Patents

Literature

36results about How to "Not easy to go offline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

MEMS (micro-electromechanical system) chip and wafer level encapsulation cover plate grounding method of MEMS chip

ActiveCN103145088AThe overall thickness is thinFirmly attachedDecorative surface effectsSolid-state devicesElectricityMiniaturization

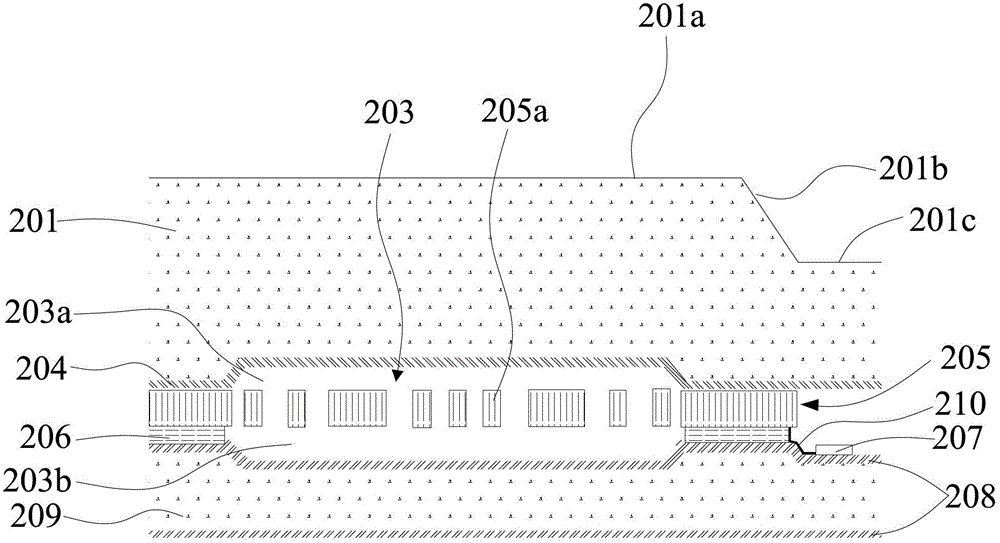

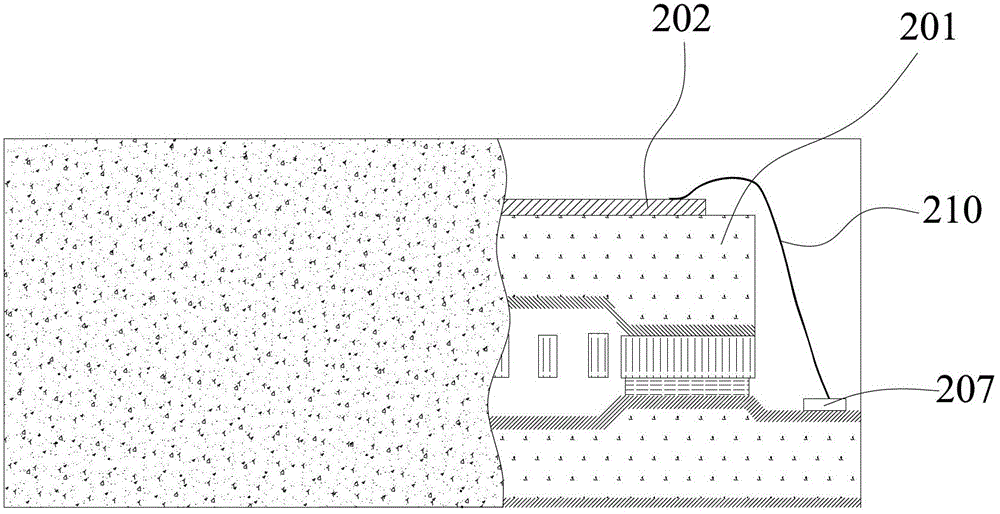

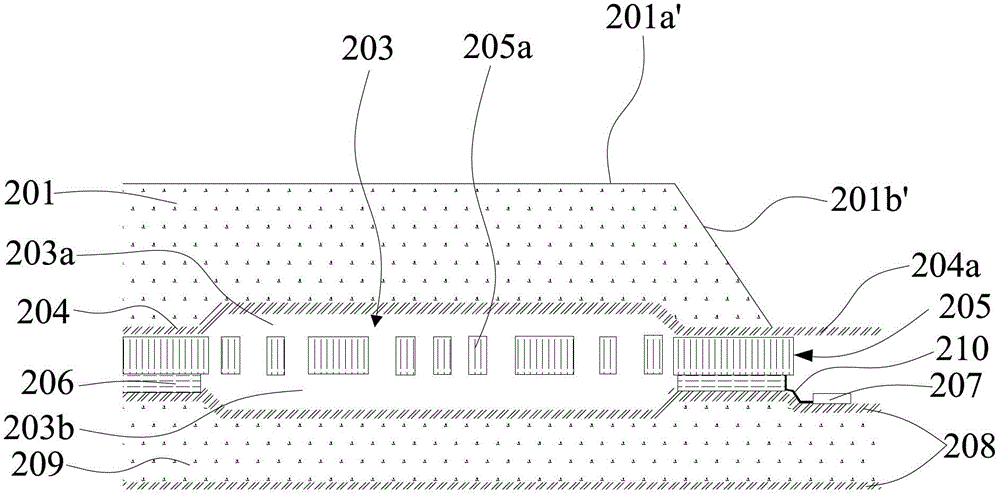

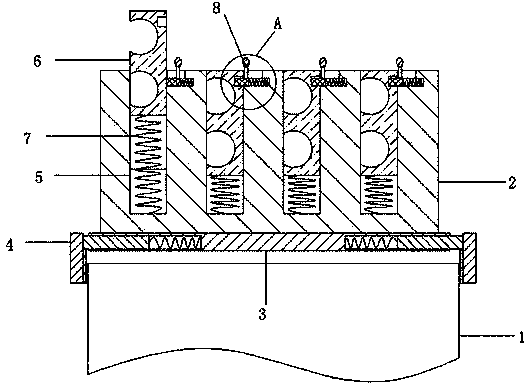

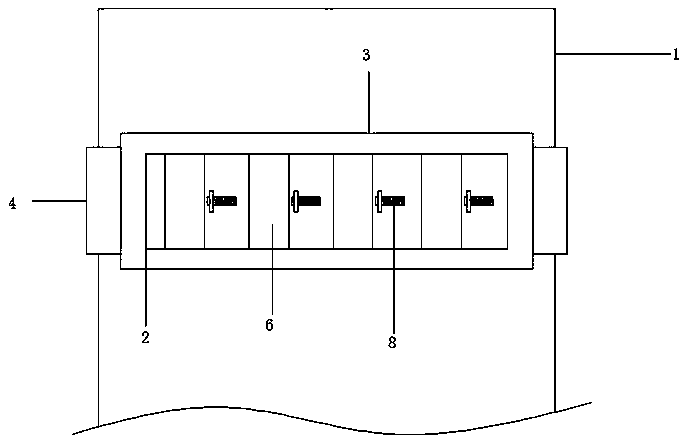

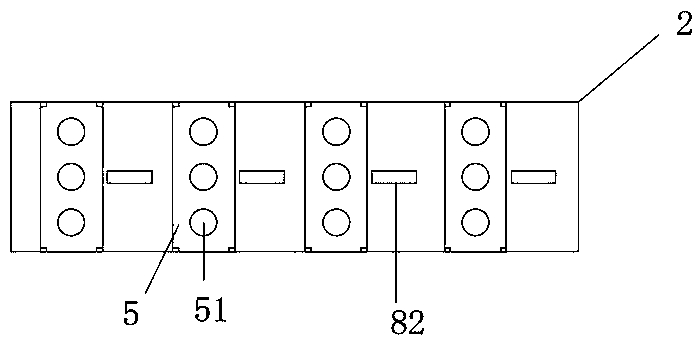

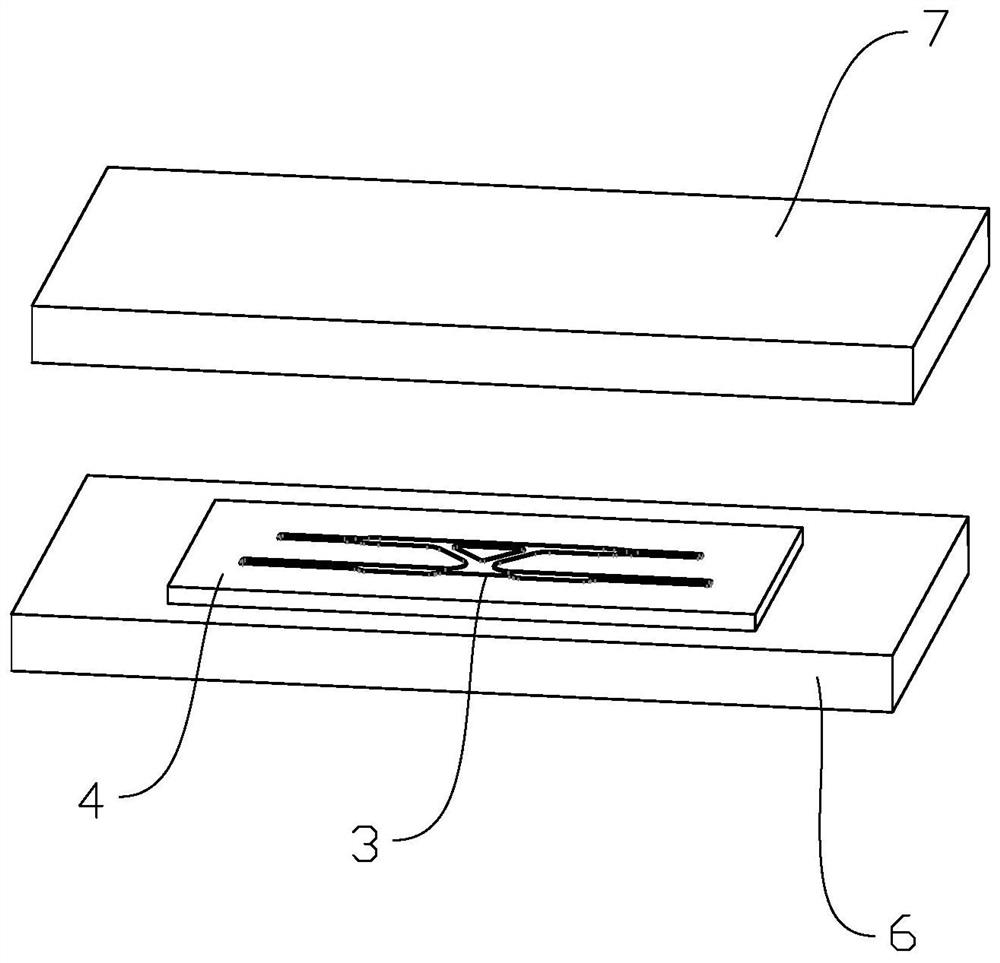

The invention relates to an MEMS (micro-electromechanical system) chip and a wafer level encapsulation cover plate grounding method of the MEMS chip. The MEMS chip consists of a cover plate, a cover plate insulating layer, an MEMS structure layer, a conducting welding flux layer, a bottom plate insulating layer and a bottom plate, wherein a metal conducting wire is arranged on the cover plate, the cover plate is electrically connected with the MEMS structure layer through the metal conducting wire, a pressure welding block is arranged on the bottom plate insulating layer, and the pressure welding block is electrically connected with the MEMS structure layer through a grounding conducting wire. In the subsequent encapsulation process, the cover plate grounding goal can be realized only when the pressure welding block is connected onto an encapsulation carrier. The cover plate grounding method is characterized in that firstly, the maskless lithography is carried out, the MEMS structure layer is exposed, then, the metal conducting wire is sputtered on the cover plate and the MEMS structure layer, and the cover plate and the MEMS structure layer are electrically connected through the metal conducting wire. Therefore, the cover plate and the pressure welding block realize the electric connection through the metal conducting wire and the grounding conducting wire, and the goal of the cover plate grounding is reached. The method provided by the invention has the advantages that the total thickness of the chip is reduced, the miniaturization encapsulation is convenient, the metal conducting wire is formed through deposition by a sputtering method, the cost is low, and the wire loosing cannot easily occur.

