Thread replacing device and carpet embroidering machine with same

An embroidery machine and carpet technology, which is applied to the field of a thread changing device for a carpet embroidery machine and a carpet embroidery machine, can solve the problems of easy breakage of silk threads, reduced work efficiency, large workload, etc., and achieves the phenomenon that the thread is not easy to be disconnected and reduces the cost of a single product. , the effect of low-pitched work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The transmission device is a worm gear transmission device; wherein the central axis of the worm gear is connected with the main shaft of the motor; the worm is connected with the threading frame. The reliability of the action is high, and it is easy to maintain.

Embodiment 2

[0045] The transmission device is a rack and pinion transmission device; the central axis of the gear is connected with the main shaft of the motor; the rack is connected with the threading frame. The reliability of the action is high, and it is easy to maintain.

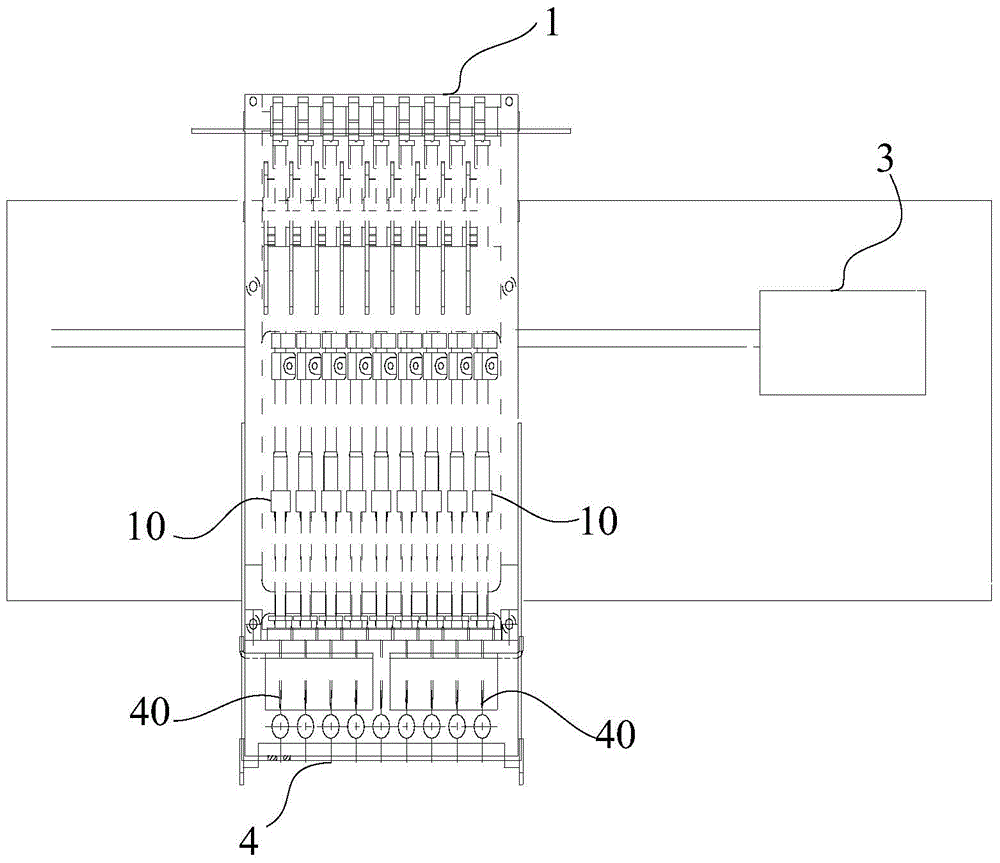

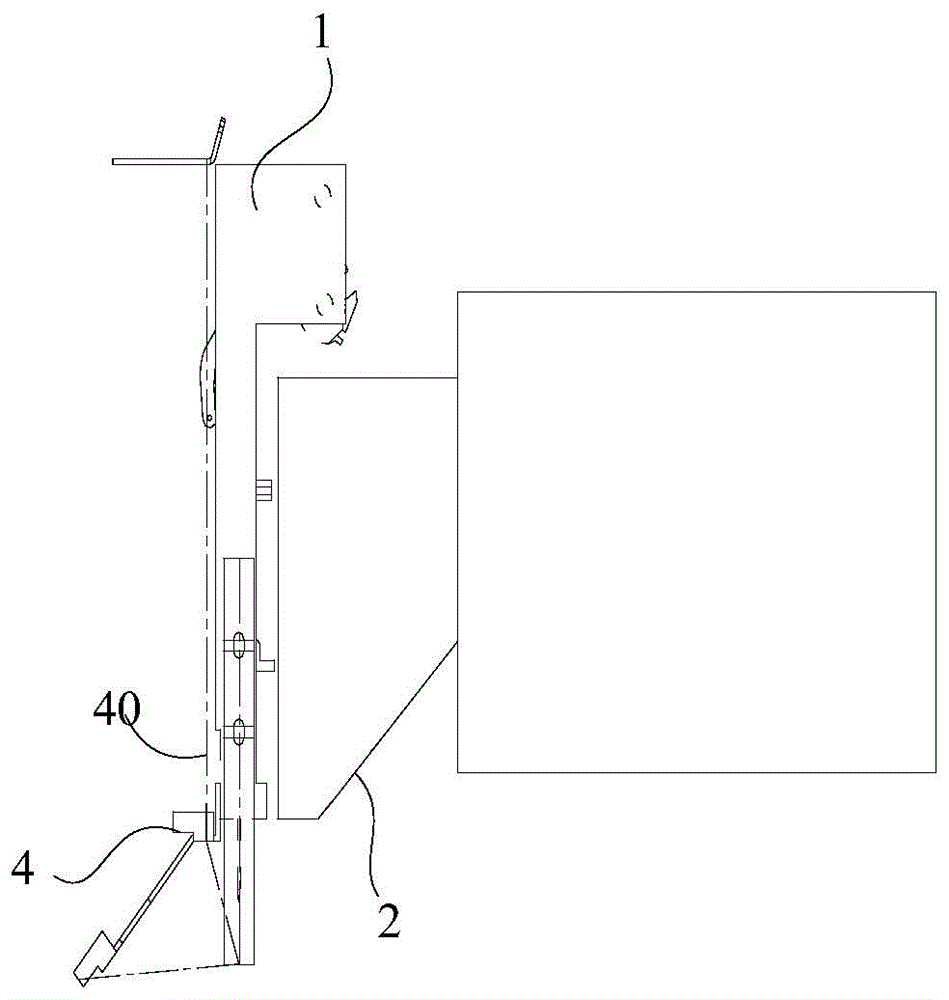

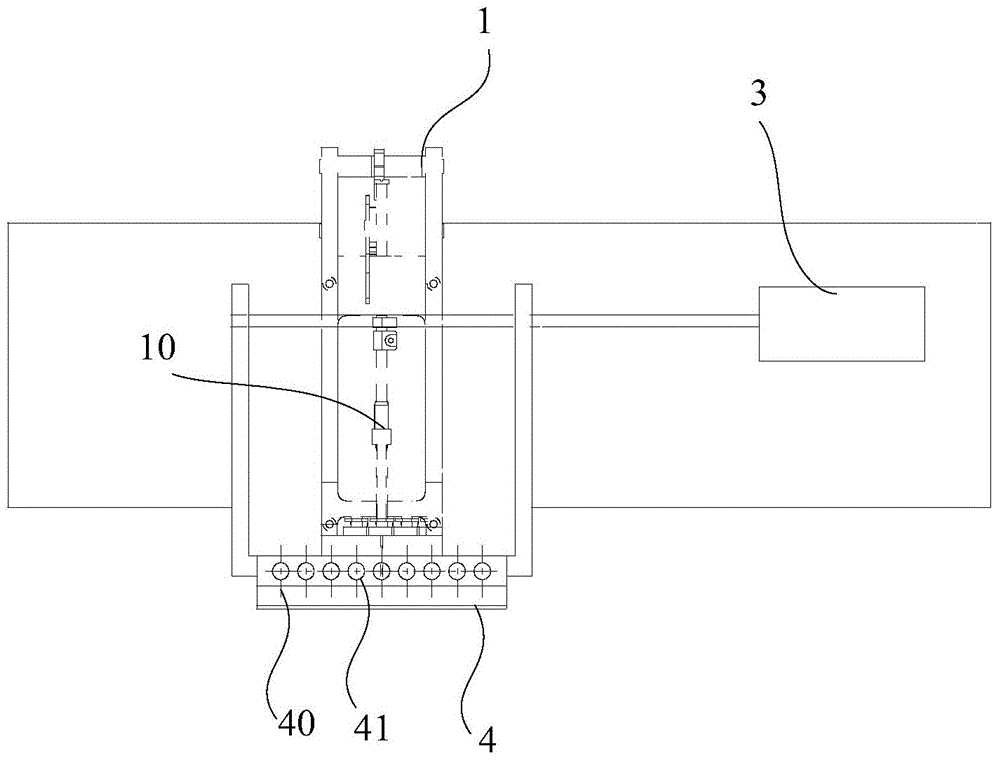

[0046] Such as Figure 5 , Image 6 As shown, the present invention also provides a carpet embroidery machine, which at least includes a machine head box 2 and a thread changing device; the thread changing device is the carpet embroidery machine thread changing device of any of the above-mentioned embodiments; wherein the needle in the carpet embroidery machine thread changing device The rod frame 1 is fixed on the head case 2, and the needle bar 10 is set against the main shaft on the head case 2.

[0047] The original color changing box 3 drives the needle bar frame 1 and the threading frame 4 to move laterally and left and right at the same time. The color-changing structure of the needle bar only changes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com