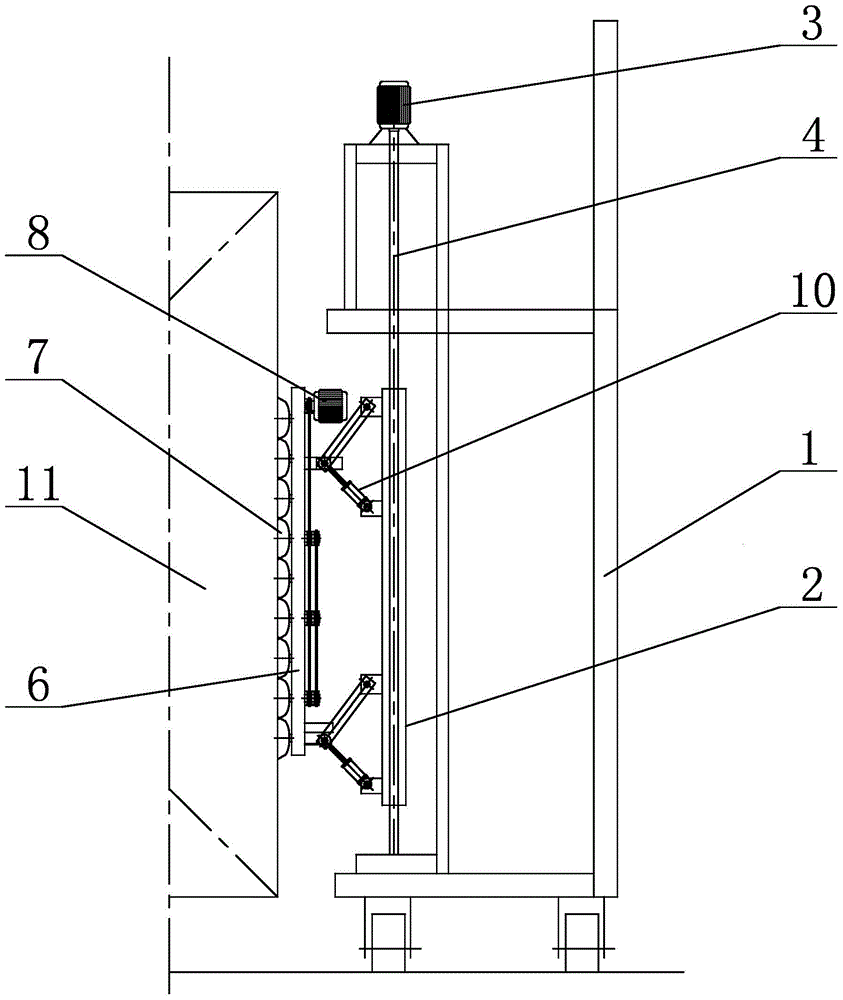

Speed monitoring and braking device for vertical lifting equipment

PendingCN108033330ANot affected by lifting heightNo additional space requiredLifting framesElevatorsIdler-wheelArresting gear

The invention discloses a speed monitoring and braking device for vertical lifting equipment. The equipment includes an idler wheel, a rotating shaft, a centrifugal block, a centrifugal block balancing mechanism, a main-engine safety switch and a brake triggering device; the idler wheel tightly presses a guide rail, the rotating shaft is arranged on the idler wheel in a penetrating mode and connected with a carriage body, the centrifugal block can be movably arranged on the idler wheel in the radial direction of the idler wheel, the centrifugal block balancing mechanism includes a compressibleelastic part, the compressible elastic part is arranged between the centrifugal block and the circumference of the idler wheel, and after the centrifugal block is sensed, a first trigger mechanism ofthe main-engine safety switch is switched off; the brake triggering device includes a lifting rod and a second triggering mechanism, the lifting rod is connected with a safety gear lifting device, and after the centrifugal block is sensed, the second triggering mechanism of the lifting rod is triggered; in the radial direction of the idler wheel, the second triggering mechanism is farther away from the rotating shaft than the first triggering mechanism. According to the speed monitoring and braking device for the vertical lifting equipment, the situation that the use cost increases due to theincrease of the lifting height is avoided, when a steel wire rope is completely disconnected, effective braking can also be achieved, and no extra space for a machine rood and a wellhole is needed.

Owner:GUANGZHOU GUANGRI ELEVATOR IND

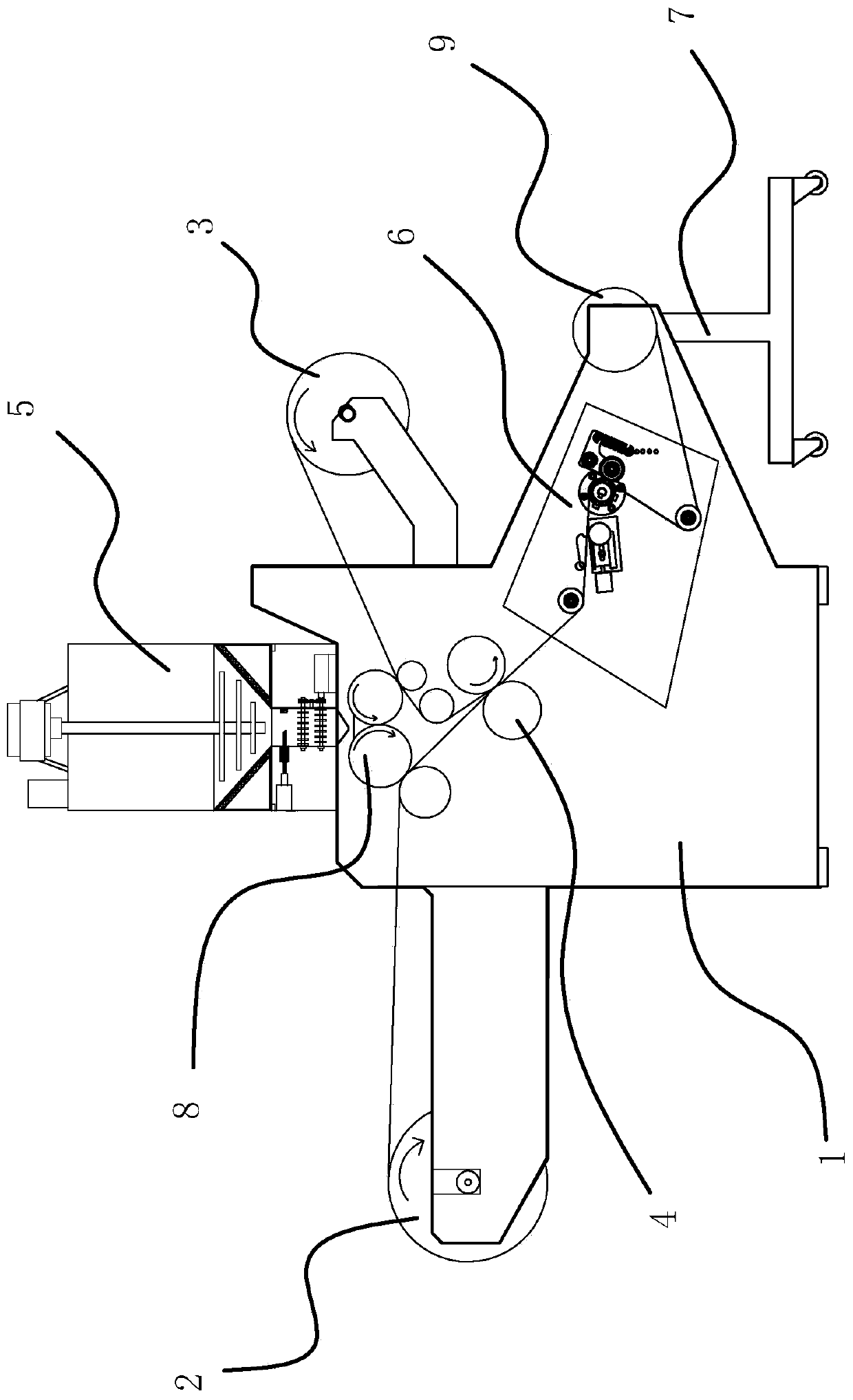

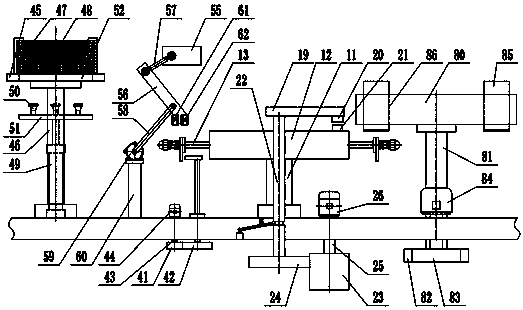

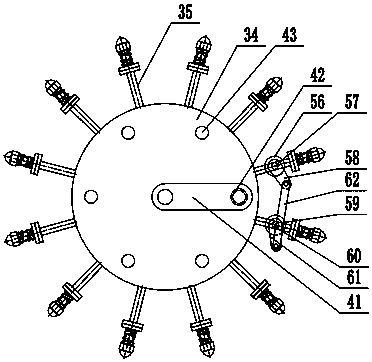

Rotary packaging bag filling and heat sealing device

InactiveCN108382654AAchieve clampingEasy to holdWrapper twisting/gatheringEngineeringMechanical engineering

The invention provides a rotary packaging bag filling and heat sealing device and belongs to the technical field of processing of tuber mustards. The device comprises a supporting pedestal, a fillingturning plate mechanism, a bag supply mechanism, a bag picking mechanism, a bag opening mechanism, an automatic separating mechanism and a heat sealing mechanism; the filling turning plate mechanism comprises a turning plate conveying component, a turning plate driving component and a bag receiving driving component; the bag supply mechanism is arranged at the left side of the filling turning plate mechanism; the bag picking mechanism is arranged between the bag supply mechanism and the filling turning plate mechanism; the bag opening mechanism is arranged at the front side of a filling turning plate; the automatic separating mechanism is arranged at the right side of the filling turning plate; and the heat sealing mechanism is arranged at the rear side of the filling turning plate. The device provided by the invention can be used for quickly implementing filling and heat sealing of tuber mustard packaging bags, is reasonable and compact in structure and is high in production efficiency.

Owner:桐乡市大周商贸有限公司

Financial documents arranging and binding device

The invention discloses a financial documents arranging and binding device. The financial documents arranging and binding device comprises a rack and a punch assembly, the rack is provided with a conveyor belt mechanism, and the rack above the conveyor belt mechanism is provided with a punch assembly, the punch assembly comprises punch heads, an inverted U-shaped plate for installing the punch heads and a driving unit for driving the up and down movement of the inverted U-shaped plate. The left side of the punch assembly is provided with a neat assembly which comprises an electric push rod, agear, a core, a pawl, a toothed bar and a driving rod. The number of the punch heads is two in total and the punch heads are fixedly installed on two mounting blocks correspondingly, a two-way screw rod penetrates through the two mounting blocks. The financial documents arranging and binding device also comprises a pressing assembly. The pressing assembly comprises a telescopic rod, a pressing plate and a spring. The financial documents arranging and binding device is provided with the neat assembly and the conveyor belt mechanism so as to automatically tidy the bound financial documents, facilitate punching and improve the binding efficiency; can adjust the distance between two punch heads so as to achieve the effect of adjusting the punching distance; and has a pressing assembly so as tocompress the financial documents when punching.