Owner:ANHUI BEIFANG XINDONG LIANKE MICROSYST TECH

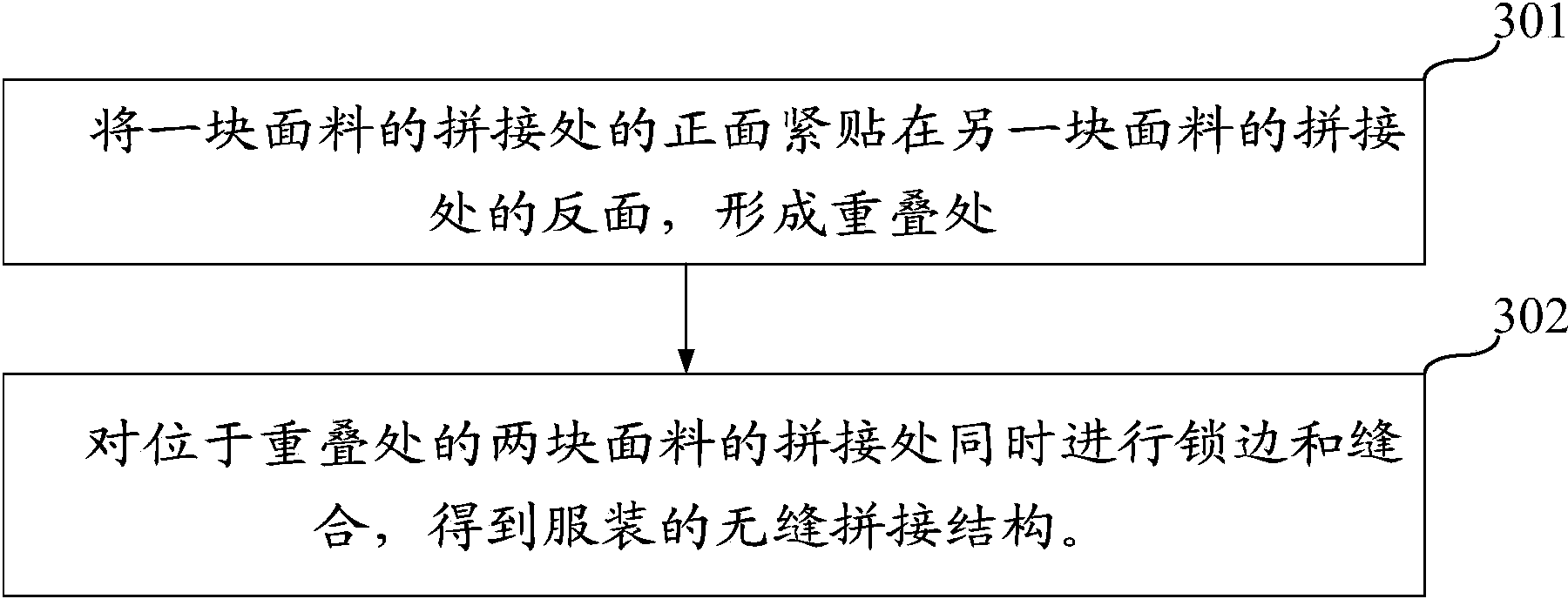

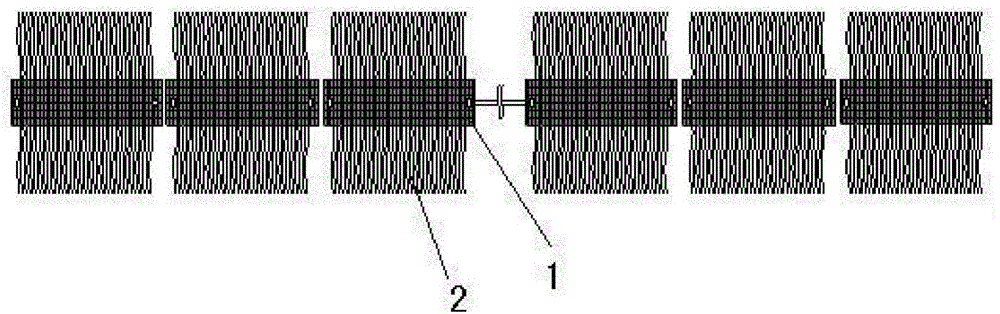

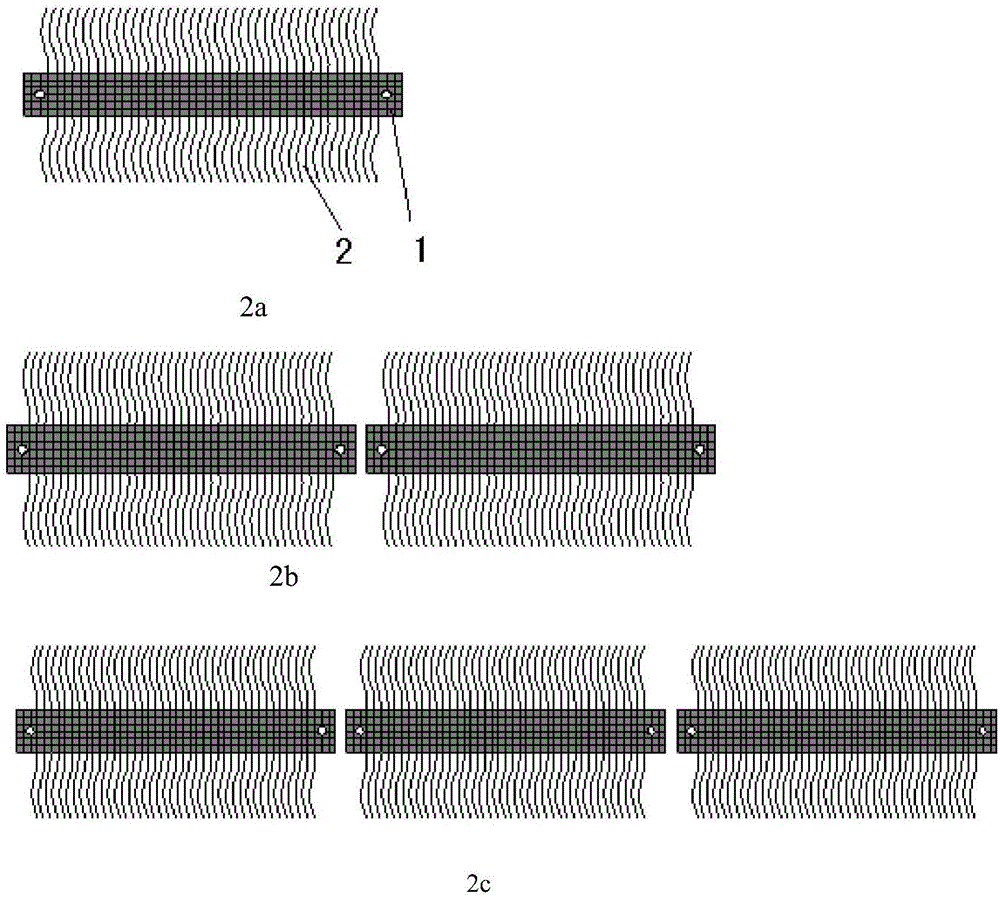

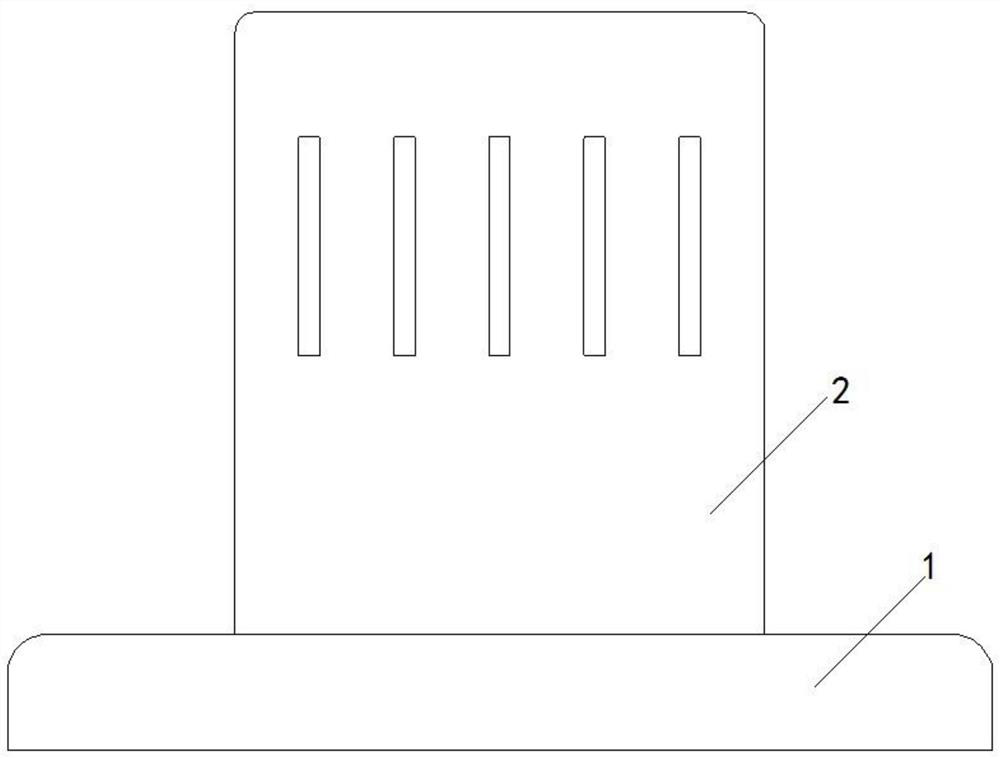

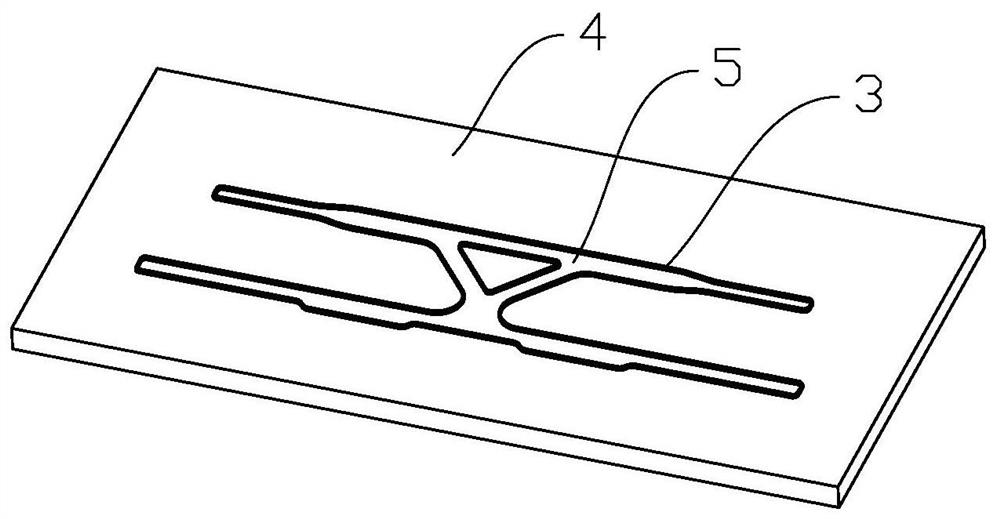

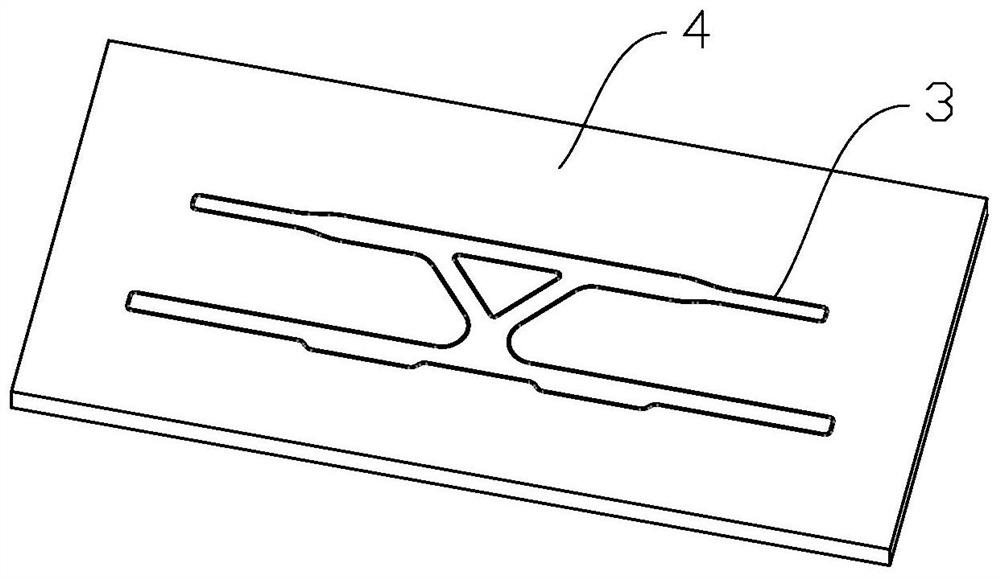

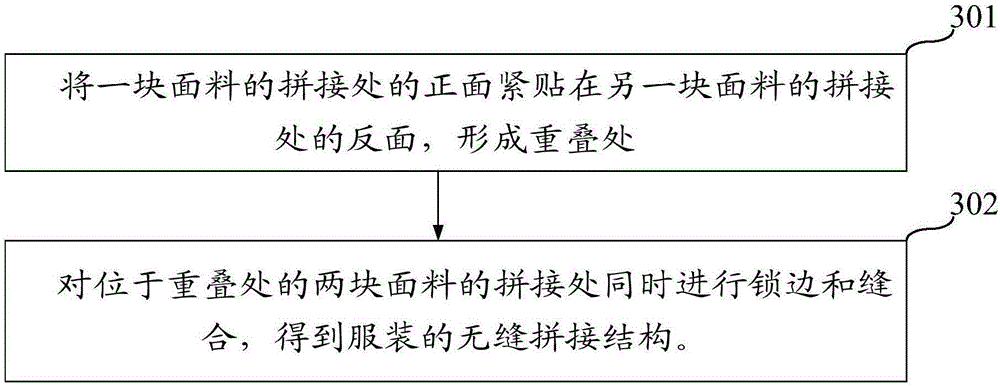

Clothing seamless splicing structure and clothing seamless splicing method

The invention relates to the field of clothing, in particular to a clothing seamless splicing structure and a clothing seamless splicing method. The clothing seamless splicing structure comprises two fabrics to be spliced, the front side of the splicing position of one fabric and the reverse side of the splicing position of the other fabric are overlapped and sewn, and overlock is arranged at the splicing positions of the two fabrics. The splicing principle is that firstly, overlapping is performed in the mode that the front side is tightly attached to the reverse side, so that a protruding overlapping portion formed when the front side is tightly attached to front side is avoided, and therefore the overlapping positions of the two fabrics are made to be smoother; secondly the splicing positions are overlocked and sewn simultaneously so that the two fabrics are connected together, and meanwhile the problem that the edges of the fabrics loose threads is avoided. Therefore, the clothing seamless splicing structure is shaped like a plane, the structure is smoother, and the clothing with the seamless splicing structure is not prone to rubbing skin while being worn next to the skin, is more comfortable to wear, and has the advantages of being firm and not prone to loosing the threads.

Owner:周剑

Plant fiber spool and its preparation method

InactiveCN1911618AHigh strengthImprove toughnessWood working apparatusDomestic articlesBobbinPlant fibre

The present invention is plant fiber bobbin for spinning and its making process. The plant fiber bobbin is made with the materials including plant fiber 50-90 weight portions, water soluble synthetic resin 5-30 weight portions, and starch gum 5-25 weight portions. The making process includes the following steps: 1. crushing plant fiber and mixing with water soluble synthetic resin and starch gum; 2. feeding the mixture into forming mold; and 3. molding at 100 deg.c-150 deg.c and 25-65 Kg / sq cm for 30-80 sec. The plant fiber bobbin has high strength, high toughness, low eccentricity and less deformation and may be used widely in textile industry.

Owner:刘正泉

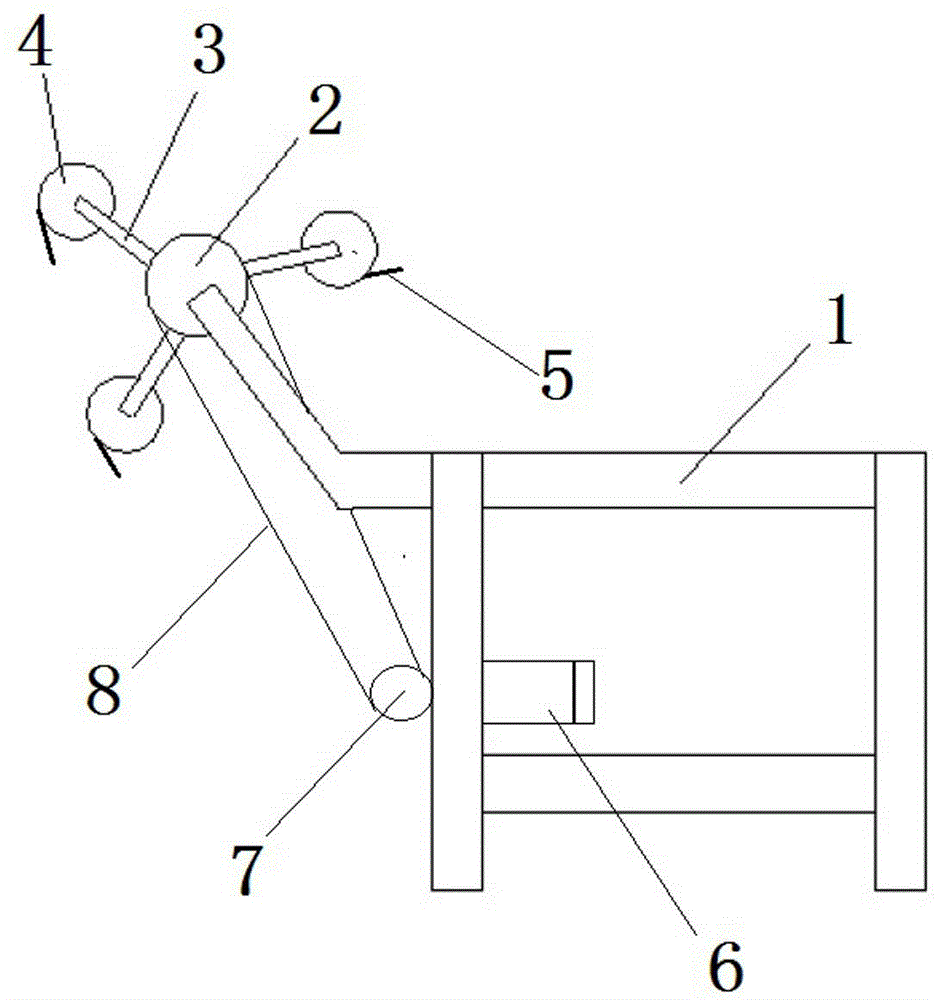

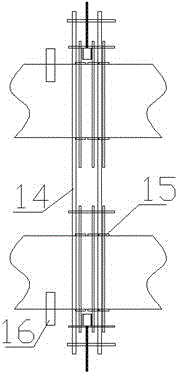

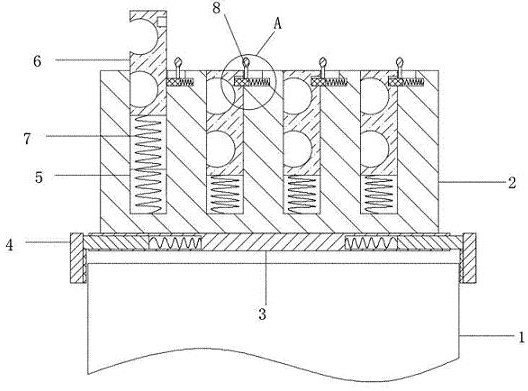

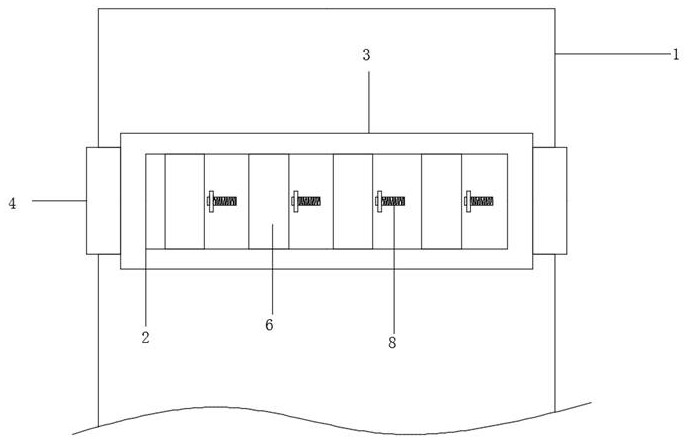

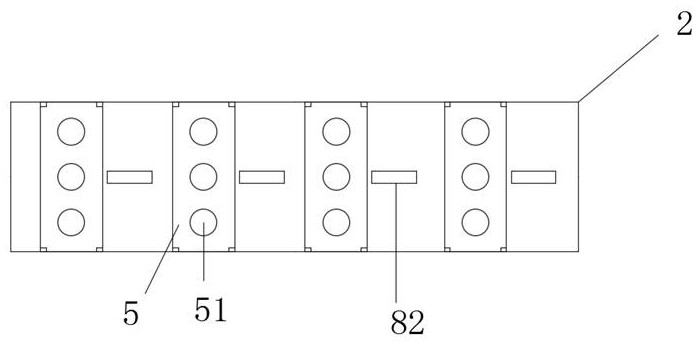

Improved Textile Machine Winding Device

PendingCN106064760ANot easy to go offlineImprove textile efficiencyFilament handlingDrive motorEngineering

The invention discloses an improved winding device for a textile machine, comprising a bracket, an end of the bracket is provided with a motor-driven rotating shaft, and a plurality of supporting arms are arranged on the rotating shaft at uniform intervals along the rotating shaft. A take-up roller is arranged on the take-up roller, a wire fixer is arranged on the take-up roller, a drive motor is installed in the bracket, and the drive shaft of the drive motor is connected with the drive roller, and the drive roller and the rotating shaft are conveyed by a belt Connection, because the winding device of a textile machine of the present invention is provided with a plurality of support arms at uniform intervals along its circumference on the rotating shaft, and the support arms are provided with take-up rollers, which can be used to realize the winding by relying on the rotation of the rotating shaft. The on-line replacement of the rollers does not need to stop the textile machine, and the yarn fixer is used to fix the textile thread when taking up the thread, so that it is not easy to fall off the thread, so the spinning efficiency of the present invention is high.

