Spiral extrusion type excrement solid-liquid separation device capable of controlling solid humidity

A technology of screw extrusion and solid-liquid separation, applied in the direction of presses, manufacturing tools, etc., can solve the problems that the microbial reaction environment cannot be effectively controlled, the screen-type solid-liquid separation device is easy to block, and the solid water content is high. Oxygen composting efficiency, meeting the needs of the living environment of fungi, and remarkable dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

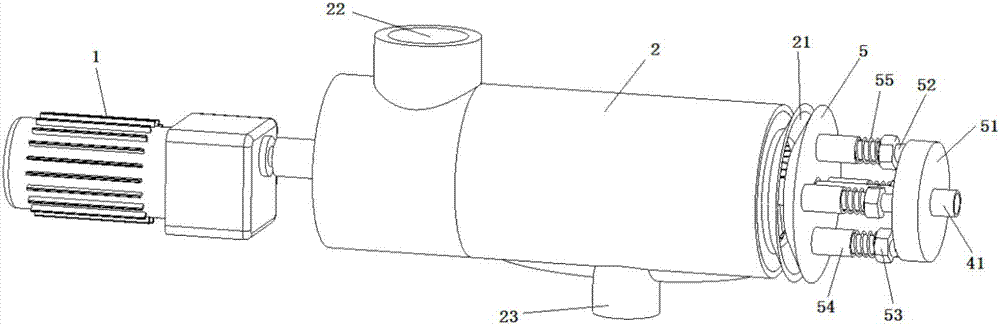

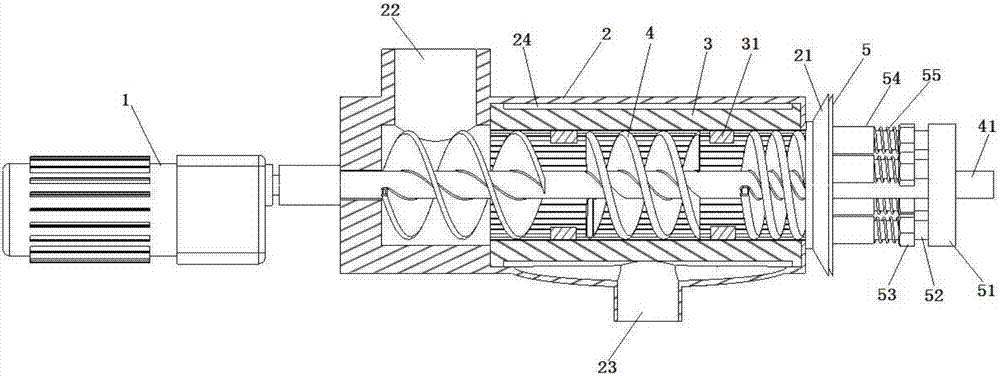

[0019] Specific implementation mode one: combine Figure 1~3 Describe this embodiment, the screw extrusion solid-liquid separation device of controllable solid humidity in this embodiment, the device consists of a motor 1, a separator housing 2, a screen cylinder 3, an auger 4 and a discharge port compression cover 5 constitute;

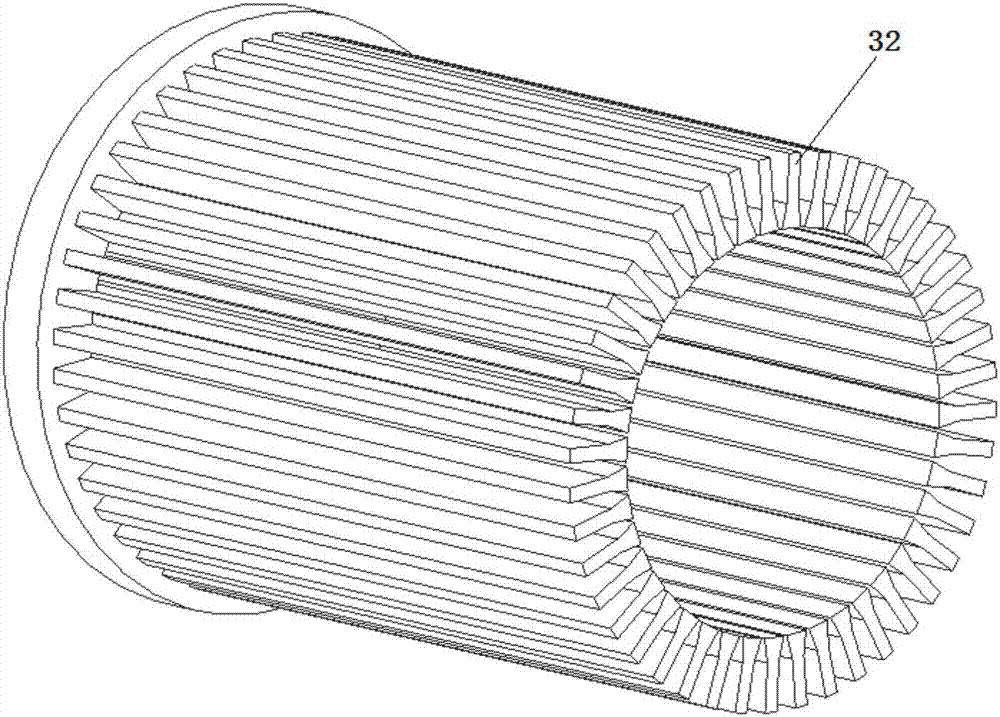

[0020] The screen cylinder 3 is composed of a plurality of equidistant strip plates 32. The cross section of the strip plate 32 is wedge-shaped, and the longer side of the wedge is set toward the center of the screen cylinder 3. Several blocking materials are arranged on the inner wall of the screen cylinder 3. tooth 31;

[0021] The separator housing 2 is cylindrical, one end of the separator housing 2 is a closed end, the other end of the separator housing 2 is provided with a tapered opening 21, and the outer circumference of the separator housing 2 is close to the separator. The closed end of the shell 2 is provided with a material inlet 22, an...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and Embodiment 1 is that four screw rods 52 are arranged on the side of the compression cover limiting disc 51 close to the tapered opening 21 . Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0029]Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that four cylinders 54 with vertical bottoms are arranged on the larger bottom surface of the compression cover 5 of the discharge port. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com