Multifunctional dust removing device for film production

A dust removal device and multi-functional technology, which is applied in the field of multi-functional dust removal devices for film production, can solve the problems of affecting the normal coating operation of film products, increasing production costs, and inconvenient processing, and achieves simple structure, reasonable structure setting, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

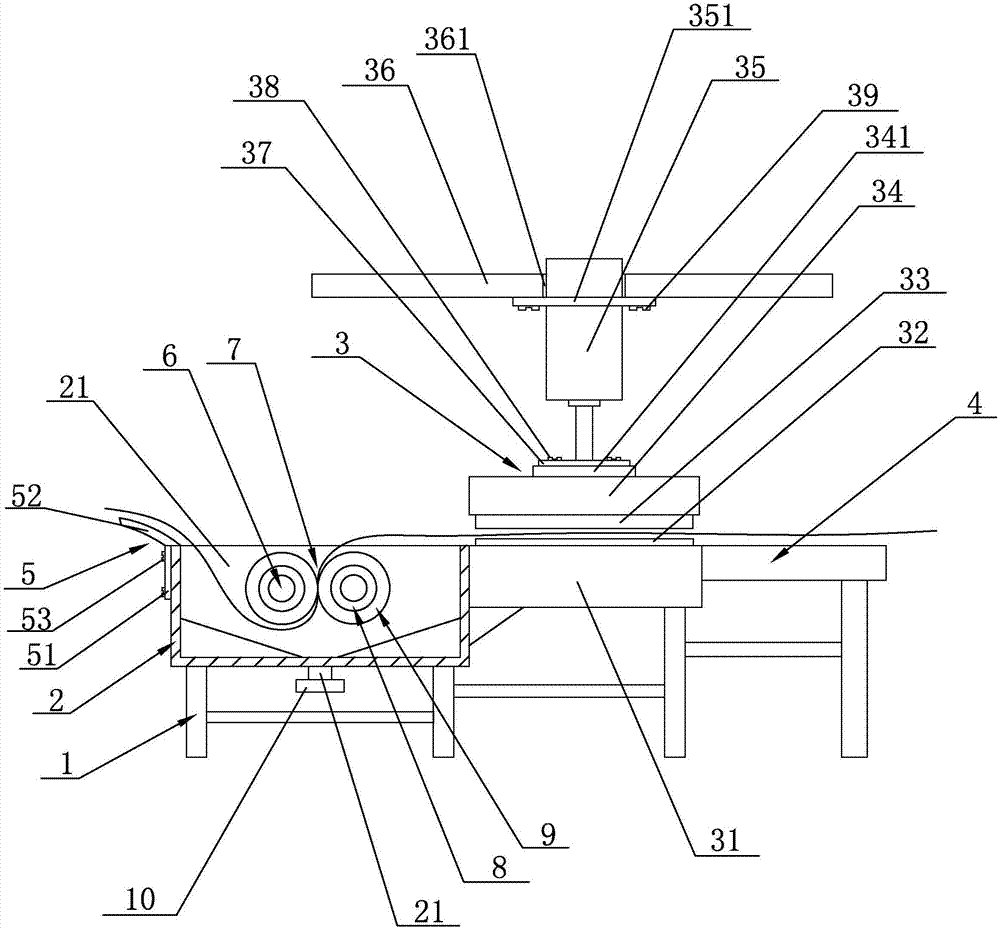

[0018] see figure 1 , a kind of multifunctional dedusting device for film production disclosed by the present invention comprises a support 1, and the upper end of the support 1 is sequentially provided with a dust removal box 2, a lifting mop device 3 and a positioning platform 4 from left to right, and the dust removal box 2 A storage groove 21 with an opening facing upwards is arranged inside, and a film guide device 5 is detachably arranged on the left upper end of the storage groove 21. Two positioning shafts 6 are arranged in the storage groove 21, and the two positioning shafts 6 Set at the same height, a film cleaning channel 7 is formed between two positioning shafts 6, and a roller 8 is sleeved on each positioning shaft 6, and a brush 9 is integrally arranged on each roller 8; the lifting mop device 3 includes a base 31, a first cleaning cloth 32, a second cleaning cloth 33, a lifting plate 34, a cylinder 35 and a crossbeam 36, the lower end surface of the first clea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com