Owner:王敏

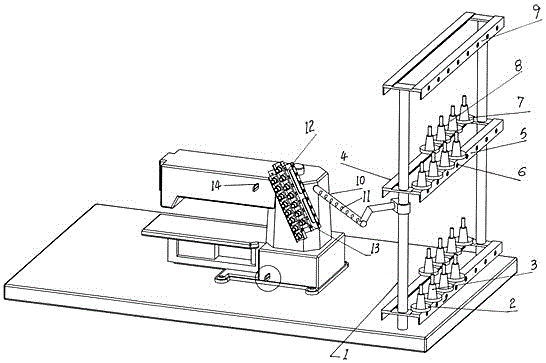

Thread bracket for sewing reflective stripes

InactiveCN106120185AImprove securityImprove bindingSpool-pin assembliesThread-break detectorsArchitectural engineeringSewing needle

The invention discloses a thread bracket for sewing reflective stripes. The thread bracket comprises thread rollers. A rack is formed by two round steel pipes which are spaced by a distance and fixed to one end of a sewing machine. An inner threading plate and an outer threading plate are arranged in the middle of the rack, a top layer threading plate is fixed to the head of the rack, a lower thread tray is arranged below the inner threading plate and the outer threading plate, an upper thread tray is arranged between the inner threading plate and the outer threading plate, the upper thread rollers are arranged on the upper thread tray, the lower thread rollers are arranged on the lower thread tray, threading holes are formed in the plate surfaces of the inner threading plate and the outer threading plate, a thread adding device is fixed to a machine head at one end of the sewing machine, a thread guide pipe is arranged in a suspended mode at the position above the thread adding device and in the middle of the inner threading plate, thread guide holes are formed in the thread guide pipe, thread separating rollers are arranged on the thread adding device, a thread distribution plate is fixed to the part, blow the thread separating rollers, of the sewing machine, two sets of threads are arranged in thread outlet holes of the thread distribution plate respectively in a penetrating mode, and the four threads in each set are threaded into a sewing needle to carry out sewing along the two sides of each reflective stripe.

Owner:新乡市新科防护科技有限公司

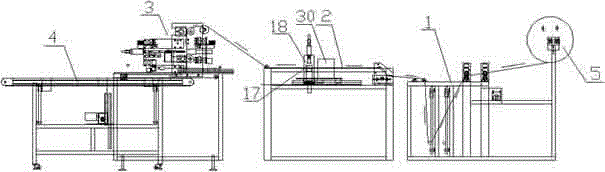

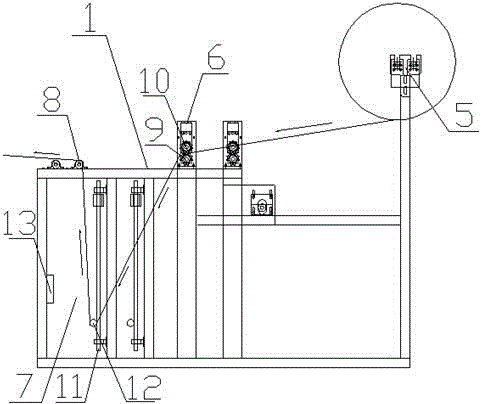

Automatic towel machine

InactiveCN106743898ARealize integrationNot easy to go offlineArticle deliveryWebs handlingEngineeringTowelettes

The invention discloses an automatic towel machine. The automatic towel machine comprises a towel feeding mechanism, an ultrasonic labelling mechanism, a towel transverse cutting mechanism and a towel arranging mechanism which are sequentially arranged in the towel conveying direction. The towel feeding mechanism is used for unwinding and feeding of towels. The ultrasonic labelling mechanism is used for labelling of the towels. The towel transverse cutting mechanism is used for cutting off the labelled towels. The towel arranging mechanism are used for arranging and stacking the cut towels. Through the automatic towel machine, automatic label folding and labelling of towel labels and automatic cutting and arranging of the towels can be achieved, so that towel production integration is achieved, existing manual operation is replaced, the production efficiency is improved, the production cost is lowered, the cut towels do not need to be subjected to edge covering treatment and are attractive in appearance, and thread looseness of the edges of the towels is not liable to occur.

Owner:常熟寿胜自动化机械有限公司

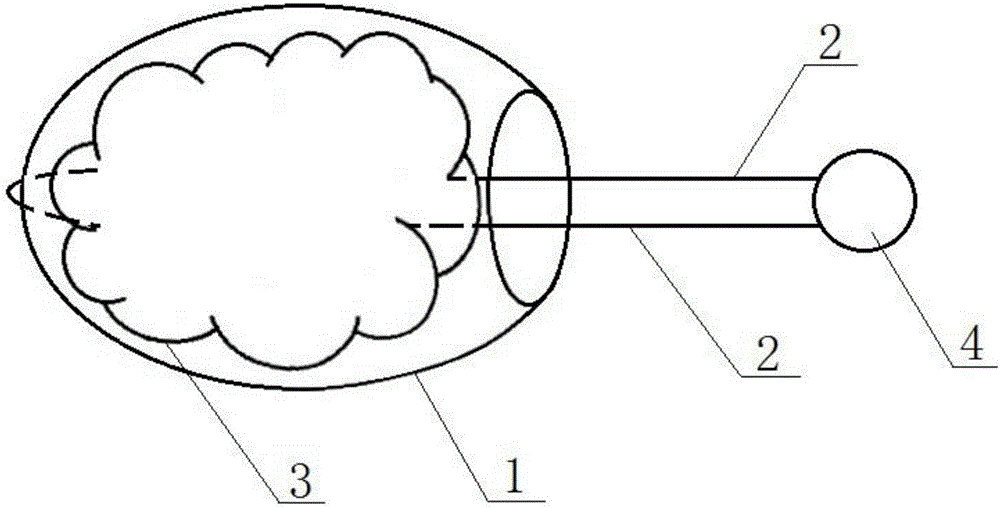

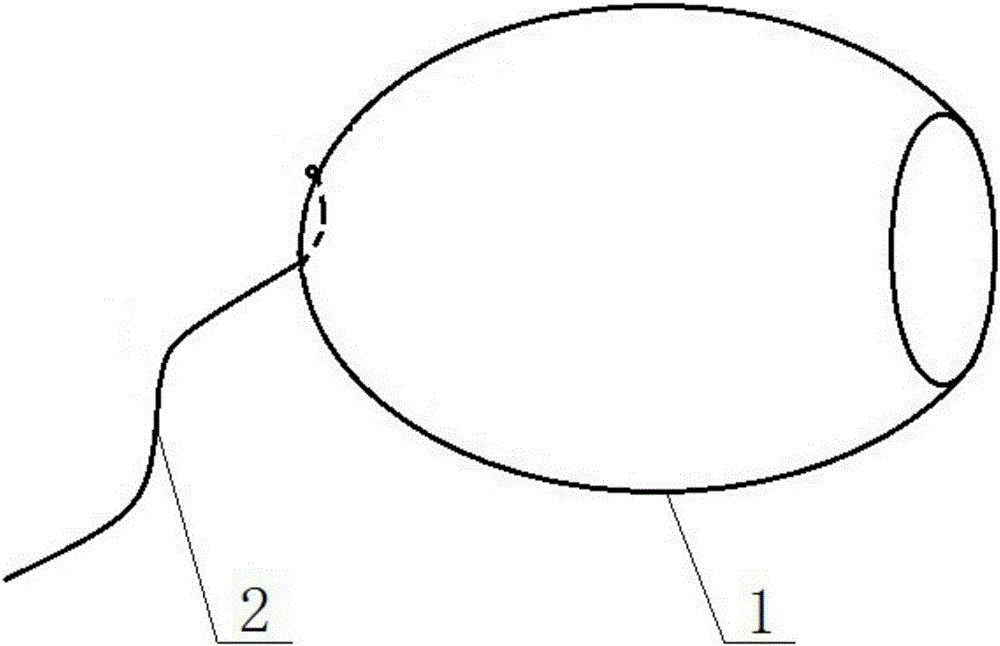

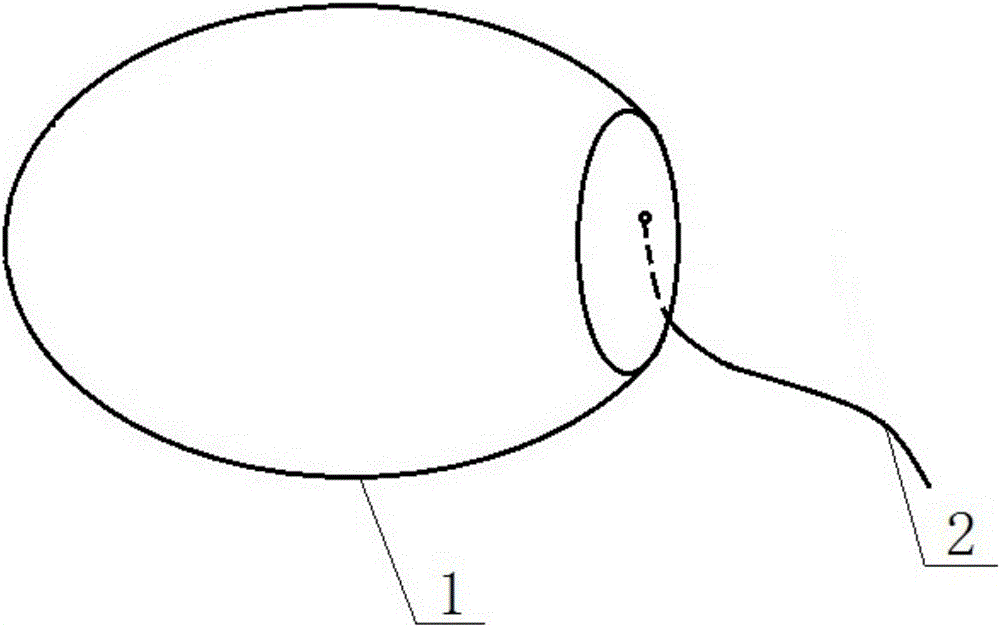

Novel contraceptive

InactiveCN106821585AThe pull wire is strong and resistant to pullingNot easy to go offlineFemale contraceptivesDrugFilling materials

The invention relates to a novel contraceptive, in particular to a contraceptive, more particularly to a female contraceptive, and is intended to provide a novel contraceptive that has long acting effect, good safety, simple structure, good convenience of use and high comfort. The novel contraceptive comprises a cocoon, filling material and a pull cord. During insertion of the novel contraceptive into the vagina, the filling material may never be squeezed out; natural cocoon has compact solid silk and good adsorbing property and permeability, and can lock and control the release of a drug used herein, so that the drug has long acting time; in addition, the cocoon never deforms within a short time owing to the large size, supporting of the filling material and its inherent tension, and may be placed in the vagina to provide a good barrier for semen ejaculated. The novel contraceptive is applicable to the field of medicine.