Owner:李慧卿

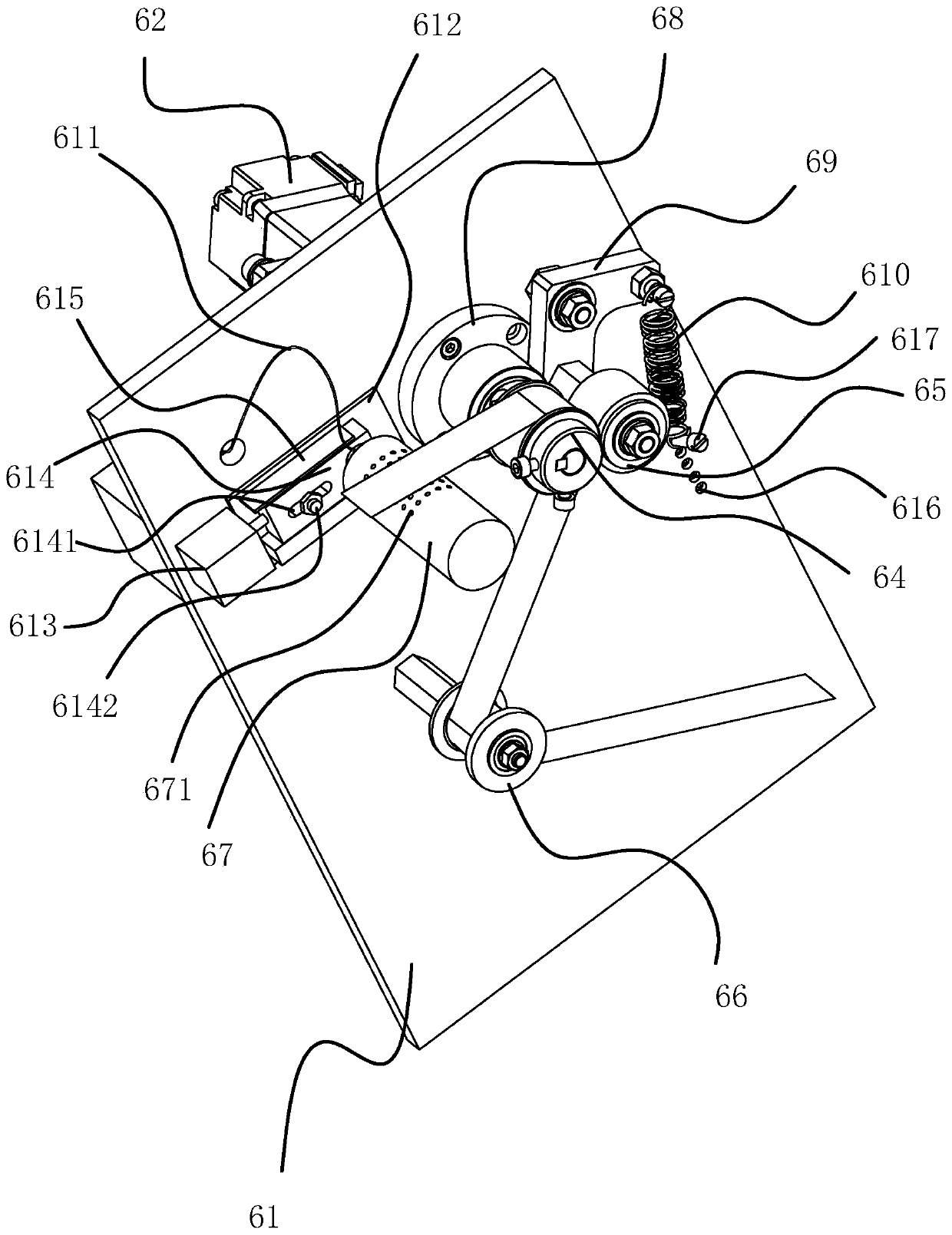

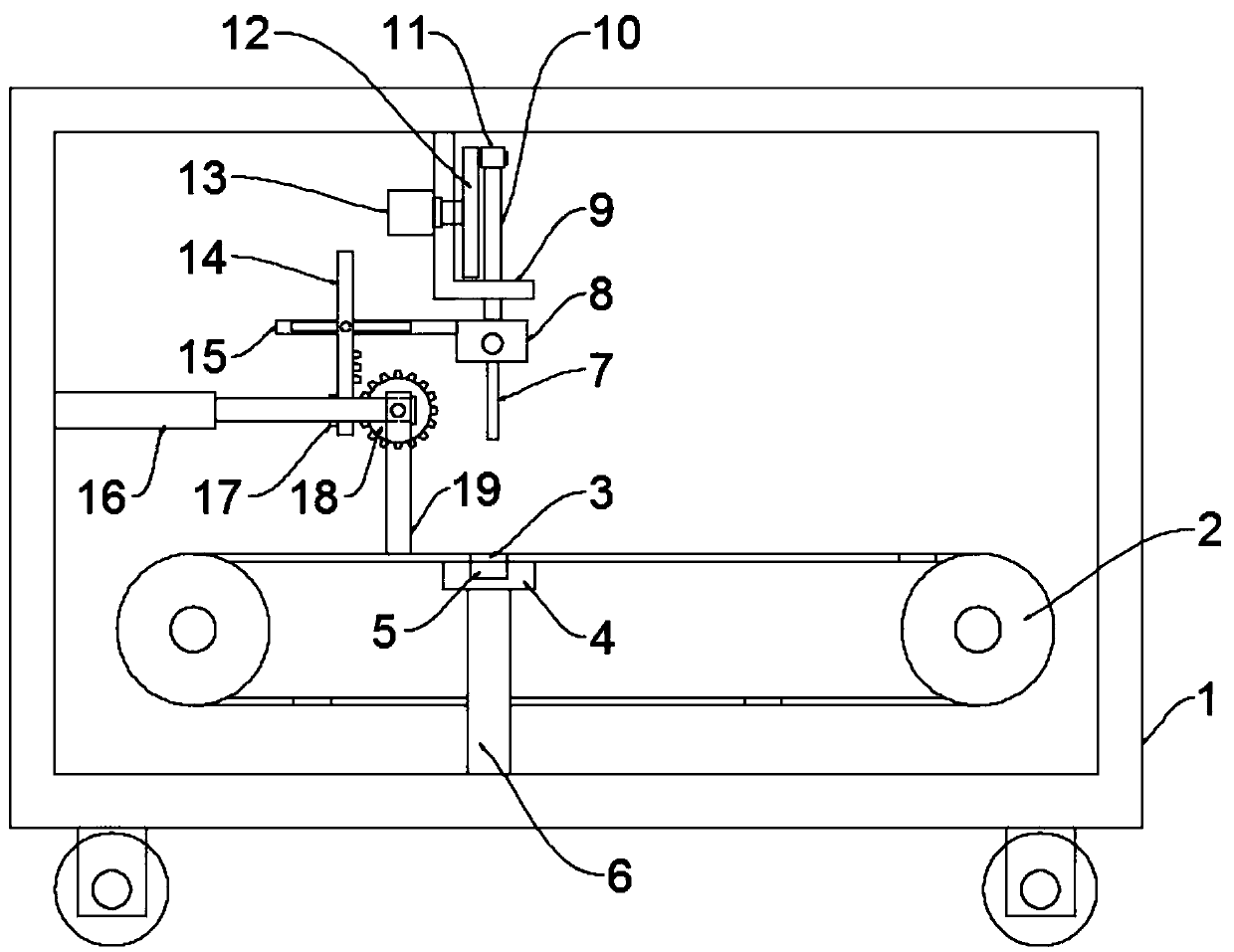

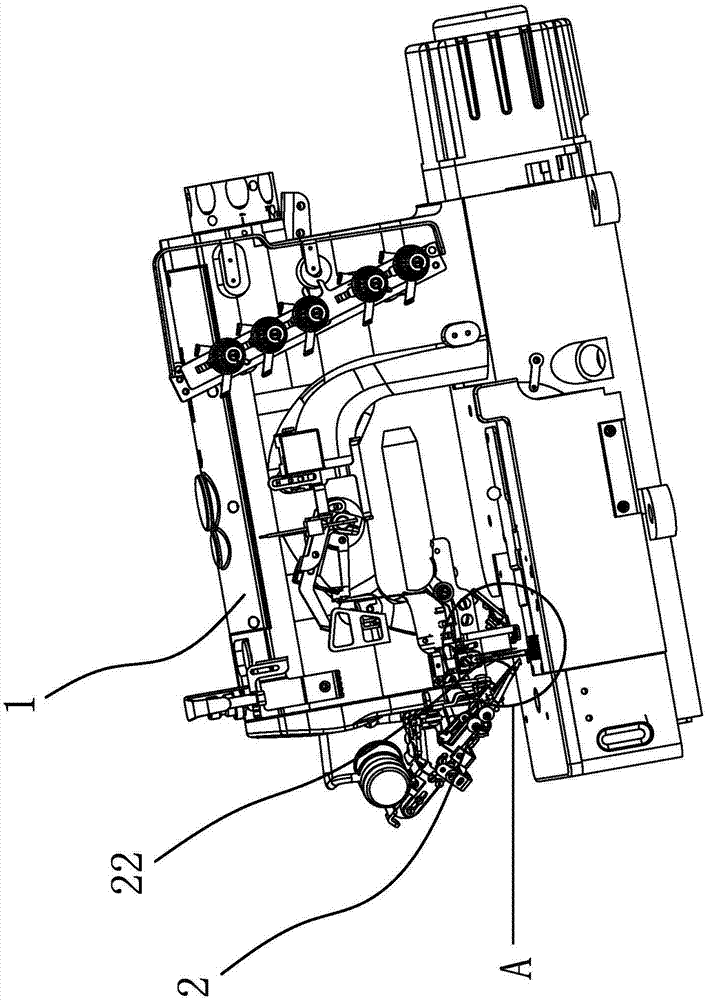

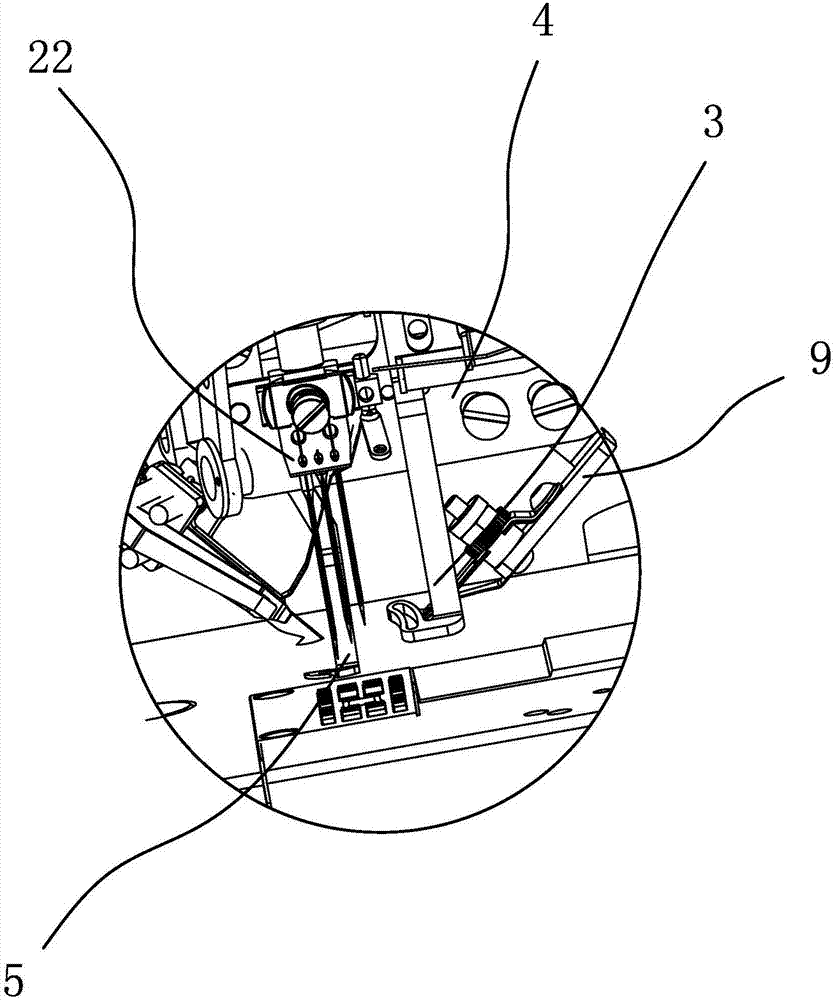

Thread pulling device

ActiveCN107268203AAdjust the pressing forceAdjust elastic deformation forceNeedle severing devicesSoftware engineeringJumping

The invention provides a thread pulling device, and belongs to the technical field of machines, which can solve the problem that the conventional thread pulling devices are large in size, and often release threads. The thread pulling device includes an installation plate, a thread clamping assembly, a thread pulling cutter, and a drive member; the installation plate is long-bar-shaped; the drive member is fixed on one end of the installation plate, and the thread pulling cutter is hinged to the other end of the installation plate; one end of a transmission connection rod is hinged to the thread pulling cutter, and the other end of the transmission connection rod is hinged to a drive crank; the drive member is connected to the drive crank; a return spring is arranged between the drive crank and the installation plate; an installation sheet is detachably connected to the installation plate; the installation sheet is positioned under the transmission connection rod, and one end of the installation sheet extend under the installation plate; and the thread clamping assembly is fixed on the extension end, and is opposite to the thread pulling cutter. The thread pulling cutter and the thread clamping assembly are split, and the thread pulling device is reasonable in space layout and is small in size; after the thread pulling cutter returns, a pulling hook is positioned on the right side or under the right side of a needle; and the thread pulling device is stable in sewing, and can void thread jumping.

