Infrared positioning hot melting clothing drilling machine

A technology for positioning heat and drilling machines, applied in the field of garment processing, can solve the problems affecting the quality of garment processing, easy off-line at the opening, and decline in clothing quality, and achieve simple structure, difficult off-line, and reduced labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

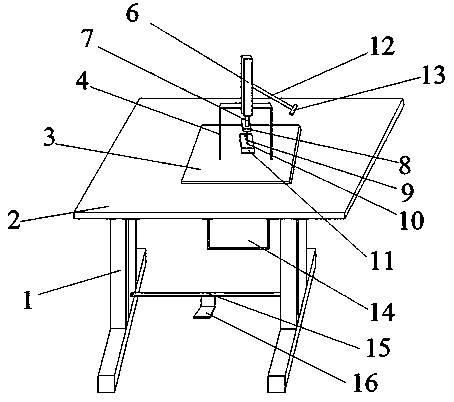

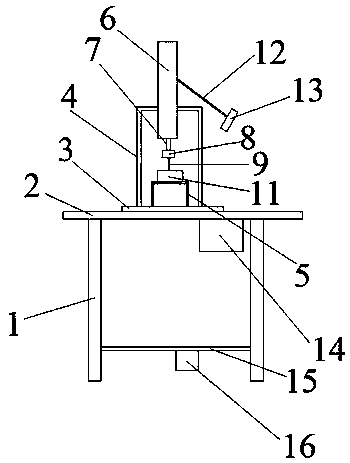

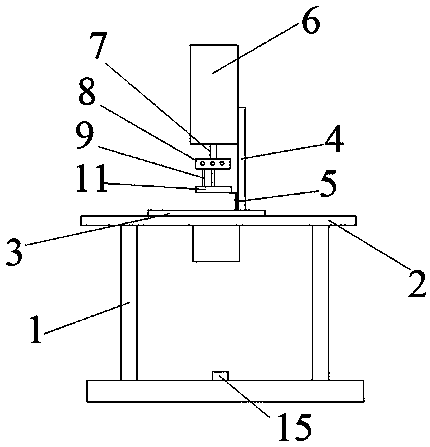

[0024] An infrared positioning heat-melting clothing drilling machine, comprising a frame 1 and an infrared lamp 13, an operation table 2 is installed on the frame 1, a base 3 is installed on the operation table 2, and the upper panel of the base 3 is connected to a bracket 4 and a support plate 5, The drive device is installed above the support 4, the bottom of the drive device 4 is connected with a connecting plate 8, the drive device includes a pneumatic cylinder 6 and a piston rod 7, one end of the piston rod 7 is movably connected in the pneumatic cylinder 6, and the other end of the piston rod 7 is connected to the cylinder rod 7. The upper surface of the connecting plate 8 is connected. Two drilling pins 9 are installed on the connecting plate 8, and the piston rod 7 in the driving device drives the connecting plate 8 and the drilling pins 9 to reciprocate up and down. The support plate 5 is provided with a heating well 11, and the heating pipe is connected in the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com