Owner:健务(上海)生物科技有限公司

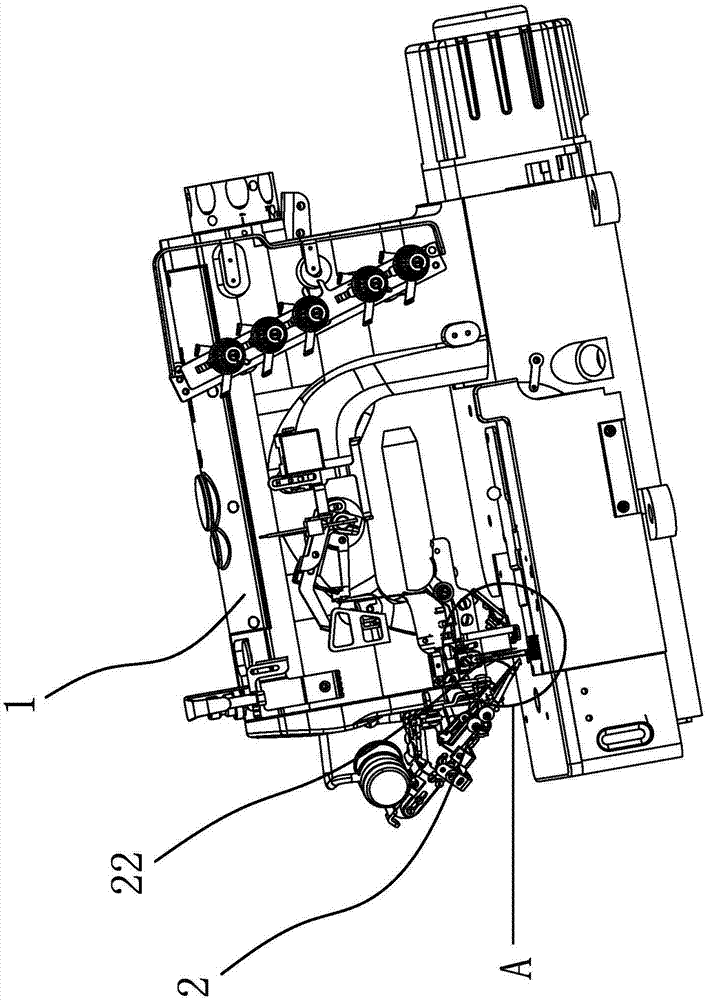

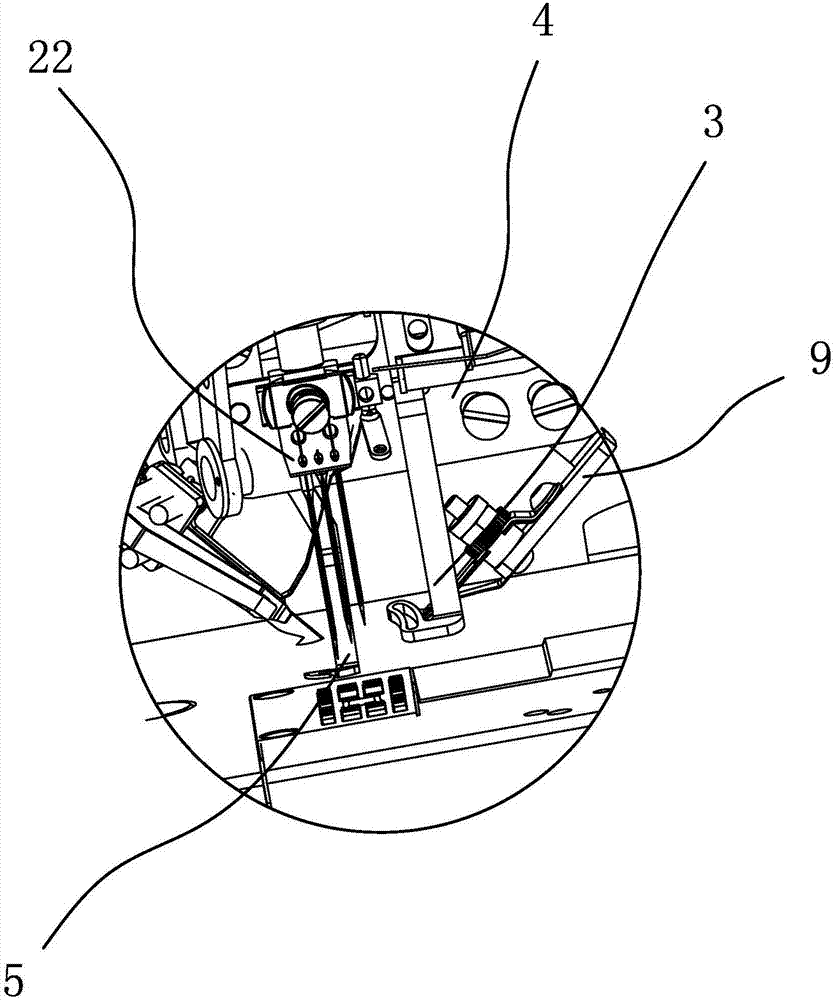

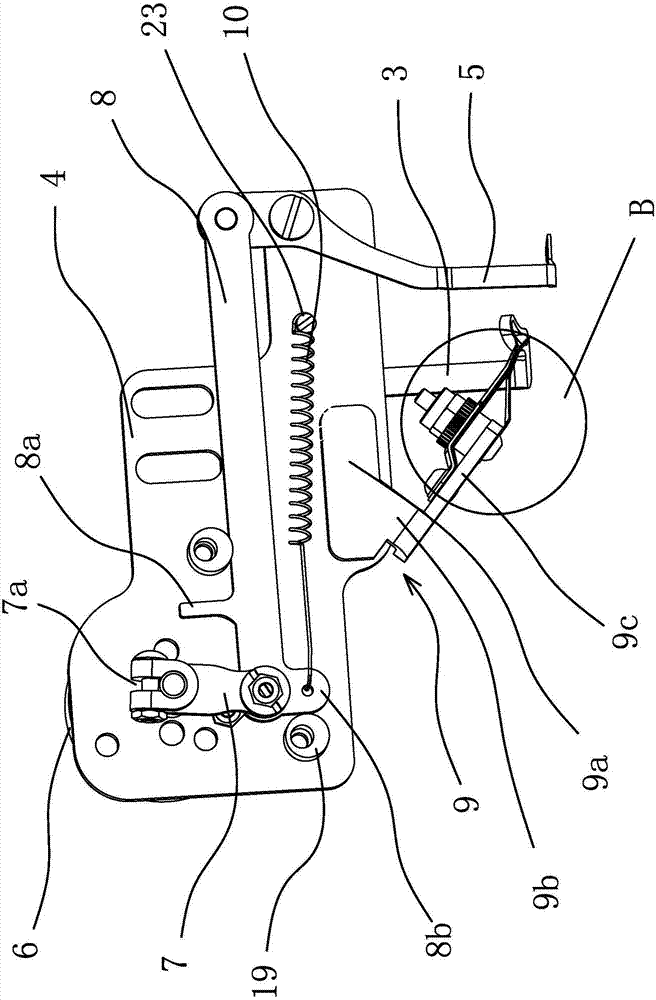

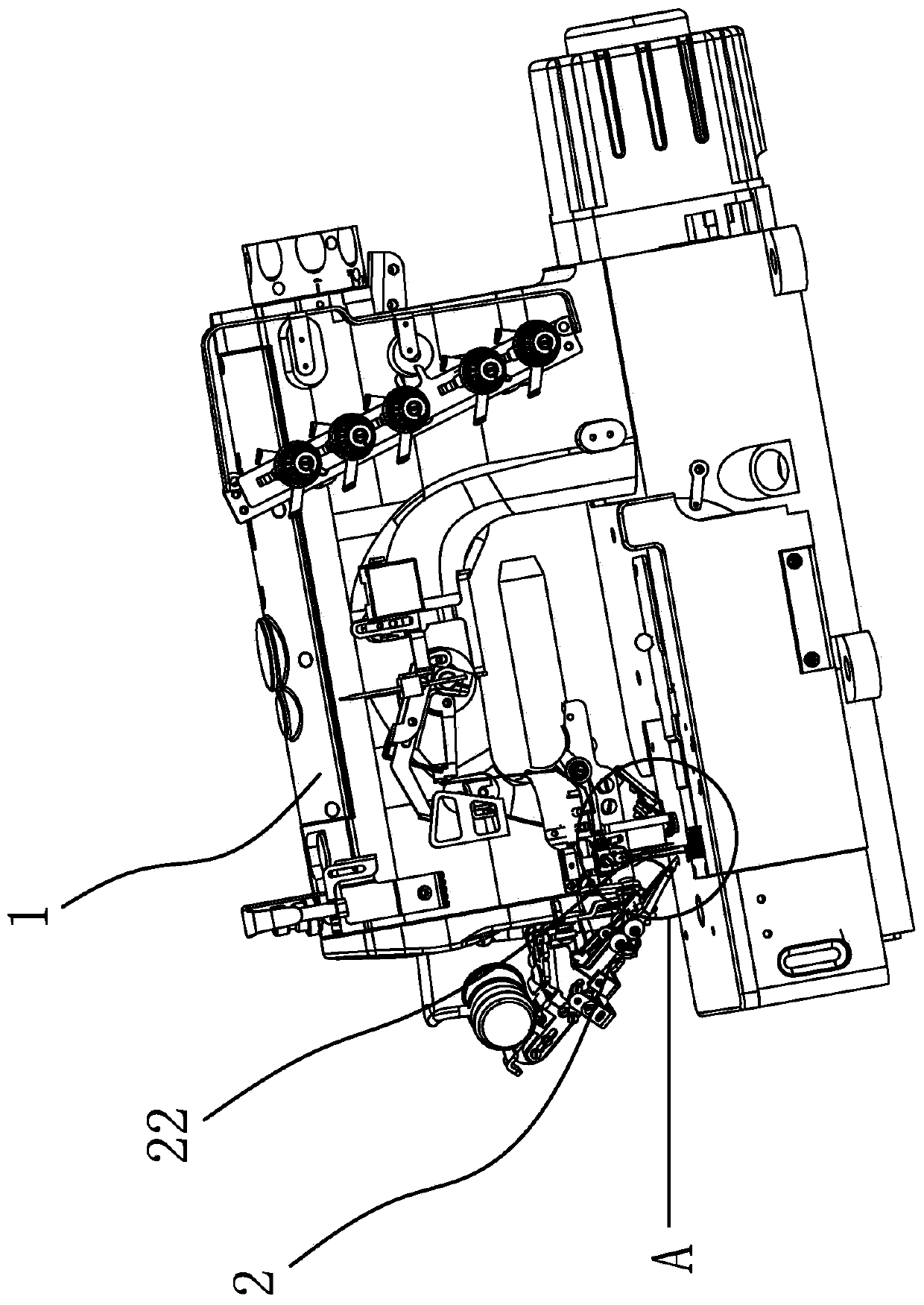

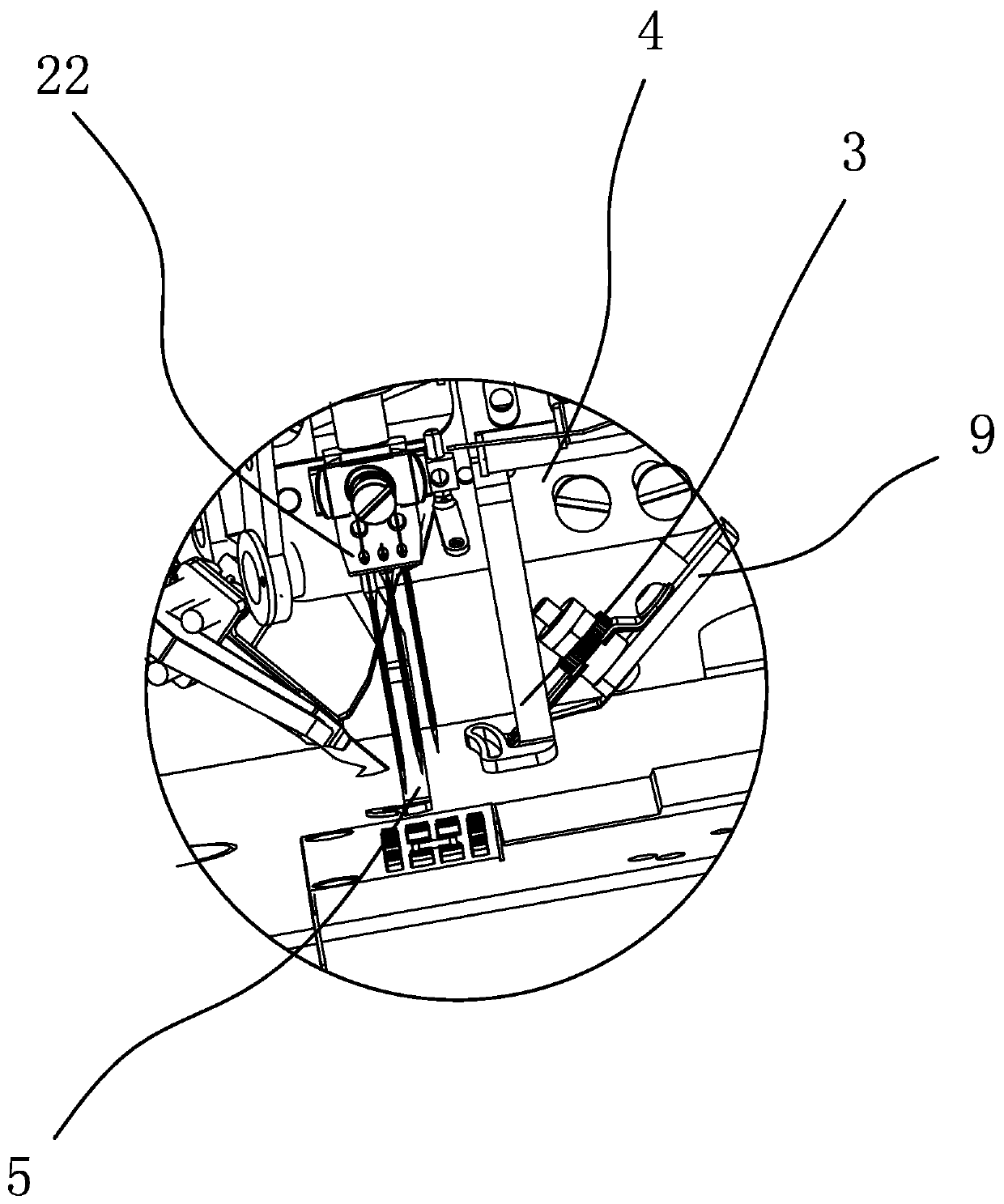

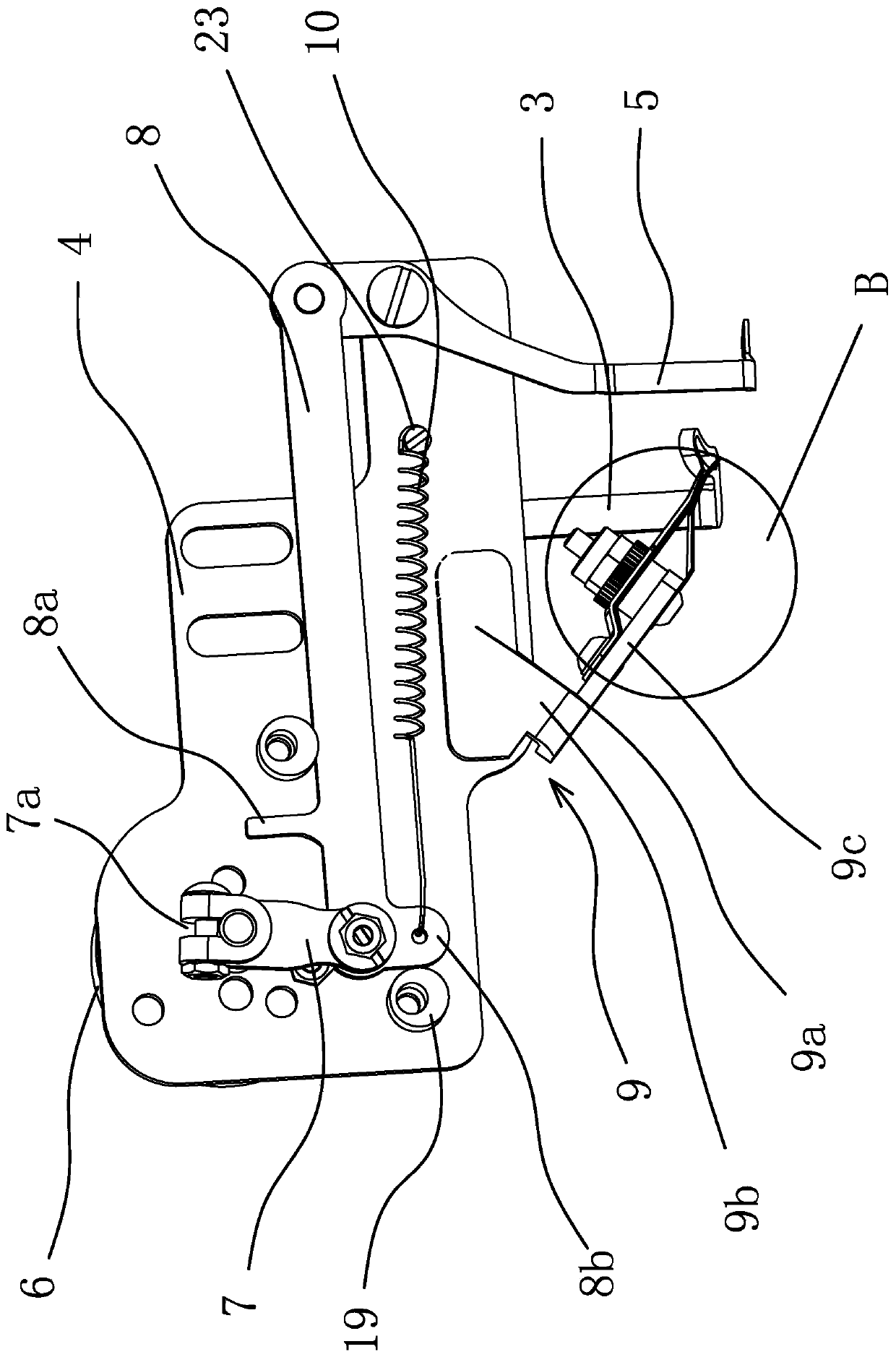

Sewing anti-thread-breakage device of sewing machine

ActiveCN107254745ANot easy to go offlineRealize hook lineNeedle severing devicesSewing-machine control devicesEngineeringSewing machine

The invention provides a sewing anti-thread-breakage device of a sewing machine, and belongs to the technical field of machinery. The problem that thread breakage is likely to happen to an existing sewing machine during sewing is solved. The sewing anti-thread-breakage device of the sewing machine comprises a mounting plate, a thread clamping assembly, a driving part and a thread drawing knife, the mounting plate is attached to the front end of a machine shell and is located on the rear side of a decorative thread cutter assembly, the driving part is fixed at one end of the mounting plate, and the middle of the thread drawing knife is hinged to the other end of the mounting plate; the two ends of a transmission connecting rod are hinged to the thread drawing knife and a driving crank respectively, and the driving part is connected with the driving crank; and a mounting piece is detachably connected to the portion, below the transmission connecting rod, of the mounting plate; the thread clamping assembly is fixed on the mounting piece and is opposite to the thread drawing knife, and a needle feeding and thread passing plate and the thread drawing knife are located on the two sides of the mounting plate respectively; a pulling hook of the thread drawing knife is not higher than the bottom of the needle feeding and thread passing plate, and a return spring is further arranged on the mounting plate. After the thread drawing knife of the sewing anti-thread-breakage device returns to the original position, the pulling hook is just located on the right side or the lower right portion of the needle feeding and thread passing plate, sewing is more stable, and skipped stitches and thread breakage are not likely to occur.

Owner:JACK SEWING MASCH CO LTD

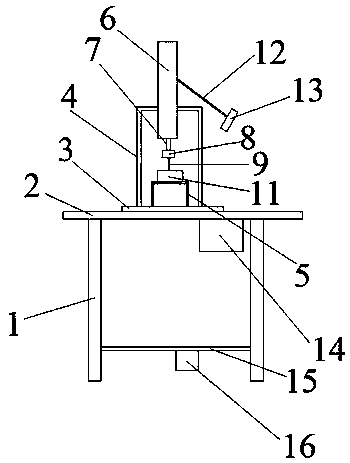

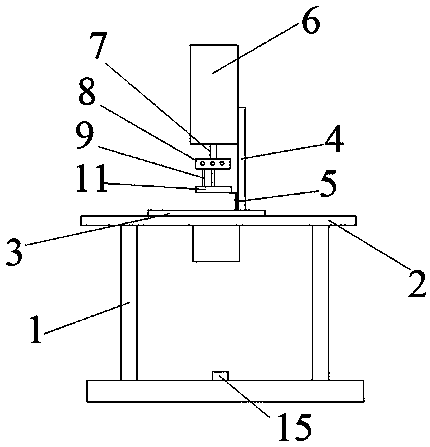

Infrared positioning hot melting clothing drilling machine

InactiveCN109602114AQuality improvementNot easy to go offlineClothes making applicancesInfrared lampReciprocating motion

The invention discloses an infrared positioning hot melting clothing drilling machine. The infrared positioning hot melting clothing drilling machine comprises a frame and an infrared lamp, wherein anoperating board is mounted on the frame; a base is mounted on the operating board; an upper panel of the base is connected with a bracket and a supporting plate; a driving device is mounted above thebracket; a connecting plate is connected with the bottom of the driving device; at least one drilling pin is mounted on the connecting plate; the driving device drives the connecting plate and the drilling pin to perform longitudinal reciprocating motions; a heating well is arranged on the supporting plate; a heating tube is connected with the interior of the heating well; at least one perforative through hole is formed in a position, corresponding to the drilling pin, on the heating well; the bottom of the drilling pin is arranged in the through hole; the infrared lamp is connected with thedriving device through a supporting rod; the center of an irradiation cross light source of the infrared lamp is aligned with a clothing drilling position. The infrared positioning hot melting clothing drilling machine is simple in structure and convenient to operate, ensures that the clothing drilling position is not off-line after drilling through the machine and is artistic in appearance, and is high in garment processing quality.

