MEMS (micro-electromechanical system) chip and wafer level encapsulation cover plate grounding method of MEMS chip

A technology of wafer-level packaging and grounding method, which is applied in the fields of crafts, decorative arts, and measuring devices used to produce decorative surface effects, and can solve problems such as flushing out lines, affecting yields, and long grounding wires, etc., to achieve packaged finished products High efficiency, firm adhesion, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

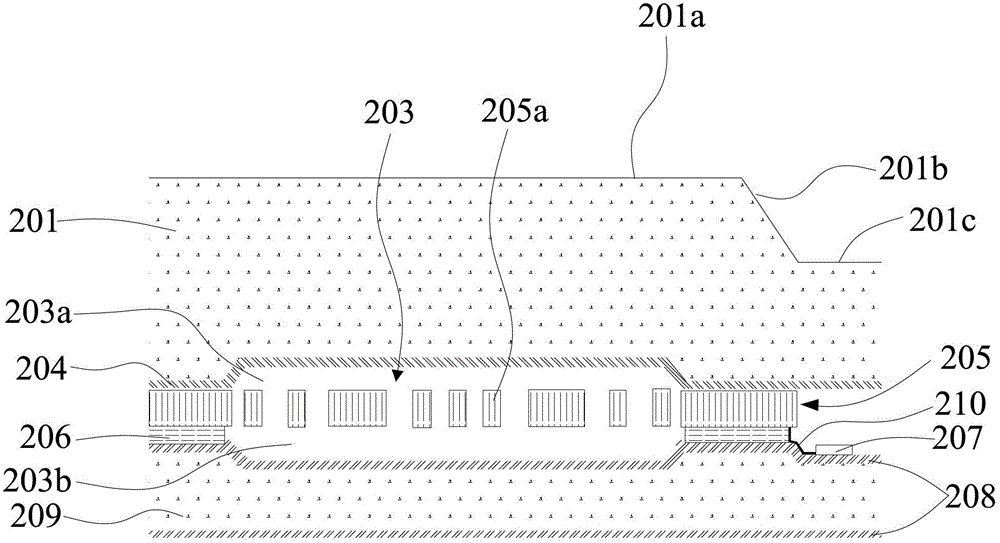

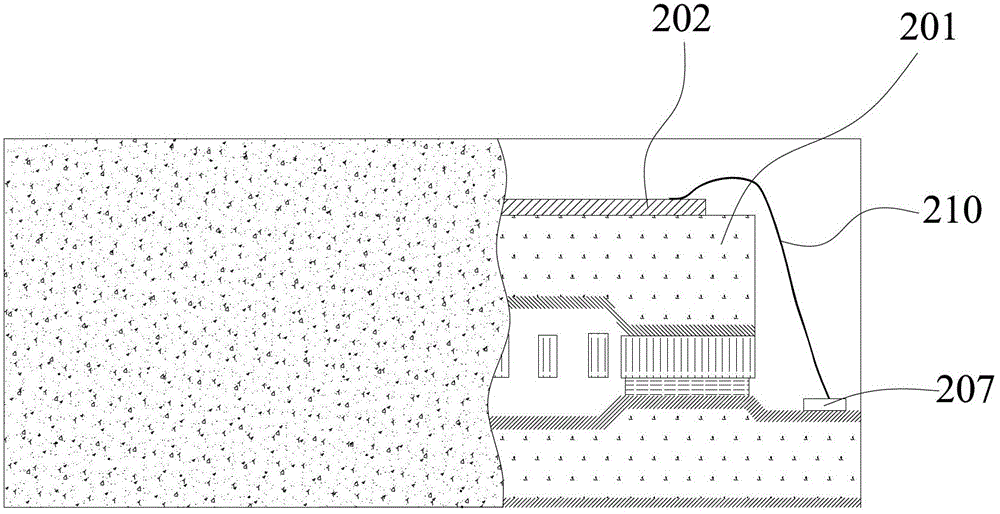

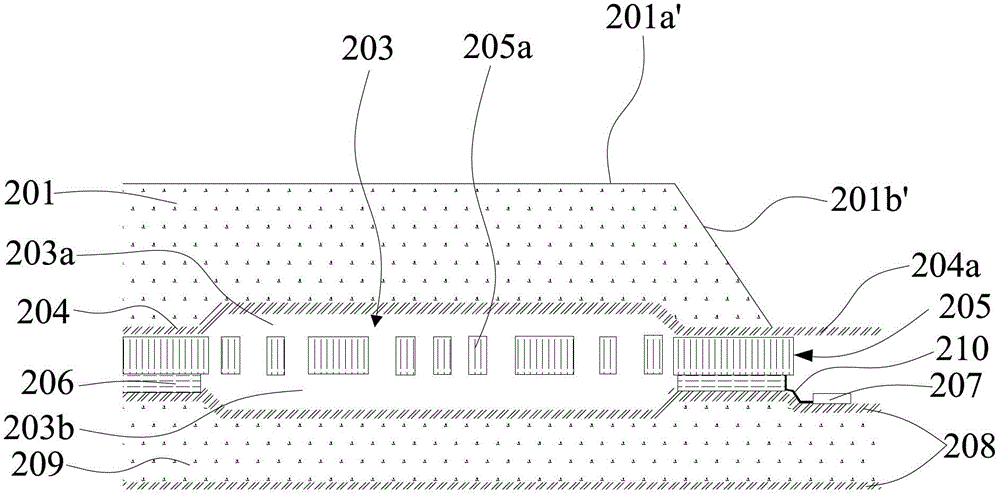

[0024] Such as Figure 6 and Figure 7 As shown, the MEMS chip is composed of a cover plate 201, a MEMS structure layer 205 and a bottom plate 209. The bottom of the cover plate 201 has an upper cavity 203a with an opening downward, and the bottom plate 209 has an upper cavity 203b with an upward opening. The upper cavity 203a Form a sealed cavity 203 with the lower cavity 203b, the movable part 205a of the MEMS structure layer 205 is located in the sealed cavity 203, and can move freely in the sealed cavity 203, there is a cover plate insulation between the cover plate 201 and the MEMS structure layer 205 The layer 204 is isolated, and there are metal wires 202 on the surface 201a' of the cover plate and the inclined side surface 201b' of the cover plate, wherein the metal wire 202 on the inclined side surface of the cover plate electrically connects the cover plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com