Quick-idle-stroke and slow-pressurization main hydraulic cylinder translation type symmetric elbow rod servo press

A technology of servo presses and main hydraulic cylinders, applied in presses, stamping machines, manufacturing tools, etc., can solve problems such as plate damage, lower sliders, and large motor power, and achieve simple structure, simple control, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

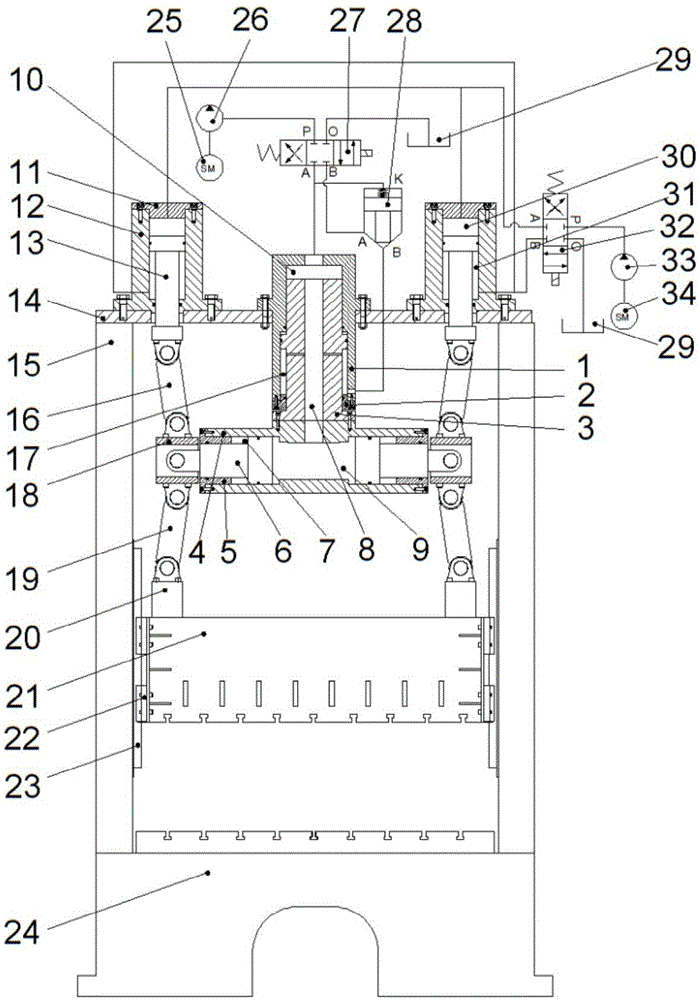

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0017] As shown in the attached figure, the main hydraulic cylinder translational symmetrical toggle servo press with fast idle stroke and slow speed boost has a completely symmetrical structure except for the main hydraulic cylinder 1 arranged in the center. The servo press includes the main hydraulic cylinder Cylinder 1, the upper end of the main hydraulic cylinder 1 is fixedly connected to the support plate 14, the support plate 14 is connected to the pillar 15, the pillar 15 is fixed on the base 24, and the lower end of the first piston 3 in the main hydraulic cylinder 1 is connected to the lower end of the main hydraulic cylinder 1 from the The first end cover 2 protrudes from the middle of the horizontal cylinder 4 and is fixedly connected to the upper end of the horizontal cylinder 4. The second piston 6 is symmetrically installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com