Owner:湖南省国锦湘安实业有限公司

Manufacturing method of RFID washing tag

PendingCN109146042AImprove toleranceWide operating temperature rangeRecord carriers used with machinesComposite substrateElectrical and Electronics engineering

The invention provides a manufacturing method of an RFID washing tag, comprising the following steps: providing an RFID chip, binding the RFID chip to a PCB, and packaging the RFID chip with black glue to prepare a COB; providing a cloth substrate, depositing an adhesive film on the cloth substrate to prepare a composite substrate; adopting a computer embroidery machine to stitch metal wires on the adhesive film surface of the composite substrate to obtain an RFID antenna; SMT mounting process being adopted to mount the COB on the adhesive film surface with metal wires sewn on the composite substrate; The composite substrate on which the COB is attached is covered with the composite substrate, and the adhesive film surfaces of the two layers of the composite substrate being arranged opposite to each other, and RFID washing labels are obtained after being sequentially subjected to ultrasonic compression, heating lamination and ultrasonic slitting.

Owner:深圳市钛格智联科技有限公司

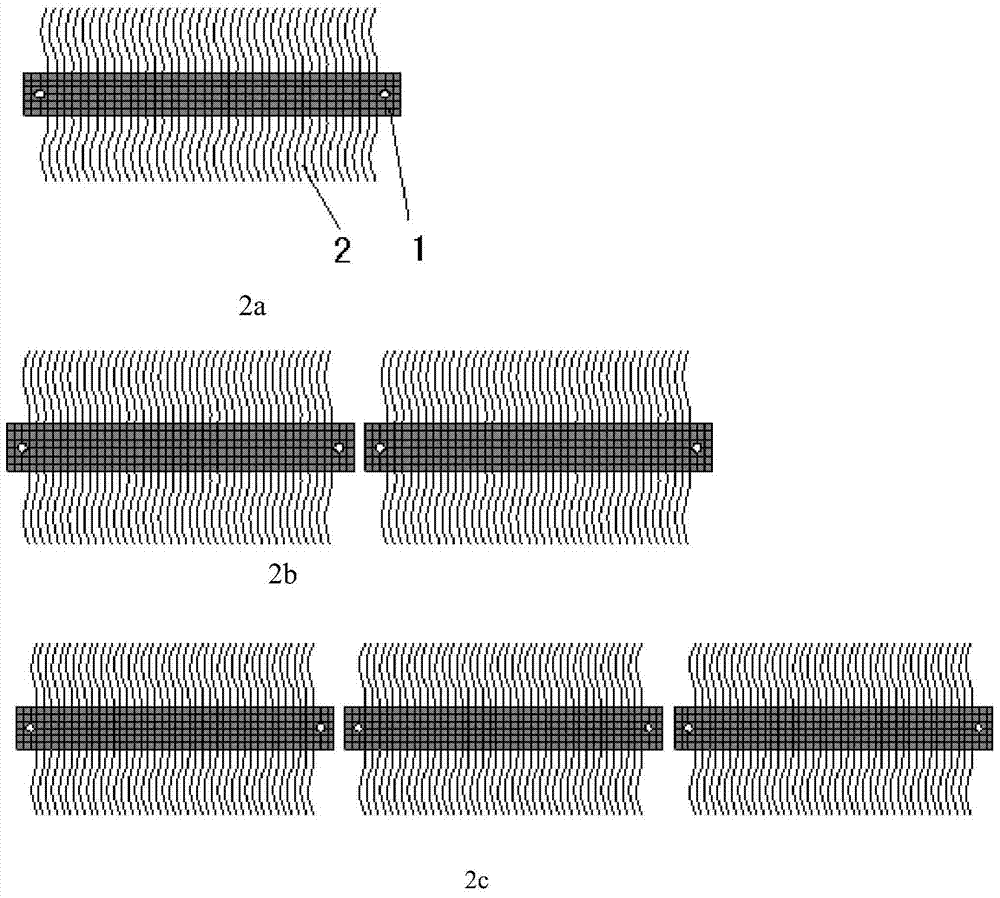

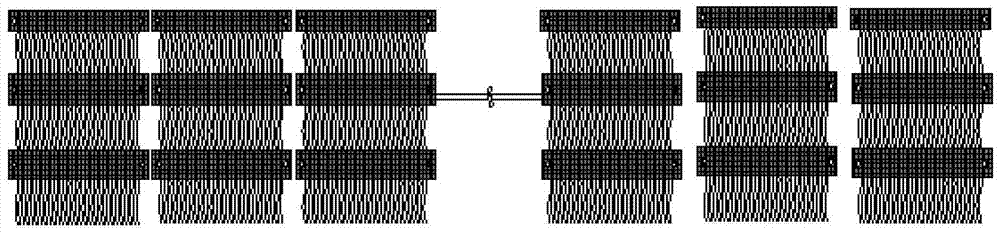

Deformable carbon fiber ecological grass fabric, weaving method and weaving device

The invention provides a deformable carbon fiber ecological grass fabric which is used for river-lake eutrophication control, raw water treatment, sewage treatment and ecological in-situ remediation. The deformable carbon fiber ecological grass fabric involves a deformable concept, appearance designs, a weaving method, a weaving device and a deforming method. The deformable carbon fiber ecological grass fabric has the multiple appearance designs and is a carbon fiber ecological belt composed of a supporting cloth and a function layer. The supporting cloth is a blended carbon fiber sheet formed by weaving a composite material and carbon fibers or activated carbon fibers. The function layer is woven through warp and weft open threads formed by carbon fibers with the specific area larger than 800 m<2> / g or 1000 m<2> / g. The composite material is composed of various waterproof polymer synthesis fibers. The fabric concept means that the appearance design of a kind of carbon fiber ecological grass has changeability, and namely one type of carbon fiber ecological grass fabric can be conveniently changed to another type of products or other two or more types of products according to user requirements.

Owner:武汉环天禹生物环保科技有限公司

Manufacturing method of health-care stockings with heel protection, moisturizing and crack prevention functions

ActiveCN105926095AIncrease contact areaImprove fitLiquid/gas/vapor removalShaping/stretching tubular fabricsYarnEngineering

The invention discloses a manufacturing method of health-care stockings with heel protection, moisturizing and crack prevention functions. The manufacturing method comprises steps as follows: 1) manufacturing of yarn for moisturizing layers; 2) manufacturing of yarn for medicine layers; 3) manufacturing of heel protection foot pads; 4) sewing of elastic gauze structures; 5) sewing of upper and lower protecting edges; 6) sizing treatment; 7) pre-drying treatment; 8) drying treatment; 9) checking and packaging. Through overlapped and staggered weaving of the moisturizing layers and the medicine layers, the contact area and the attaching degree of the heel protection foot pads and foot heels are increased, substances in the moisturizing layers and the medicine layers can act on the foot heels in real time, and the heel protection, moisturizing and crack prevention functions can be really realized. The production method is simple and easy to operate and high in practicability and facilitates large-scale production, the produced health-care stockings don't easily loose threads, have long service life and also have the heel protection, moisturizing and crack prevention functions, and medicines can be added according to demands of a user for heal treatment.

Owner:ZHEJIANG SAMERI ENTERPRISE CO LTD

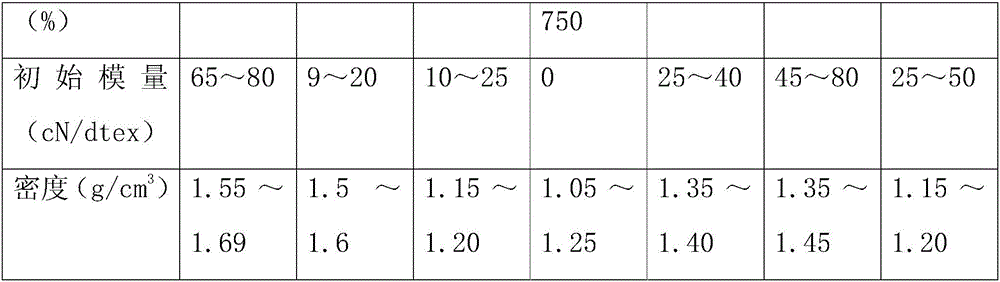

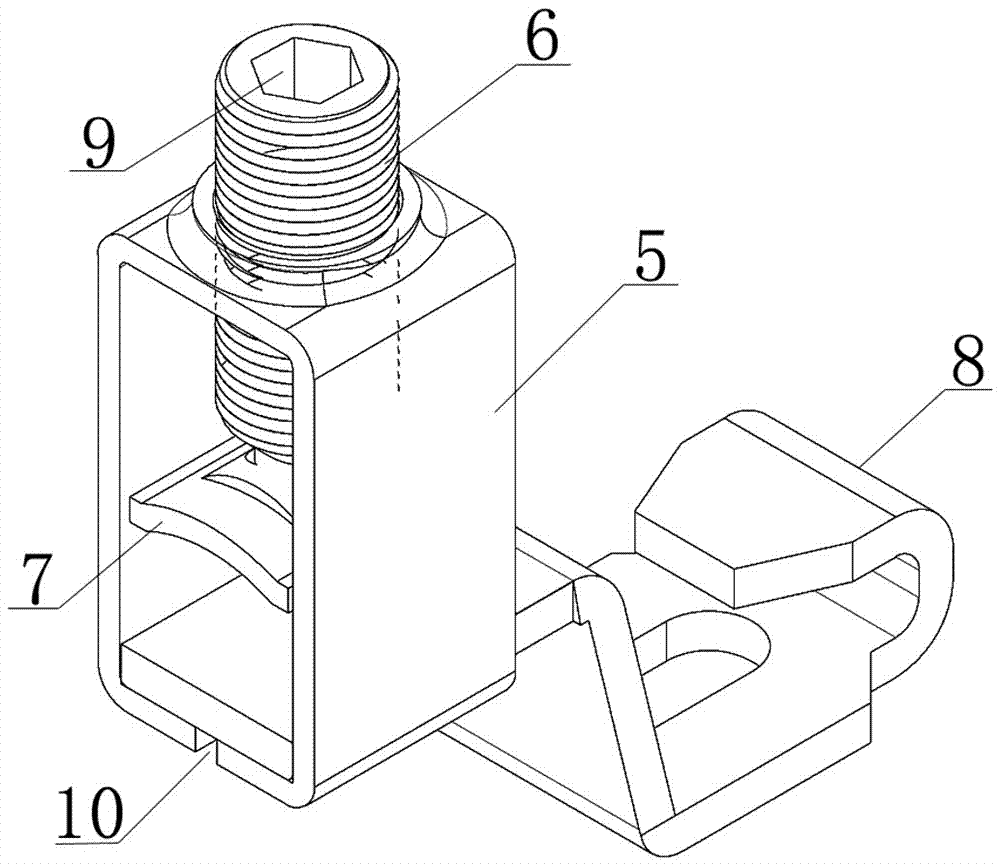

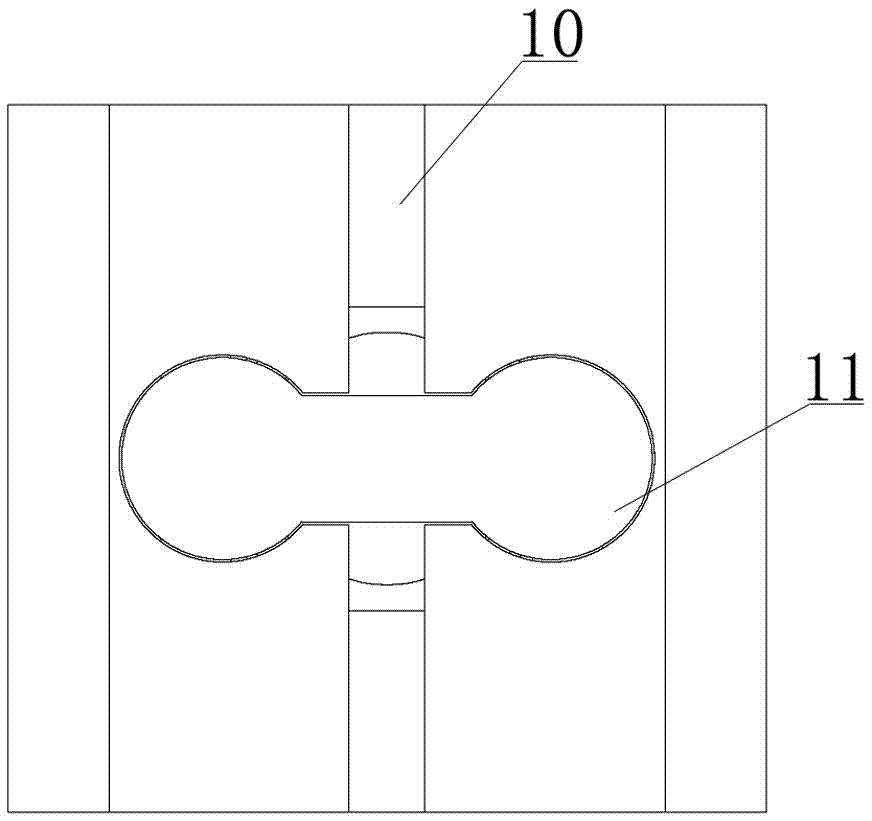

Cage-shaped fastening pressing plate type Wiring device used for molded case circuit breaker

InactiveCN107204261ASimple structureImprove reliabilityProtective switch terminals/connectionsEngineeringBone shape

The invention provides a cage-shaped fastening pressing plate type Wiring device used for a molded case circuit breaker. The wiring device comprises a wiring frame which can be fixed in a mounting base on the two corresponding side edges of the molded case circuit breaker and is formed by an upper edge, a lower edge, a left edge and a right edge in an encircling manner; a screw hole is formed in the upper edge of the wiring frame; a stud capable of rotating up and down is configured in the screw hole; a tile-shaped gasket is connected with the lower end part of the stud; a static contact internally connected with a breaker is configured on the lower edge of the wiring frame; a polygon sunken hole is formed in the upper end part of the stud; a narrow groove is formed in the lower edge of the wiring frame and parts of the wiring frame on the two sides of the narrow groove are spliced together by a 'bone-shaped' nonmagnetic material. The wiring device has the characteristics of being simple in structure, high in reliability, good in wiring fastness, uneasy in wire off, convenient in use and the like.

Owner:ZHEJIANG MAXGE ELECTRIC TECH

Textile thread positioning structure for producing and processing textiles

InactiveCN112249814ARelieve pressureReduce reaction forceFilament handlingMechanical engineeringIndustrial engineering

The invention relates to the technical field of production and processing of textiles and discloses a textile thread positioning structure for producing and processing textiles. The textile thread positioning structure comprises a base, wherein a shell is fixedly mounted on the right side of the top end of the base; a tension spring is fixedly mounted at the top of the inner wall of the shell; anda thread guide plate is fixedly mounted at the bottom end of the tension spring. According to the textile thread positioning structure for producing and processing textiles, when a textile machine accelerates suddenly in the working process, the pressure generated by a thread to a limiting block is increased suddenly, the limiting block transmits the pressure to a circle center of a second rotating column at the moment; a first moving block and a second moving block start to draw close inwards under the action of the pressure; the air of the first moving block is compressed and enters an airbag through a ventilation head; a second telescopic rod contracts, and the spring contracts, so that the pressure of the thread is greatly reduced, the counter-acting force applied to the thread is reduced, the possibility of thread breakage is reduced, and the effect that the thread is not easily broken is achieved.

Owner:新昌县奔力机械有限公司

Method for manufacturing cloth carving art

InactiveCN101244675ANot easy to go offlineNot easy to fall offDecorative surface effectsSpecial ornamental structuresAdhesiveEngineering

The invention relates to a making method of fabric- carving art, belonging to a carving method, which is characterized in that: first a manuscript is made, characters and paintings are arranged on a base fabric according to the paper for making manuscript, and the frame lines of the characters and the paintings are duplicated on the back of the base fabric; the base fabric is embroidered with patterns; the front face of the base fabric is scratched with adhesive, and then adhered with the fabric with characters and paintings, and then the adhesive position is ironed from the back of the base fabric; a sewing machine is used to perform sewing according to the lines of the characters and paintings duplicated on the back of the base fabric, on the front face of the base fabric, a clipper is used to cut outline edges coarsely according to the sewing lines of characters and paintings sewed by the sewing machine, so as to remove excessive portion of the fabric with characters and paintings, the fabric with characters and paintings is cut out approximate outlines of the characters and paintings; and then the clipper is used to trim the approximate outlines of the characters and paintings until the edges of the sewing lines are trimmed. The making method of fabric- carving uses the fabric as carrier to create a new artistic form, and can keep the styles of characters and paintings not be damaged for long time, moreover the fabric craftwork made by adopting the invention facilitates long-term storage and enjoying.

Owner:杨新明

High-strength silk yarn

The invention provides high-strength silk yarn. The yarn includes the innermost center yarn, intermediate yarn outside the center yarn and cladding yarn outside the intermediate yarn. The center yarnincludes spandex fiber, ply yarn and a tubular structure braided fabric body from inside to outside; the intermediate yarn is mulberry silk, and the mulberry silk is wound around the outside of the center yarn with high twist; acetate silk serves as the cladding yarn, the acetate silk is wound around the outside of the mulberry silk with the twist of 150-200, the outside of the acetate silk is further provided with a glass fiber layer of a net structure, and mesh holes of the glass fiber layer are filled with metal powder. The provided silk yarn has the advantages of being high in strength, long in service life, and low in cost and has broad market prospects.