Owner:JACK SEWING MASCH CO LTD

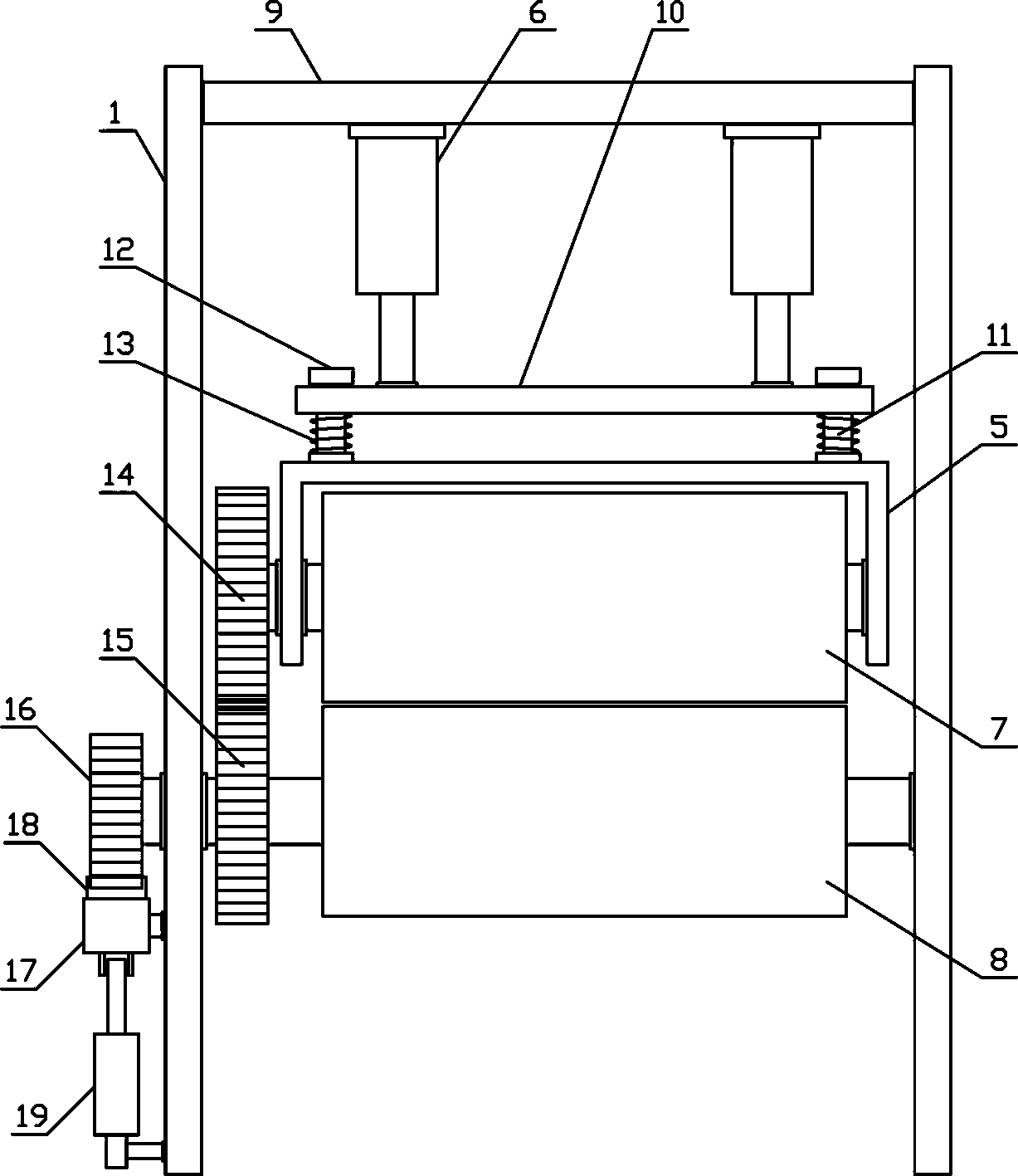

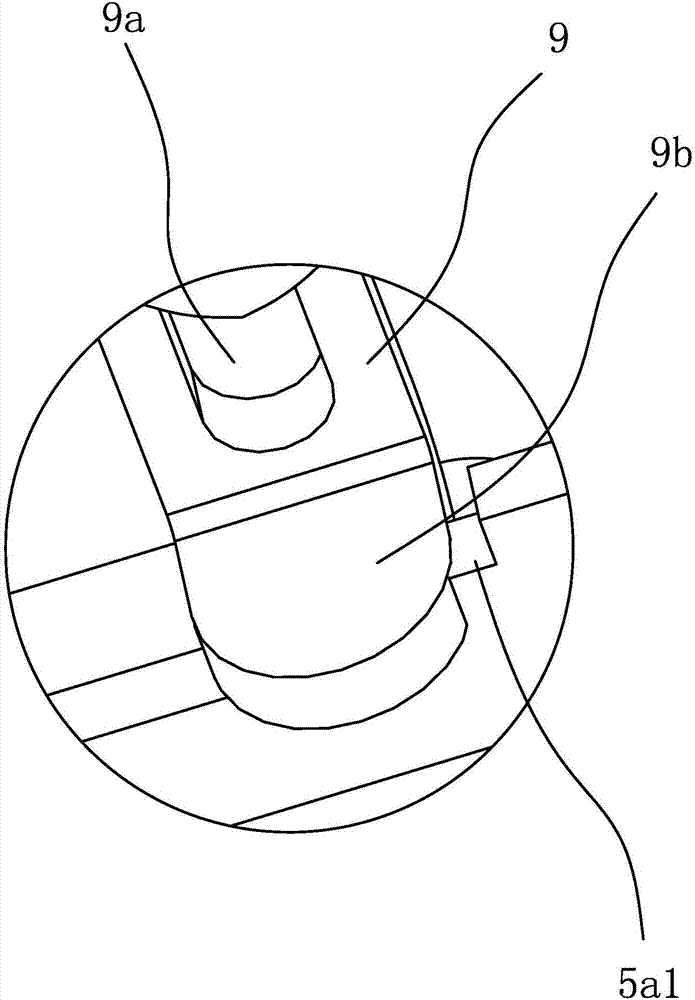

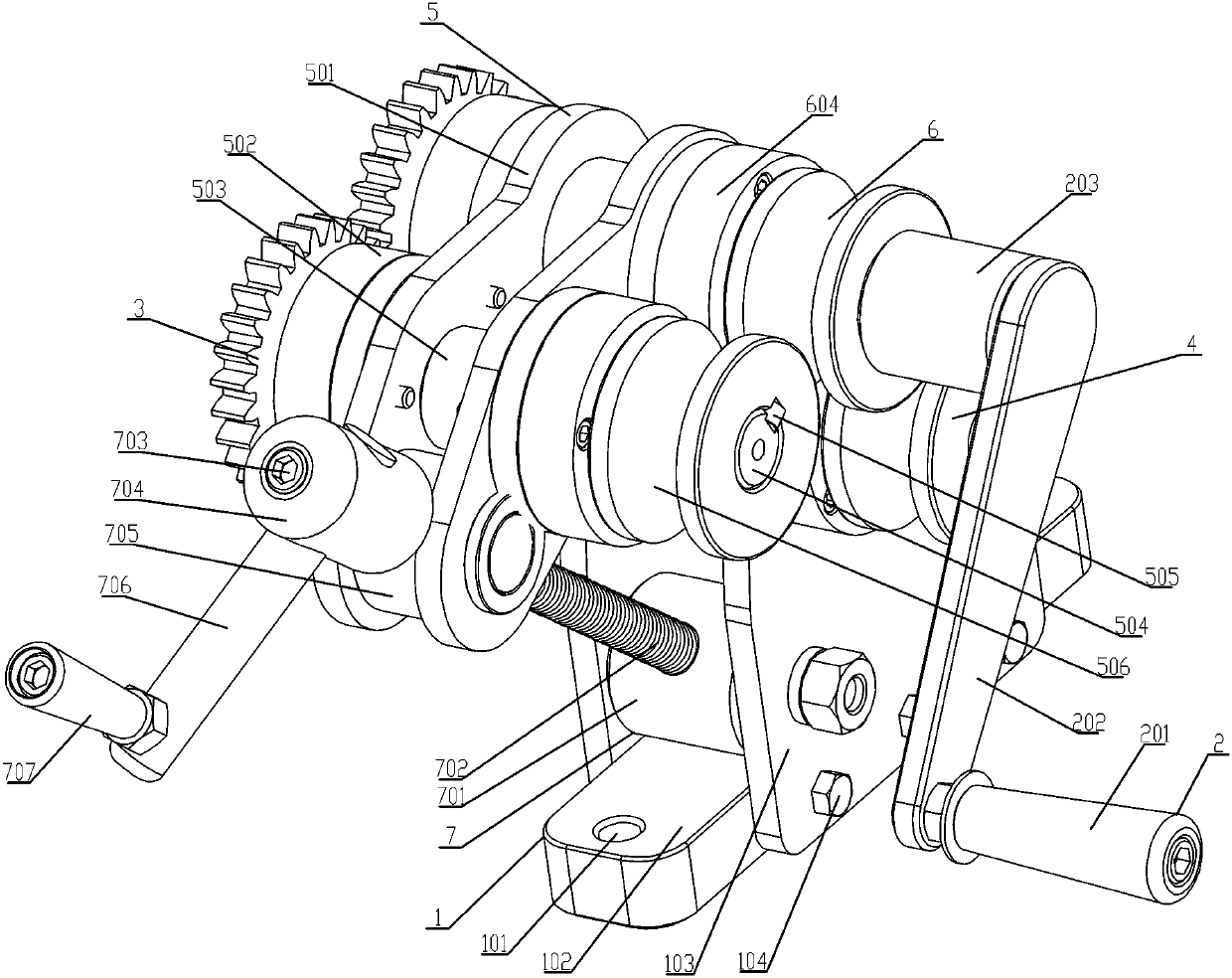

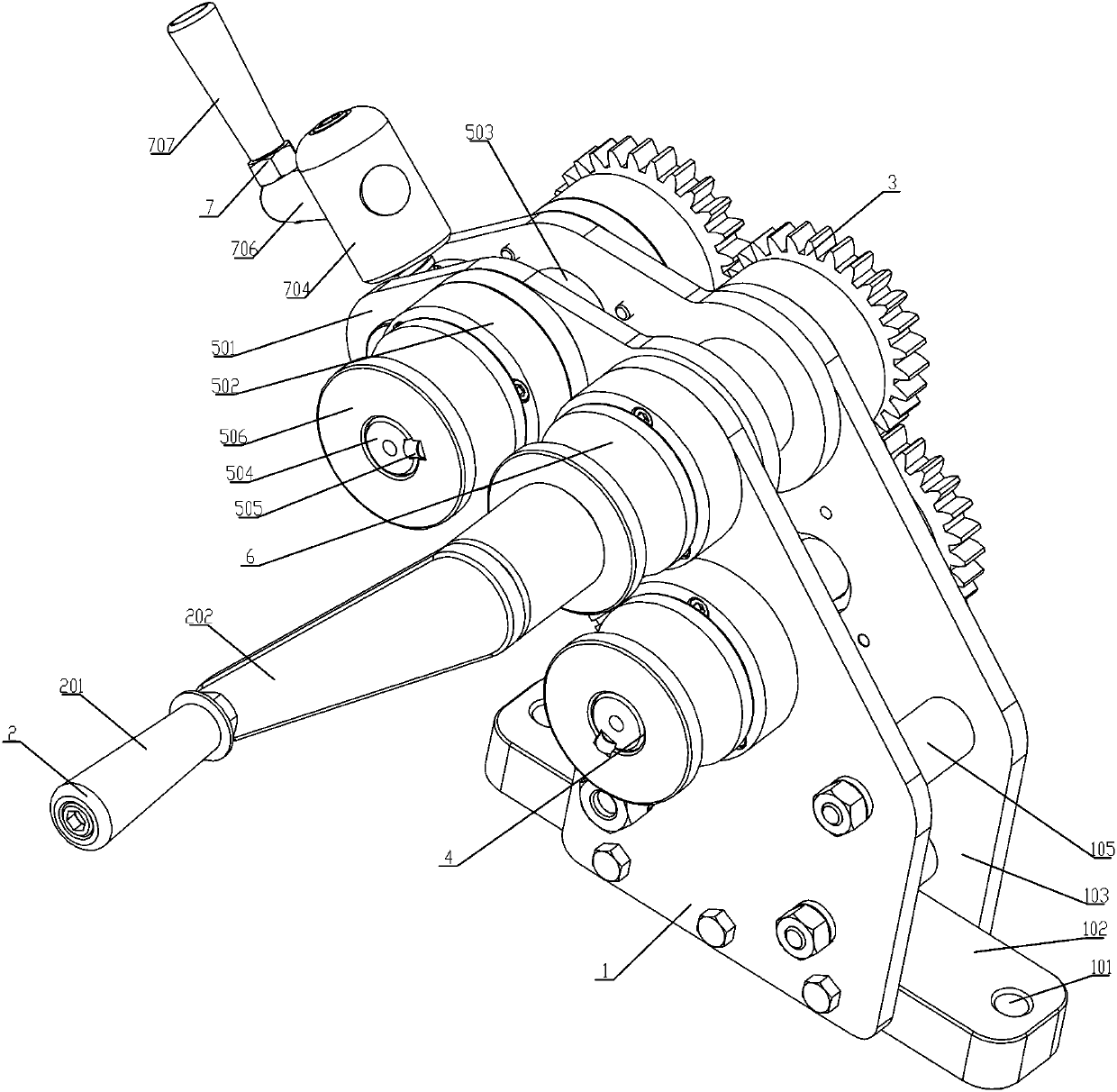

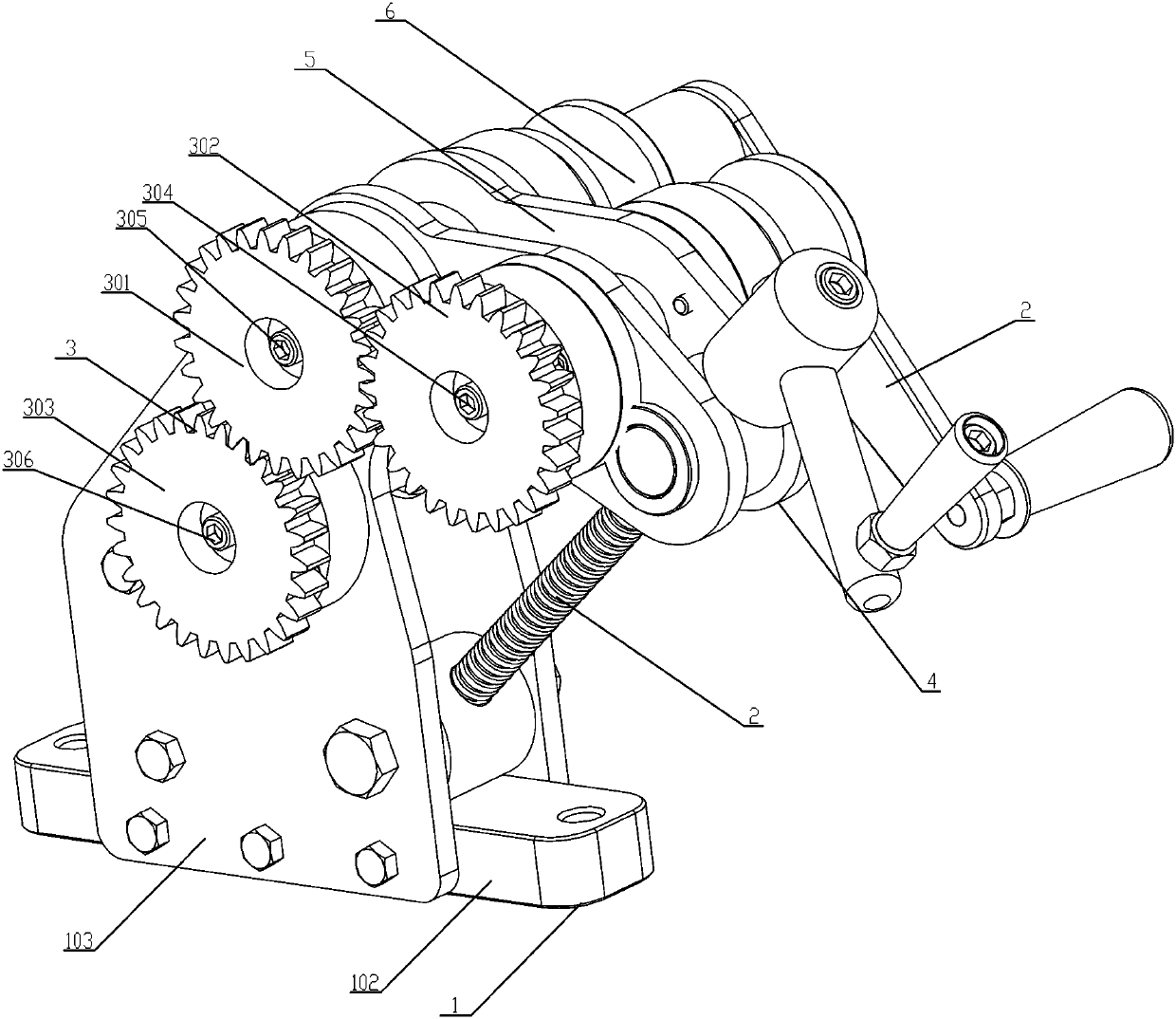

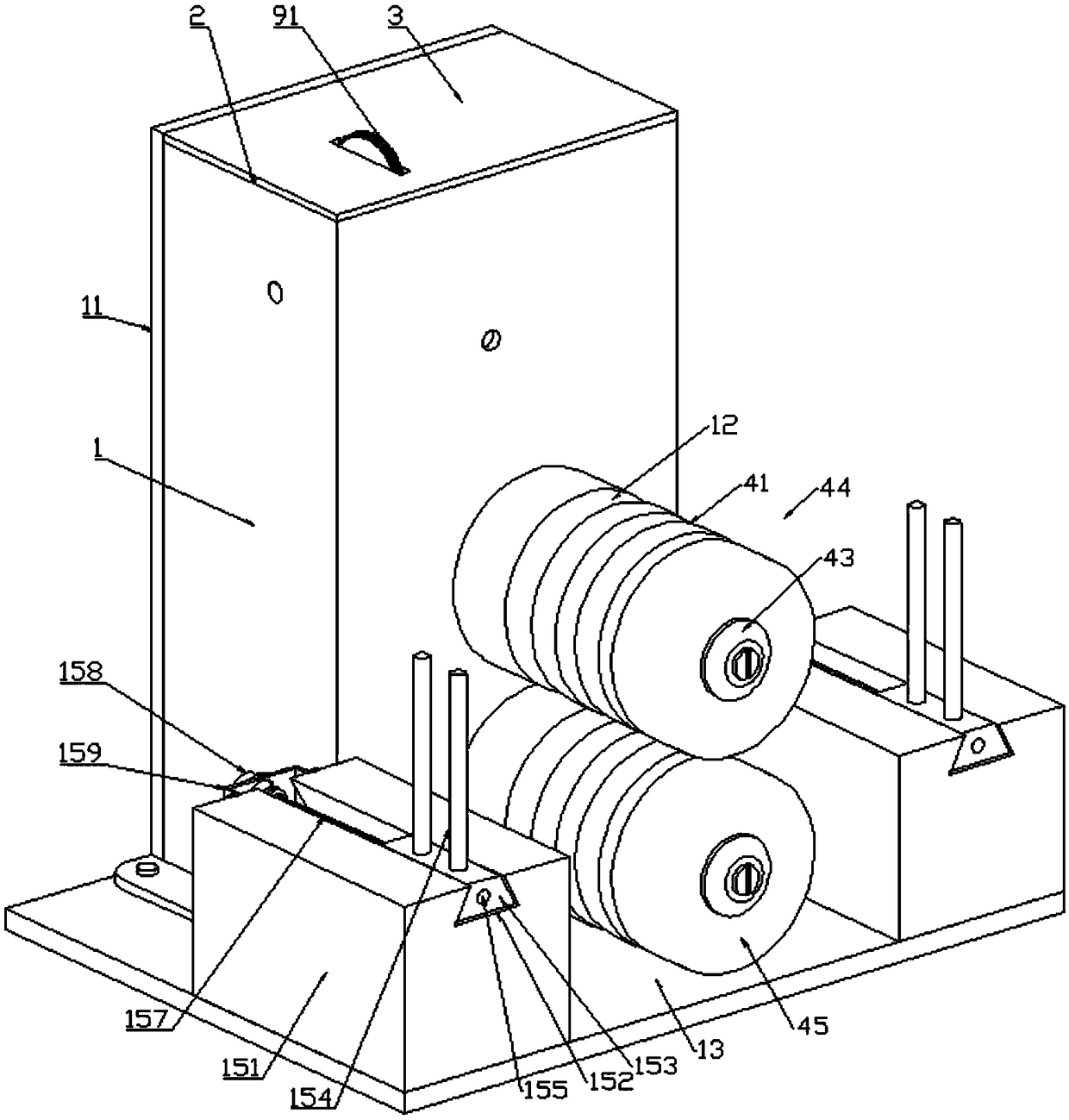

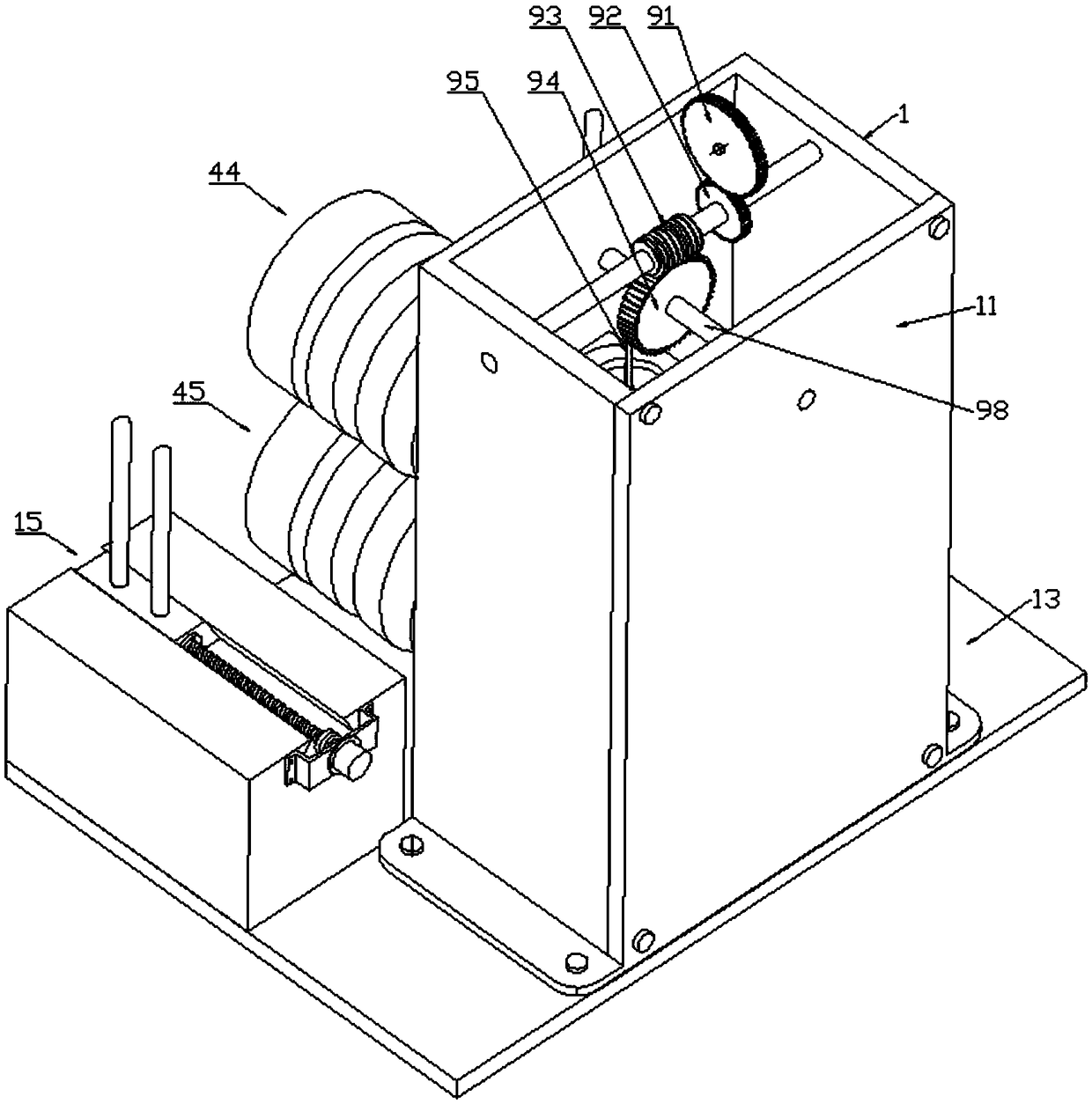

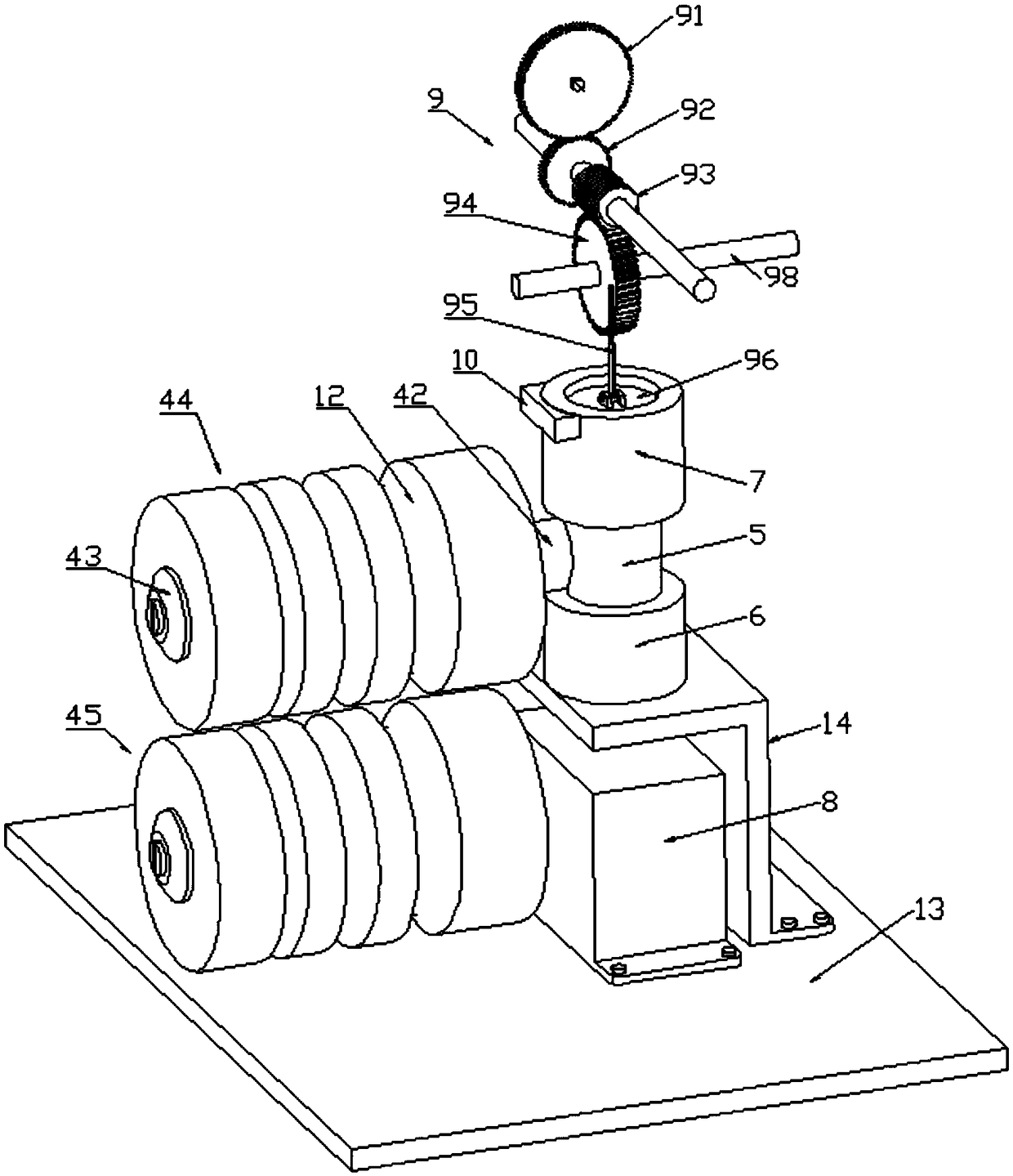

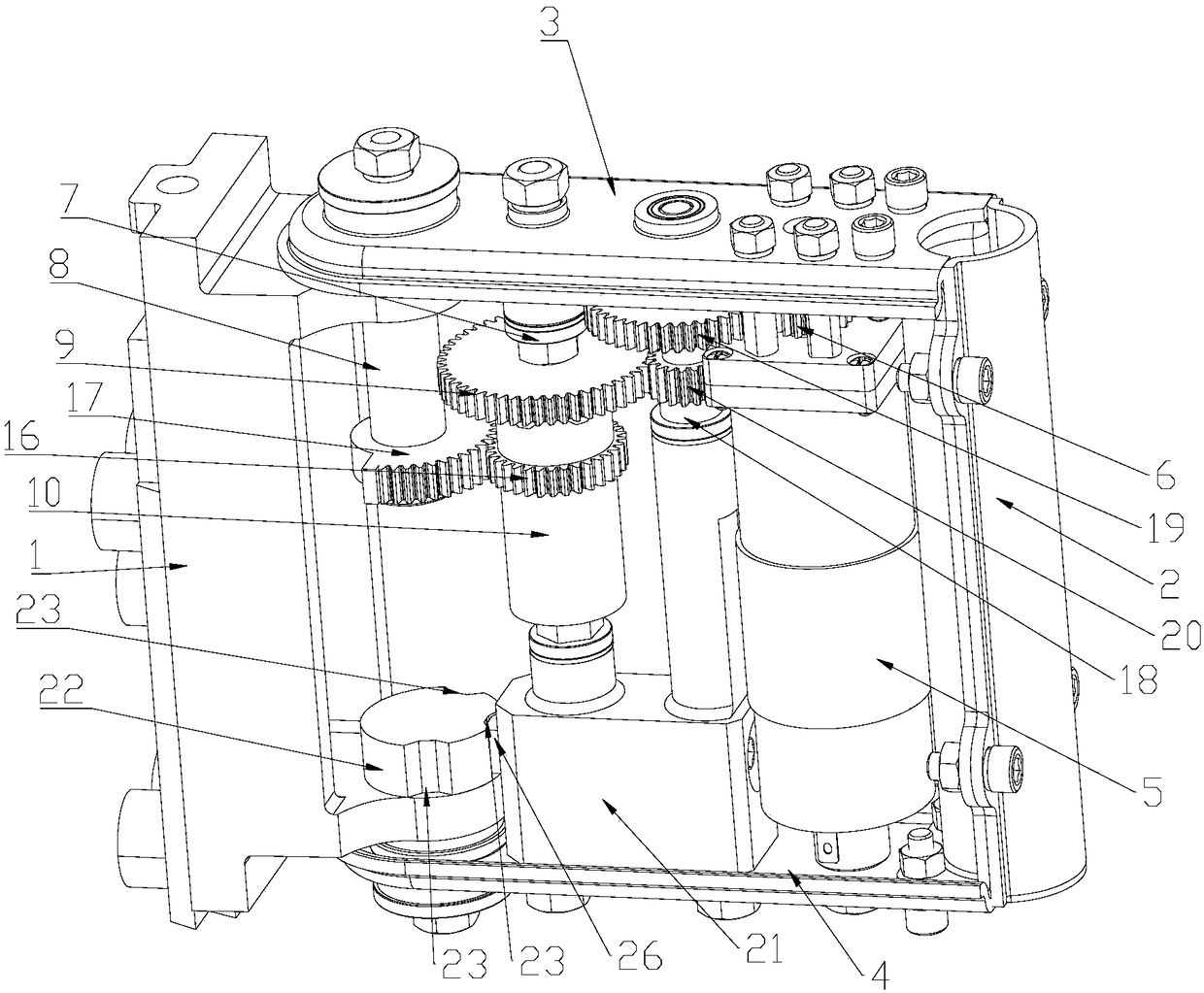

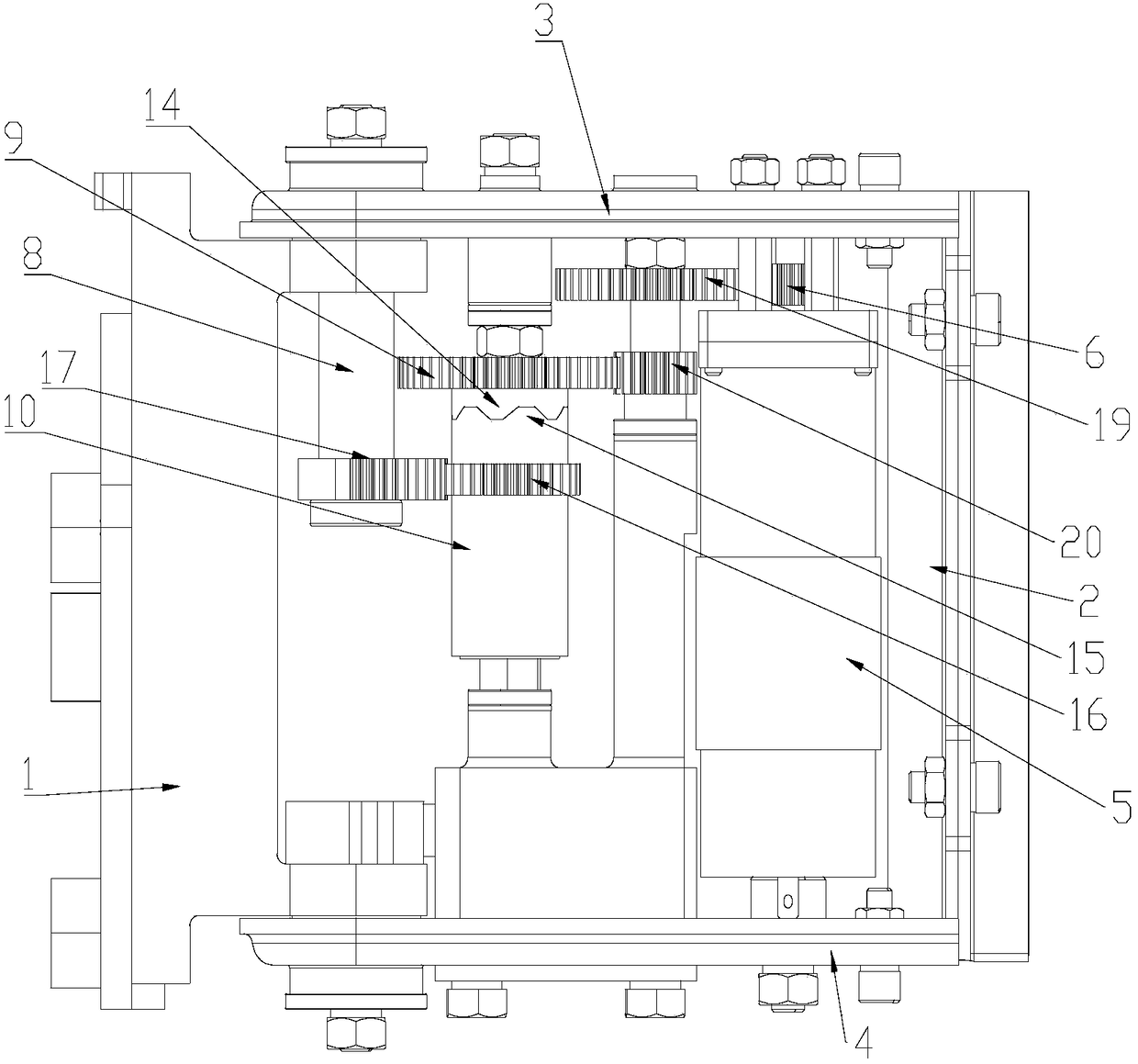

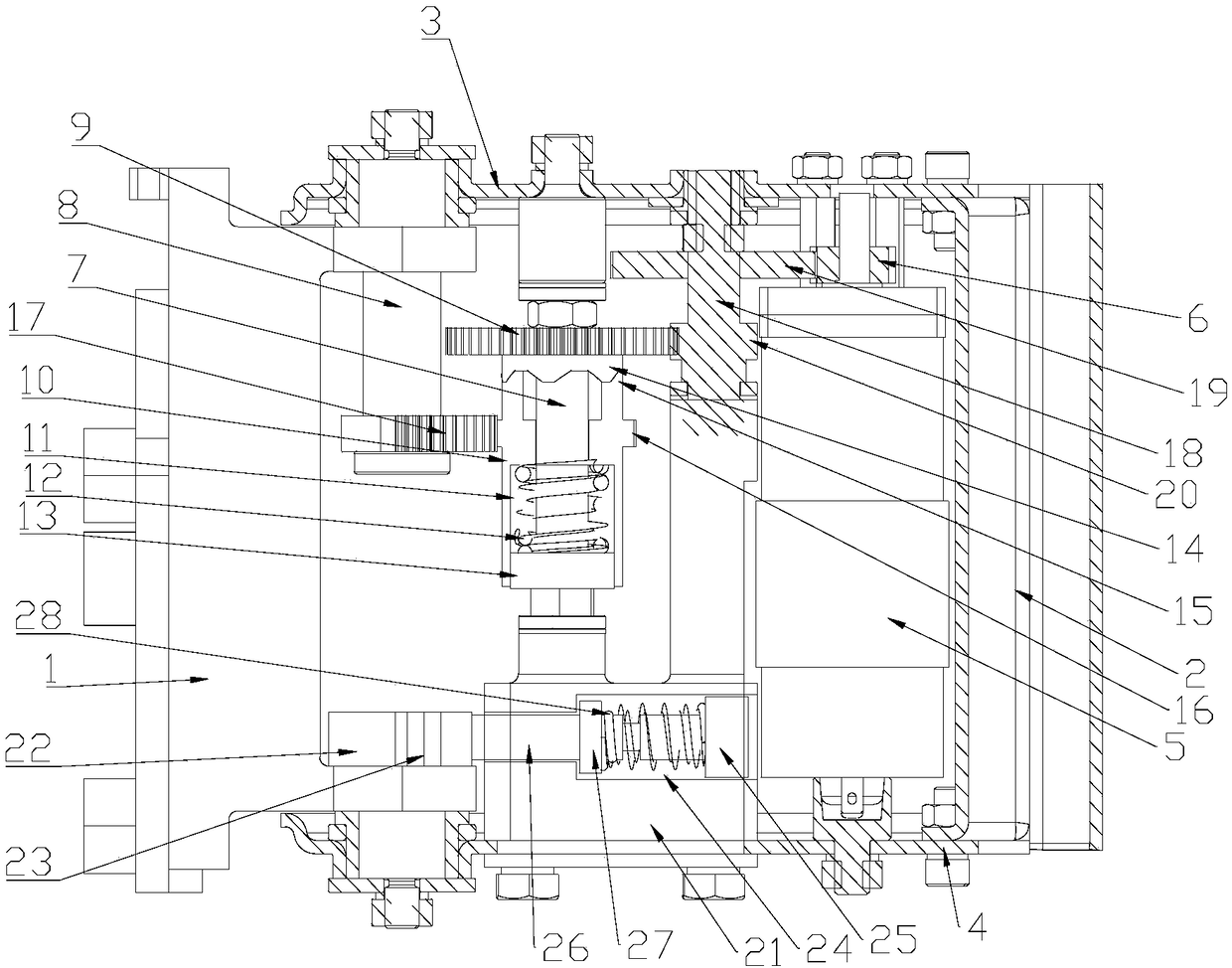

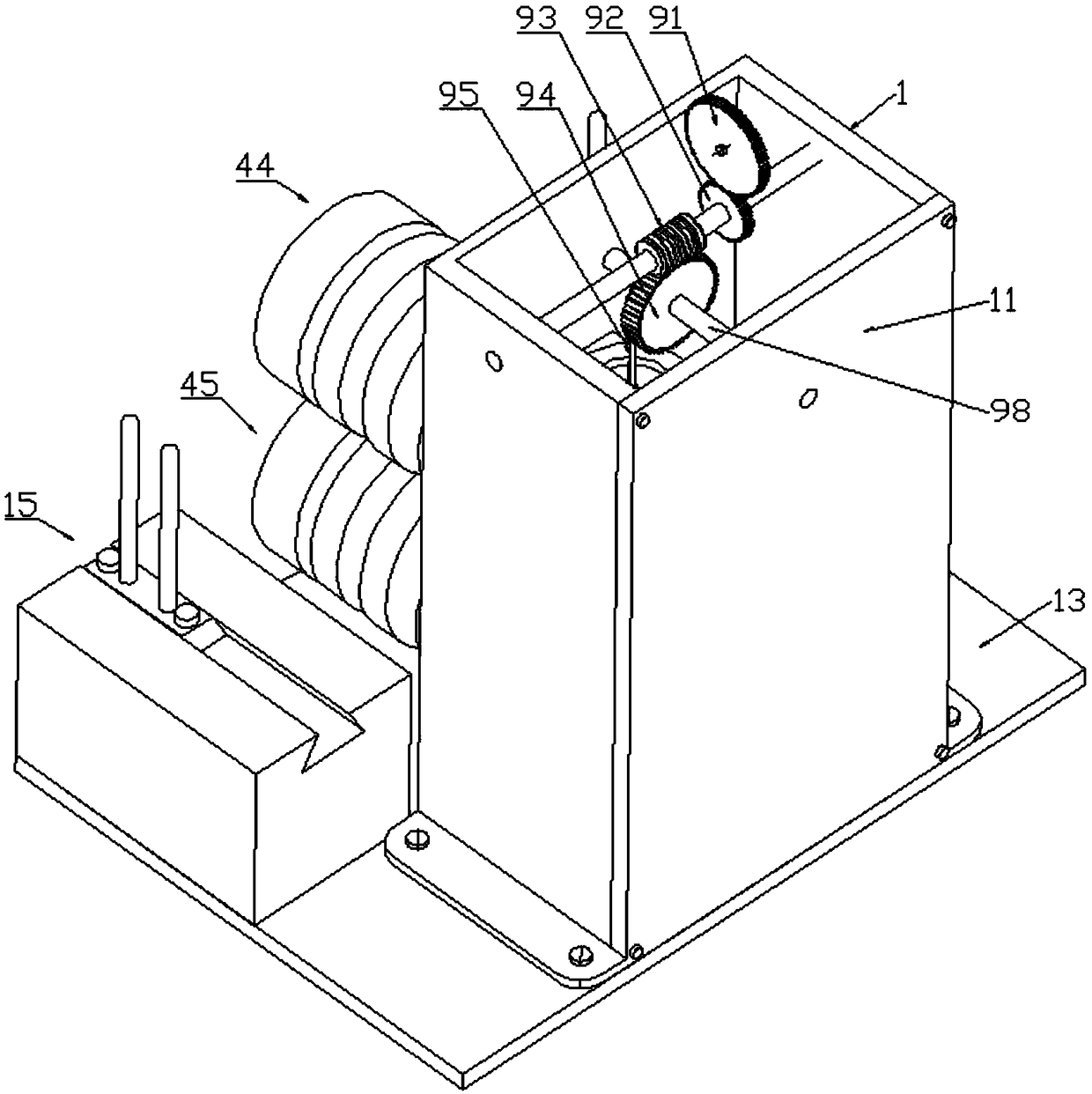

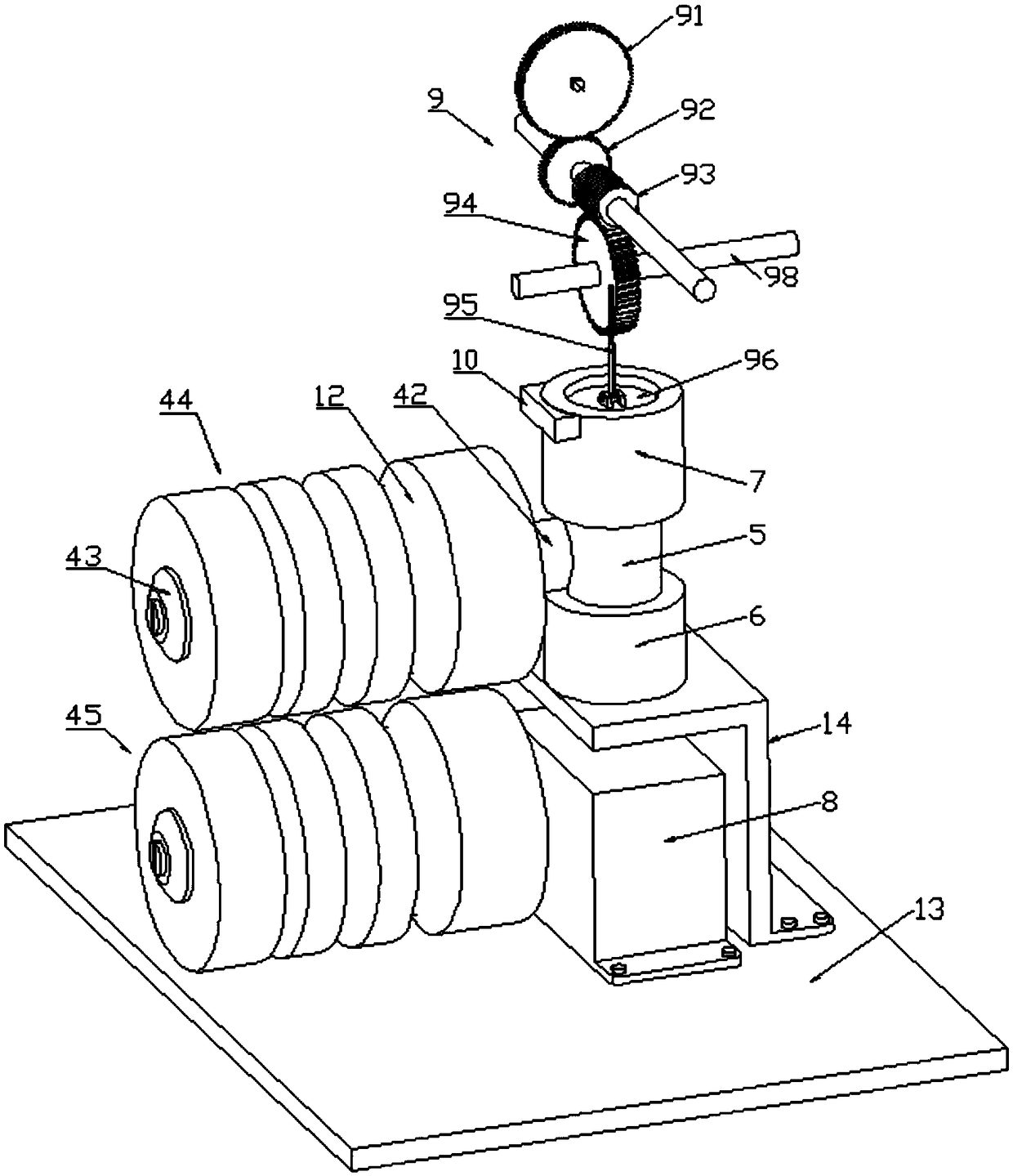

Straightening device based on screw compression adjustment and using method

The invention provides a straightening device based on screw compression adjustment and a using method. A bottom compression roller structure is supported and mounted between rack vertical plates of arack structure; a top compression roller structure is supported and mounted at the tops of the rack vertical plates, and the top compression roller structure is matched with the bottom compression roller structure; a power mechanism for driving the main shaft to rotate is mounted on the main shaft where the top compression roller structure is located in a matched manner; a swing compression roller mechanism is mounted on the main shaft where the top compression roller structure is located in a running fit manner; a screw type swing arm adjusting mechanism used for adjusting the rotating angleof the swing compression roller mechanism and the rack structure is installed between the swing compression roller mechanism and the rack structure. Gear transmission mechanisms used for driving thebottom compression roller structure, the top compression roller structure and the swing compression roller mechanism to rotate synchronously are installed at the other ends of main shafts of the bottom compression roller structure, the top compression roller structure and the swing compression roller mechanism. According to the straightening device, the rotating angle between the straightening compression rollers can be adjusted in a screw transmission mode, then the pressing force in the straightening process is adjusted, and the optimal straightening effect is achieved.

