Woodworking machining center

A processing center and woodworking technology, applied in wood processing equipment, manufacturing tools, multi-purpose machinery, etc., can solve problems such as poor stability, achieve the effects of ensuring stability, reducing driving parts, and improving positioning stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

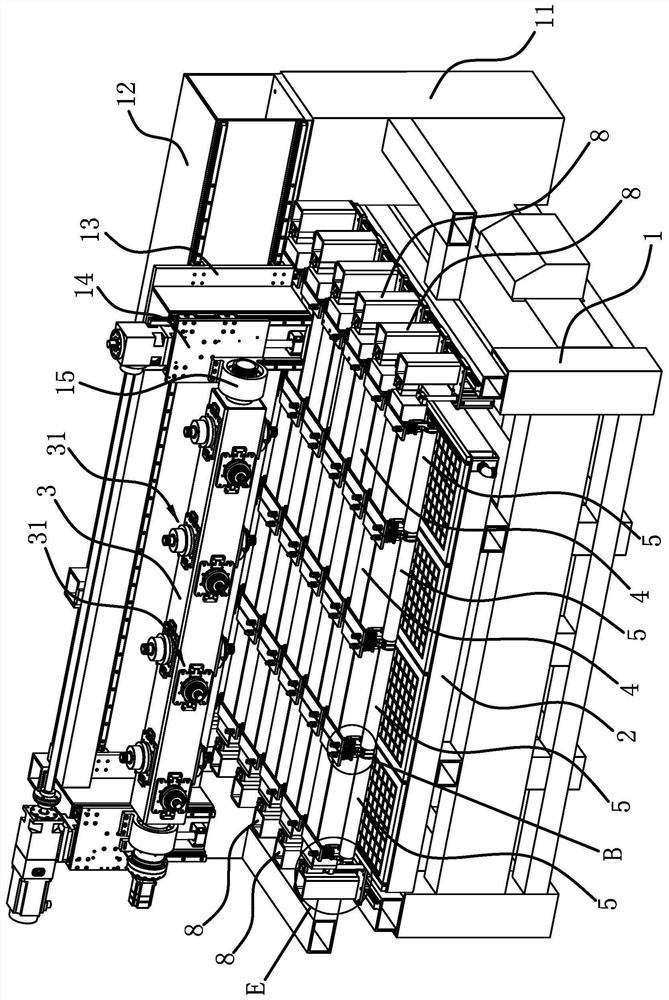

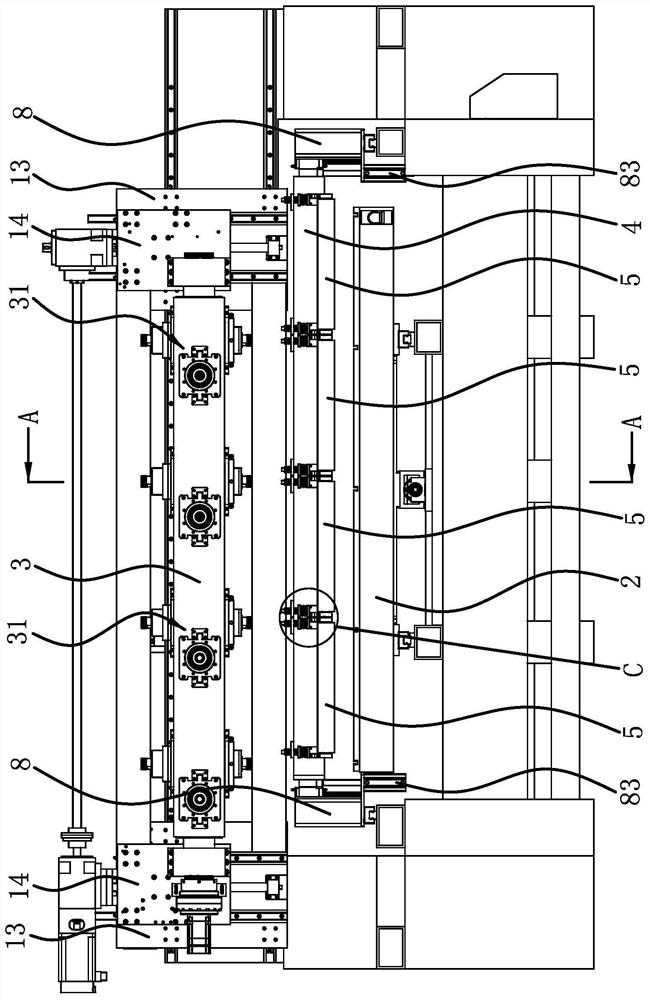

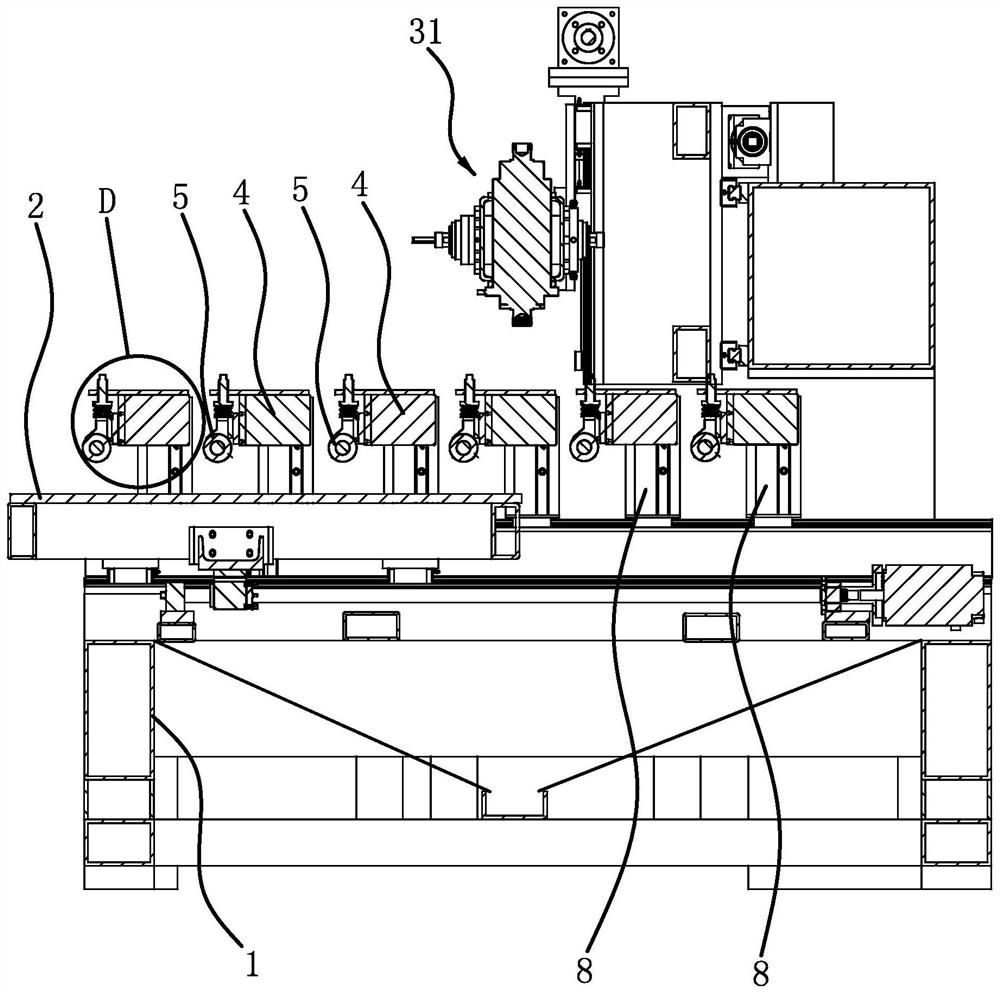

[0035] Such as figure 1 , figure 2 , image 3 As shown, a woodworking processing center includes a frame 1, a tool rack 3 and a processing platform 2. The frame 1 has two vertical columns 11, and a crossbeam 12 arranged horizontally is fixed between the tops of the two columns 11. On the crossbeam 12, two horizontal carriages 13 are slidingly connected in the horizontal direction, and the vertical carriages 14 are slidingly connected in the vertical direction on the two horizontal carriages 13, and supports 15 are fixed on the sides of the two vertical carriages 14. , the tool holder 3 is in the shape of a strip, and the two ends of the tool holder 3 are respectively rotatably connected to the two supports 15, so that the tool holder 3 is arranged laterally, and the tool holder 3 is provided with a number of processing components 31 along the length direction. Component 31 then comprises the processing motor that is fixed on the tool holder 3 and the cutter that is installe...

Embodiment 2

[0039] The structure of this woodworking processing center is basically the same as that of Embodiment 1, the difference is that Figure 9 , Figure 10 As shown, the pressure roller 5 is connected on the lifting frame 4 through an elastic member, the two ends of the rotating shaft 51 of the pressing roller 5 are provided with connecting sleeves 53, the bearing 65 is arranged between the connecting sleeve 53 and the rotating shaft 51, and the connecting parts include springs. The steel wire 9 and the fixed ring 10, the fixed ring 10 is sleeved on the lifting frame 4 and locked and fixed on the lifting frame 4 by a plurality of bolts 101 penetrating in the radial direction, the spring steel wire 9 includes a fixed section 91, an elastic section 92 and a connection Section 93, fixed section 91 and connecting section 93 are all in a spiral shape, and elastic section 92 is located between fixed section 91 and connecting section 93. 93 helical sleeve is set on the connecting sleeve...

Embodiment 3

[0041] The structure of this woodworking processing center is basically the same as that of Embodiment 1. The difference is that the elastic member includes two elastic cylinders. It is connected with the connecting frames 6 at both ends of the pressure roller 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com