Quilting device for four-needle quilt quilting machine

A quilting machine and quilting technology, which is applied to sewing machines for bedding, sewing equipment, textiles and papermaking, etc. It can solve the problems of not being suitable for mass production, a large amount of manpower and material resources, and non-standard stitch pitches. To achieve the effect of product quality assurance, production efficiency improvement, and firm stitches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

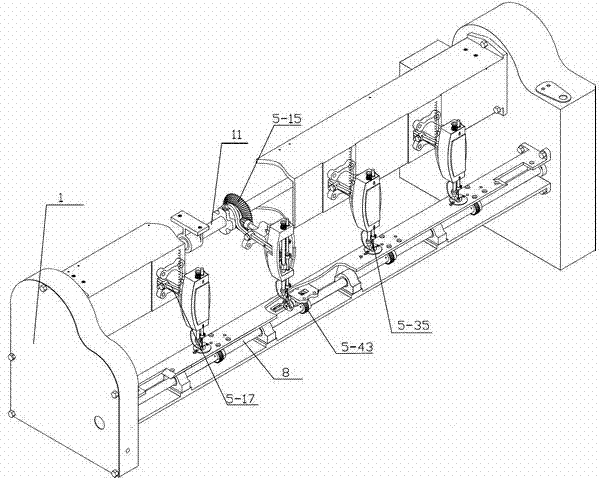

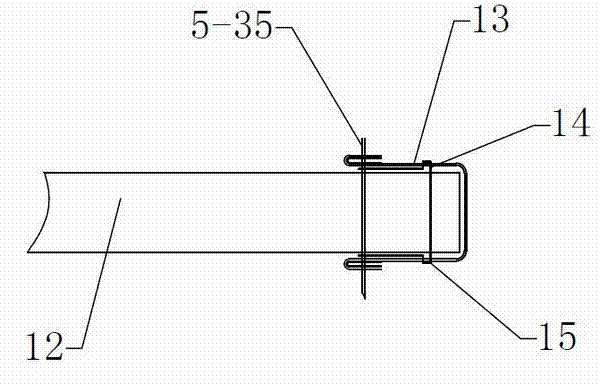

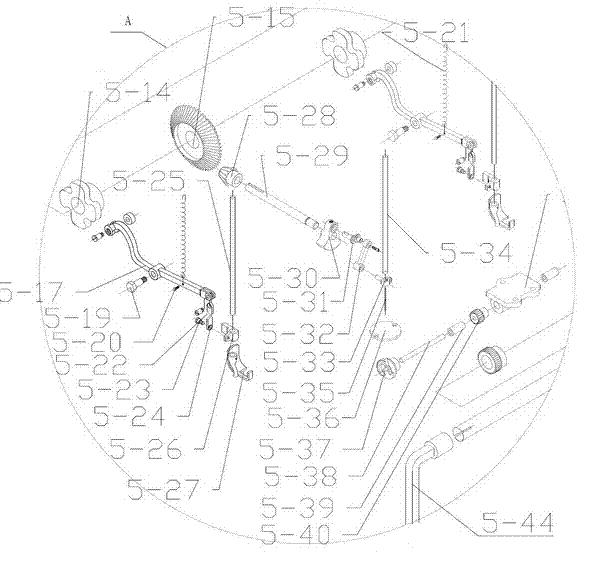

[0012] See attached figure 1 , 2 And attached Figure 4 , the present invention comprises the upper beam shaft 11 that is arranged on the frame 1 to control the action of the needle stile and the presser foot, the lower beam shaft 8 that controls the action of the rotary hook, one end of the upper beam shaft 11 is provided with a fixed gear 7, and the rest of the entire length is on the upper beam shaft 8. Four bevel gears 5-15 are evenly distributed, and they are meshed with 4 small bevel gears 5-28 respectively, and the motion is passed to the head shaft 5-29 arranged on the head; the other end of the head shaft 5-29 A bar head 5-30 is provided, and is connected with one end of the chicken leg bone 5-32 through a small elbow 5-31, and the other end of the chicken leg bone 5-32 is connected with the needle stile storehouse 5-33, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com