Owner:CHINA THREE GORGES UNIV

Tuber mustard packaging bag picking device

The invention provides a tuber mustard packaging bag picking device and belongs to the technical field of tuber mustard processing equipment. The tuber mustard packaging bag picking device comprises abag supply mechanism, a bag picking mechanism and a filling turning plate mechanism; feeding sucking discs of the bag supply mechanism are installed at an equal interval on a sucking disc supportingplate; the lower end of a bag picking rod of the bag picking mechanism is hinged with the upper end of a bag picking rocker bar; a first bag picking finger and a second bag picking finger are installed at the lower end of the bag picking rod; the filling turning plate mechanism comprises a turning plate conveying component, a turning plate driving component and a bag receiving driving component; filling clamping components of the turning plate conveying component are arranged at an equal internal at the outer side of a filling turning plate in a surrounding manner; a turning plate grabbing sleeve of the turning plate driving component is installed at the other end of the turning plate driving plate; turning plate driving blocks are uniformly distributed and installed on the filling turningplate at an equal interval; and the two ends of a jacking rod synchronous rod of the bag receiving driving component are correspondingly hinged to the other end of a first bag receiving jacking plateand the other end of a second bag receiving jacking plate. The tuber mustard packaging bag picking device provided by the invention quickly realizes one-by-one picking of tuber mustard packaging bags, sends the tuber mustard packaging bags to the filling turning plate one by one, and is reasonable in structure.