Owner:嘉兴市优泰纺织新材料有限公司

Deformable carbon fiber ecological grass fabric, weaving method and weaving equipment

The invention provides a deformable carbon fiber ecological grass fabric which is used for river-lake eutrophication control, raw water treatment, sewage treatment and ecological in-situ remediation. The deformable carbon fiber ecological grass fabric involves a deformable concept, appearance designs, a weaving method, a weaving device and a deforming method. The deformable carbon fiber ecological grass fabric has the multiple appearance designs and is a carbon fiber ecological belt composed of a supporting cloth and a function layer. The supporting cloth is a blended carbon fiber sheet formed by weaving a composite material and carbon fibers or activated carbon fibers. The function layer is woven through warp and weft open threads formed by carbon fibers with the specific area larger than 800 m<2> / g or 1000 m<2> / g. The composite material is composed of various waterproof polymer synthesis fibers. The fabric concept means that the appearance design of a kind of carbon fiber ecological grass has changeability, and namely one type of carbon fiber ecological grass fabric can be conveniently changed to another type of products or other two or more types of products according to user requirements.

Owner:武汉环天禹生物环保科技有限公司

Wire arranging device convenient for fixing wire harness for computer host

ActiveCN111446669ANot easy to go offlineEasy to replaceElectrical apparatusDigital processing power distributionComputer-aidedRetaining harness

Owner:徐州企润食品有限公司

Manufacturing method of medical bandage

PendingCN113599658ANot easy to go offlineNot easy to threshingRespiratory masksMetal working apparatusHygieneBandage

The invention discloses a manufacturing method of a medical bandage. The manufacturing method comprises the following steps that a raw material belt with a three-layer structure of sticking cloth, a sponge sheet and Lycra cloth is cut on a heated cutter according to the shape of the bandage, and the sponge sheet is hot-melted and welded with the sticking cloth and the Lycra cloth at a notch while cutting, so that the sponge layer is heat-sealed on the inner side through the sticking cloth layer and the Lycra cloth layer to obtain a bandage body; and the hook and loop hooking surface is fixedly connected to the free end of a connecting belt of the bandage body. The process is simple, the bandages of different structures and shapes on the plane can be rapidly formed, and the manufactured bandages are not prone to thread loosening, threshing and delaminating, good in hygiene and comfortable to wear.

Owner:中山市鑫威织造有限公司

Sewing prevention device for sewing machine

ActiveCN107254745BNot easy to go offlineAdjust the pressing forceNeedle severing devicesSewing-machine control devicesCrankEngineering

The invention provides a sewing anti-thread-breakage device of a sewing machine, and belongs to the technical field of machinery. The problem that thread breakage is likely to happen to an existing sewing machine during sewing is solved. The sewing anti-thread-breakage device of the sewing machine comprises a mounting plate, a thread clamping assembly, a driving part and a thread drawing knife, the mounting plate is attached to the front end of a machine shell and is located on the rear side of a decorative thread cutter assembly, the driving part is fixed at one end of the mounting plate, and the middle of the thread drawing knife is hinged to the other end of the mounting plate; the two ends of a transmission connecting rod are hinged to the thread drawing knife and a driving crank respectively, and the driving part is connected with the driving crank; and a mounting piece is detachably connected to the portion, below the transmission connecting rod, of the mounting plate; the thread clamping assembly is fixed on the mounting piece and is opposite to the thread drawing knife, and a needle feeding and thread passing plate and the thread drawing knife are located on the two sides of the mounting plate respectively; a pulling hook of the thread drawing knife is not higher than the bottom of the needle feeding and thread passing plate, and a return spring is further arranged on the mounting plate. After the thread drawing knife of the sewing anti-thread-breakage device returns to the original position, the pulling hook is just located on the right side or the lower right portion of the needle feeding and thread passing plate, sewing is more stable, and skipped stitches and thread breakage are not likely to occur.

Owner:JACK SEWING MASCH CO LTD

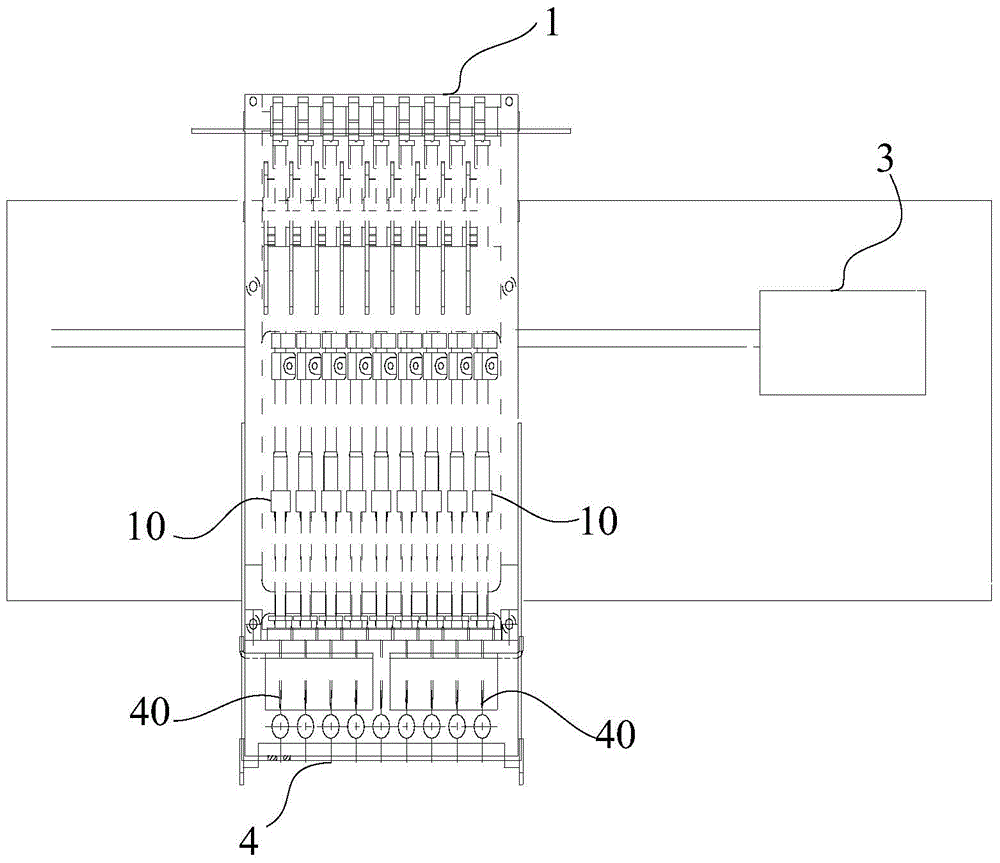

Quilting device for four-needle quilt quilting machine

The invention discloses a quilting device for a four-needle quilt quilting machine. The quilting device comprises a machine frame, an upper beam shaft which is arranged on the machine frame and is used for controlling a needle frame and a presser foot to act, a lower beam shaft for controlling a rotating shuttle to act and a machine head assembly, wherein a gear is fixed to one end of the upper beam shaft; four bevel gears and four four-tooth cams are distributed on the upper beam shaft uniformly; the four bevel gears are meshed with four bevel pinions; the bevel gears are matched with the bevel pinions, so that the motion is transferred to a machine head shaft on a machine head; the machine head assembly comprises the machine head shaft, a roller rod, a needle frame library and a presserfoot frame library; a groove wheel, a first gear, a sliding sleeve gear and a fixed gear are fixed to one end of the lower beam shaft, and a movable crank handle is arranged at the other end of the lower beam shaft; and four second straight gears are distributed on the full length of the lower beam shaft, and the four second straight gears are matched with four spindle head rod frame bases on themachine frame. By the quilting device, quilts can be quilted quickly, quilting line traces are regular and attractive, and the efficiency and the quality of products are high.

Owner:JIHUA 3502 PROFESSIONAL GARMENT

A wire management device for a computer mainframe to facilitate fixing wire harnesses

ActiveCN111446669BNot easy to go offlineEasy to replaceElectrical apparatusDigital processing power distributionComputer-aidedCable management

The invention discloses a wire management device for a computer mainframe which is convenient for fixing wire harnesses in the technical field of computer auxiliary equipment. There are telescopic splints on both sides of the horizontal plate, and the cable management case is installed on the main machine through the telescopic splints. The top surface of the cable management case is provided with storage grooves at intervals, and the front and rear sides of the storage grooves run through the cable management case. The bottom wall of the storage tank is provided with a spring slot. When using the present invention, the device is installed on the back of the host through the telescopic splint, and then the buckle mechanism is pulled to make the wire harness plate pop out, and the connecting cable is placed in the arc slot on it, and then Press and embed the wire harness plate into the wire management shell, and the buckle mechanism will automatically clamp the wire harness plate. This kind of wire harness method is stable and reliable, the cable is not easy to disconnect, and it is also very convenient to replace the cable. This kind of wire harness management The method is to bind the cables vertically, which occupies less space and is more practical.

Owner:徐州企润食品有限公司

Plant fiber spool and its preparation method

InactiveCN100389943CHigh strengthImprove toughnessWood working apparatusDomestic articlesBobbinPlant fibre

The present invention is plant fiber bobbin for spinning and its making process. The plant fiber bobbin is made with the materials including plant fiber 50-90 weight portions, water soluble synthetic resin 5-30 weight portions, and starch gum 5-25 weight portions. The making process includes the following steps: 1. crushing plant fiber and mixing with water soluble synthetic resin and starch gum; 2. feeding the mixture into forming mold; and 3. molding at 100 deg.c-150 deg.c and 25-65 Kg / sq cm for 30-80 sec. The plant fiber bobbin has high strength, high toughness, low eccentricity and less deformation and may be used widely in textile industry.

Owner:刘正泉

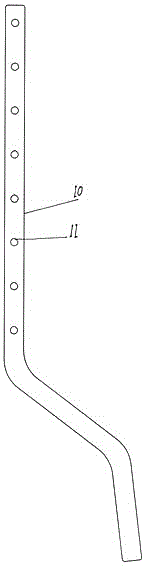

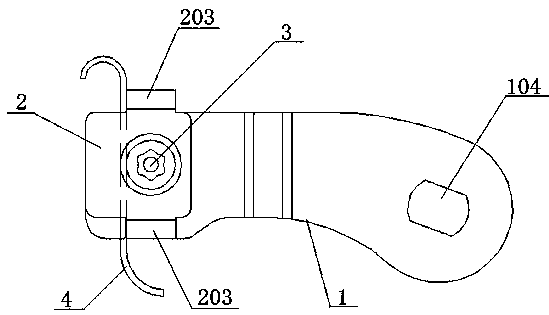

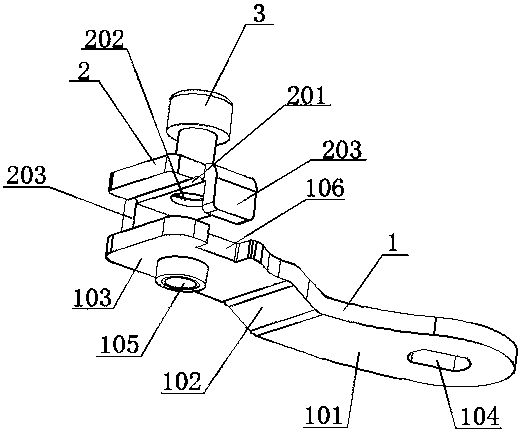

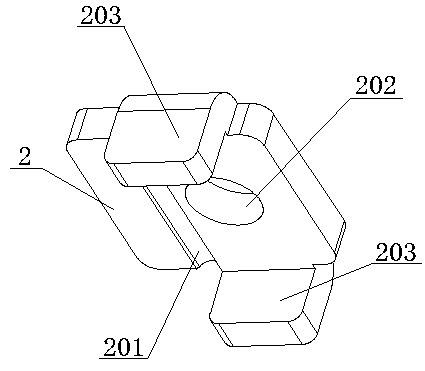

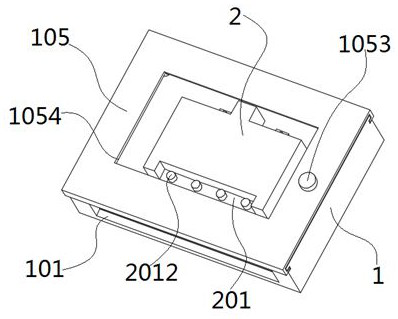

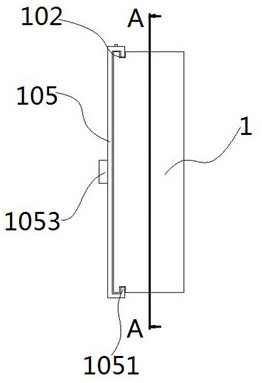

Novel wire-type crank structure

PendingCN110395347AAvoid breakingReasonable structural designShaft for linear movementCycle brakesEngineeringCam

The invention discloses a novel wire-type crank structure. The structure comprises a wire-type crank body (1), a wire pressing plate (2) and an anti-theft bolt (3), wherein the wire-type crank body iscomposed of a crank body flat plate (101), a forming curved plate (102) and a brake cable positioning plate (103), one end of the crank body flat plate is connected with the brake cable positioning plate through the forming curved plate, a cam shaft mounting hole (104) is formed in the other end of the crank body flat plate, a first threaded hole (105) matched with the anti-theft bolt is formed in the brake cable positioning plate, a wire pressing groove (201) and a second threaded hole (202) which is matched with the anti-theft bolt are formed in the wire pressing plate, limiting flanges (203) are arranged on the two sides of the wire pressing plate respectively, a receding groove (106) is formed in one side of the brake cable positioning plate, and the limiting flange on one side of thewire pressing plate is matched and clamped with the receding groove. According to the structure, a brake cable can be completely installed in the wire pressing groove, the brake cable cannot be broken easily, the brake cable is limited by limiting flanges arranged on the two sides of the wire pressing plate, and the sliding wire is not easy to generate.

Owner:KARASAWA TRAFFIC EQUIP TAIZHOU

Method for manufacturing cloth carving art

InactiveCN101244675BNot easy to go offlineNot easy to fall offDecorative surface effectsSpecial ornamental structuresAdhesiveEngineering

Owner:杨新明

Anti-creeping relay

InactiveCN112151308AProtection from damageProtection against leakageElectromagnetic relay detailsEngineeringStructural engineering

The invention discloses an anti-creeping relay, and relates to the technical field of relays. The relay comprises a shell and a relay body, a plurality of fixing holes and wire holes are formed in oneside face of the shell, the relay body is arranged on one surface in the shell, the relay body is of a hollow convex structure, a second groove is formed in one surface of the relay body, and a through hole is formed in the other side face of the relay body; fixing plates are arranged on the two opposite surfaces in the relay body, a round hole is formed in one surface of each fixing plate, a connecting plate is arranged between the two opposite surfaces in the relay body, screw holes are formed in the two sides of one surface of each connecting plate, the screw holes are matched with the round holes through binding posts, and a magnet is arranged on the upper surface in the relay body. The shell is arranged outside the relay, so that the relay is conveniently protected from being damageddue to extrusion or treading, and electric leakage of the relay is avoided; and a wiring bolt is arranged in the relay body, so that the wiring bolt can be prevented from being damaged due to long-time exposure, and electric leakage can be avoided.

