Re-conveying device in carbon fibre laying head

A laying head and carbon fiber technology, which is applied in the field of carbon fiber laying equipment, can solve the problems of complex and huge re-feeding mechanism, shutdown failure, and many motor transmission structures, and achieve the effect of strong scalability and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

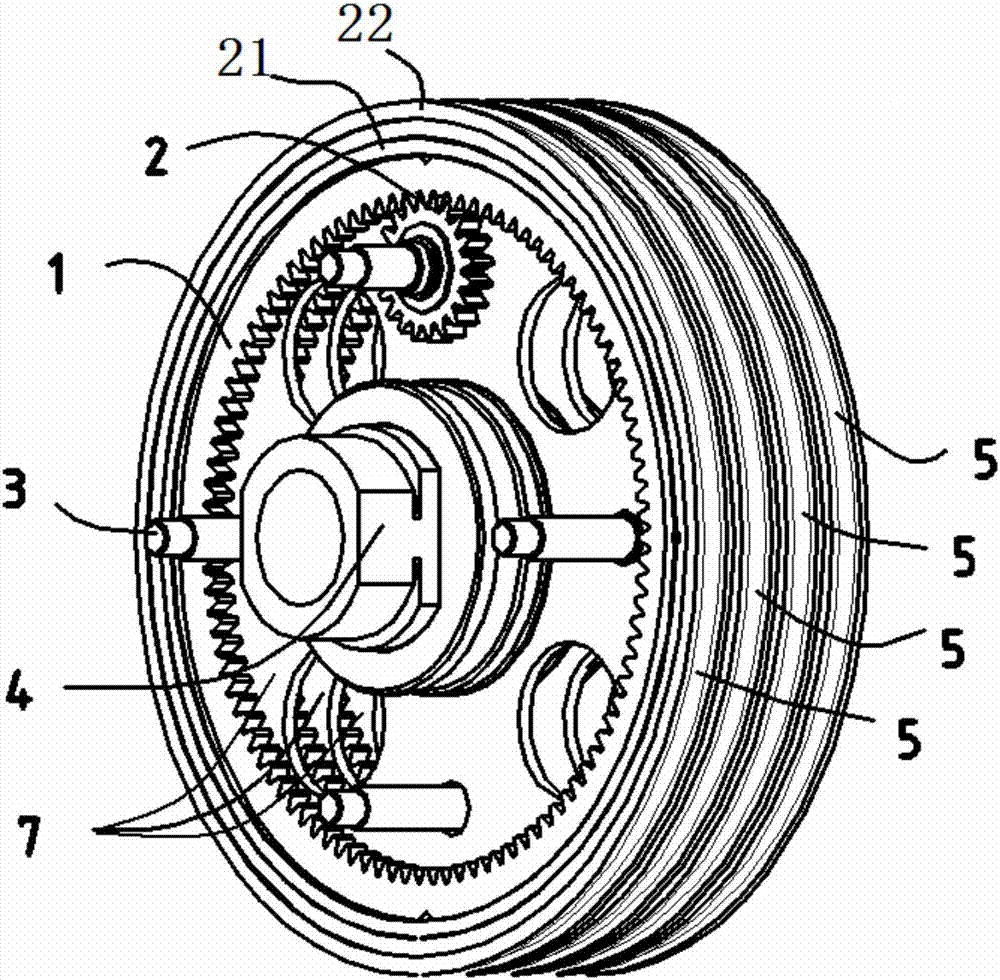

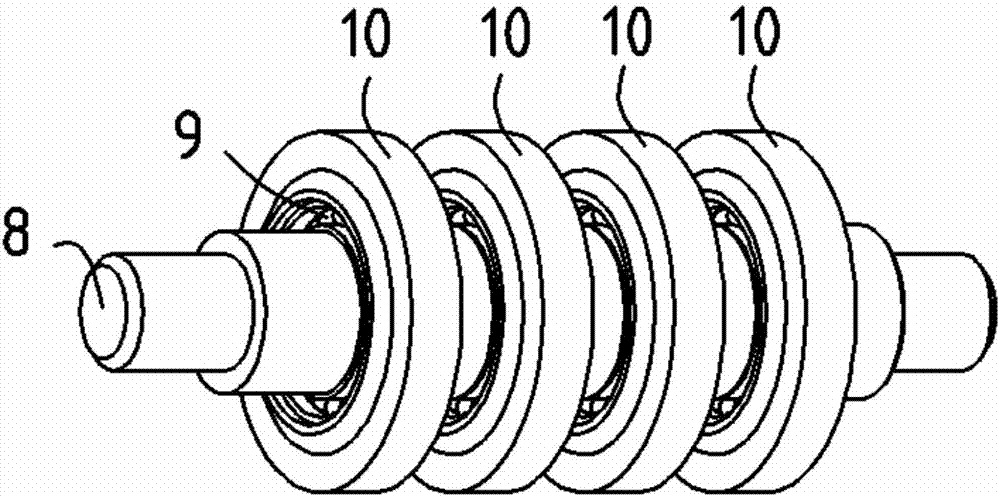

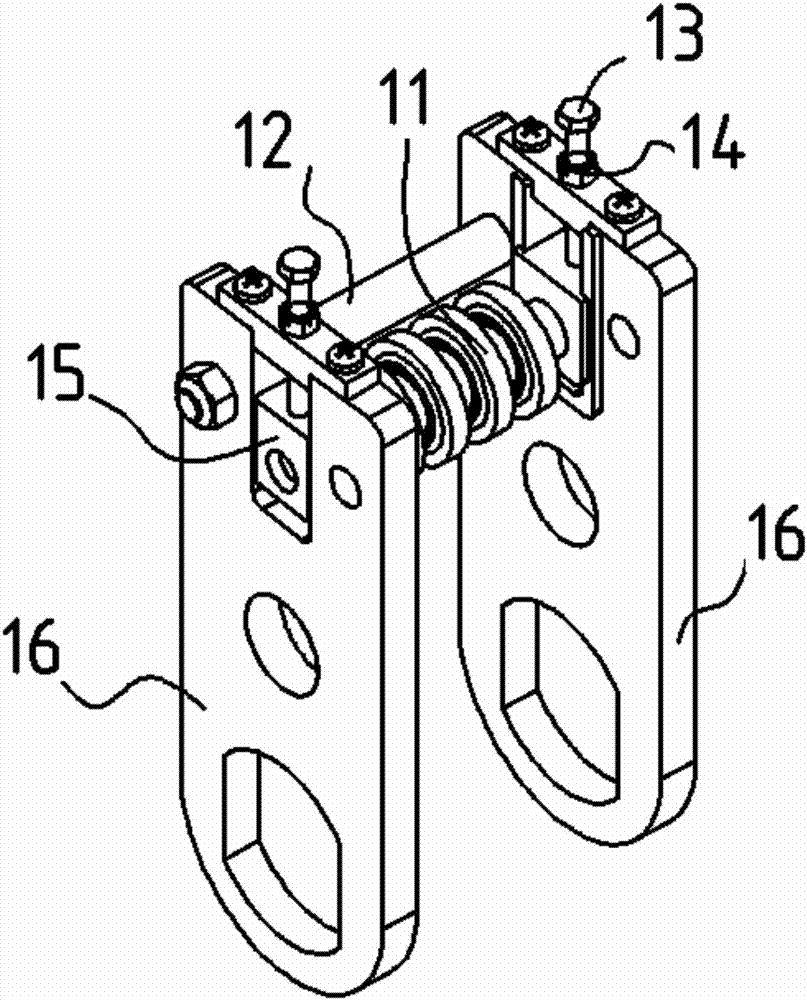

[0024] Such as Figure 4 As shown, a re-feeding device in a carbon fiber laying head includes a fixed shaft 4 and four parallel driving wheels 6 that are sleeved on the fixed shaft 4 (in this embodiment, four driving wheels 6 are used, but in fact there is no Not limited to four, can be reduced or expanded according to the actual situation), the driving wheel 6 includes an internal meshing ring gear 1 and a gear 2, and both sides of the ring gear 1 are embedded with bearings 21, and the bearings 21 are sleeved on the support disc 7, The support disc 7 is installed on the fixed shaft 4, and the gear shafts 3 of all the gears 2 pass through the support disc 7 and are connected to the respective corresponding motors 20, and all the motors 20 are concentrated at one end of the fixed shaft 4 (in practical applications, when the When needing to re-send a lot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com