Owner:桐乡市大周商贸有限公司

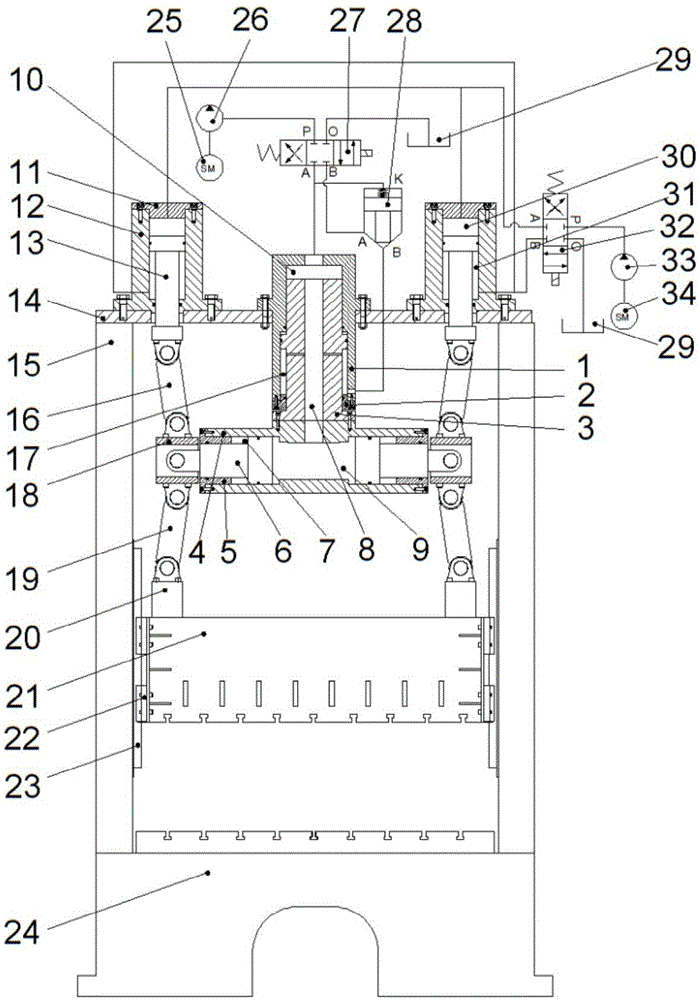

Quick-idle-stroke and slow-pressurization main hydraulic cylinder translation type symmetric elbow rod servo press

The invention discloses a quick-idle-stroke and slow-pressurization main hydraulic cylinder translation type symmetric elbow rod servo press; the press adopts a quick-idle-stroke and slow-pressurization-stroke mode; when a main slide block is in idle stroke, a second hydraulic pump is driven by a second servo motor, oil is pumped into a secondary hydraulic cylinder, and a piston in the secondary hydraulic cylinder downwards moves to drive a piston in the main hydraulic cylinder to communicate with a horizontal cylinder, an elbow rod and a slide block to downwards move to finish the idle stroke; when a nominal pressure stroke is begun, a first hydraulic cylinder is driven by a first servo motor, oil is pumped into a main hydraulic cylinder, a piston communicated with the horizontal cylinder moves to the left and right sides, and the slide block begins the nominal pressure stroke under the transmission of an elbow rod mechanism; and after the punching is finished, a reversing valve changes an oil inlet direction to finish a return process. The press is simple in structure and long in service life, and can adjust the strokes as needed.

Owner:XI AN JIAOTONG UNIV

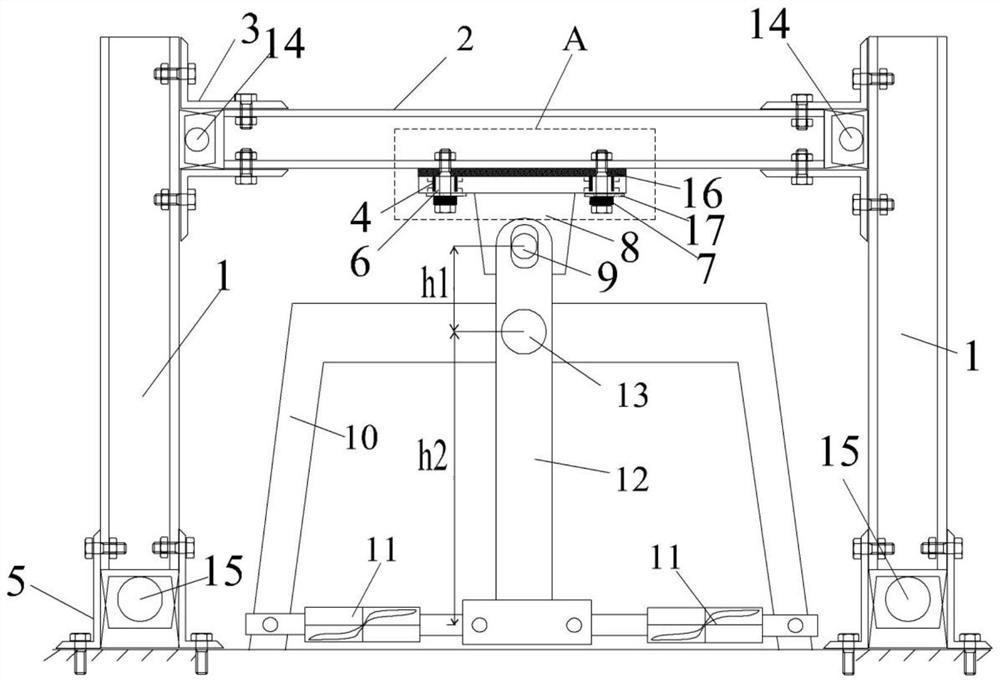

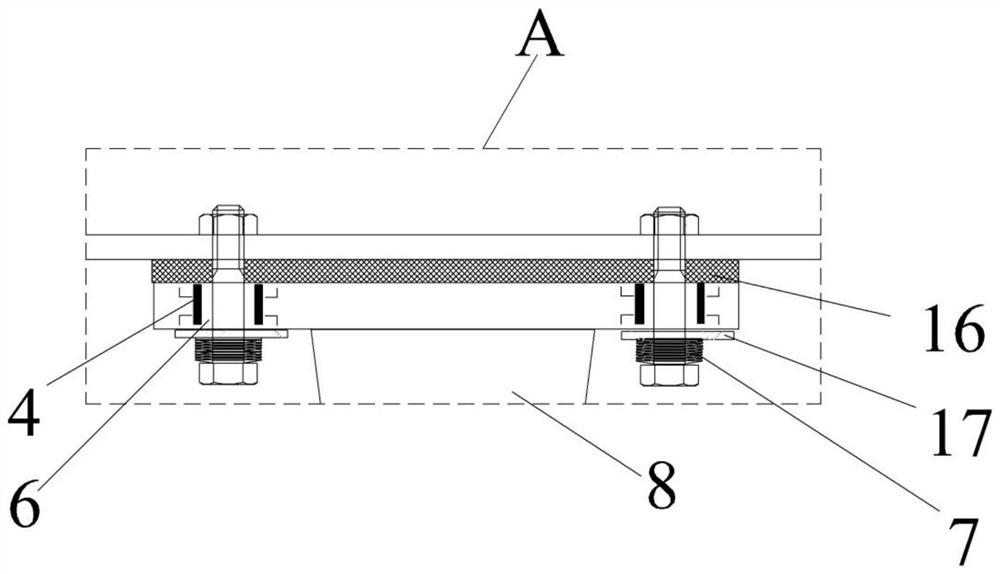

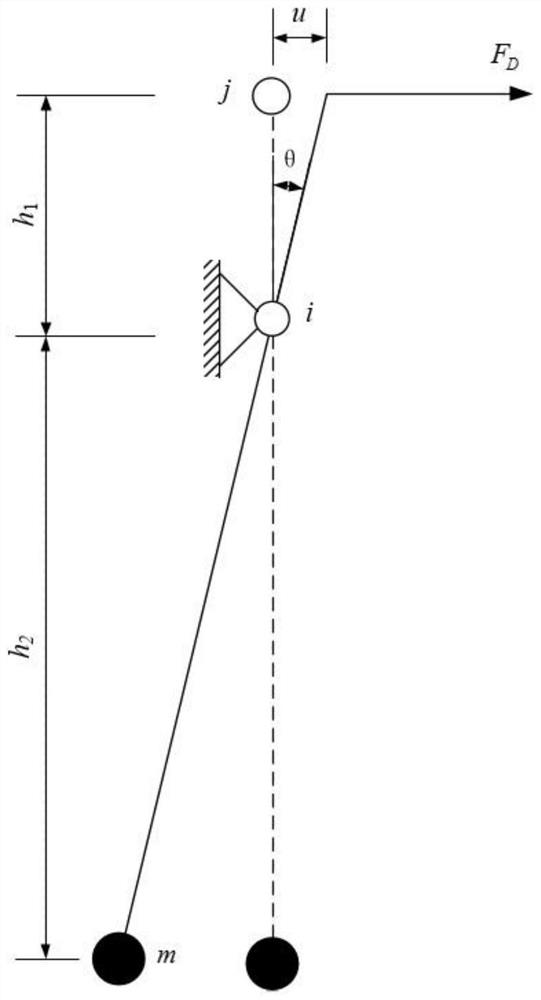

Lever-type inerter synergistic shape memory alloy self-resetting structural system

ActiveCN112031504AGood effectFlexible adjustment of the natural vibration periodProtective buildings/sheltersShock proofingStructural systemMechanical engineering

The invention provides a lever-type inerter synergistic shape memory alloy self-resetting structural system. The structural system comprises two columns, a beam, a connecting block, a level, a mass block, a rigid bracket, and self-resetting dampers. The two columns are installed at the two ends of the beam respectively to form an n-shaped frame structure. The connecting block is arranged in the middle of the beam. The top end of the lever is connected with the connecting block in a movable mode, and the connecting block moves horizontally to drive the lever to swing. The mass block is arrangedat the bottom end of the lever. The rotating fulcrum of the lever is arranged on the rigid bracket. The self-resetting dampers are mounted between the rigid bracket and the lever. According to the structural system, large inertia is provided for the structural system with small mass by utilizing the mass amplification effect of inertia, so that the effect of flexibly adjusting the natural vibration period of the structural system is achieved; and the energy consumption efficiency of the self-resetting dampers can be remarkably improved through the deformation amplification effect of the lever, and the self-resetting acting force of the self-resetting dampers on the structure is improved.

Owner:HENAN POLYTECHNIC UNIV

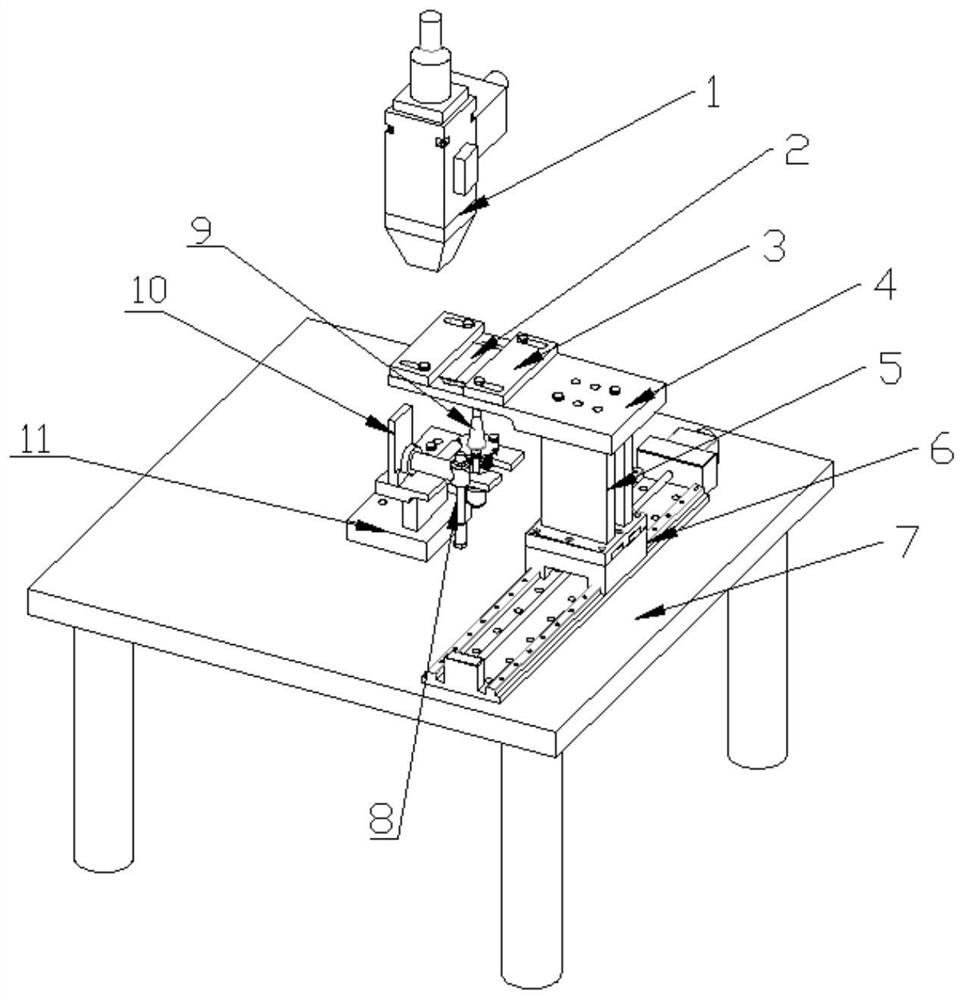

Method for inhibiting laser welding deformation

InactiveCN112475608ARealize researchImplementing Systematic ReviewsMechanical vibrations separationLaser beam welding apparatusUltrasonic vibrationHeat sink

The invention provides a method for inhibiting laser welding deformation, which comprises the step of using a device for inhibiting laser welding deformation. The device comprises a laser welding headfor welding, a sample clamp used for clamping a sample to be welded, a moving structure, a heat sink structure used for cooling a weld joint subjected to laser welding, and an ultrasonic vibration structure used for making contact with the surface of the sample to be welded. The method is characterized in that in the welding process, the moving structure bears the sample clamp and the sample to move, and the laser welding head, the heat sink structure and the ultrasonic vibration structure are all fixed; or the moving structure bears the laser welding head, the heat sink structure and the ultrasonic vibration structure to move, and the sample clamp and the sample are fixed. The method for inhibiting laser welding deformation provided by the invention can effectively inhibit the deformation of the laser welding sample.