Owner:闫志伟

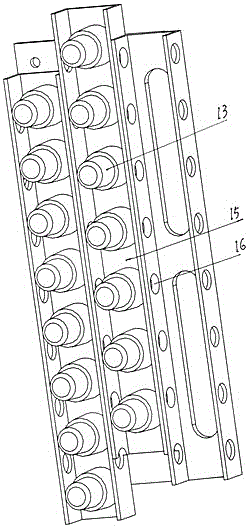

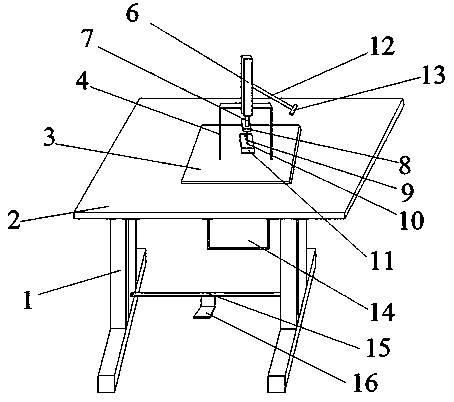

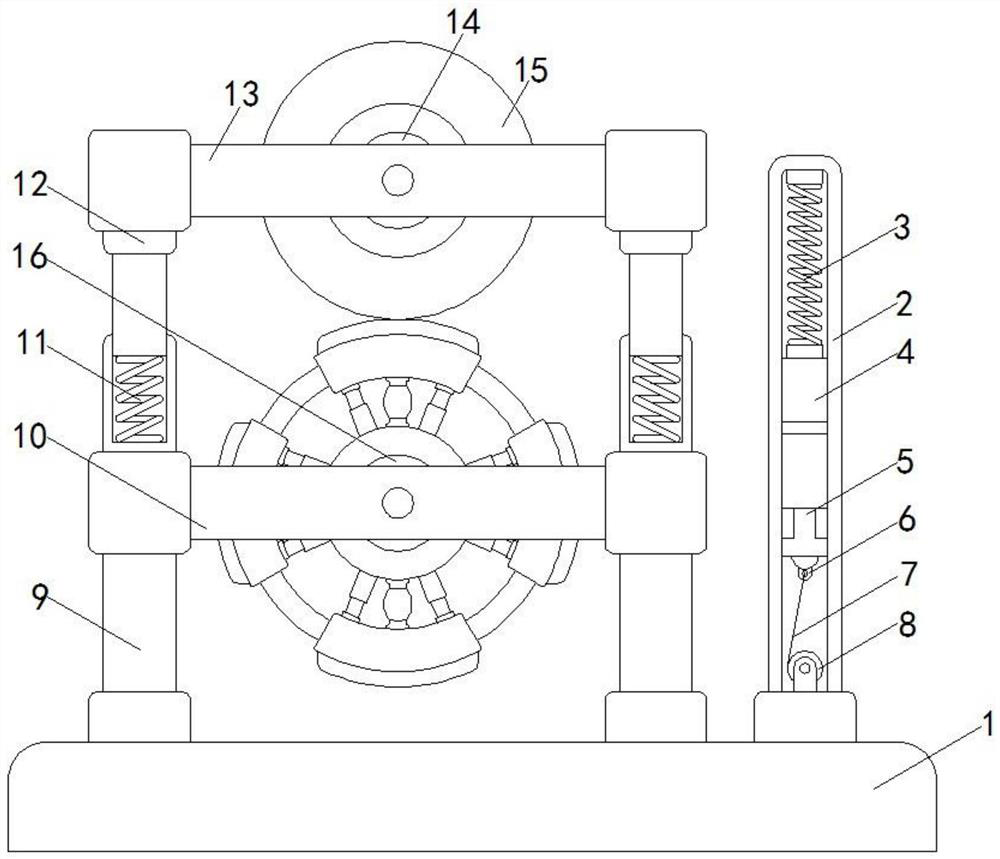

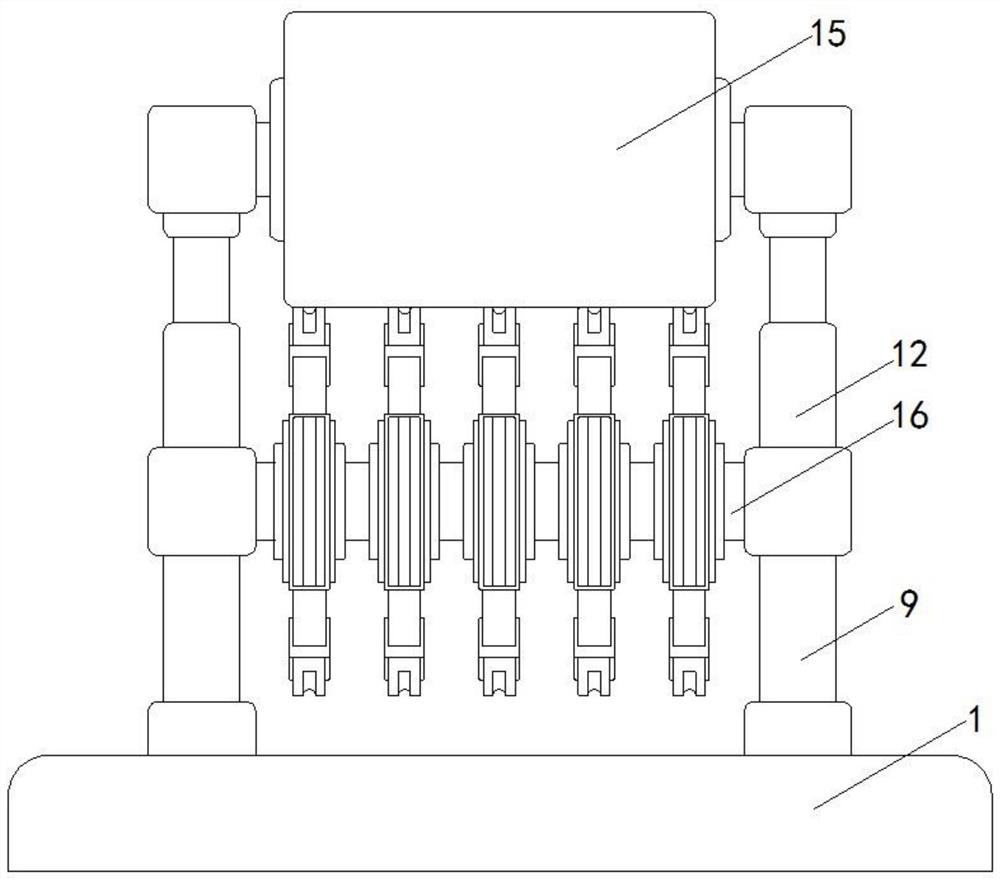

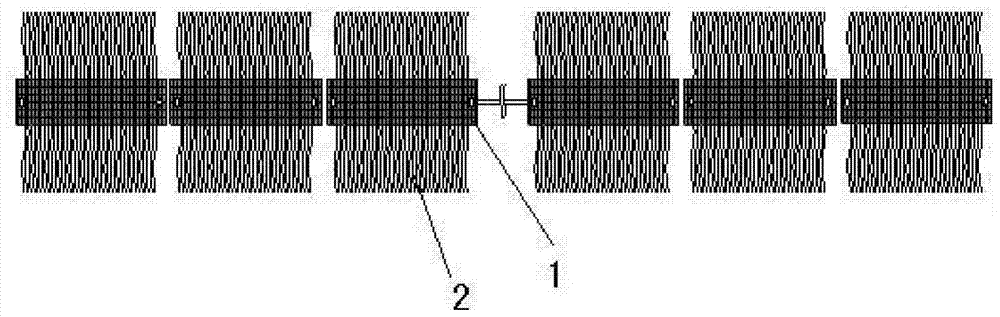

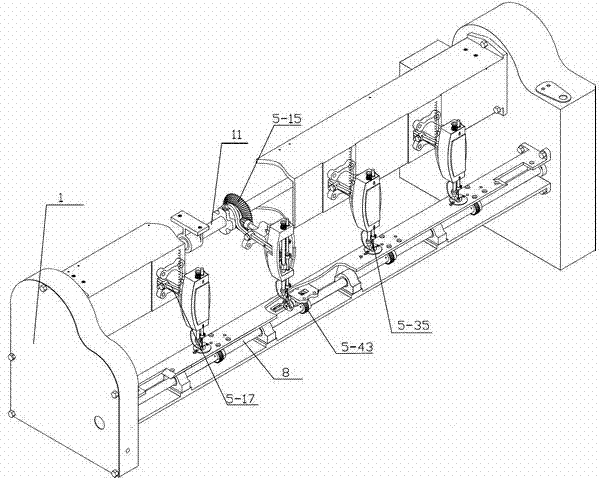

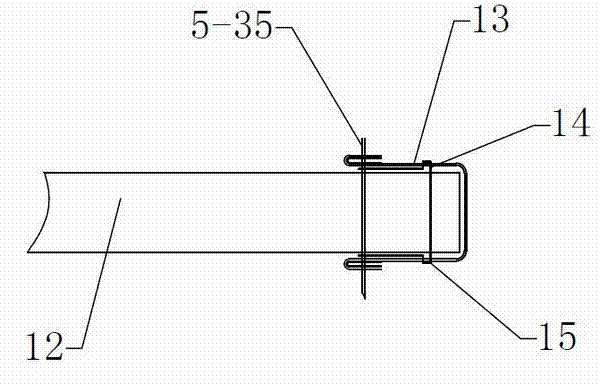

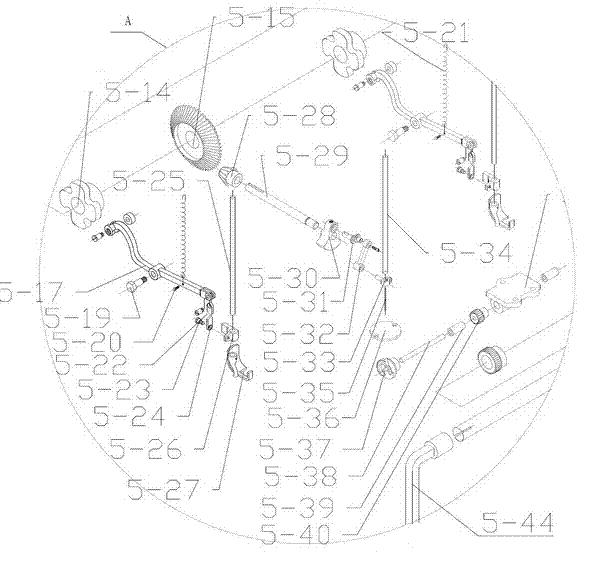

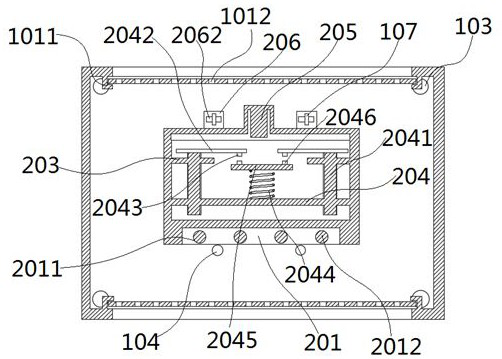

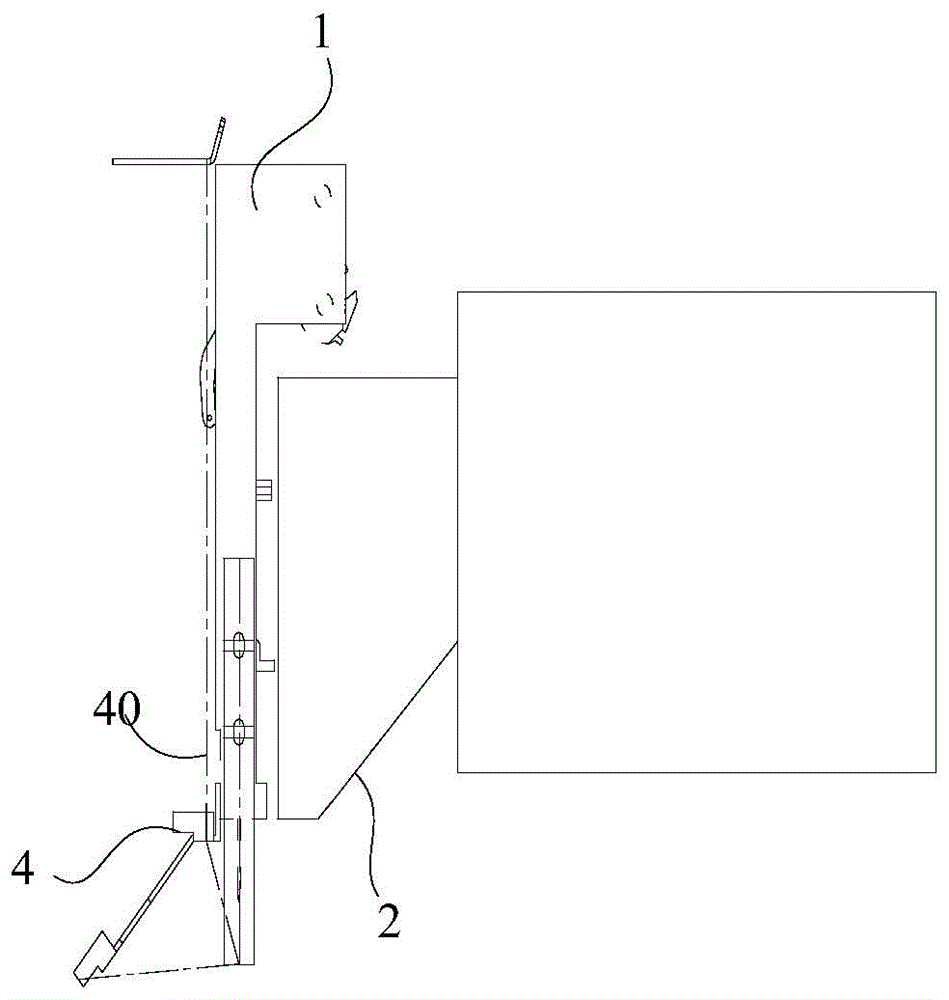

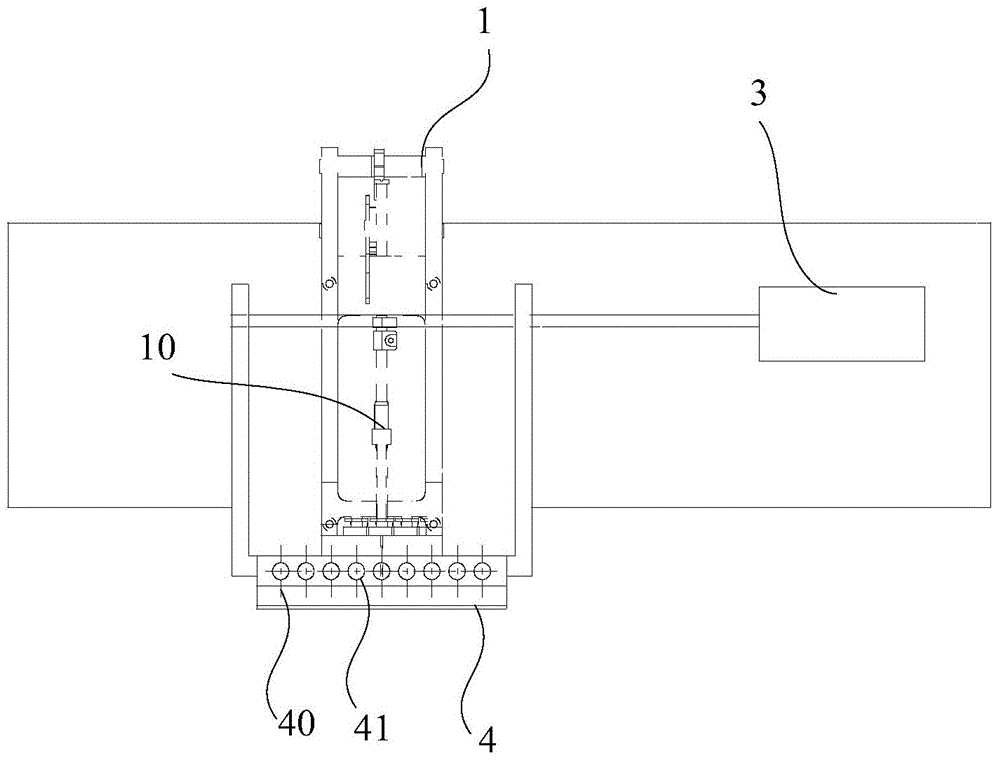

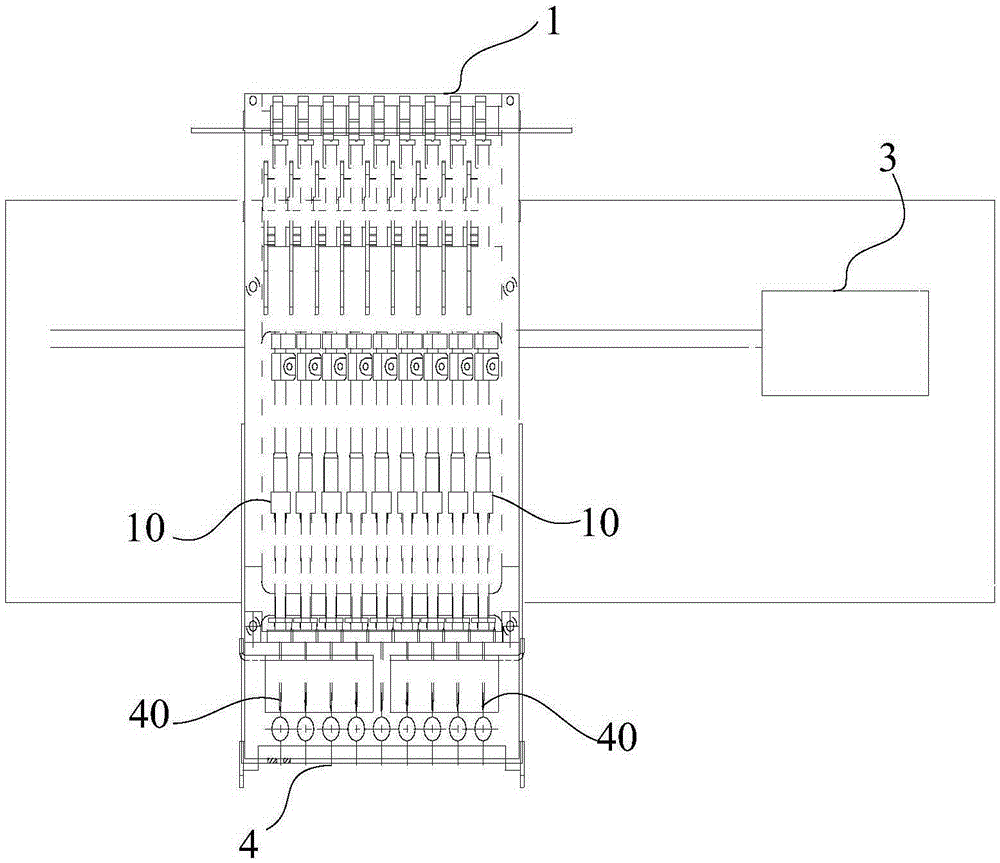

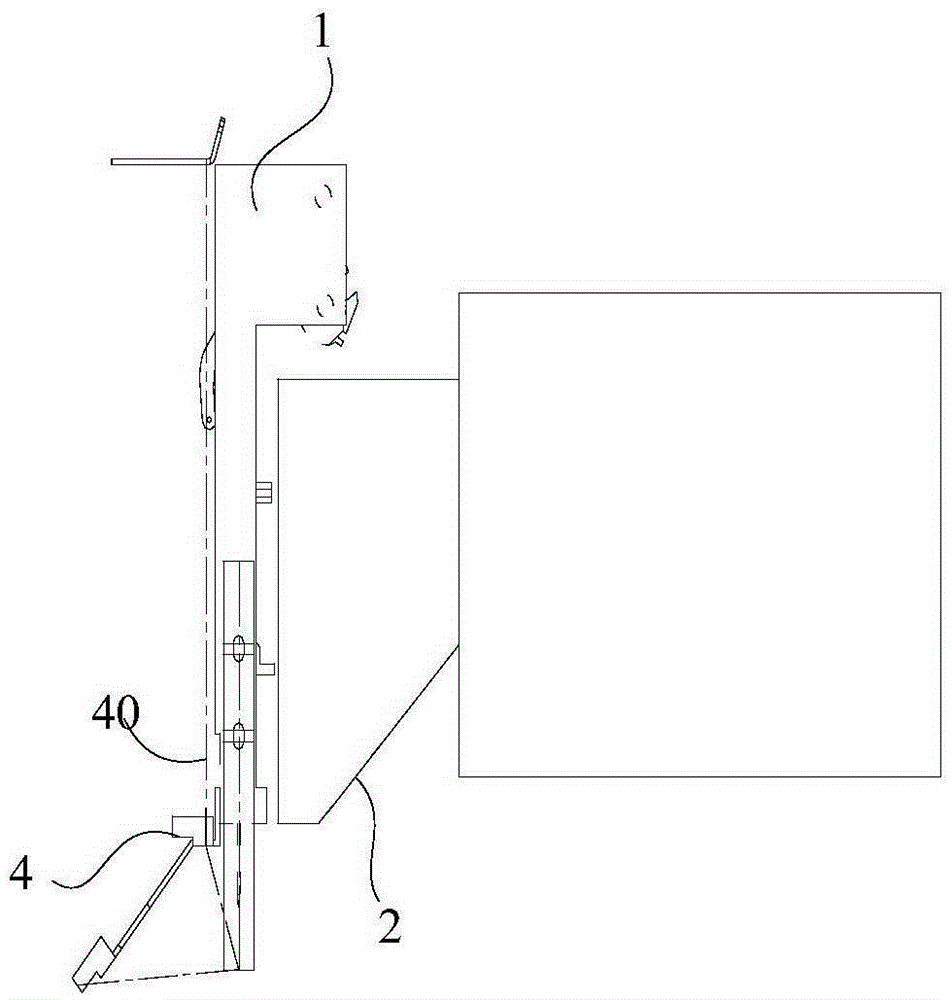

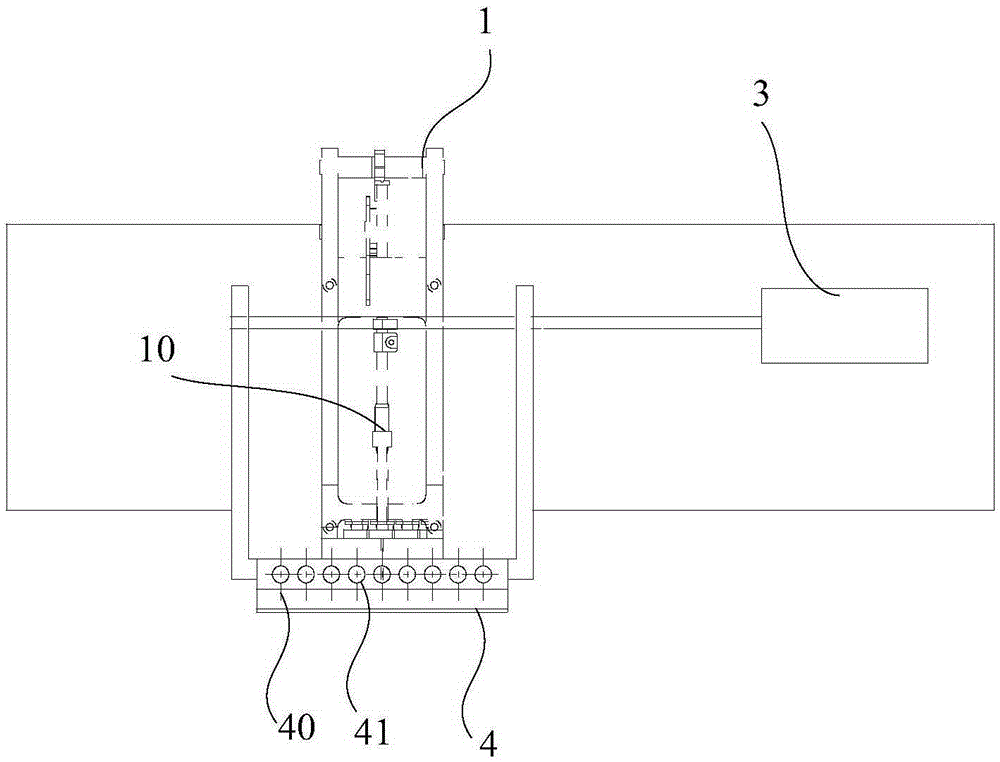

Thread replacing device and carpet embroidering machine with same

ActiveCN104060418ALow costReduce workloadEmbroidering machines apparatusEngineeringUltimate tensile strength

The invention provides a thread replacing device and a carpet embroidering machine with the same. The thread replacing device comprises a needle bar rack, a threading frame and a color replacing box, wherein a needle bar is arranged on the needle bar rack; the color replacing box is connected with the threading frame and used for driving the threading frame to transversely move relative to the needle bar. The needle bar rack is of a single needle bar structure; the needle bar rack is fixed to a machine head box, a moving function is cancelled, and thus the possibility that the failure occurs due to movement is lowered; with the single needle bar, a small axis thread is not required to be arranged in the space for storing threads for each needle bar, but a large roll of threads is stored in the space, so that the total quantity of used threads is not changed, but the cost is reduced; with the single needle bar, workers only need to thread the needle bar once, and the needle bar is capable of working all the time and is unlikely to loose threads, so that the work amount of the workers is reduced. With the thread replacing device, the cost of a single product can be effectively reduced, the working efficiency can be improved, and the labor intensity of the workers can be reduced.

Owner:BEIJING DAHAO TECH

Carpet embroidery machine thread changing device and carpet embroidery machine

ActiveCN104060418BLow costReduce workloadEmbroidering machines apparatusEngineeringUltimate tensile strength

The invention provides a thread replacing device and a carpet embroidering machine with the same. The thread replacing device comprises a needle bar rack, a threading frame and a color replacing box, wherein a needle bar is arranged on the needle bar rack; the color replacing box is connected with the threading frame and used for driving the threading frame to transversely move relative to the needle bar. The needle bar rack is of a single needle bar structure; the needle bar rack is fixed to a machine head box, a moving function is cancelled, and thus the possibility that the failure occurs due to movement is lowered; with the single needle bar, a small axis thread is not required to be arranged in the space for storing threads for each needle bar, but a large roll of threads is stored in the space, so that the total quantity of used threads is not changed, but the cost is reduced; with the single needle bar, workers only need to thread the needle bar once, and the needle bar is capable of working all the time and is unlikely to loose threads, so that the work amount of the workers is reduced. With the thread replacing device, the cost of a single product can be effectively reduced, the working efficiency can be improved, and the labor intensity of the workers can be reduced.

