Improved guiding device used for pressing and connecting automobile wire harnesses

A technology for guiding devices and automobile wires, which is applied in connection, transportation and packaging, and circuit/collector components, etc. It can solve the problems of no auxiliary guiding mechanism, inability to adjust the pressing force, and unsuitability for smooth wire harnesses, etc., to achieve Simple structure, self-locking function, ingenious design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

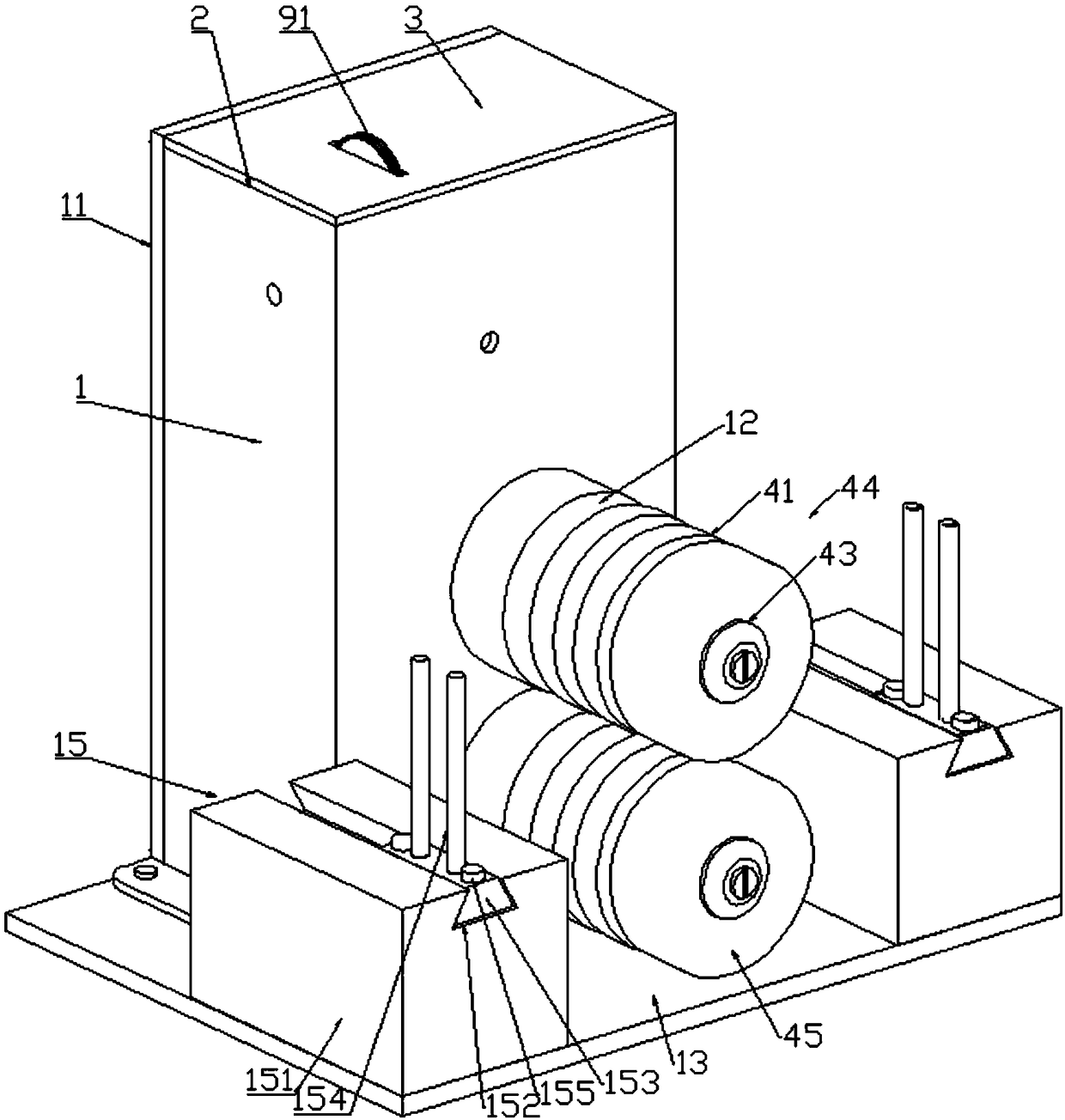

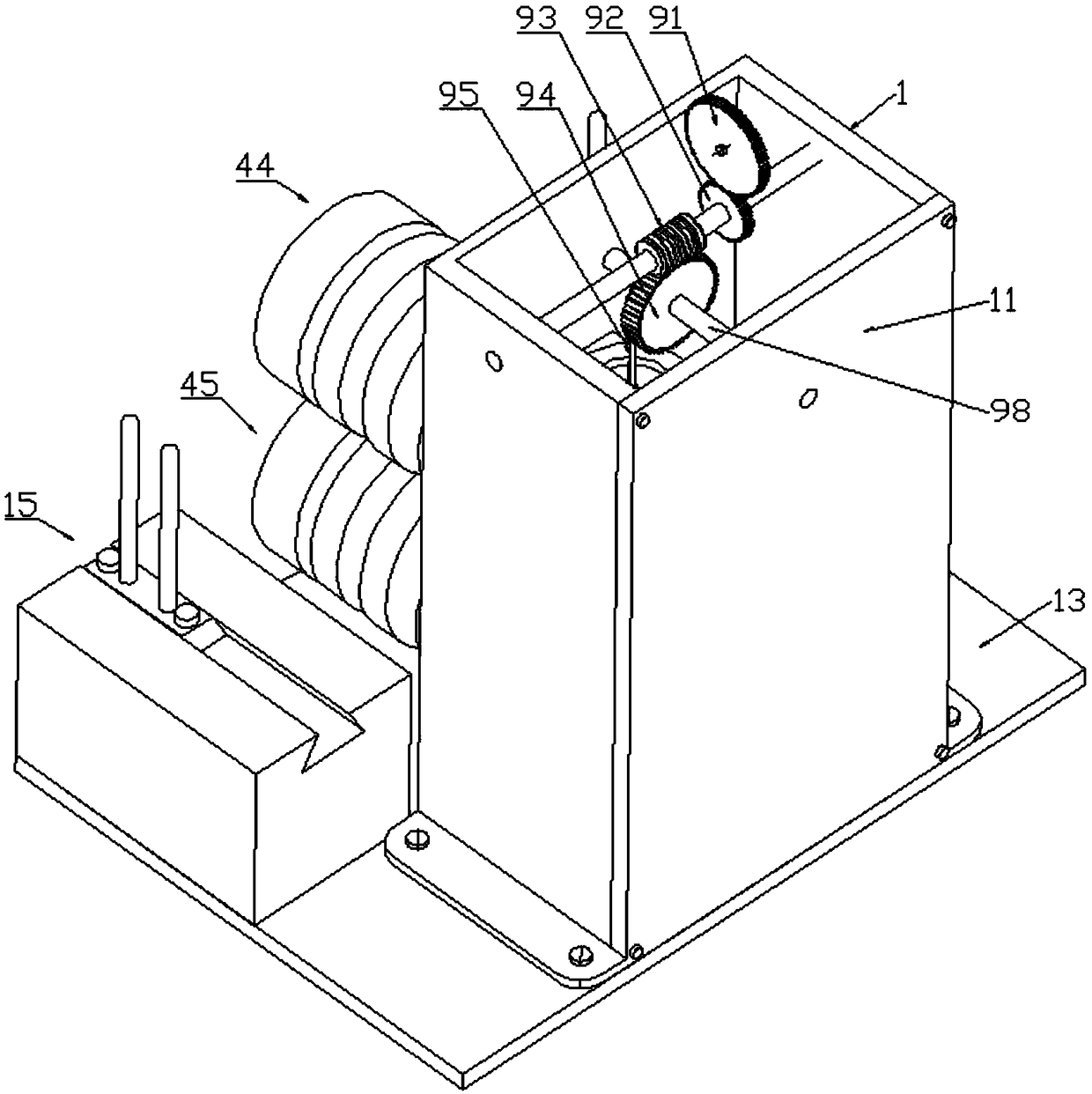

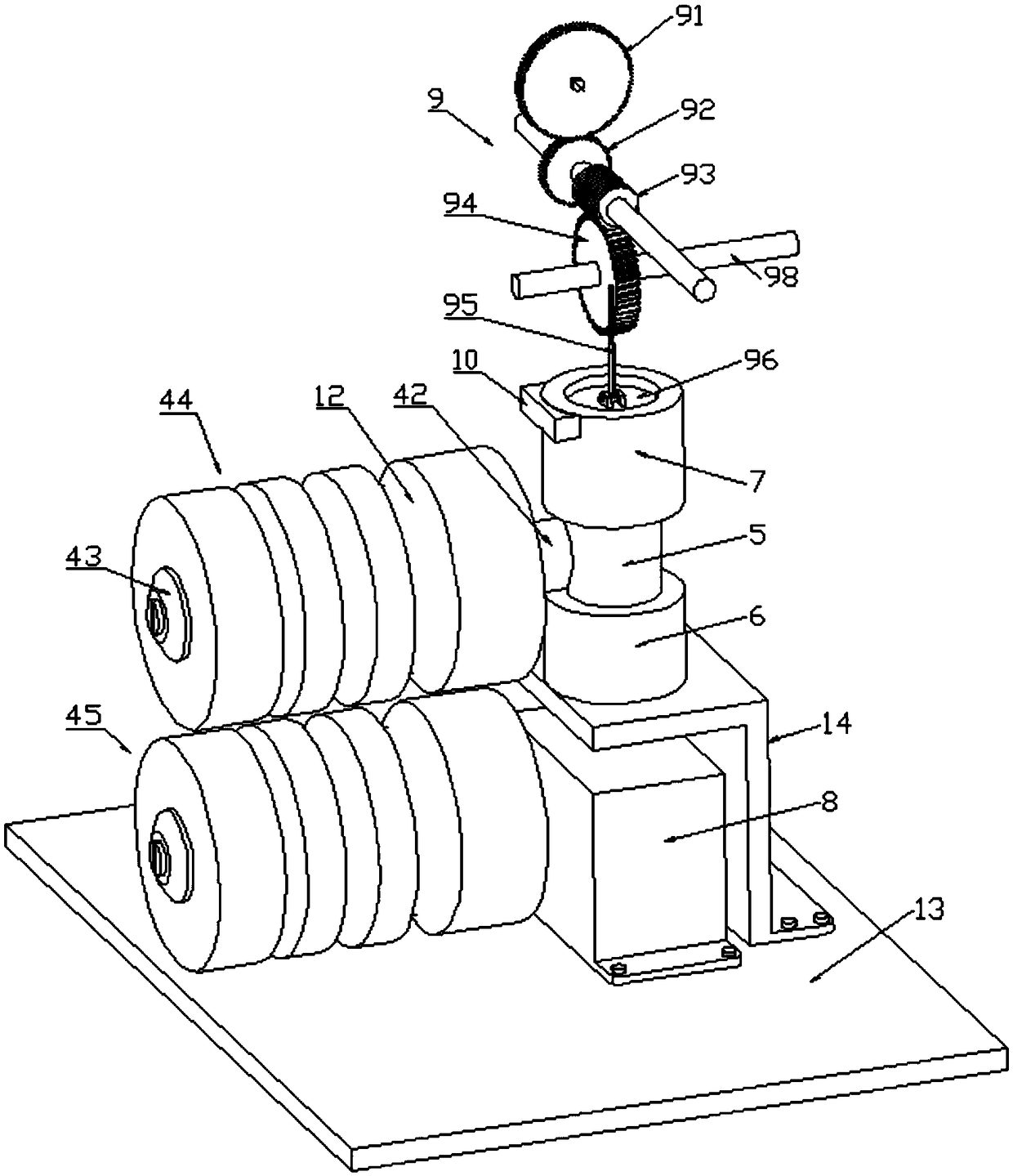

[0030] Such as Figure 1 to Figure 7 As shown, an improved guide device for crimping automotive wire harnesses, including a casing 1, a guide assembly 4, a drive assembly 9 and an auxiliary guide mechanism 15, the upper and lower ends of the casing 1 are