Owner:HUNAN UNIV

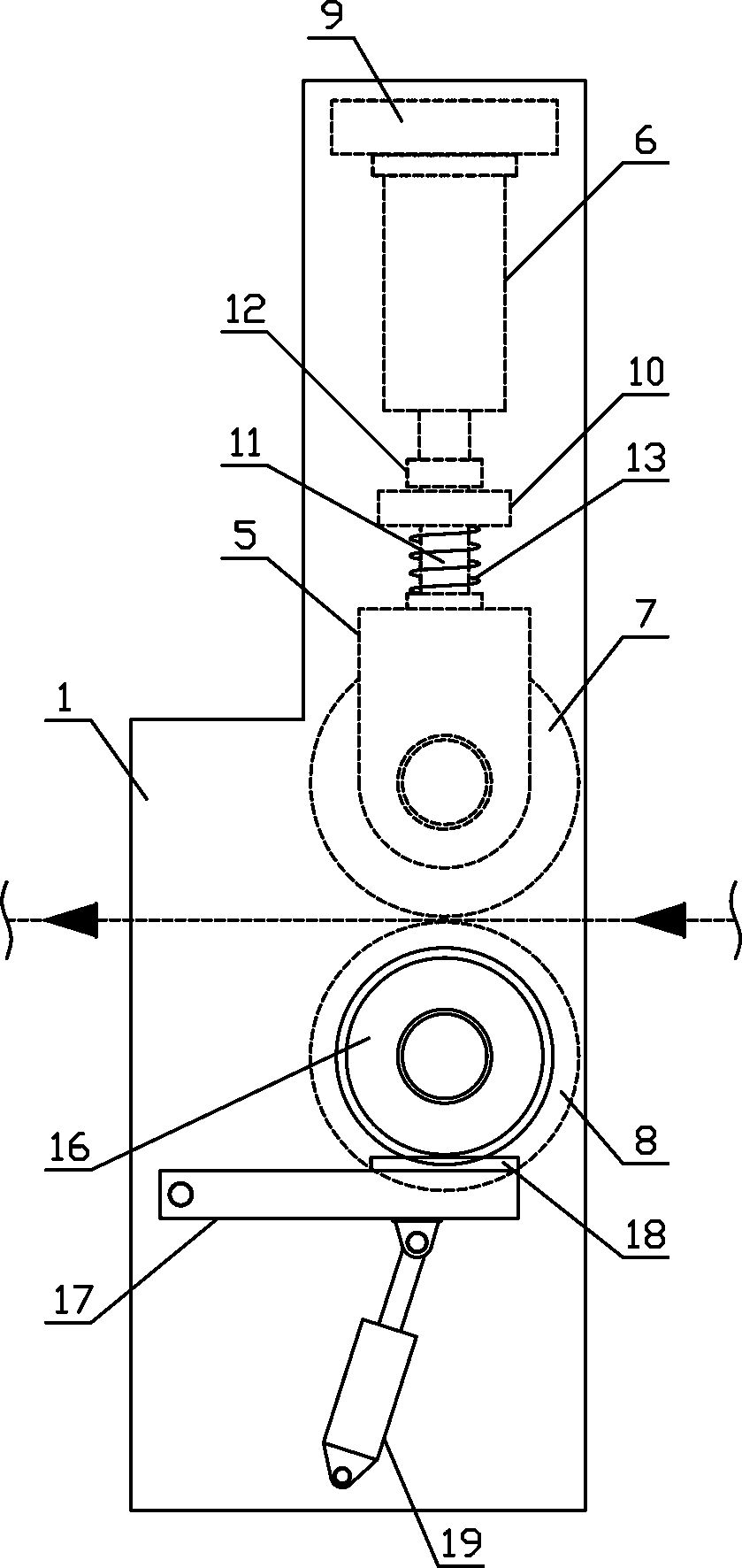

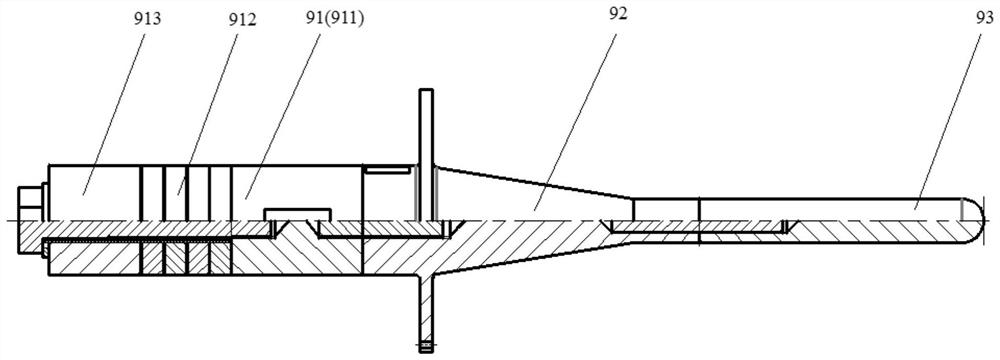

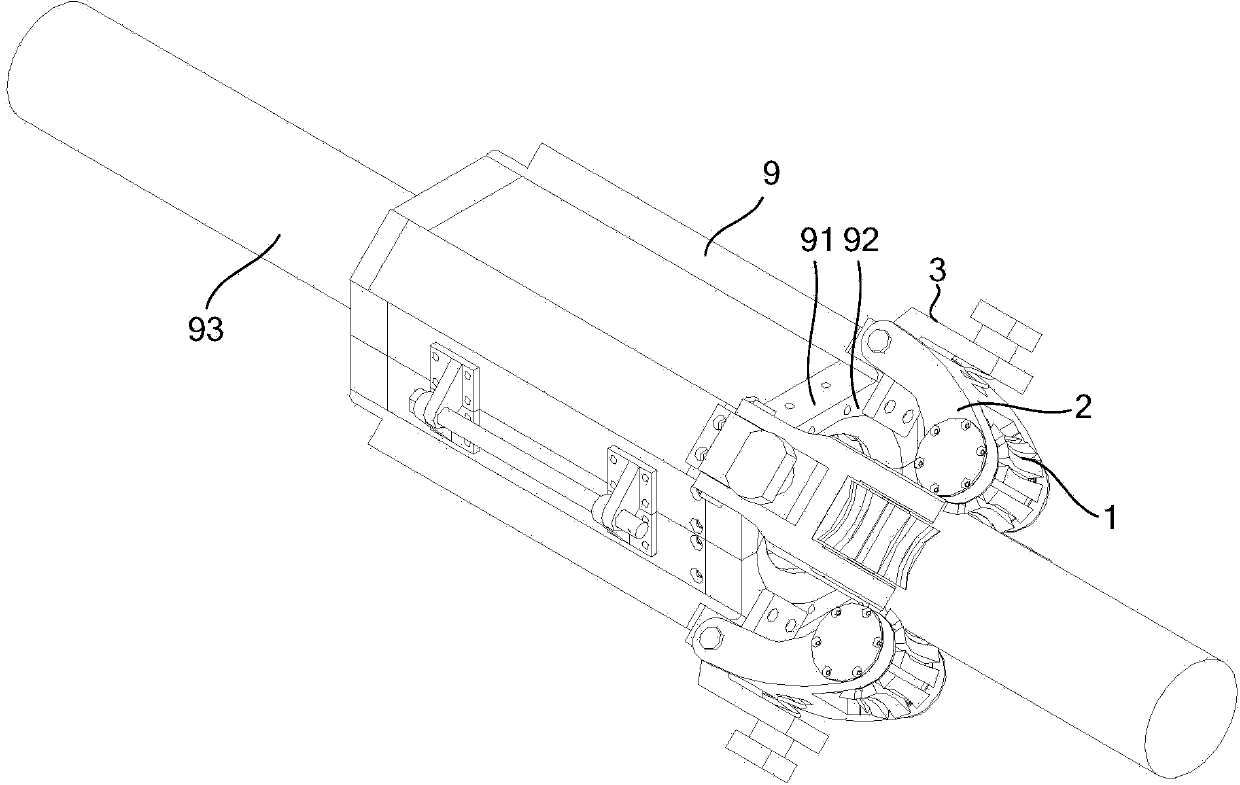

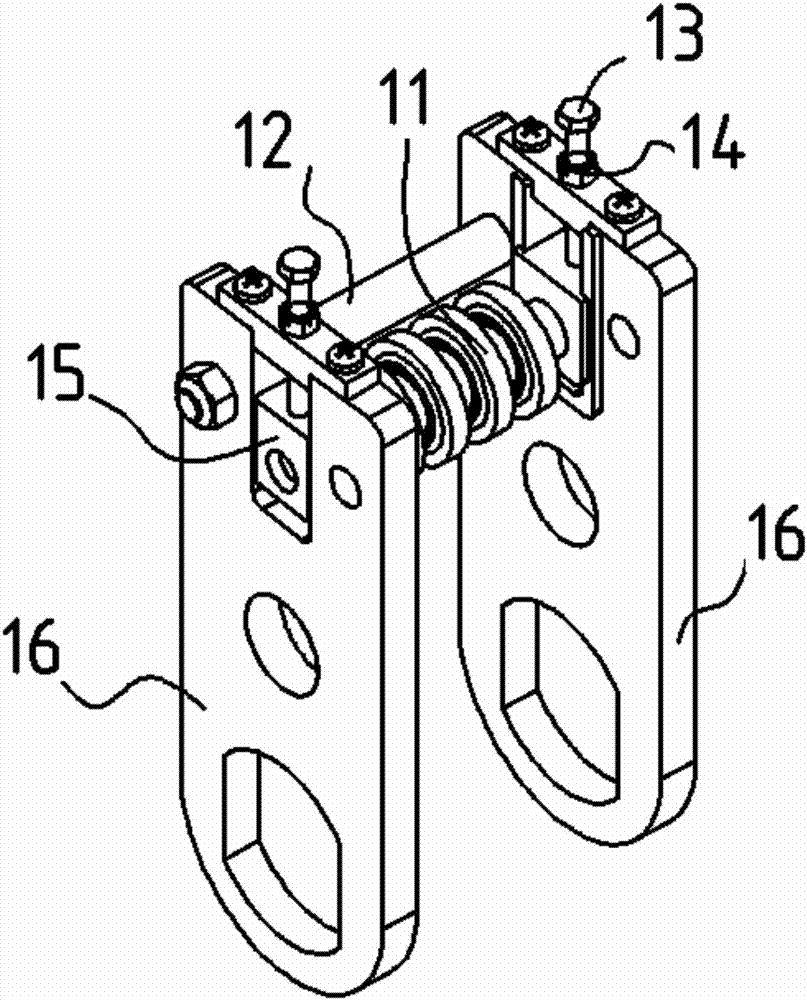

Mooring rope clearing device and pressure regulating mechanism thereof

ActiveCN103691686AAdjust the pressing forceEasy to cleanCleaning using toolsEngineeringMechanical engineering

The invention discloses a mooring rope clearing device and a pressure regulating mechanism of the mooring rope clearing device. The pressure regulating mechanism is used for regulating pressure that a roller wheel of the mooring rope clearing device presses a mooring rope; the pressure regulating mechanism comprises a connecting base, a connecting shaft, an elastic part and a roller wheel bracket used for installing the roller wheel, wherein the roller wheel bracket is connected with the connecting base by the connecting shaft; and the elastic part is arranged between the connecting base and the roller wheel bracket. By additionally arranging the elastic part, pressing force of the roller wheel on the mooring rope can be adjusted, so that attachments on the mooring rope can be cleared better.

Owner:深圳市润渤船舶与石油工程技术有限公司

Automatic guiding device for automobile wire harness pressure connection

ActiveCN108792809AAchieve the right orientationAdjust the pressing forceLine/current collector detailsVehicle connectorsEngineeringMachining

The invention discloses an automatic guiding device for automobile wire harness pressure connection and relates to the technical field of wire harness machining. The automatic guiding device comprisesa machine shell, guiding assemblies, a driving assembly and auxiliary guiding mechanisms; openings are formed in the upper end and the lower end of the machine shell correspondingly; a top cover is mounted at the upper end of the machine shell; the two guiding assemblies include the first guiding assembly and the second guiding assembly which are of the same structure; the driving assembly is disposed in the machine shell and drives the first guiding assembly to move up and down; and the auxiliary guiding mechanisms are mounted on the two sides of the guiding assemblies. The automatic guidingdevice for automobile wire harness pressure connection is simple in structure and convenient to operate; by arranging the two guiding assemblies, correct guiding of an automobile wire harness duringconveying is achieved; by means of the driving assembly, up-and-down position adjustment of the first guiding assembly is achieved, and thus the tight pressure between the guiding assemblies and the wire harness is adjusted; and by the aid of the auxiliary guiding mechanisms, the wire harness can be pre-guided.

