Automatic towel machine

A towel machine and towel technology, applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of low processing efficiency, loss of raw material waste, uneven incision, etc., to reduce production costs, improve production efficiency, The effect of not easily disconnected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

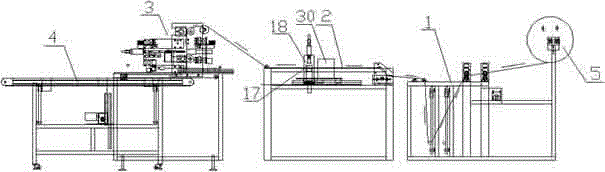

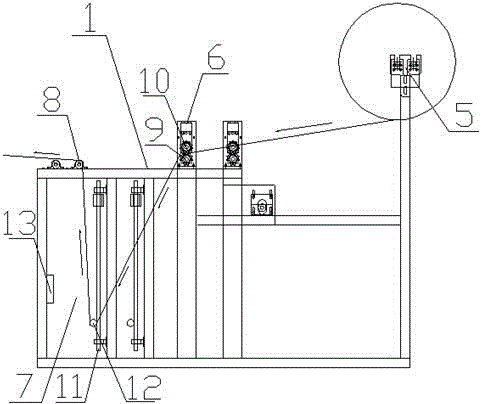

[0027] see Figures 1 to 4 As shown, an automatic towel machine includes a towel feeding mechanism 1, an ultrasonic superscripting mechanism 2, a towel cross-cutting mechanism 3, and a towel finishing mechanism 4 arranged in sequence according to the towel conveying direction, and the towel feeding mechanism is used for placing towels Roll feeding, the ultrasonic labeling mechanism is used to label towels, the towel cross-cutting mechanism is used to cut towels after labeling, and the towel finishing mechanism is used to arrange and stack the cut towels.

[0028] In this embodiment, the towel feeding mechanism includes a towel roll placement roller 5 , a towel pull-out assembly 6 , a towel tension stop assembly 7 and a towel pull-out roller 8 arranged in sequence.

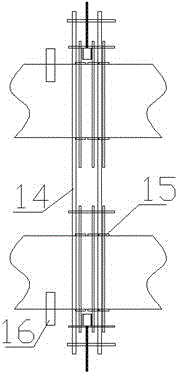

[0029] The towel pull-out assembly includes a main transmission wheel 9 and a driven wheel 10 arranged above the main transmission wheel, the driven wheel has a degree of freedom in the vertical direction, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com