provided with openings 2, and the casing 1 The upper end of 1 is equipped with top cover 3, and described guide assembly 4 has two and is respectively guide assembly one 44 and guide assembly two 45, and the structure composition of guide assembly one 44 and guide assembly two 45 is identical, and described drive assembly 9 is set Inside the casing 1 and drive the guide assembly 1 44 to move up and down, the auxiliary guide mechanism 15 is installed on both sides of the guide assembly;

[0031] The guide assembly 4 includes a guide roller sleeve 41, a transverse shaft 42 and a cover 43. The guide roller sleeve 41 is sleeved in the transverse shaft 42 and positioned by the cover 43 located at the outer end of the transverse sha...

Embodiment 2

[0038] Such as Figure 1 to Figure 7 As shown, an improved guide device for crimping automotive wire harnesses, including a casing 1, a guide assembly 4, a drive assembly 9 and an auxiliary guide mechanism 15, the upper and lower ends of the casing 1 are provided with openings 2, and the casing 1 The upper end of 1 is equipped with top cover 3, and described guide assembly 4 has two and is respectively guide assembly one 44 and guide assembly two 45, and the structure composition of guide assembly one 44 and guide assembly two 45 is identical, and described drive assembly 9 is set Inside the casing 1 and drive the guide assembly one 44 to move up and down, the auxiliary guide mechanism 15 is installed on both sides of the guide assembly;

[0039]The guide assembly 4 includes a guide roller sleeve 41, a transverse shaft 42 and a cover 43. The guide roller sleeve 41 is sleeved in the transverse shaft 42 and positioned by the cover 43 located at the outer end of the transverse sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com