Owner:WUHU BOKANG ELECTRICAL

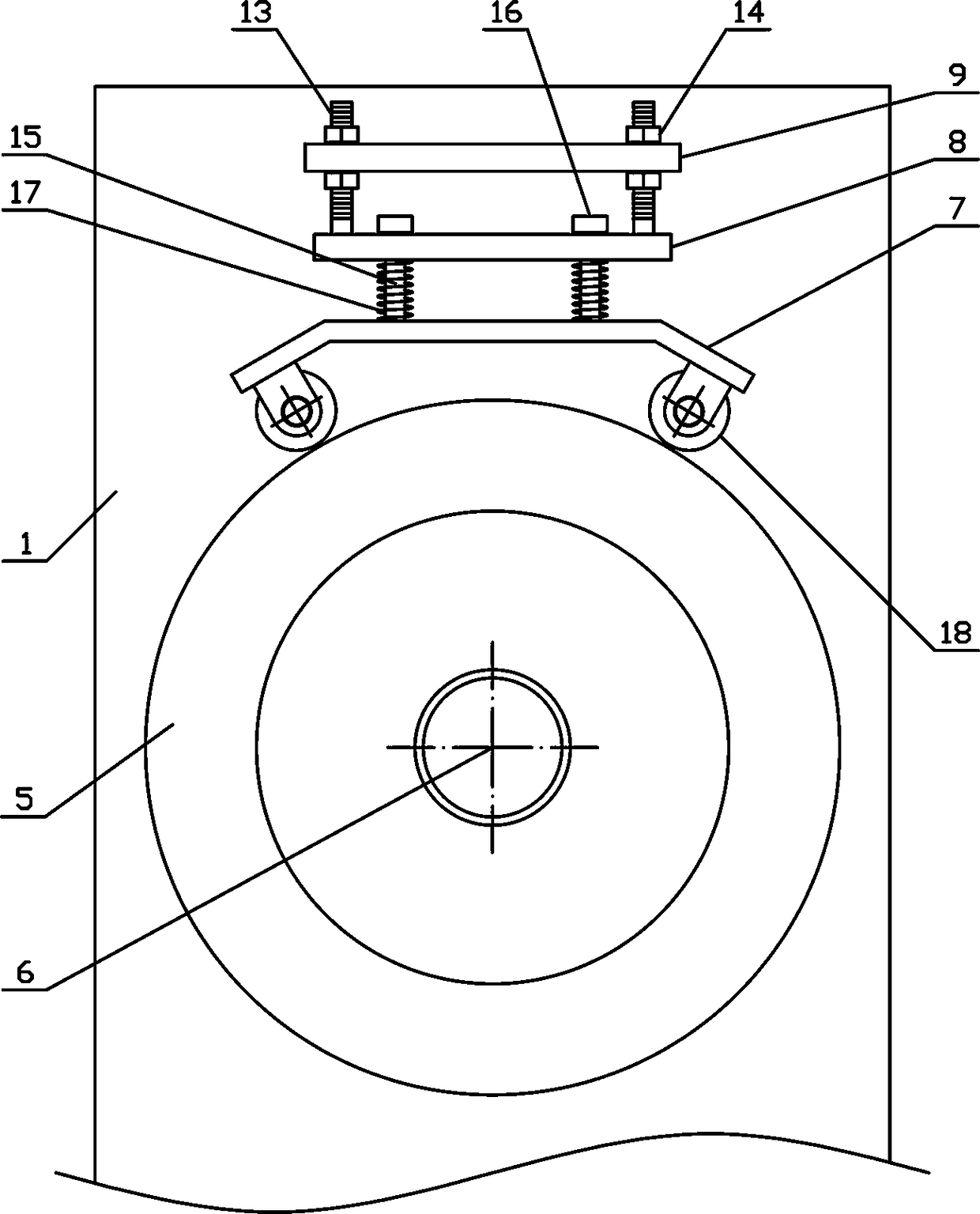

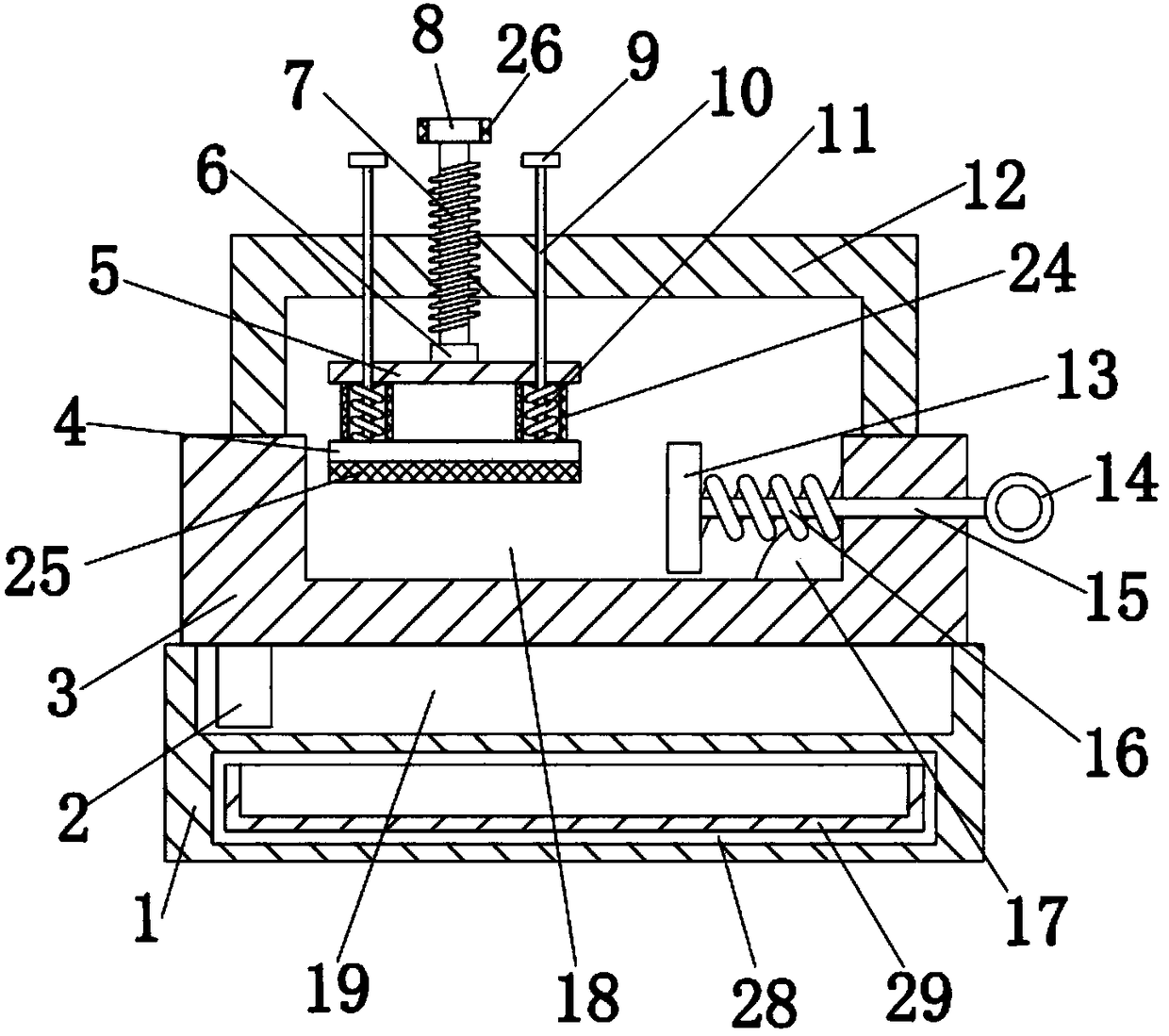

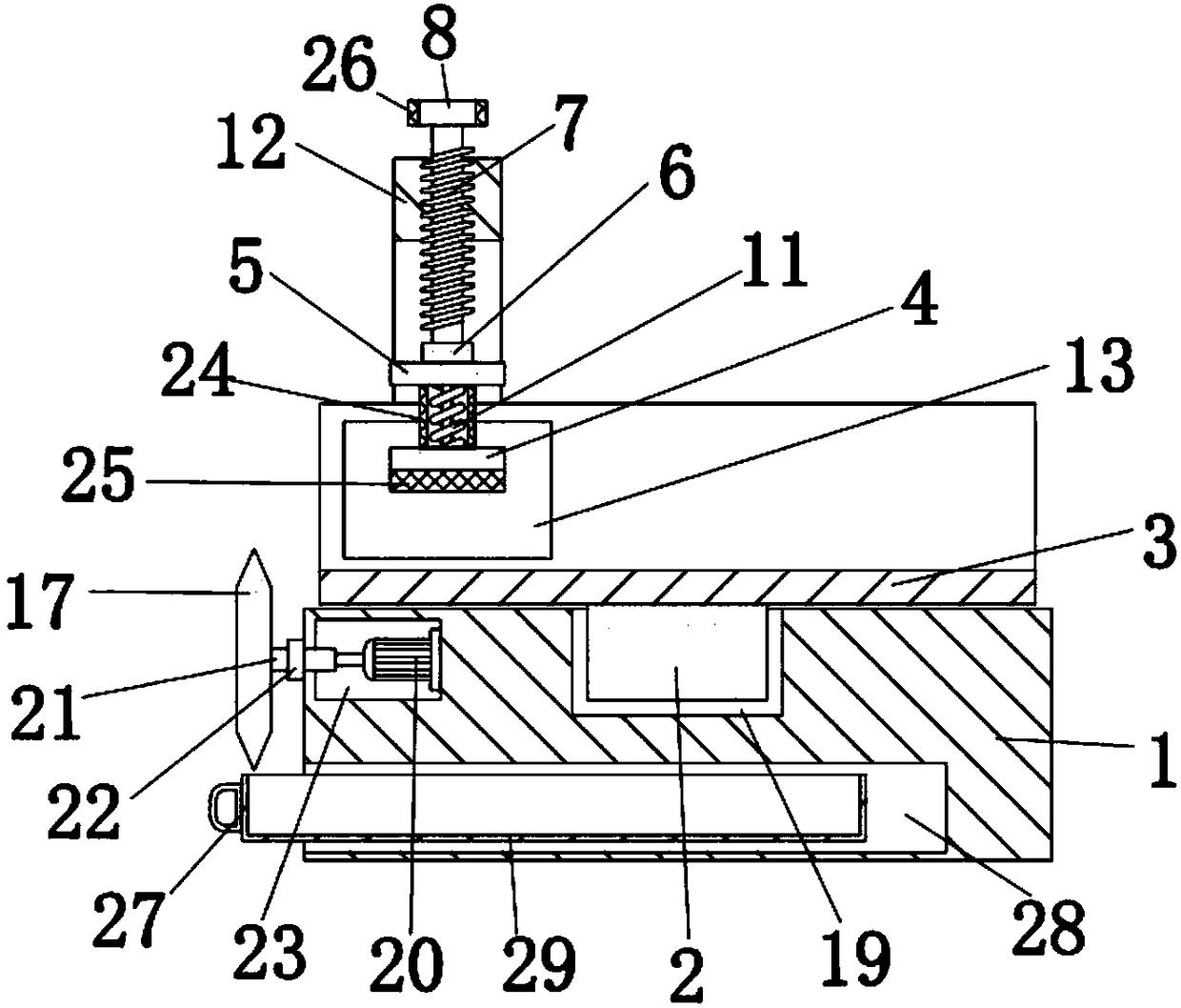

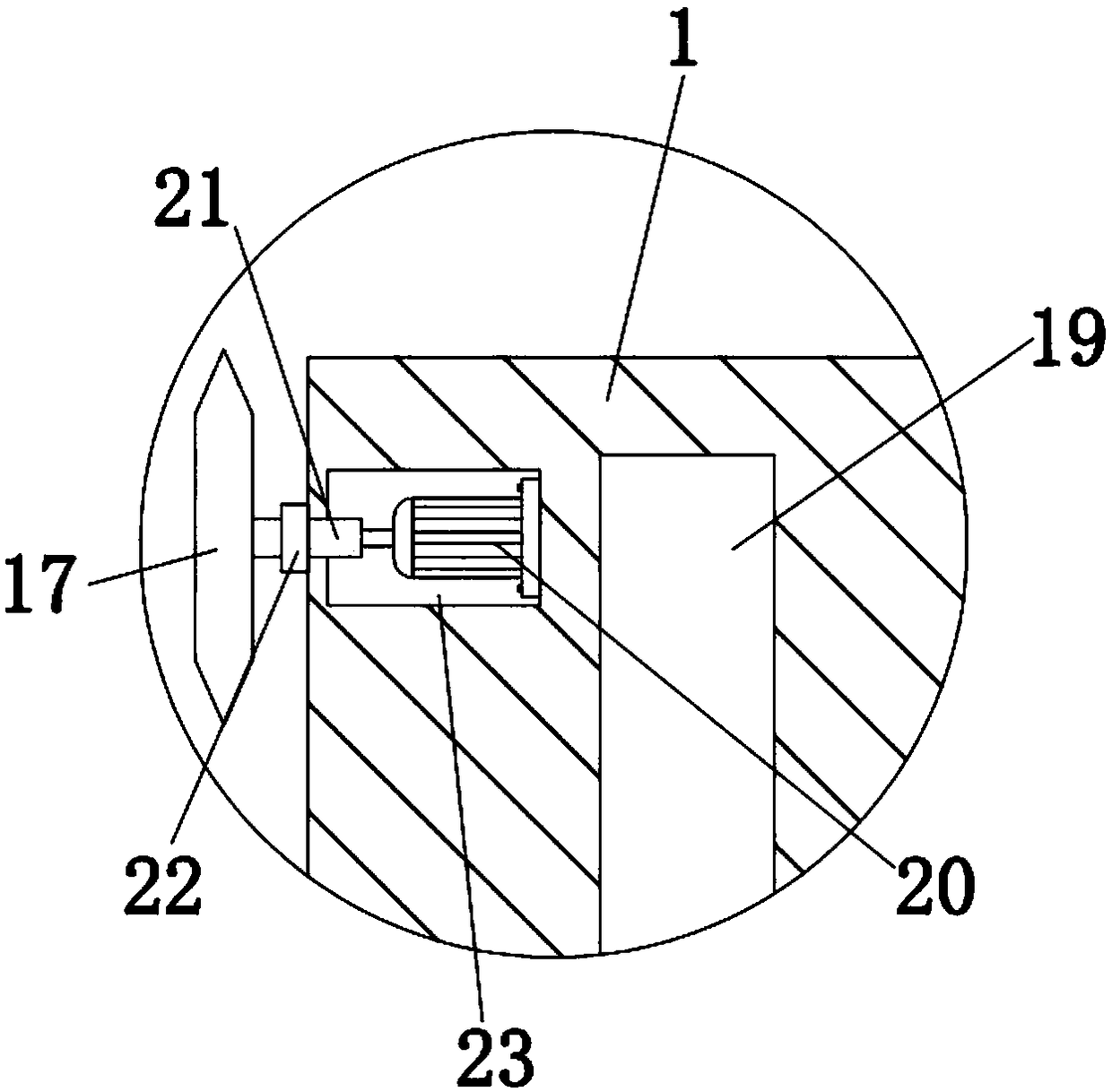

Clamping head for splitting machine

InactiveCN105270894AAdjust the pressing forceModerate pressing forceWebs handlingEngineeringMechanical engineering

The invention relates to the technical field of clamps, in particular to a clamping head for a splitting machine. The clamping head for the splitting machine comprises a box body and further comprises an air valve, chutes, a first spring, an ejector rod, a support part, a second spring, a pressing plate, a first cavity and a second cavity. An upper top plate and a lower bottom plate of the box body are concavely provided with the chutes. The pressing plate is clamped into the chutes. The ejector rod is arranged in the side wall of the box body in a penetrating mode and stretches into one end in the box body to be fixed onto the pressing plate. One end, extending outside the box body, of the ejector rod is provided with a support part in a rotary mode. The box body is divided by the pressing plate into the first cavity and the second cavity. The first spring and the second spring are extruded into the second cavity by means of the pressing plate. The air valve is arranged to a top plate of the first cavity in a penetrating mode. Gas is injected into the first cavity. Proper clamping force can be provided by gas and springs due to flexibility.

Owner:WUXI JIAMEIDA RUBBER & PLASTIC EQUIP

Passenger vehicle anti-collision electric folding rearview mirror support

Owner:CHANGZHOU KAILING AUTOMOBILE FITTINGS

Improved guiding device used for pressing and connecting automobile wire harnesses

ActiveCN108821019AAchieve the right orientationAdjust the pressing forceLine/current collector detailsFilament handlingEngineeringMachining

The invention discloses an improved guiding device used for pressing and connecting automobile wire harnesses, and relates to the technical field of wire harness machining. The improved guiding devicecomprises a machine shell, guiding assemblies, a driving assembly and auxiliary guiding mechanisms, openings are formed in the upper end and the lower end of the machine shell respectively, a top lidis installed at the upper end of the machine shell, the two guiding assemblies comprise the first guiding assembly and the second guiding assembly which are identical in structure, the driving assembly is arranged inside the machine shell and drives the first guiding assembly to move vertically, and the auxiliary guiding mechanisms are installed on the two sides of the guiding assemblies. The improved guiding device is simple in structure and convenient to operate; by arranging the two guiding assemblies, the automobile wire harnesses are correctly guided in the process of conveying; the driving assembly is utilized for adjusting the vertical position of the first guiding assembly to be used for adjusting the pressing force between the guiding assemblies and the wire harnesses.

Owner:捷凌电子(重庆)有限公司

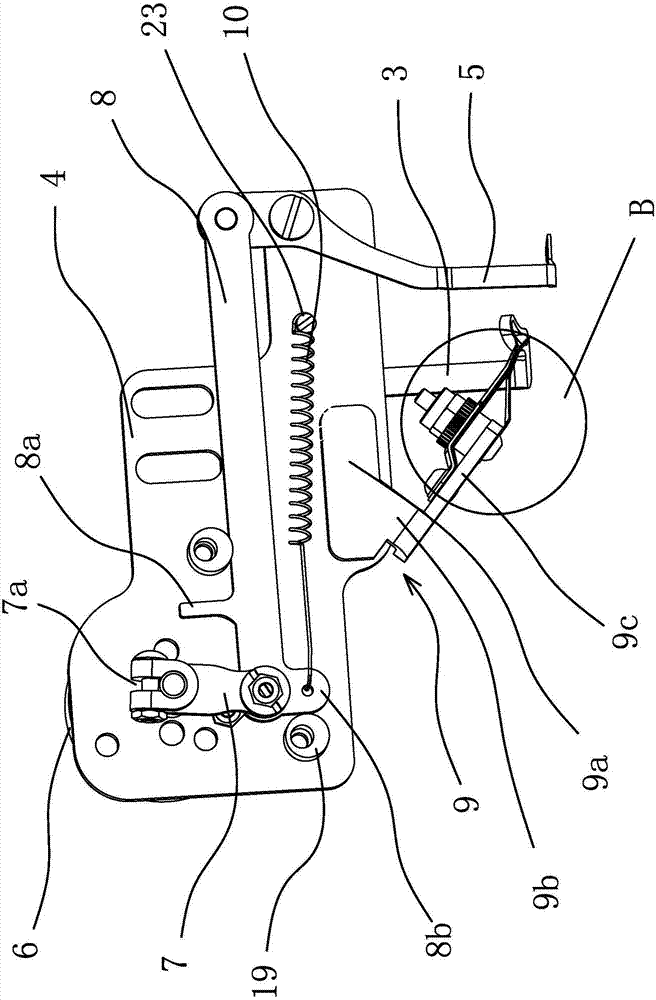

Sewing anti-thread-breakage device of sewing machine

ActiveCN107254745ANot easy to go offlineRealize hook lineNeedle severing devicesSewing-machine control devicesEngineeringSewing machine

The invention provides a sewing anti-thread-breakage device of a sewing machine, and belongs to the technical field of machinery. The problem that thread breakage is likely to happen to an existing sewing machine during sewing is solved. The sewing anti-thread-breakage device of the sewing machine comprises a mounting plate, a thread clamping assembly, a driving part and a thread drawing knife, the mounting plate is attached to the front end of a machine shell and is located on the rear side of a decorative thread cutter assembly, the driving part is fixed at one end of the mounting plate, and the middle of the thread drawing knife is hinged to the other end of the mounting plate; the two ends of a transmission connecting rod are hinged to the thread drawing knife and a driving crank respectively, and the driving part is connected with the driving crank; and a mounting piece is detachably connected to the portion, below the transmission connecting rod, of the mounting plate; the thread clamping assembly is fixed on the mounting piece and is opposite to the thread drawing knife, and a needle feeding and thread passing plate and the thread drawing knife are located on the two sides of the mounting plate respectively; a pulling hook of the thread drawing knife is not higher than the bottom of the needle feeding and thread passing plate, and a return spring is further arranged on the mounting plate. After the thread drawing knife of the sewing anti-thread-breakage device returns to the original position, the pulling hook is just located on the right side or the lower right portion of the needle feeding and thread passing plate, sewing is more stable, and skipped stitches and thread breakage are not likely to occur.