Owner:BEIJING DAHAO TECH

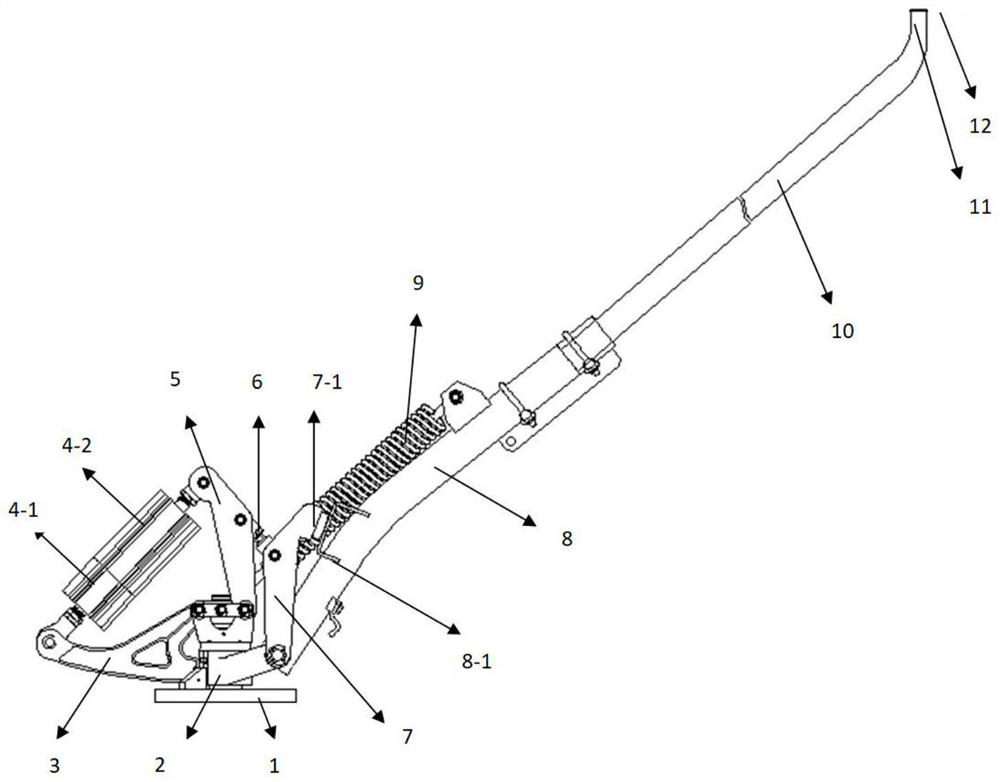

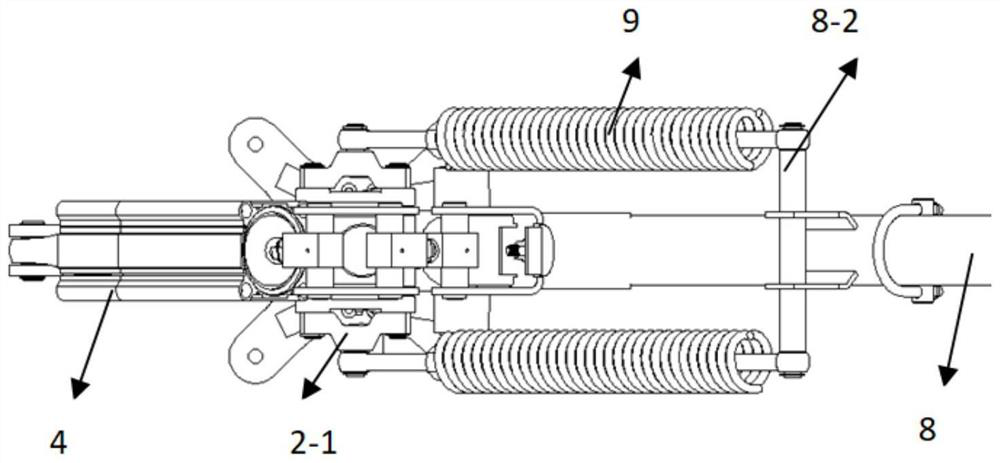

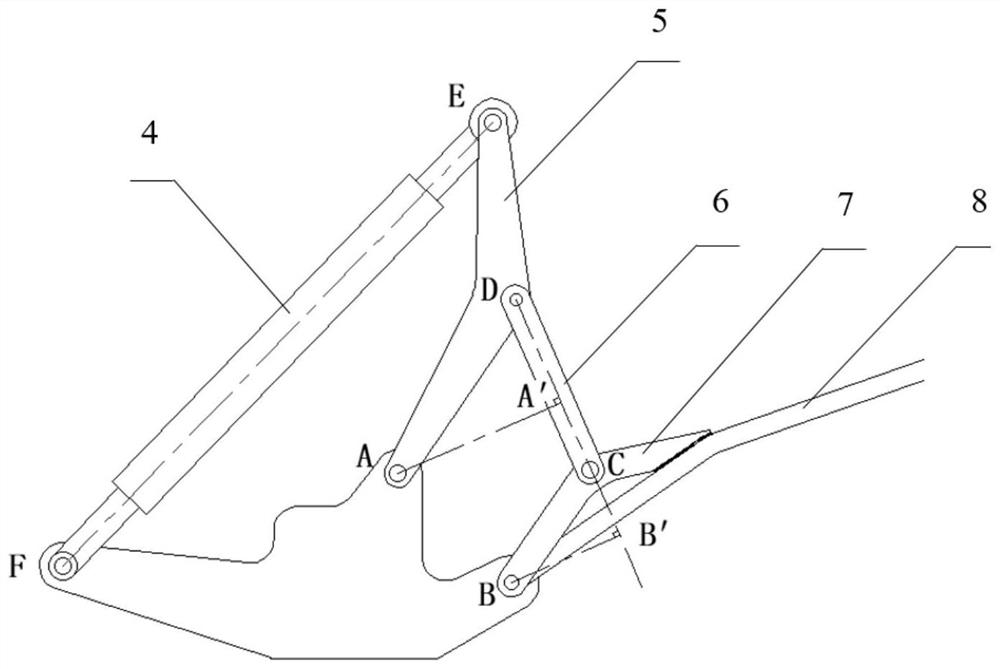

Multi-connecting-rod transmission mechanism for current collecting frame and control method of multi-connecting-rod transmission mechanism

PendingCN114776778AShorten the timeShorten cylinder strokeGearingFluid-pressure actuatorsControl theoryMechanical engineering

According to the multi-connecting-rod transmission mechanism for the current collecting frame and the control method of the multi-connecting-rod transmission mechanism, compared with a three-connecting-rod transmission mechanism, a four-connecting-rod transmission mechanism and other transmission mechanisms in the prior art, amplification of transmission torque is achieved through the multi-connecting-rod structure, and the time for lowering a current collecting rod is effectively shortened; through multiple times of rotation pair transition, the stroke of the air cylinder is reduced; meanwhile, the trolley pole is in movable contact connection with the connecting rod mechanism, rotation is more flexible, the trolley pole is not limited by resistance of an air cylinder in the vehicle running process, the trolley pole can flexibly swing up and down along with the wire net, stable net touching force is kept, and wire disengaging is not prone to occurring; the overall height of the connecting rod structure is reduced, and the height limiting problem of the roof is solved; an emergency return device is arranged, so that the danger caused by accidental off-line is avoided; in addition, the axial length of the lead screw assembly is adjustable, and stable net touching force can be provided for road sections with different wire net heights; the trolley pole can be separated from the transmission connecting rod mechanism and can rotate to the position close to the ground, personnel do not need to climb to a car roof, and maintenance is convenient.

Owner:SUZHOU KAIBO YIKONG DRIVE TECH CO LTD

Clothing seamless splicing structure and seamless splicing method

The invention relates to the field of clothing, in particular to a clothing seamless splicing structure and a clothing seamless splicing method. The clothing seamless splicing structure comprises two fabrics to be spliced, the front side of the splicing position of one fabric and the reverse side of the splicing position of the other fabric are overlapped and sewn, and overlock is arranged at the splicing positions of the two fabrics. The splicing principle is that firstly, overlapping is performed in the mode that the front side is tightly attached to the reverse side, so that a protruding overlapping portion formed when the front side is tightly attached to front side is avoided, and therefore the overlapping positions of the two fabrics are made to be smoother; secondly the splicing positions are overlocked and sewn simultaneously so that the two fabrics are connected together, and meanwhile the problem that the edges of the fabrics loose threads is avoided. Therefore, the clothing seamless splicing structure is shaped like a plane, the structure is smoother, and the clothing with the seamless splicing structure is not prone to rubbing skin while being worn next to the skin, is more comfortable to wear, and has the advantages of being firm and not prone to loosing the threads.

Owner:周剑

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com