Thread bracket for sewing reflective stripes

A technology for reflective strips and wire support, applied in the field of wire brackets, can solve the problems of reflective strips falling off, wearing off-line, failing to reach safety signs, etc., achieving the effects of not easy to be off-line, firm combination, and improved safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

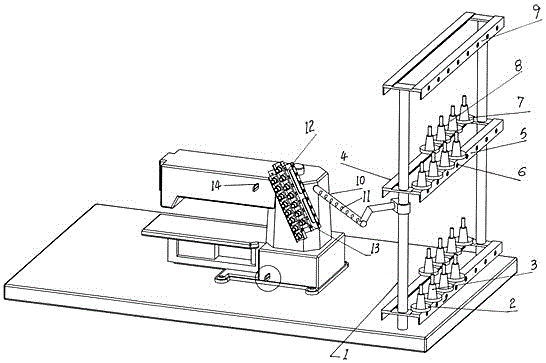

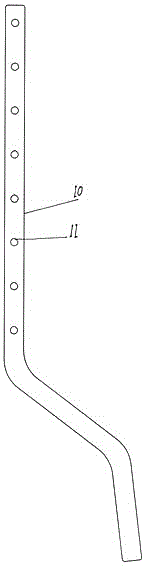

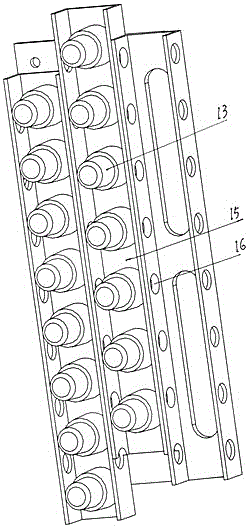

[0009] This technical solution is composed of frame 1, upper and lower thread support trays 7, 2, inner threading plate 4, outer threading plate 5, top layer threading plate 9, thread feeder 12, thread separating roller 13 and line dividing plate 14, etc. , specific examples such as figure 1 As shown, the frame is fixed at one end of the sewing machine with a distance between two round steel pipes. The inner threading plate 4 and the outer threading plate 5 are arranged in the middle of the frame, and the top threading plate is fixed on the head of the frame. 9. The lower thread support tray 2 is set under the inner and outer threading plates, the upper thread support tray 7 is set in the middle of the inner and outer threading plates, and the upper thread support tray is equipped with an upper thread roller 8, so Bottom thread roller 3 is housed on the lower thread support tray, threading hole 6 is processed on the plate surface of described inside and outside threading plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com