Owner:JACK SEWING MASCH CO LTD

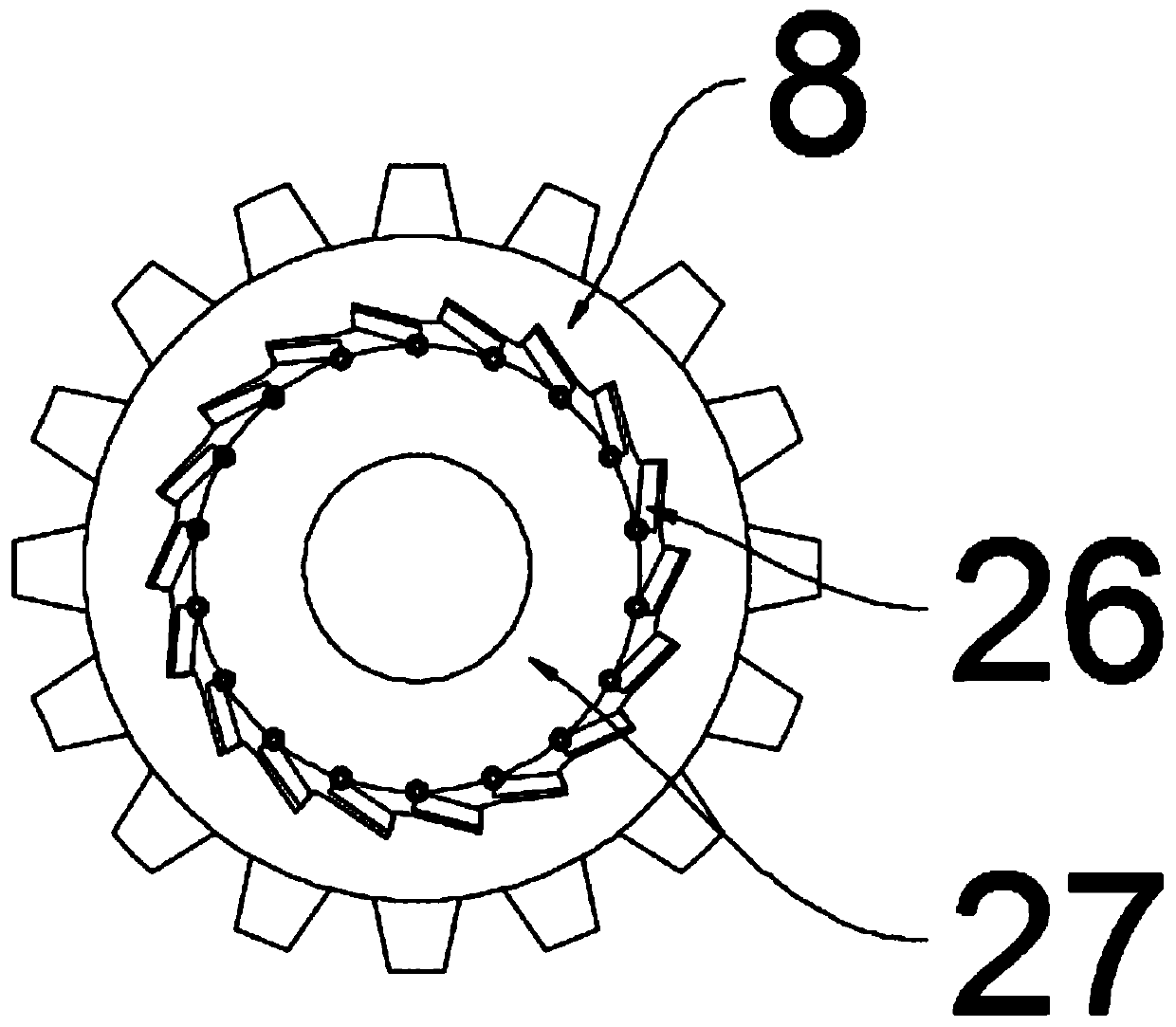

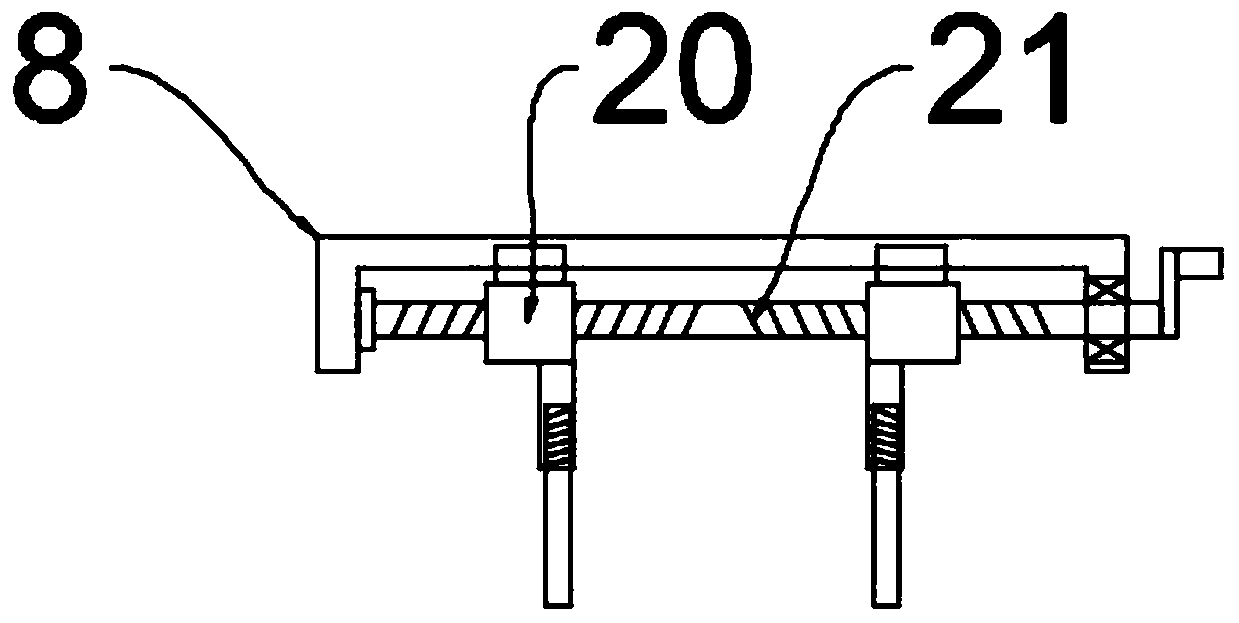

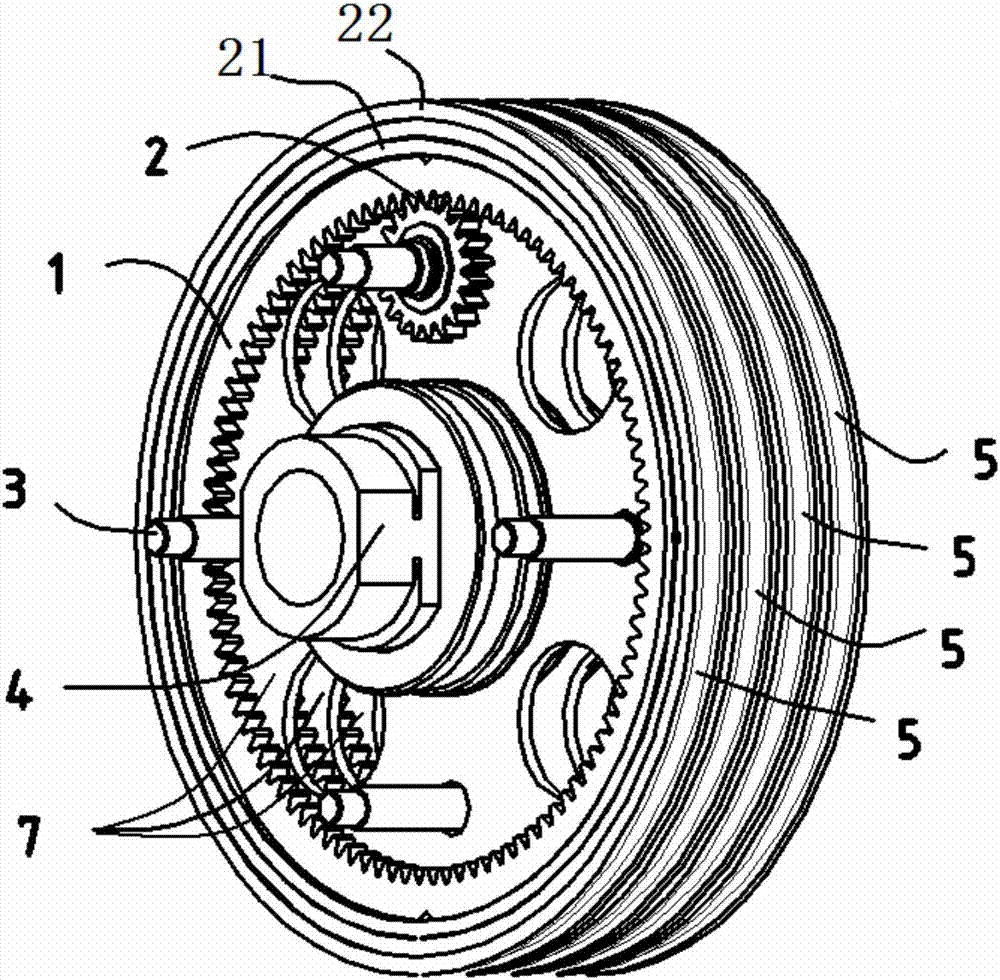

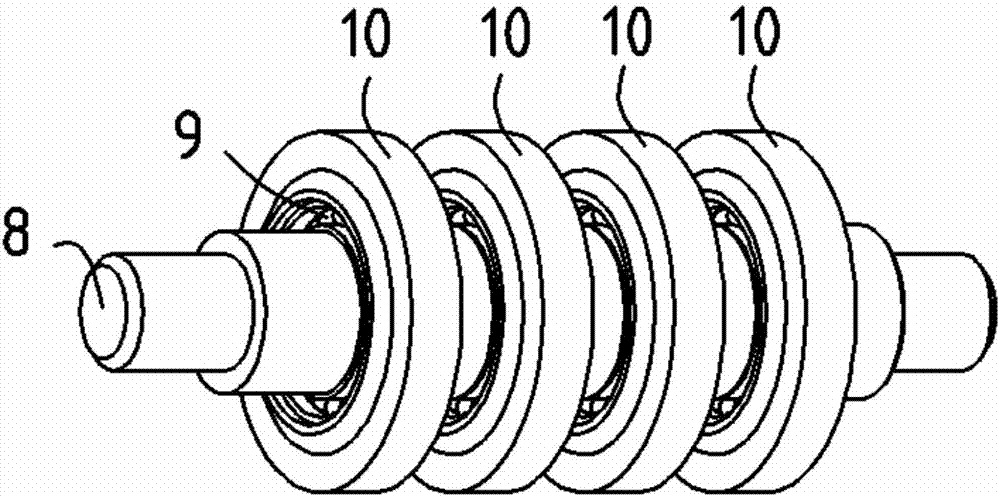

Re-conveying device in carbon fibre laying head

ActiveCN107187075AAvoid offset entanglementIncrease the number of simultaneous retransmissionsCarbon fibersEngineering

The invention relates to a re-conveying device in a carbon fibre laying head. The re-conveying device comprises a fixed shaft and a plurality of drive wheels sleeving the fixed shaft in parallel, wherein each drive wheel comprises a gear ring and a gear which are internally engaged, bearings are embedded in the two side surfaces of each gear ring, the bearings sleeve a support disc, and the support disc is installed on the fixed shaft; gear shafts of all the gears all penetrate through the support disc and are connected with the respective corresponding motors; all the motors are concentrated at one end of the fixed shaft or distributed at the two ends of the fixed shaft; a groove is formed in the outer side of each gear ring or a conveying ring with a groove fixedly sleeves the outer side of the gear ring; and press rolls in one-to-one correspondence with the grooves are arranged above the drive gears. The device realizes simultaneous laying for carbon fibre tapes at different conveying speeds. The device avoids deflection and intertwining of the carbon fibre tapes, and is high in expansibility and compact in structure.

Owner:WUHAN UNIV OF TECH

Straight line cutting machine applicable to bamboo and wood products

InactiveCN108297194AEasy to useReduce stepsProfiling/shaping machinesPulp and paper industryWood product

The invention discloses a straight line cutting machine applicable to bamboo and wood products. The straight line cutting machine comprises a bottom plate and a sliding groove. The sliding groove is formed in the top end inside the bottom plate, a base is arranged at the top end of the bottom plate and is in fit with the bottom plate, a sliding block is welded to the left side of the bottom end ofthe base, the sliding block is in sliding clamped connection with the siding groove, a through groove is formed in the middle of the top end inside the base, and a baffle is arranged on the right side inside the through groove. According to the straight line cutting machine applicable to the bamboo and wood products, by means of the cooperation of a second compression spring and the baffle, afterworkers place raw materials into the through groove, the edges, pressed in the through groove, of the raw materials are aligned to be pretightened, the operation that the workers achieve alignment ofthe raw materials by hand when clamp the raw materials is omitted, meanwhile, the raw materials are prevented from shifting in the pressing process, and convenience is brought to the workers for using the machine. By means of the cooperation of a top plate and a first compressions spring, when the raw materials are pressed, the workers can conveniently adjust the pressing intensity of a pressingplate.

Owner:安吉县杰安竹木制品工艺厂

Dust collection putty grinding device

ActiveCN104084858BRealize all-round grindingAdjust the pressing forceGrinding carriagesGrinding bedsEngineeringMoving frame

The invention discloses a dust collection type putty grinding device which comprises a trolley capable of moving transversely. The trolley is provided with a vertical moving frame and a first driving mechanism driving the vertical moving frame to vertically move. A grinding assembly, a blowing mechanism and a dust collection cover are installed on the vertical moving frame, wherein the blowing mechanism is located on one side of the grinding assembly, and both the grinding assembly and the blowing mechanism are together covered with the dust collection cover. A dust removing device is connected to the rear portion of the dust collection cover through a dust collection air pipe. The grinding assembly comprises a supporting body installed on the vertical moving frame. The supporting body is provided with a plurality of rotatable grinding heads and a second driving mechanism, wherein the grinding heads are located on the front end face of the supporting body, and the second driving mechanism drives the grinding heads to rotate. According to the dust collection type putty grinding device, putty on the side of the trolley can be automatically ground, the grinding strength is adjustable, the ideal grinding effect can be achieved, and labor is greatly saved. In addition, when the dust collection type putty grinding device is used for putty grinding, almost no dust is discharged, no pollution is produced to the environment, and no negative effects are produced on the body health of workers.

Owner:安徽中车浦镇城轨交通运维科技有限公司

Multifunctional dust removing device for film production

PendingCN106955857AReasonable structural designSimple structureCleaning using toolsThin membraneEngineering

The invention discloses a multifunctional dust removing device for film production. The multifunctional dust removing device comprises a support. A dust removing box, a lifting cloth dragging device and a positioning table are sequentially arranged at the upper end of the support from left to right. The dust removing box is internally provided with a containing groove with an upward opening. The upper left end of the containing groove is detachably provided with a film guiding device. Two positioning shafts are arranged in the containing groove. Each positioning shaft is sleeved with a roller in a connected manner, and each roller is internally provided with a brush. The lifting cloth dragging device comprises a base, first cleaning cloth, second cleaning cloth, a lifting plate, an air cylinder and a beam. The lower end face of the first cleaning cloth is connected with the base, and the upper end face of the second cleaning cloth is connected with the lower end face of the lifting plate. According to the above technical scheme, the structure design is reasonable, the structure is simple, using is convenient, the dust removing effect is good, the dust removing efficiency is high, the machining efficiency can be improved, accordingly the production cost is reduced, and practicability is high.

Owner:浙江凯阳新材料股份有限公司

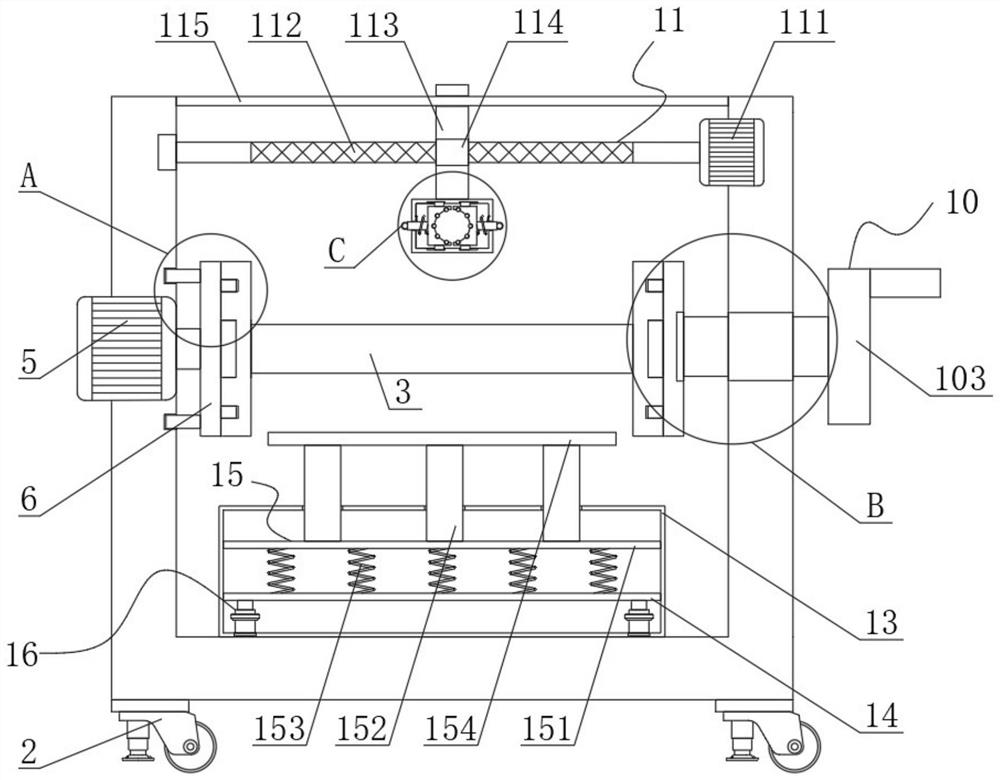

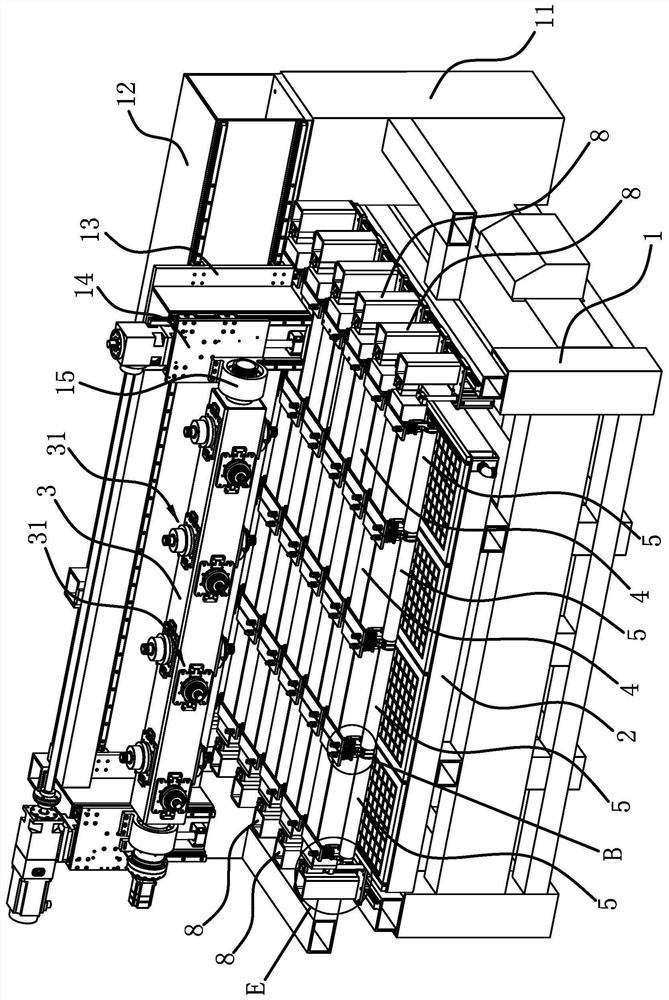

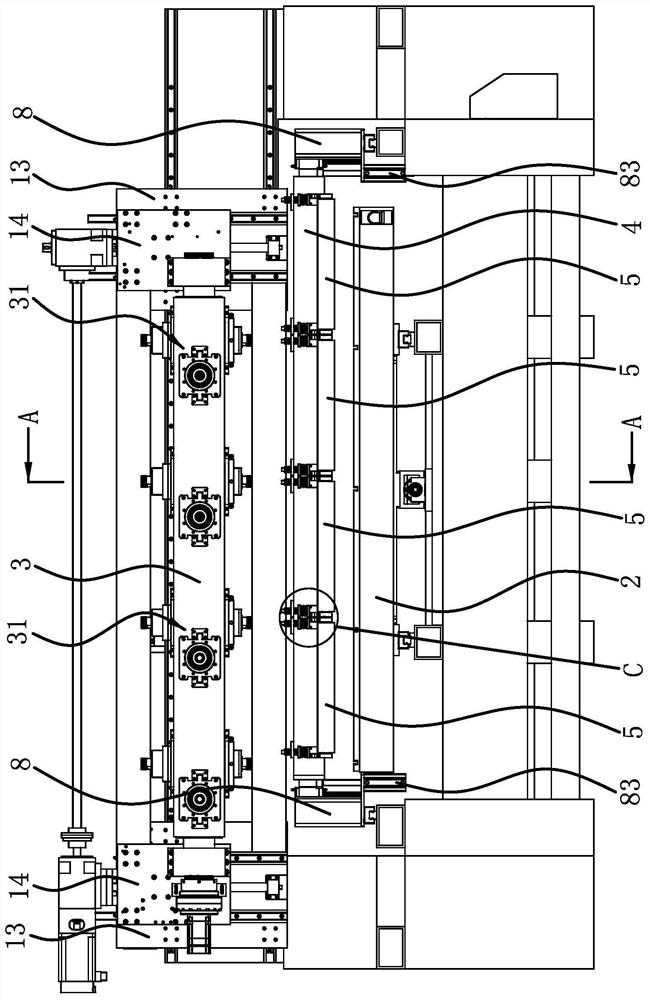

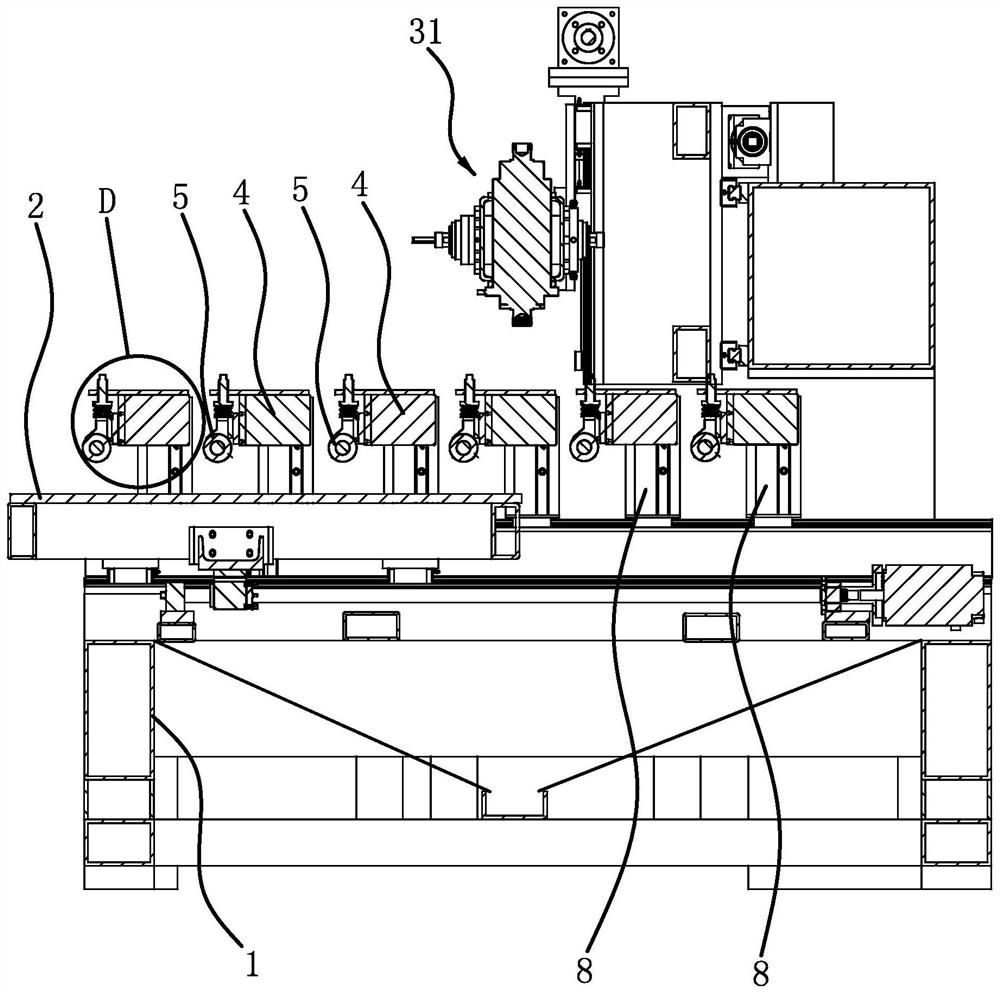

Woodworking machining center

PendingCN111958710AAvoid damageGuaranteed stabilityMulti-purpose machinesStructural engineeringMechanical equipment

The invention provides a woodworking machining center, and belongs to the technical field of mechanical equipment. The woodworking machining center solves the problem that an existing woodworking machining center is poor in stability of synchronously pressing and positioning a plurality of workpieces. The woodworking machining center comprises a rack and a machining platform horizontally arrangedon the rack, the rack is connected with a lifting frame capable of ascending and descending, the lifting frame is in a long strip shape and is arranged above the machining platform, the lifting frameis connected with a plurality of pressing rollers, the pressing rollers are sequentially arranged in the length direction of the lifting frame, and the lower portions of the pressing rollers are lowerthan the lower portion of the lifting frame; the multiple pressing rollers can independently ascend and descend relative to the lifting frame, and elastic pieces capable of enabling the pressing rollers to have the downward movement trend are arranged between the multiple pressing rollers and the lifting frame. The woodworking machining center is good in stability of synchronously pressing and positioning a plurality of workpieces.

Owner:吴善旺

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com