Mooring rope clearing device and pressure regulating mechanism thereof

A technology for pressure regulation and cleaning devices, which is applied in cleaning methods and tools, cleaning methods using tools, chemical instruments and methods, etc., and can solve the problems of insufficient cleaning effect, abrasion of mooring steel cables, and unreliable detection, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

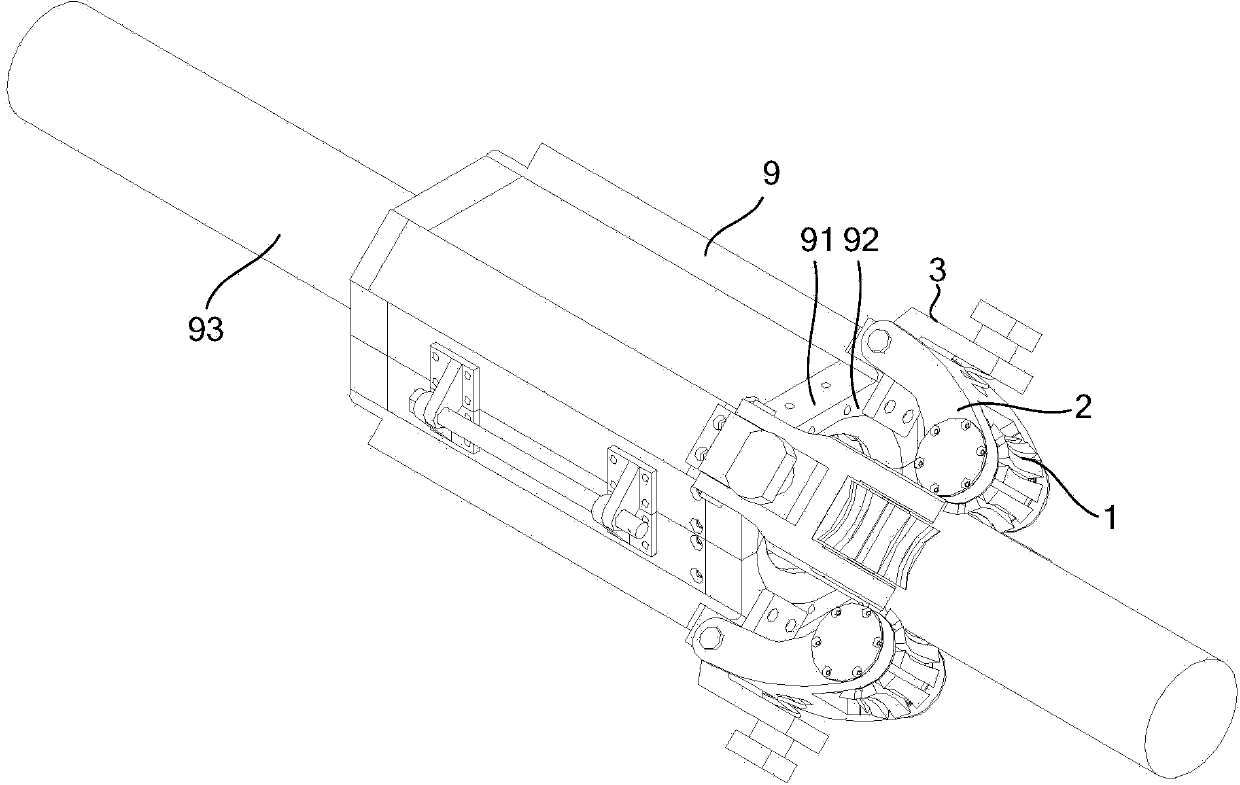

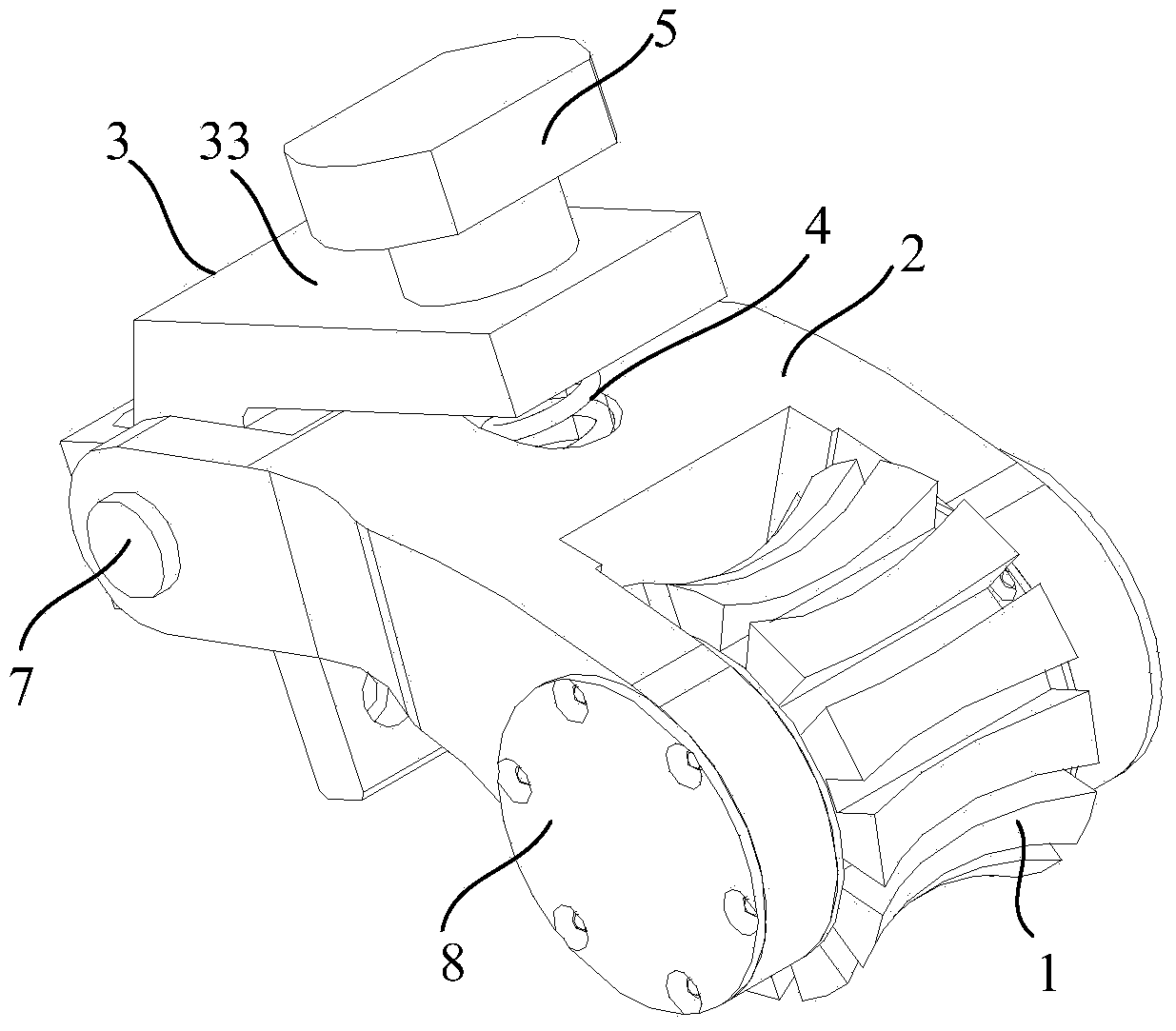

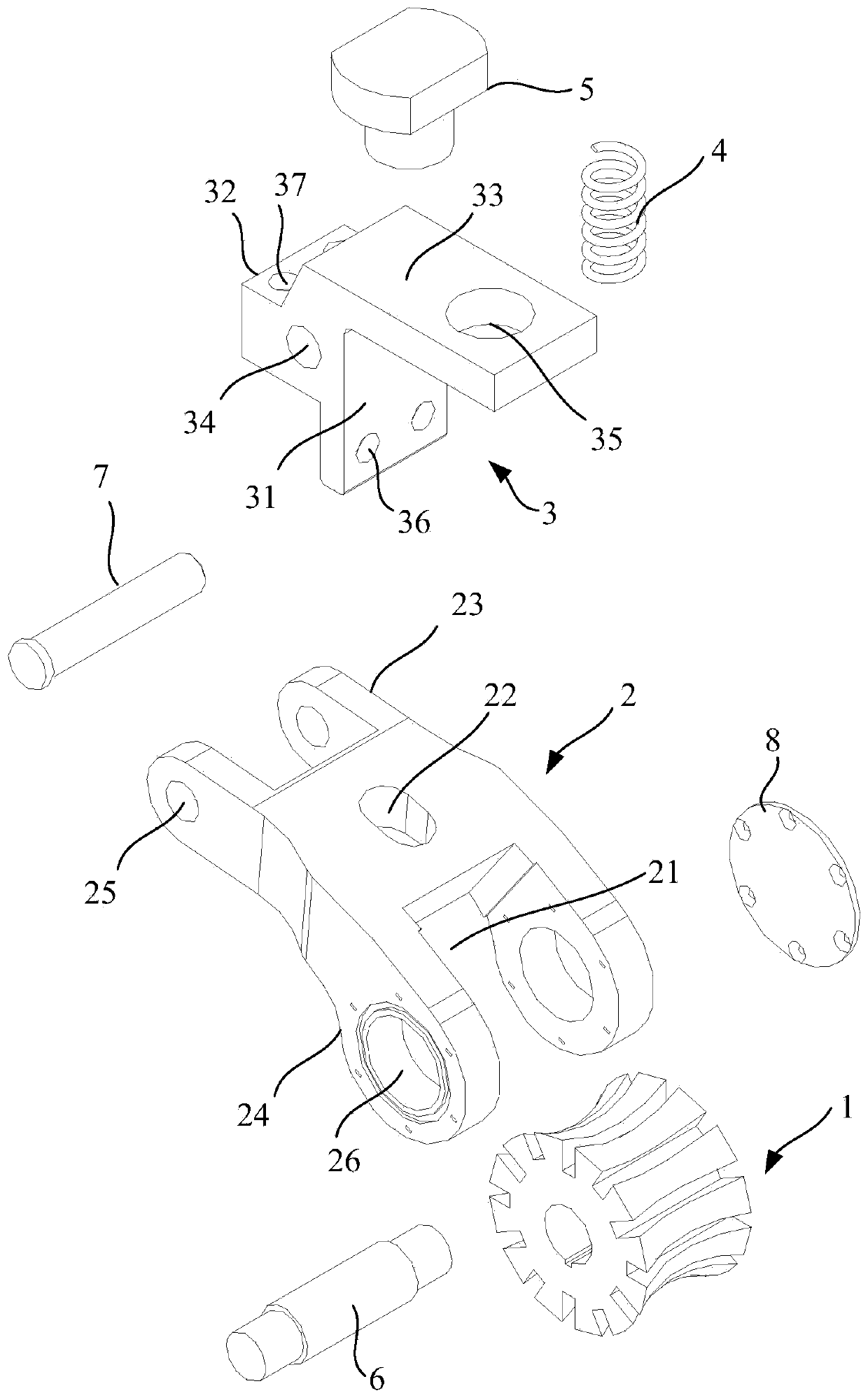

[0021] Such as Figures 1 to 4 As shown, the mooring line cleaning device includes a roller 1 , a roller bracket 2 , a connection base 3 , a connection shaft 7 , an elastic member 4 and a pressure adjustment limiter 5 .

[0022] The connecting base 3 is fixed on the shell 9 of the detection device set on the mooring line 93, and the roller bracket 2 is dynamically connected with the connecting base 3 through the connecting shaft 7. The roller bracket 2 can rotate around the connecting shaft 7, and the shell 9 has a shell front 92 parallel to the cross-section of the mooring line 93, and a shell side 91 perpendicular or nearly vertical to the shell front 92. Screw holes are provided on the shell front 92 and the shell side 91, and the connecting base 3 has The first fixed surface 31, the second fixed surface 32 and the third surface 33...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com